Graded belt type magnetic separating device

A magnetic separation device and magnetic separation technology, applied in the direction of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of lower recovery rate, inability to solve the contradiction between finished ore grade and recovery rate, metal loss and energy consumption, etc., to achieve The effect of improving magnetic separation efficiency and magnetic separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

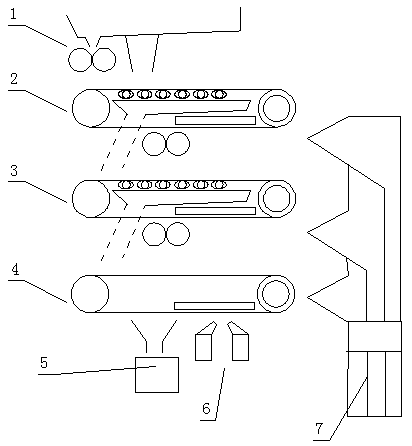

[0043] Such as figure 1 As shown, the present invention discloses a grading belt type magnetic separation device, comprising a sweeping mechanism 4 and a magnetic screening mechanism, the sweeping mechanism 4 is located below the magnetic screening mechanism, and both the sweeping mechanism 4 and the magnetic screening mechanism have magnetic Selection function, the magnetic screening mechanism has a magnetic separation belt, and the magnetic separation belt is provided with mesh.

[0044] The magnetic screening mechanism has more than two stages of magnetic separation mechanisms. The magnetic separation mechanisms are arranged overlapping from top to bottom, and the mesh size of the magnetic separation belt decreases from top to bottom. The arrangement of the multi-layer magnetic separation mechanism has more classification times, more convenient classification and improved magnetic separation efficiency.

[0045] The magnetic separation mechanism includes a magnetic roller,...

Embodiment 2

[0052] Such as figure 1 As shown, a grading belt magnetic separation system also includes a controller, a weighing mechanism, a feeding mechanism 1, a magnetic screening mechanism, a sweeping mechanism 4, a fine material collecting mechanism 5, a dust removal mechanism 6, and a waste material collecting mechanism 7 ;

[0053] The magnetic screening mechanism includes a first magnetic separation mechanism 2 and a second magnetic separation mechanism 3 arranged overlappingly from top to bottom; the first magnetic separation mechanism 2 includes a first magnetic roller, a first magnetic system, a first transmission wheel, a first magnetic Belt selection, and the first feeding hopper; the first magnetic separation belt is set between the first magnetic roller and the first transmission wheel, the first feeding hopper is located between the upper and lower belts of the first magnetic separation belt, and the first magnetic system is located The inner side of the lower belt of the ...

Embodiment 3

[0062] Based on the system of embodiment 1 structure or embodiment 2, its magnetic separation method is:

[0063] Step 1: The magnetic screening mechanism consists of two or more overlapping magnetic separation belts. After putting the ore particles with uneven sizes on the uppermost magnetic separation belt, the magnetic separation belt screens the ore particles, and the particle size is smaller than the magnetic separation belt. The ore particles in the mesh fall to the magnetic separation belt of the lower layer, and are screened again by the magnetic separation belt of the lower layer;

[0064] Step 2: After the ore particles pass through the overlapping magnetic separation belts from top to bottom, they are layered according to the size of the ore particles. The upper layer of magnetic separation belts performs magnetic separation on large particles, and the lower layer of magnetic separation belts performs magnetic separation on small particles. particles for magnetic se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com