A construction waste screening device

A screening device, construction waste technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve problems such as easy blockage, and achieve the effects of fast feeding speed, uniform suspension and enhanced efficiency, and accelerated efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

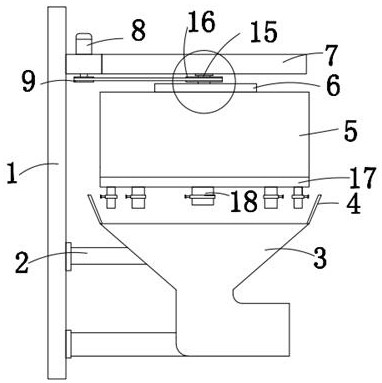

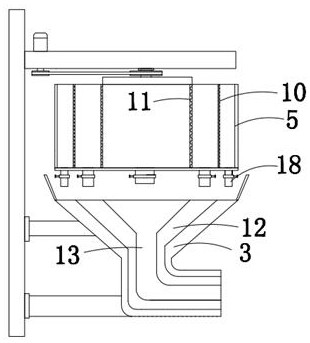

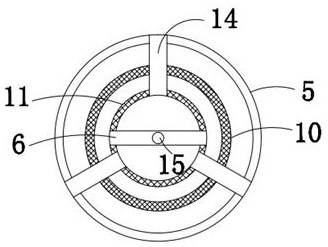

[0024]First Embodiment: SeeFigure 1-4The present invention provides a technical solution: a construction waste screening device, including a bracket 1, and a third guide bin 3 is welded to the lower end of the bracket 1 by the support rod 2, the third guide bin. 3 The second conductive bin 12 is provided inside, and the inner portion of the second conductive bunar 12 is provided with a first conductive bin 13, and a cylinder 5 is provided, the cylinder. 5 The bottom cover 17 is provided which is provided with a second screening network cartridge 10 and a first screening network cartridge 11, and the first screen barrel 11 is located in the second screen. The top of 10, the top of the cylinder 5, the second screen barrel 10, and the first screening network cartridge 11 are welded by three consecutive plates 14, and the top intermediate welding of the first screening network barrel 11 has The horizontal plate 6, the upper end of the horizontal plate 6 is provided with a rotating shaft...

no. 2 approach

[0032]Second Embodiment: As shown in claim 1, a construction waste screening device includes a stent 1, and the inner portion of the bracket is provided in the axial direction of its axial direction. The first wind turner is connected to the external electronically controlled fan. The lower end of the bracket 1 is welded to the outer surface of the third conductive bunner 3 through the hollow support rod 2 in the two horizontal directions, and the first airway is in communication with two support rods 2, said The second conductive bin 12 is provided inside the third conductive bunar 3, and the inner portion of the second conductive bin 12 is provided with a first conductive bin 13, and a cylinder 5 is provided in the upper end of the third conductive bun. , The first conductive bin 13, the second conductive bin 12, and the third conductive bin 3 are isolated from each other, the first guide bin 13, the second guide bin 12 and the third conduction The wall wall of the warehouse 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com