Patents

Literature

121results about How to "The reaction is fully and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Post-treatment process and equipment of desalted seawater

InactiveCN102826689ASimple structureThe reaction is fully and evenlyMultistage water/sewage treatmentWater/sewage treatment by substance additionPotable waterWater quality

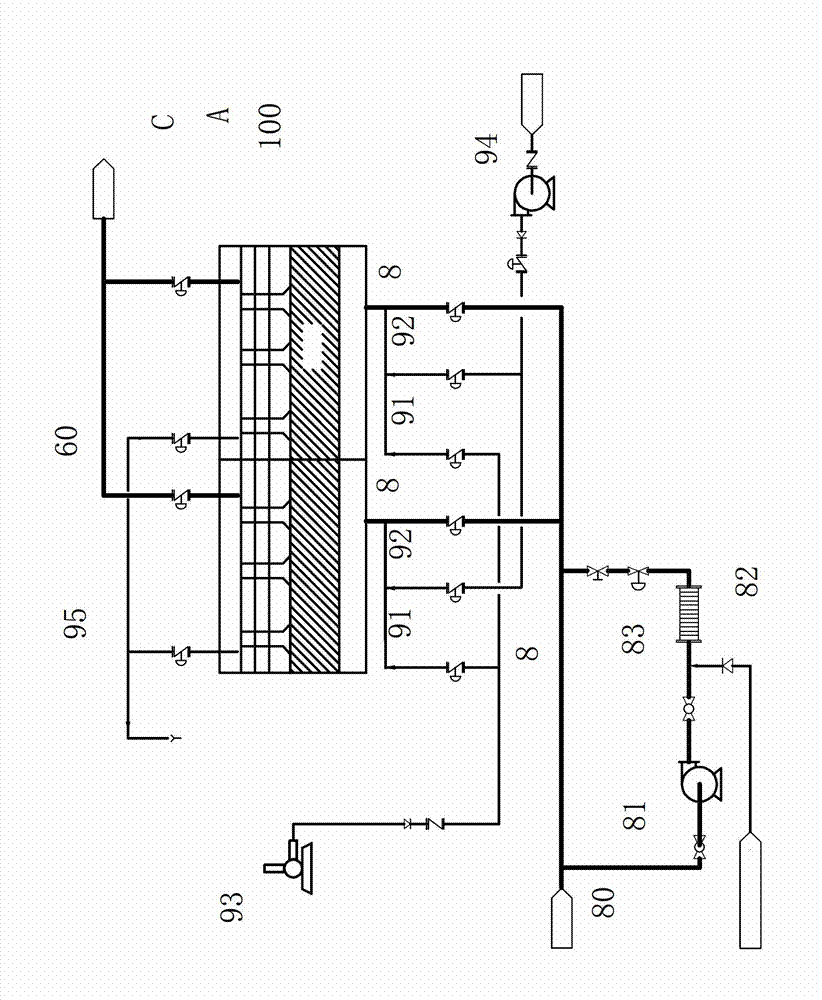

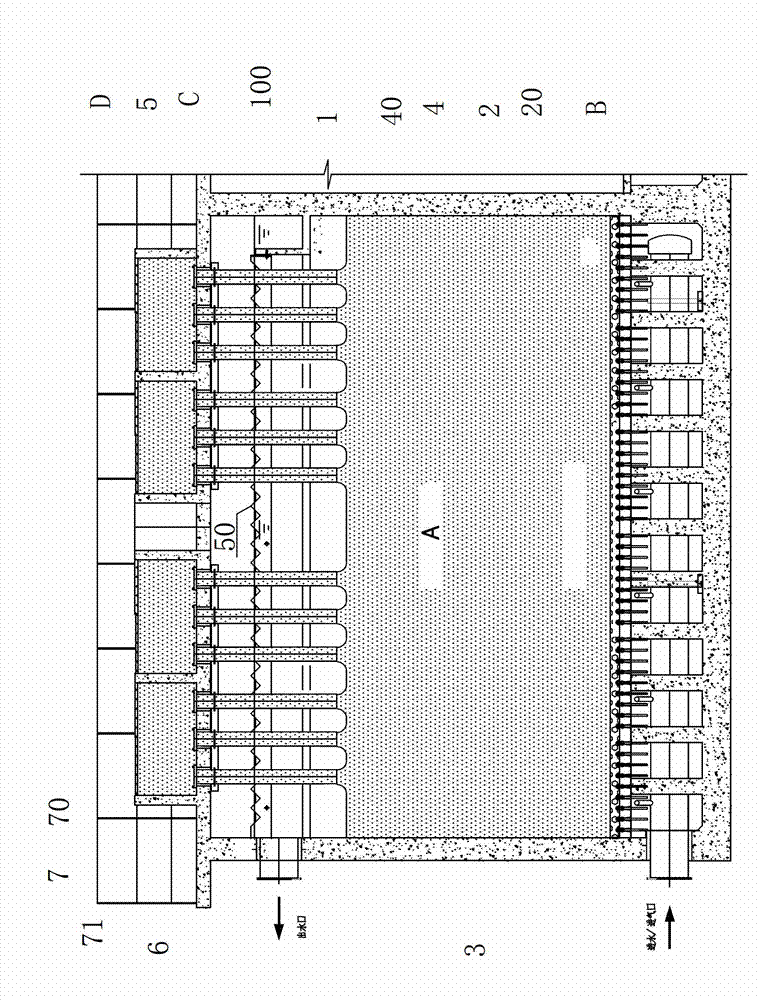

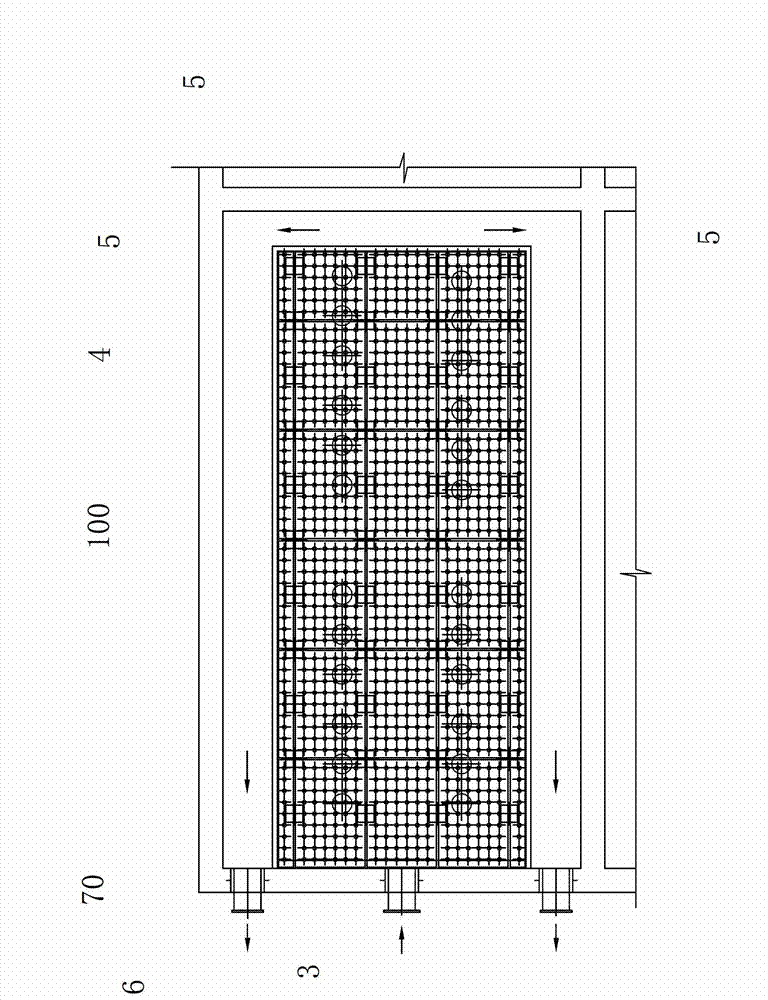

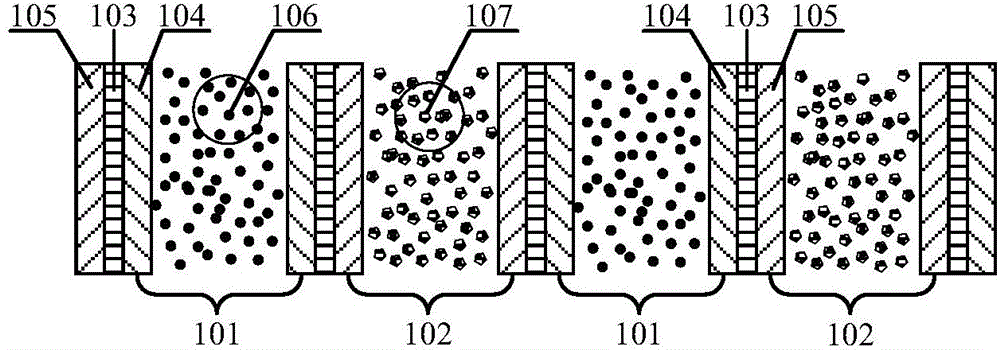

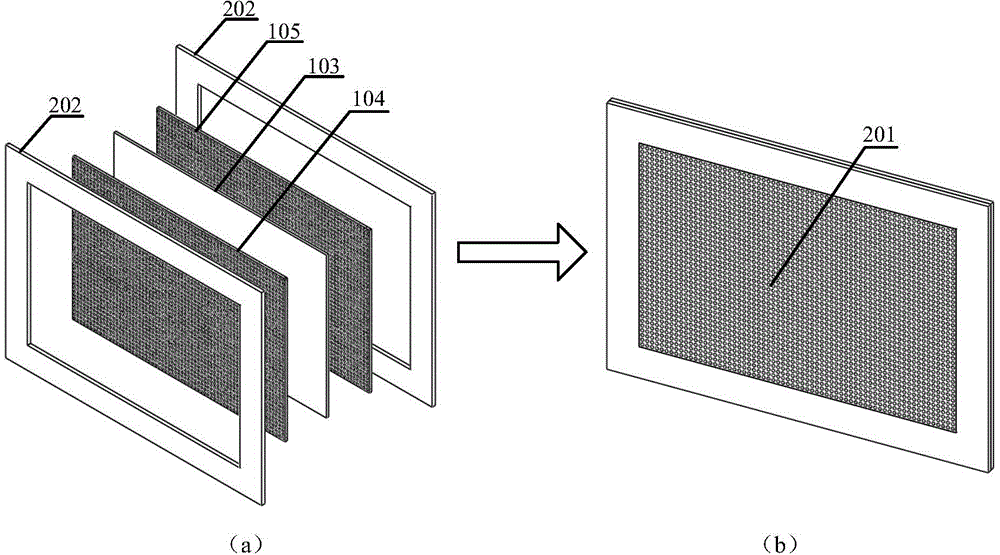

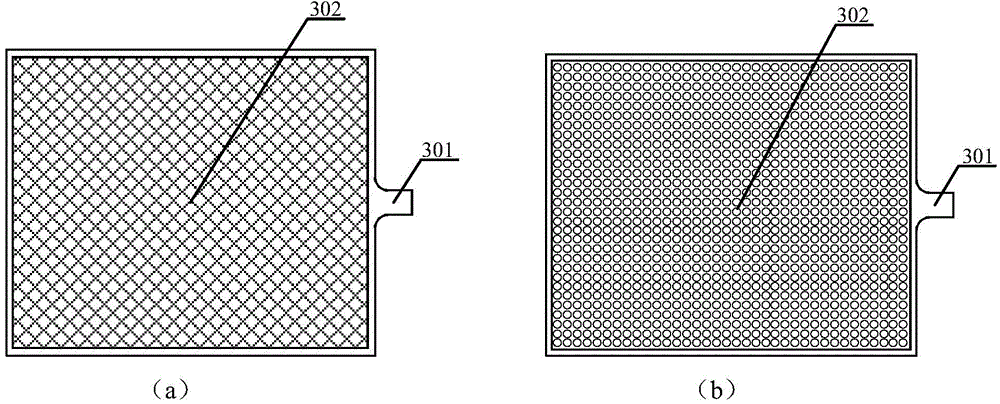

The invention provides a post-treatment process of desalted seawater, comprising the following steps of: (1) adding CO2 into seawater desalted water and sufficiently mixing; and (2) mineralizing the seawater desalted water added with the CO2 in a mineralizing pool; arranging a calcium carbonate filler bed in the mineralizing pool; and enabling the seawater desalted water added with the CO2 to pass through the calcium carbonate filler bed to be sufficiently contacted and reacted with calcium carbonate. The invention further provides post-treatment equipment applying the method disclosed by the invention. According to the post-treatment process and equipment of the desalted seawater, the seawater desalted water is subjected to mineralization treatment, so that the alkalinity and the hardness of the seawater desalted water are improved; and finally, the water quality of finished product water can accord with Chinese Drinking Water Standards GB5749-2006 and World Health Organization Standards, and the finished product water is good for health of a human body. According to the equipment disclosed by the invention, the whole structure of the mineralizing pool is simple and the reaction in the mineralizing pool is sufficient and uniform, so that the calcium carbonate is automatically supplemented into the mineralizing pool by gravity according to the consumption of the calcium carbonate.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Highly water-soluble carbon nanometer tube preparation method

The invention relates to preparation method for high water-soluble nano carbon tube, which comprises acidifying purifying treatment, acylchloridization and grafting. Wherein, based on not destroying its high length-diameter ratio and electron valence band structure, using chemical modification to graft lycine on wall and end of the tube to endow its high water-solubility of 30mg / ml and biocompatibility; reflowing the tube in HNO3 to remove the impurity metal catalyst particle and carboxylate the tube; then, reflowing tube in SOCl2 for completed acylchloridization; finally, acyl chloride group and amido in grafted lycine react to obtain the product.

Owner:JILIN UNIV

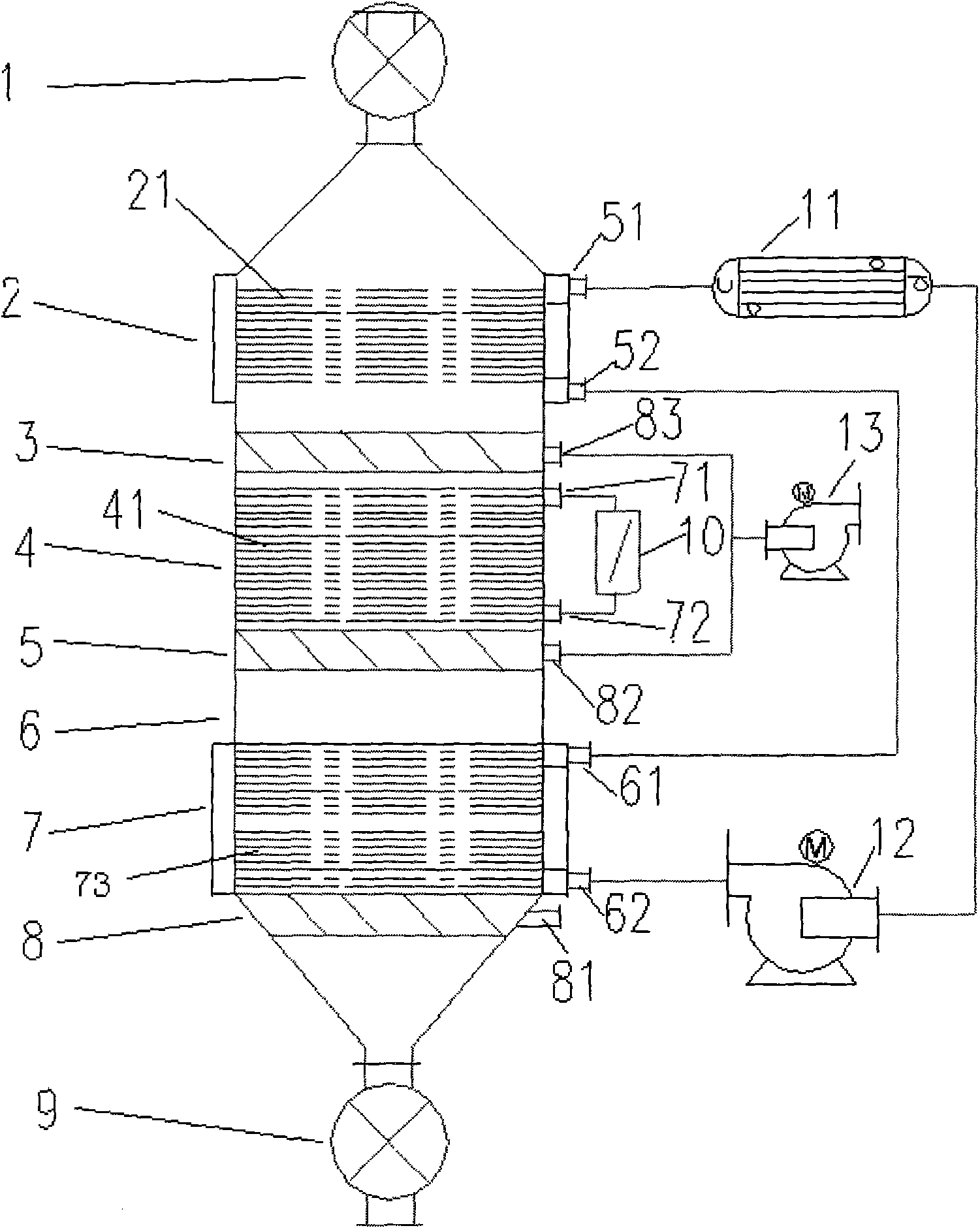

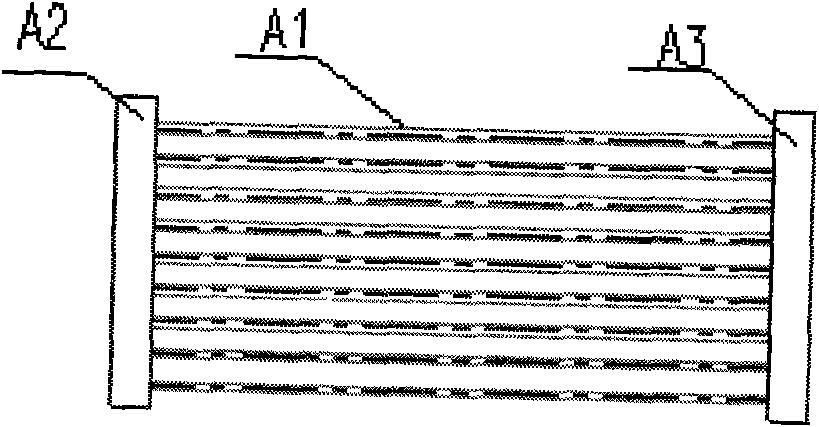

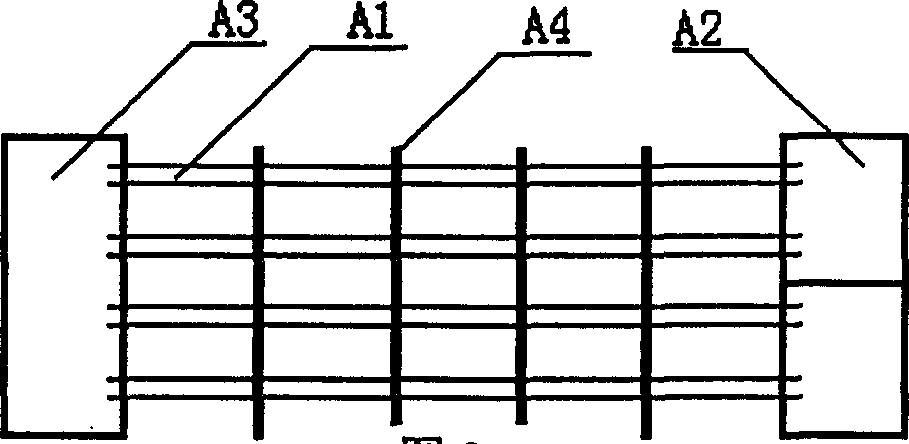

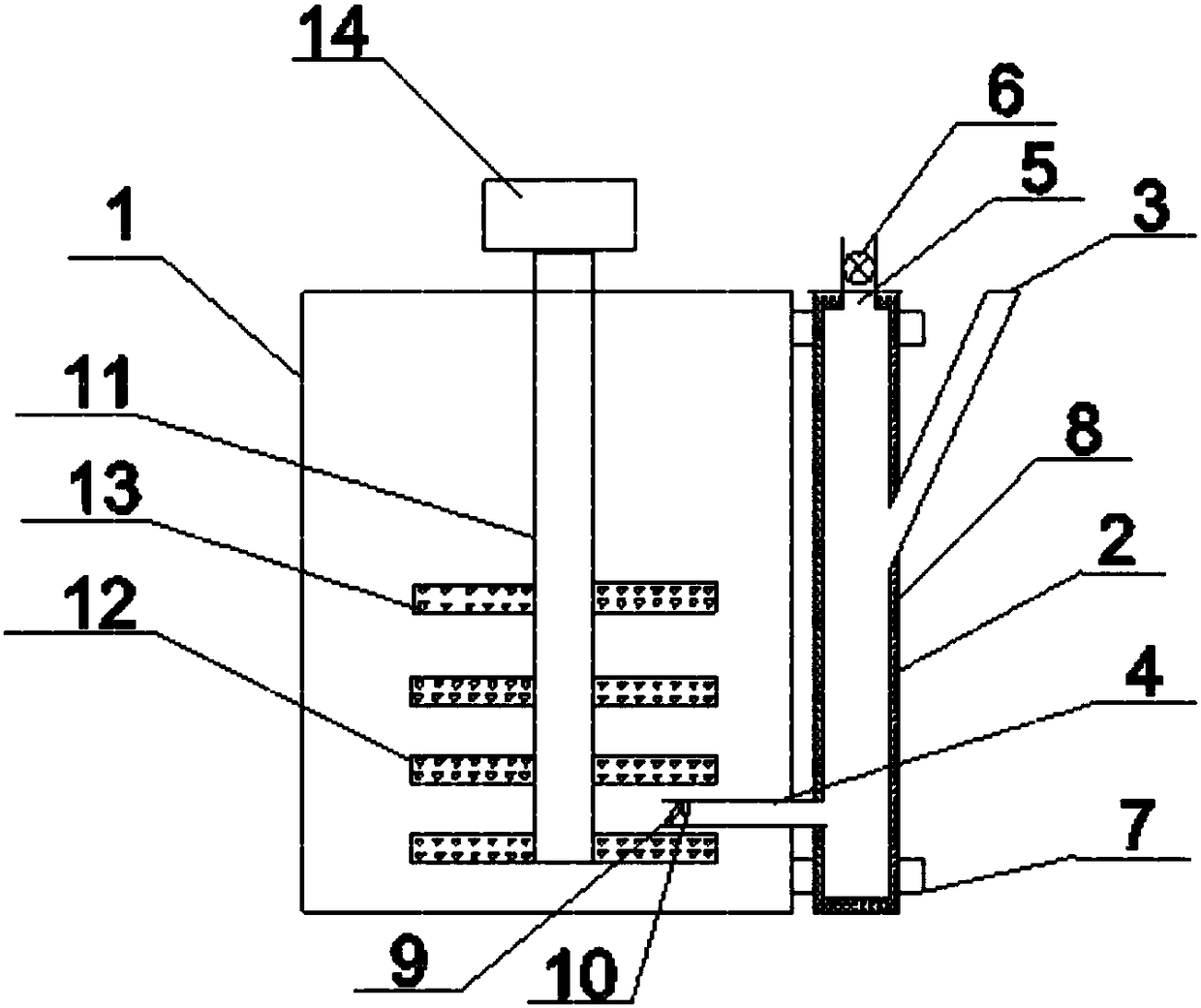

Movable desorption device of activated coke

ActiveCN101584958ASimple structureImprove space utilizationDispersed particle separationCombustible gas purificationProcess engineeringCorrosion

The invention discloses a movable desorption device of activated coke. An inlet blocking valve, a heating chamber, a reaction chamber, a cooling chamber and an outlet blocking valve are sequentially connected from top to bottom in the reactor main body; the heating chamber is provided with a heating heat exchanger therein which is connected with a thermal source device; a cooling heat exchanger is arranged in the cooling chamber; a preheating chamber is arranged between the inlet blocking valve and heating chamber and provided with a preheating heat exchanger, which forms a heat circulating system with a circulating medium heat exchanger, a circulating pump and the cooling heat exchanger; a first cloth gas guide mechanism is arranged between the preheating chamber and heating chamber; a second cloth gas guide mechanism is arranged between the heating chamber and reaction chamber; and the first and second cloth gas guide mechanisms are respectively connected with a gas recovery suction pump for recycling desorption gas. The invention has higher utility ratio of heat energy by redesigning each part in the reactor, and has more complete air suction, higher desorption efficiency and less corrosion to devices by adding the cloth gas guide mechanisms.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

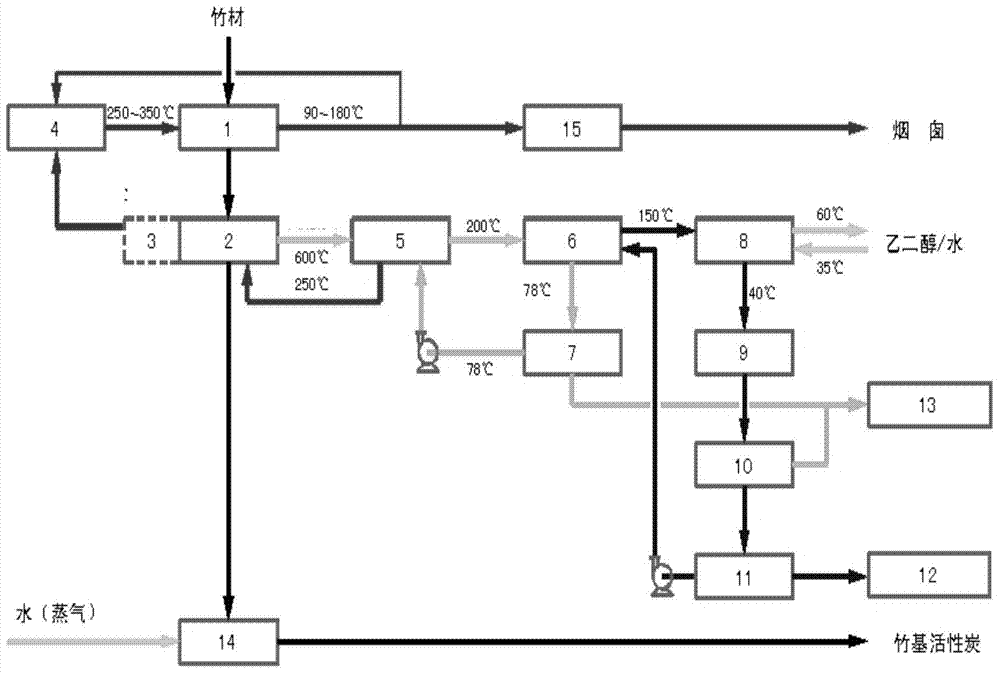

Method for preparing bamboo-based activated carbon and production device thereof

The invention provides a method for preparing a bamboo-based activated carbon and a preparation device thereof. The method comprises the following steps: A, drying, namely crushing bamboo materials at 250-350 DEG G and drying the crushed bamboo materials by drying air; B charring, namely charring the dry bamboo materials under the oxygen deficit condition by using 550-700 DEG C pyrolysis gas as thermal supports; C activating, namely spraying water steam to the charred bamboo materials, activating the bamboo carbon under the oxygen deficit condition at the activating temperature of 900-1000 DEG C, and cooling the activated bamboo carbon to obtain the bamboo-based activated carbon. The reaction is uniform and complete, the water steam in the activating process is completely contacted with the charred material, the generated activated carbon does not easily head and scale in the furnace, and the stability of product quality and the rate of carbon are improved. Moreover, the charring dry-distillation residual heat is completely utilized, the energy consumption is reduced, the charring dry-distillation by-products are recovered, the fume emission is reduced, the pollution to environment is reduced, and the comprehensive utilization rate of the bamboo materials is improved.

Owner:HUNAN HUAYIN ENERGY TECH

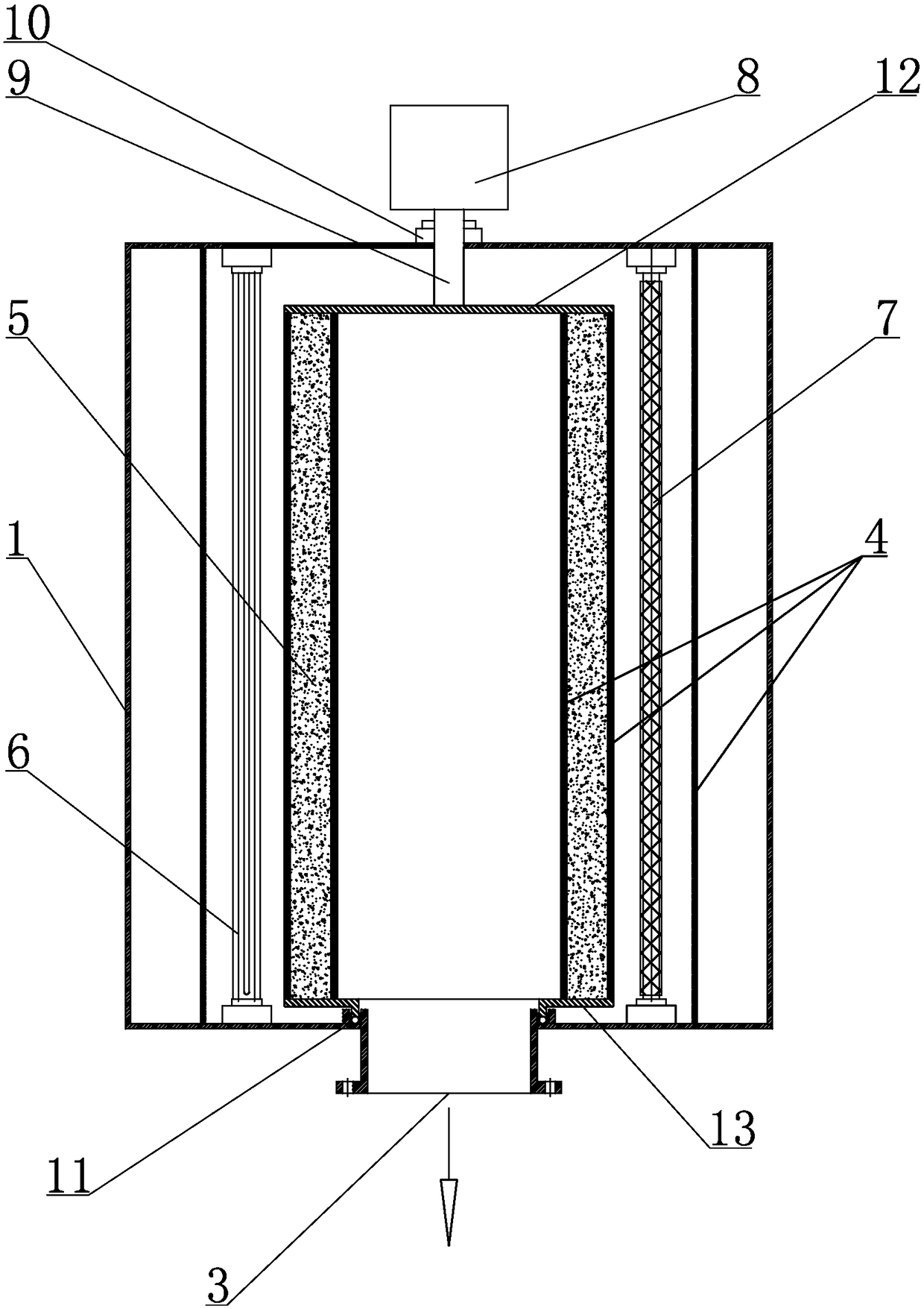

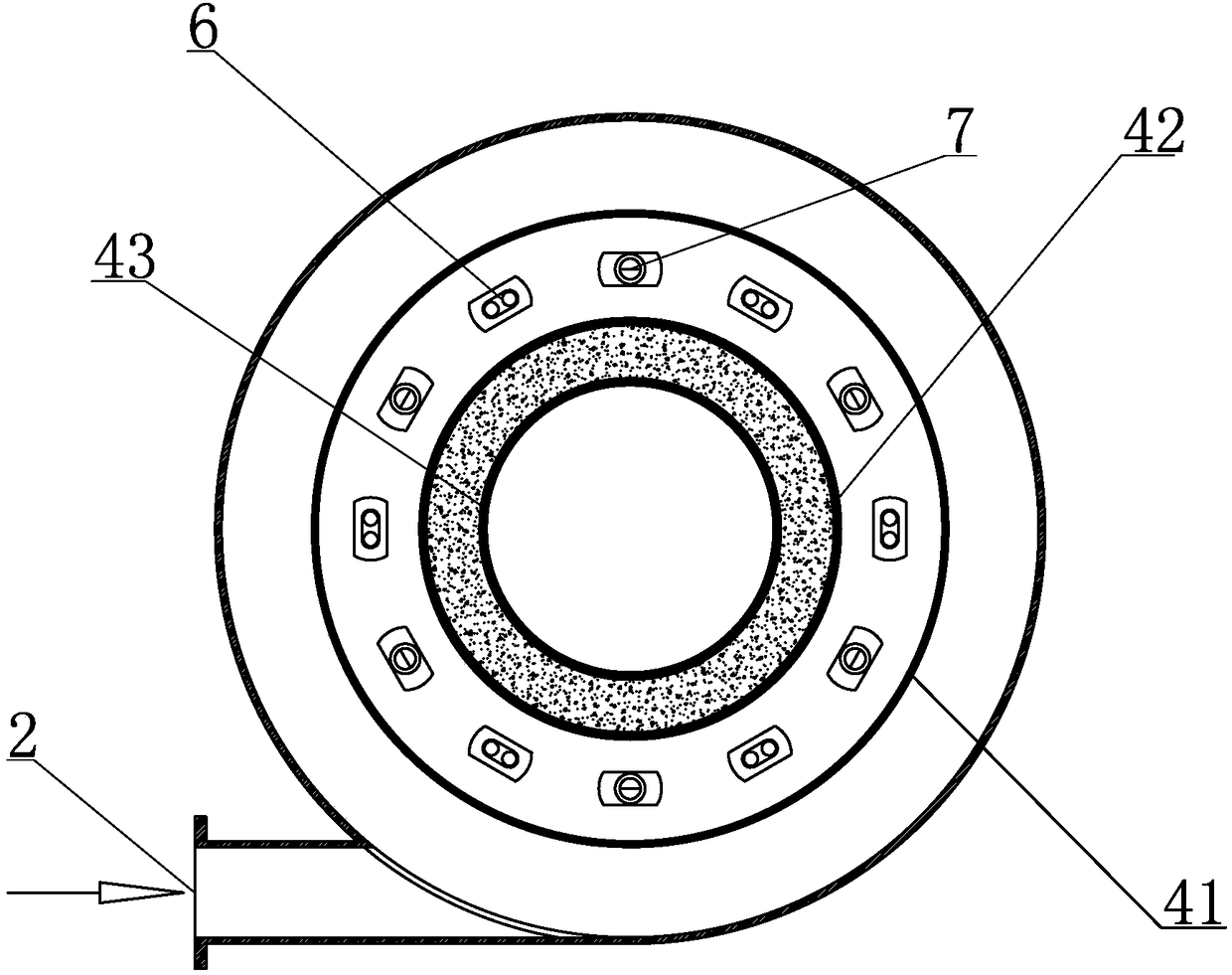

Integral type organic waste gas treatment device

PendingCN108273344AExtended service lifeImprove adsorption capacityCombination devicesGas treatmentActivated carbonEngineering

The invention discloses an integral type organic waste gas treatment device which comprises a shell, wherein an air inlet is formed in a side surface of the shell; an air outlet is formed in the upperend surface or the lower end surface of the shell; a rotating main shaft extending outside from inside is arranged inside the shell; a speed reduction motor is arranged at an end part, outside the shell, of the rotating main shaft; a first filtering cylinder, a second filtering cylinder and a third filtering cylinder are sequentially arranged inside the shell in a layer to layer manner; a plurality plasma bodies and ultraviolet lamp tubes which are distributed at annular intervals are arranged between the first filtering cylinder and the second filtering cylinder; an activated carbon layer isarranged between the second filtering cylinder and the third filtering cylinder; the upper end and the lower end of the first filtering cylinder are respectively connected with the interior of the shell; an upper sealing end cover and a lower sealing end cover are respectively arranged at two ends of the second filtering cylinder and the third filtering cylinder; the rotating main shaft penetrates through the shell, the upper end cover and the lower end cover. The integral type organic waste gas treatment device has the effects of being high in waste gas treatment efficiency, thorough in waste gas treatment, low in energy consumption and long in service life.

Owner:张世红

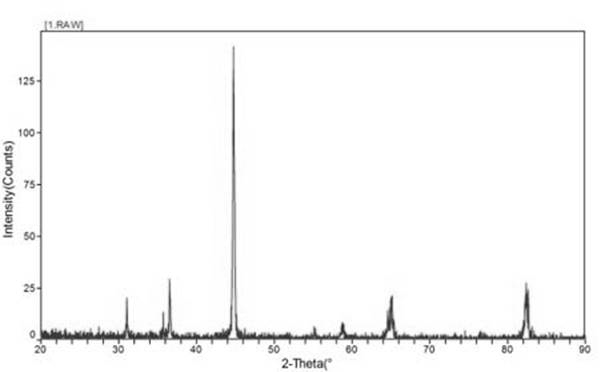

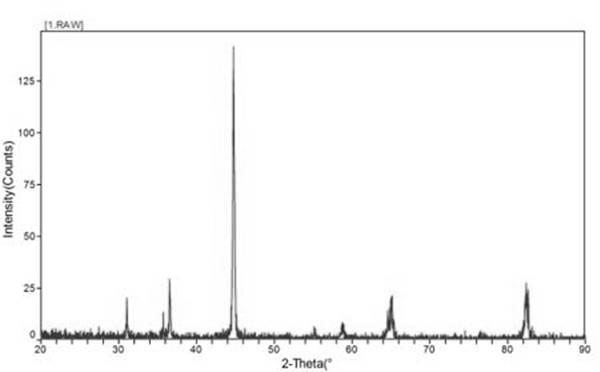

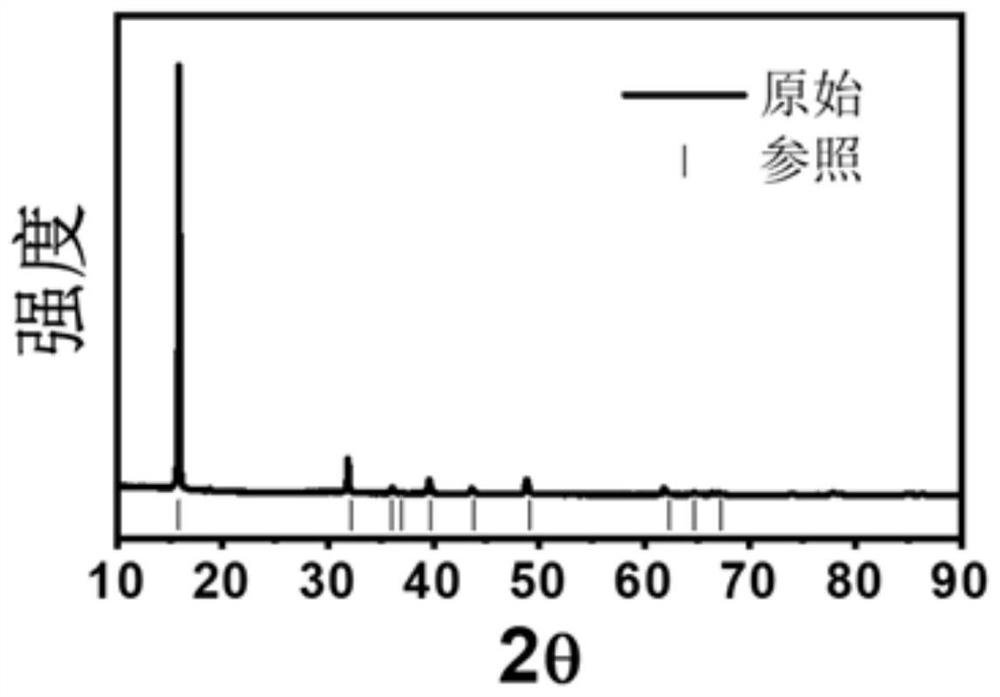

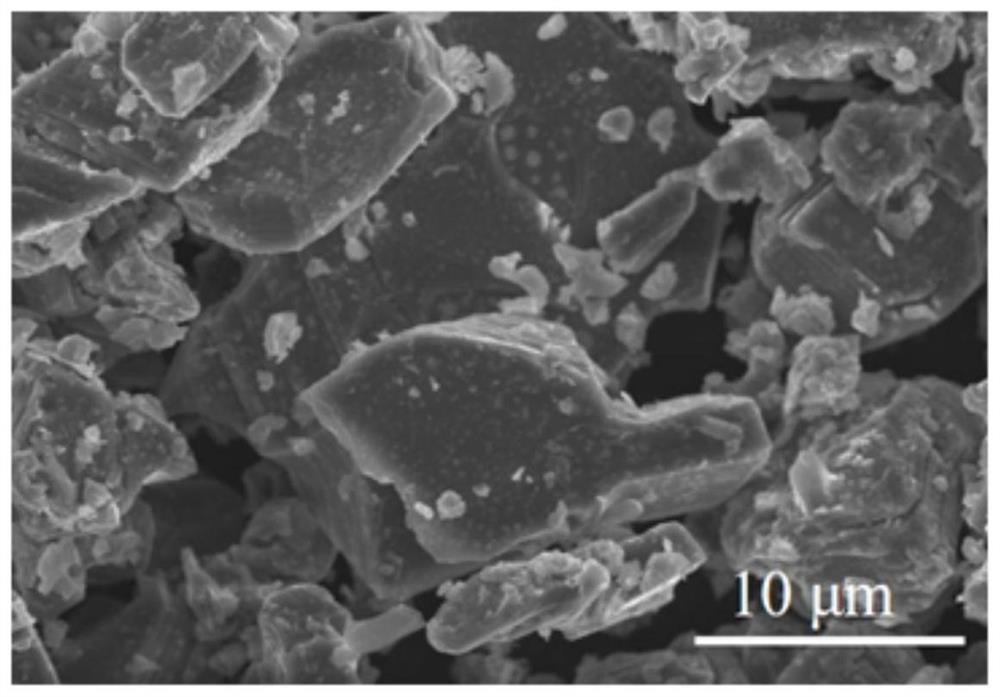

Preparation method of hercynite

InactiveCN102603315AThe reaction is fully and evenlyCompact internal structureBriquetteNeutral atmosphere

The invention provides a preparation method of hercynite, comprising the following steps of: dissolving iron salt and aluminum salt into water or alcohol to prepare a mixed solution in a molar ratio of iron ion to aluminum ion of 1:2; dropwise adding aqueous alkali into the mixed solution to neutralize till the pH value is 7; washing, dispersing and calcining precipitate; adding a binding material and graphite powder to be pressed into a briquette; sintering the briquette at the neutral atmosphere; and cooling to prepare the material. In the method, aluminum hydroxide precipitate and iron hydroxide precipitate, which are evenly mixed with each other, are generated by reaction of aqueous alkali, the aluminum salt and the iron salt react in the solution, and then the precipitate is dispersed by organic alcohol, so that the raw material can be sufficiently dispersed, the reaction is more sufficient and even, and the formed hercynite is more compact in an inner structure; and as the reductive graphite powder is added during sintering, the hercynite can be more preferably generated, so that the reaction time is shortened, and the content is increased.

Owner:HENAN UNIV OF SCI & TECH

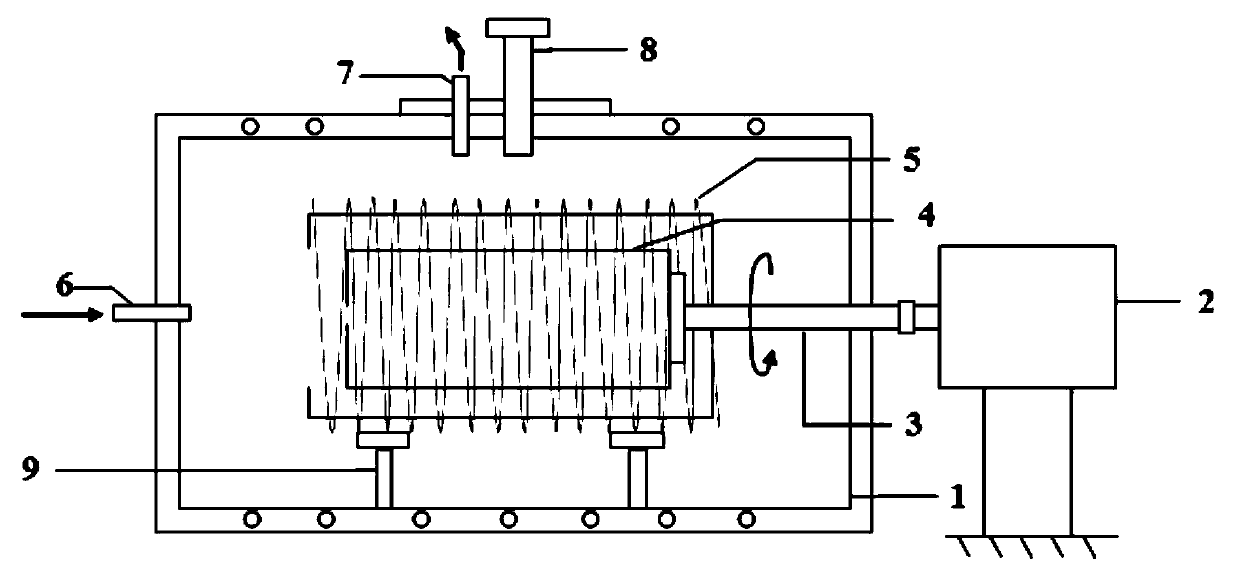

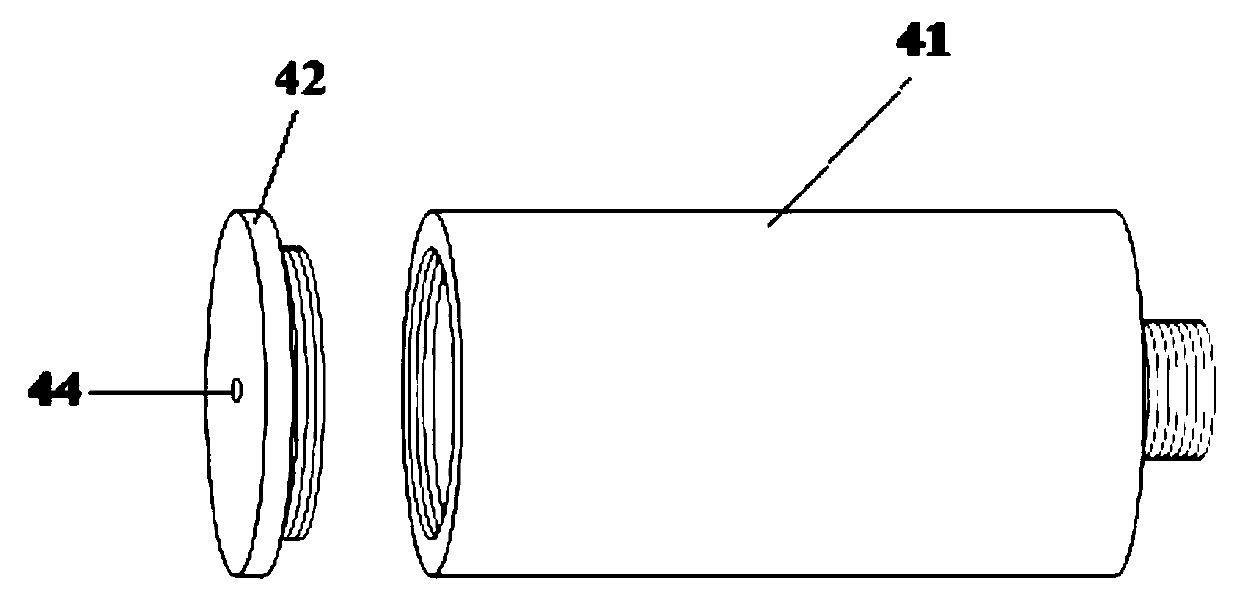

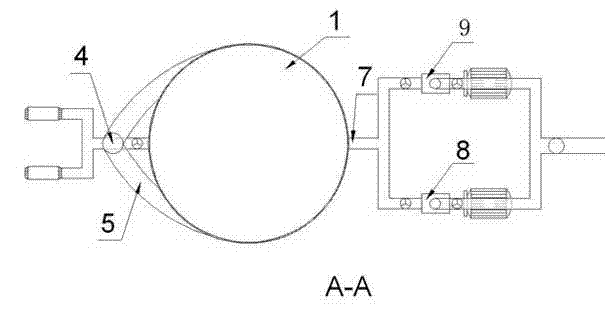

High-temperature atmosphere revolving furnace and application thereof in preparation of AION (Anterior Ischemic Optic Neuropathy) powder

ActiveCN103466668AHigh puritySmall grain sizeAluminium compoundsCrucibleAnterior ischemic optic neuropathy

The invention belongs to the field of high-temperature atmosphere furnaces, and provides a high-temperature atmosphere revolving furnace. The high-temperature atmosphere revolving furnace comprises a furnace body, a crucible and a heating insulation assembly which are positioned in the furnace body and a motor which is used for driving the crucible to rotate, wherein a gas inlet pipe, an exhaust pipe and a vacuum valve are arranged on the furnace body; the furnace body and the crucible are positioned horizontally; one end of the crucible is connected with a power output shaft of the motor positioned outside the furnace body through a connecting shaft; and the heating insulation assembly is mounted around the crucible and supported by a bracket fixed on the furnace body. The invention further provides an application of the high-temperature atmosphere revolving furnace in preparation of AION (Anterior Ischemic Optic Neuropathy) powder. When the high-temperature atmosphere revolving furnace is used for preparing the AION powder, the reaction temperature is decreased; the reaction time is shortened; and the production cost is saved.

Owner:SICHUAN UNIV

Lithium ion redox flow battery reactor

ActiveCN105489912AImprove flow uniformityImprove performanceRegenerative fuel cellsFuel cell auxillariesLithiumRedox

The invention provides a lithium ion redox flow battery reactor. The lithium ion redox flow battery reactor comprises a bipolar diaphragm, a positive electrode flow deflector and a negative electrode flow deflector, wherein the flow deflector is formed by multiple flowing channel ridges in a concentric-square-shaped frame; the flow deflector is divided into multiple parallel flow diversion channels by the flowing channel ridges; a liquid inlet and a liquid outlet are formed in the flow deflector frame corresponding to the two ends of each flow diversion channels; and the adjacent positive electrode flow deflectors or the adjacent negative electrode flow deflectors are communicated in series on the same side through communicating structures. According to the lithium ion redox flow battery reactor, each battery reaction cavity is equipped with a group of liquid inlets and liquid outlets, and the electrode suspension liquid communicating structure, so that electrode suspension liquid does not need to pass through a flow division cavity and a flow confluence cavity, instead, the electrode suspension liquid directly enters the electrode reaction cavity, so that the flow division cavity and the flow confluence cavity are eliminated, the consistency among the battery units is effectively improved, the battery performance is improved, and the structure of the reactor is greatly simplified.

Owner:南京竞予能源有限公司

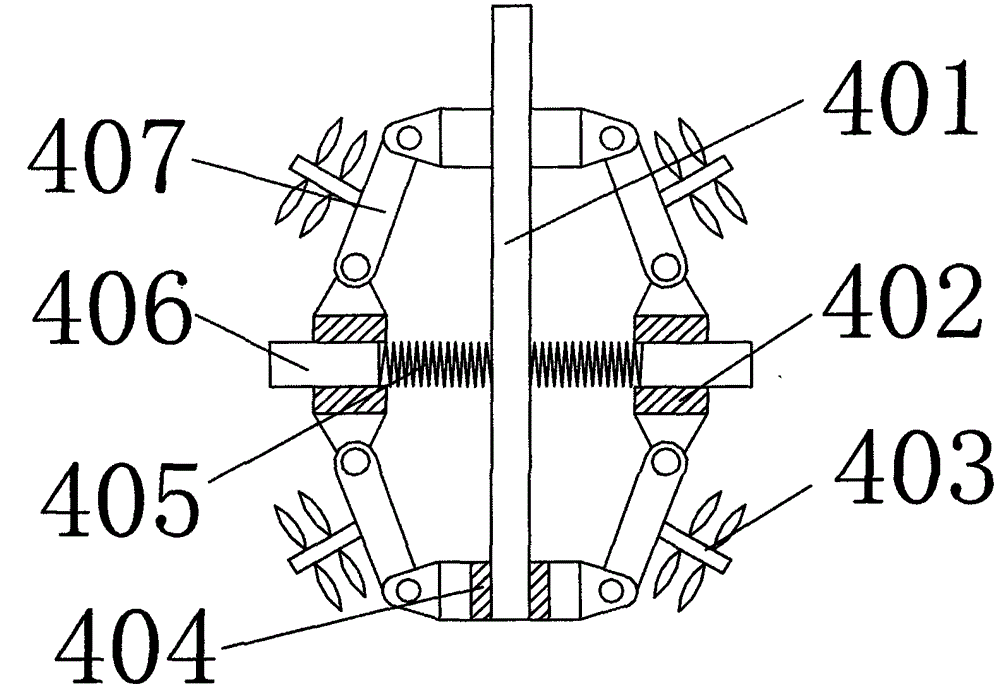

Microwave-assisted agitating ball-milling reactor

The invention provides a microwave assisted agitating ball-milling reactor. The reactor comprises a ball-milling system, a microwave-assisted system and a control system, wherein the ball-milling system includes a driving motor, a stirring rod, a stirring paddle, a ball-milling cylinder, and a milling ball placed in the ball-milling cylinder; the microwave-assisted system comprises a microwave heating cylinder, a thermal insulation wave-transparent layer, a microwave feeding port, a microwave emission source, and a microwave power source; the ball-milling cylinder is placed in the microwave heating cylinder; a layer of the thermal insulation wave-transparent layer is wrapped in the inner surface, along the circumference, of the sidewall of the microwave heating cylinder; the upper end of the stirring rod penetrates through the microwave cylinder the top wall of the ball-milling cylinder and is connected with the driving motor; the bottom end of the stirring rod extends in the ball-milling cylinder; the stirring paddle is arranged at the portion, in the ball-milling cylinder, of the stirring rod; the microwave feeding port is arranged on the sidewall of the microwave heating cylinder, and sealed and fixedly connected with the inner cavity of the microwave heating cylinder; and the microwave power source is connected with the control system. According to the reactor, the solid phase involved reaction can be more complete and uniform under the premise of achieving more precise control of the temperature.

Owner:黄湛明

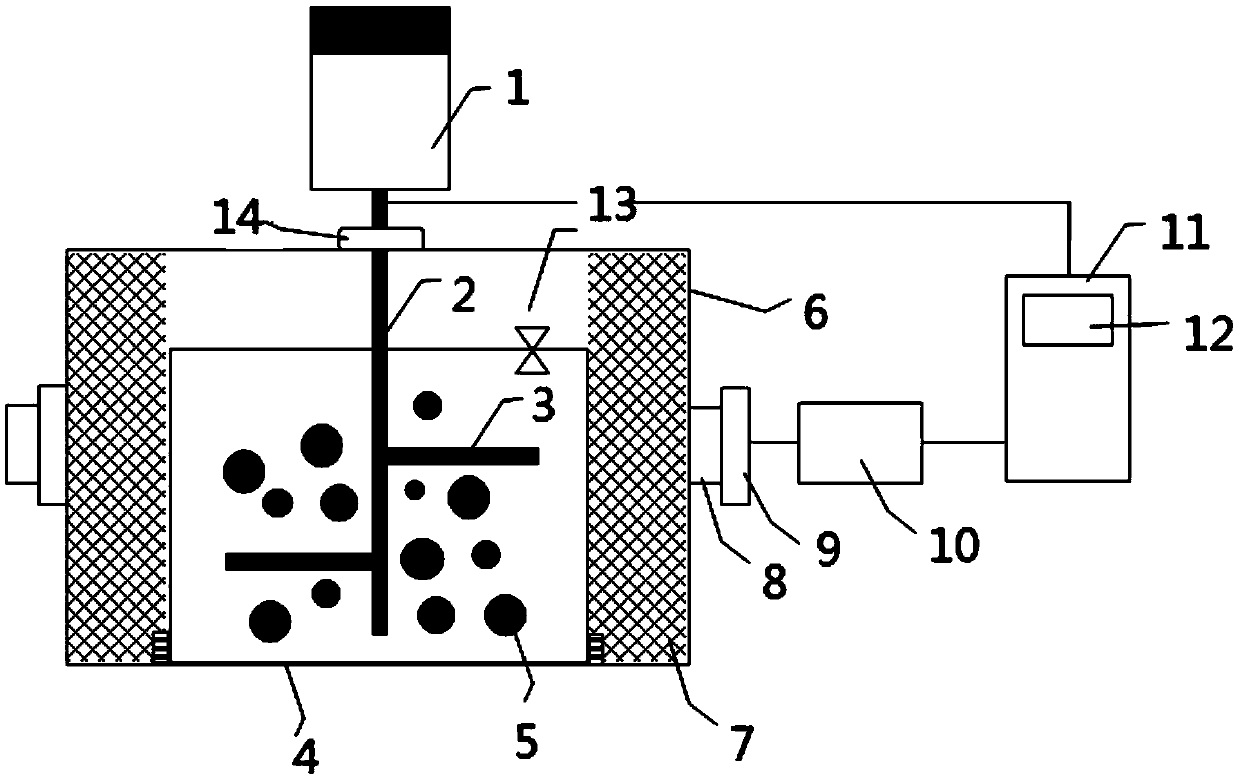

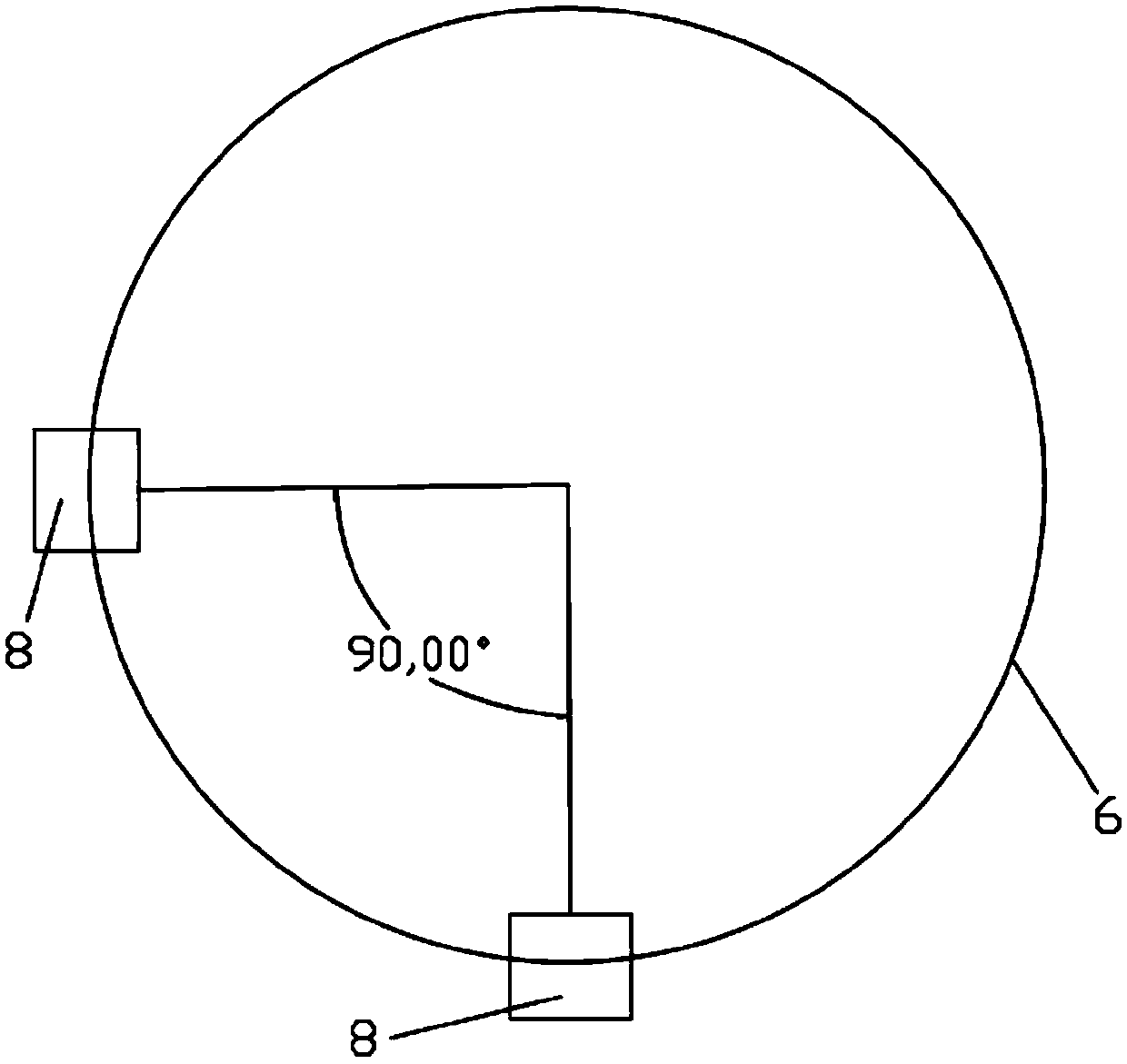

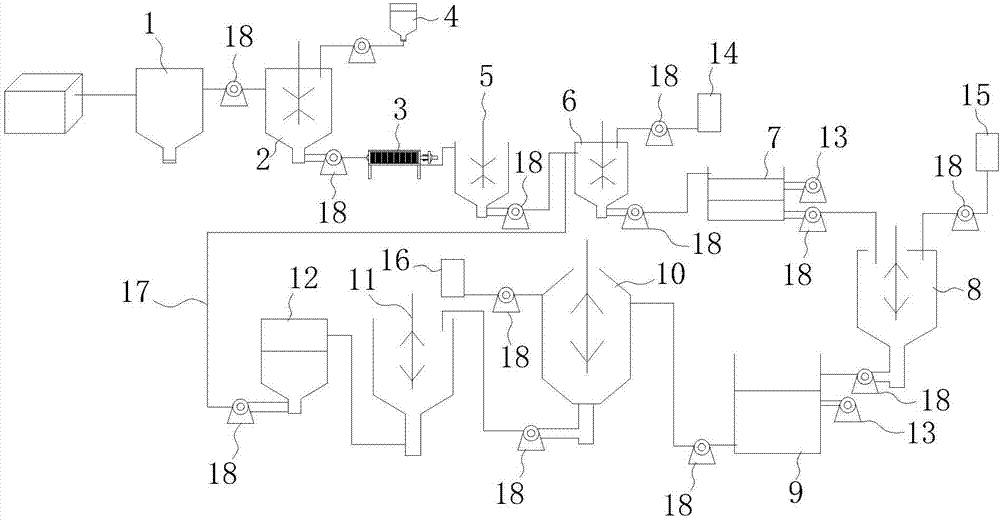

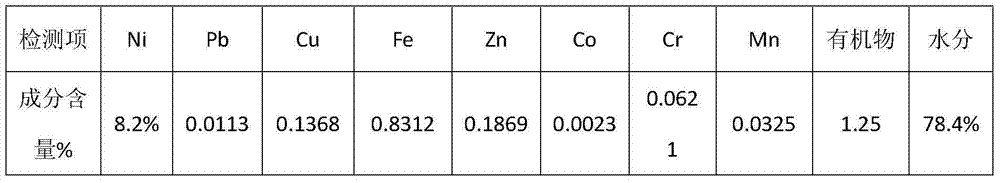

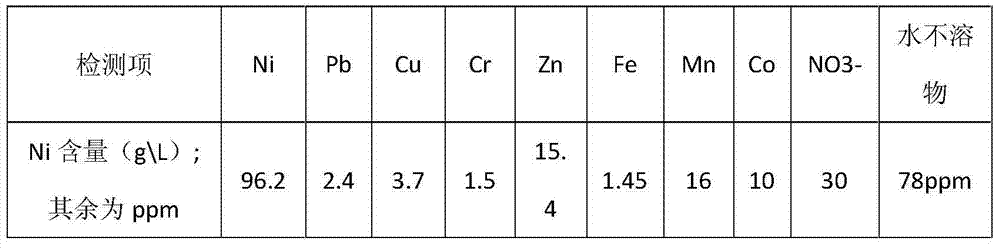

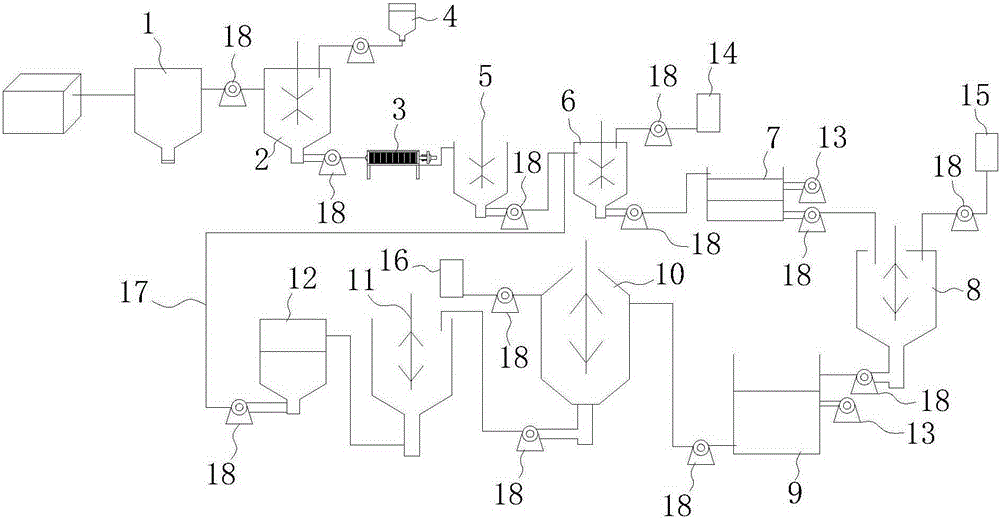

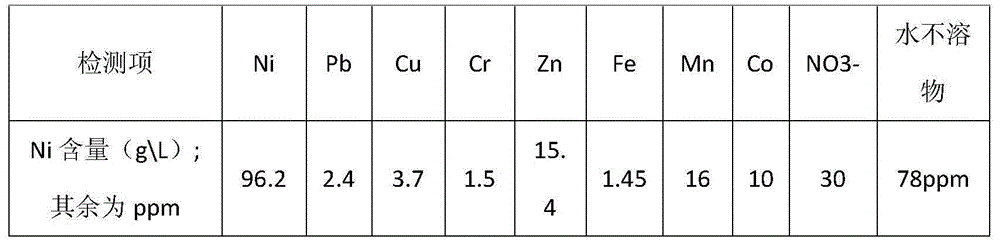

Method and equipment for preparing electroplating-grade nickel sulfate from nickel-containing wastewater produced in surface treatment process

ActiveCN104229906AReduce carryoverReduce volumeMultistage water/sewage treatmentNickel sulfatesFiltrationSulfate

The invention discloses a method and equipment for preparing electroplating-grade nickel sulfate from nickel-containing wastewater produced in a surface treatment process, and belongs to the technical field of nickel-containing wastewater treatment process. The method is characterized by comprising the following steps: (1) collecting nickel-containing wastewater; (2) performing sedimentation and press filtration on nickel in the nickel-containing wastewater, and smashing nickel mud to obtain nickel slurry; (3) dissolving the nickel slurry into acid; (4) filtering a nickel sulfate solution; (5) removing impurities from the nickel sulfate solution for purification, and performing secondary filtration; (6) performing vacuum evaporative concentration, crystallization, filtration and centrifugal drying on the nickel sulfate solution to obtain nickel sulfate crystals. The invention aims to provide the method and the equipment which can reduce the waste of nickel resources, reduce potential hazard of nickel to the natural environment and realize recycling of the nickel resources and are used for preparing the electroplating-grade nickel sulfate from the nickel-containing wastewater produced in the surface treatment process. The method and the equipment are used for treating the nickel-containing wastewater.

Owner:MEIZHOU ENVIRONMENTAL EQUIP

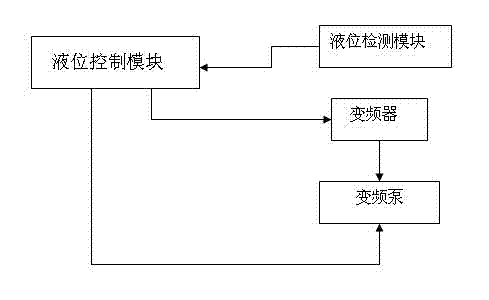

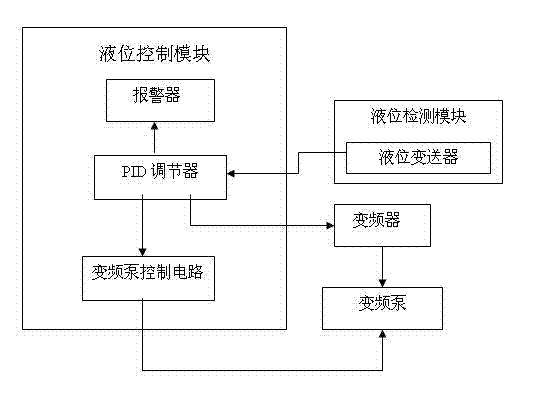

Stoving neutralizing auxiliary reaction tower

InactiveCN103173579AControl dwell timeControl unit controls dwell timePurification by oxidation/reductionPurification using alkaline earth metal compoundsChemical reactionSulfur

The invention aims to provide a stoving neutralizing auxiliary reaction tower. The stoving neutralizing auxiliary reaction tower comprises a cylindrical tank body, a stoving neutralizing reactor, a tube diffuser, a juice outlet pipe, a variable frequency juice outlet pump and a liquid level control device. By using the stoving neutralizing auxiliary reaction tower, the defects of the conventional neutralizing reaction device in a sugar refinery are overcome, and the problem of incomplete chemical reaction of the cane juice subjected to stoving liming is solved. The invention also provides a method for carrying out stoving neutralizing reaction by using the stoving neutralizing auxiliary reaction tower. According to the method, the stoving neutralizing auxiliary reaction tower is reasonably utilized, so that the standing time of the cane juice subjected to stoving liming is greatly increased, the uniformity of the cane juice is improved, the reaction of neutralized juice is more complete, and remarkable effects of improving the syrup purity, reducing the color value of white sugar and turbidity and lowering the sulfur dioxide residues are achieved.

Owner:南宁苏格尔科技有限公司

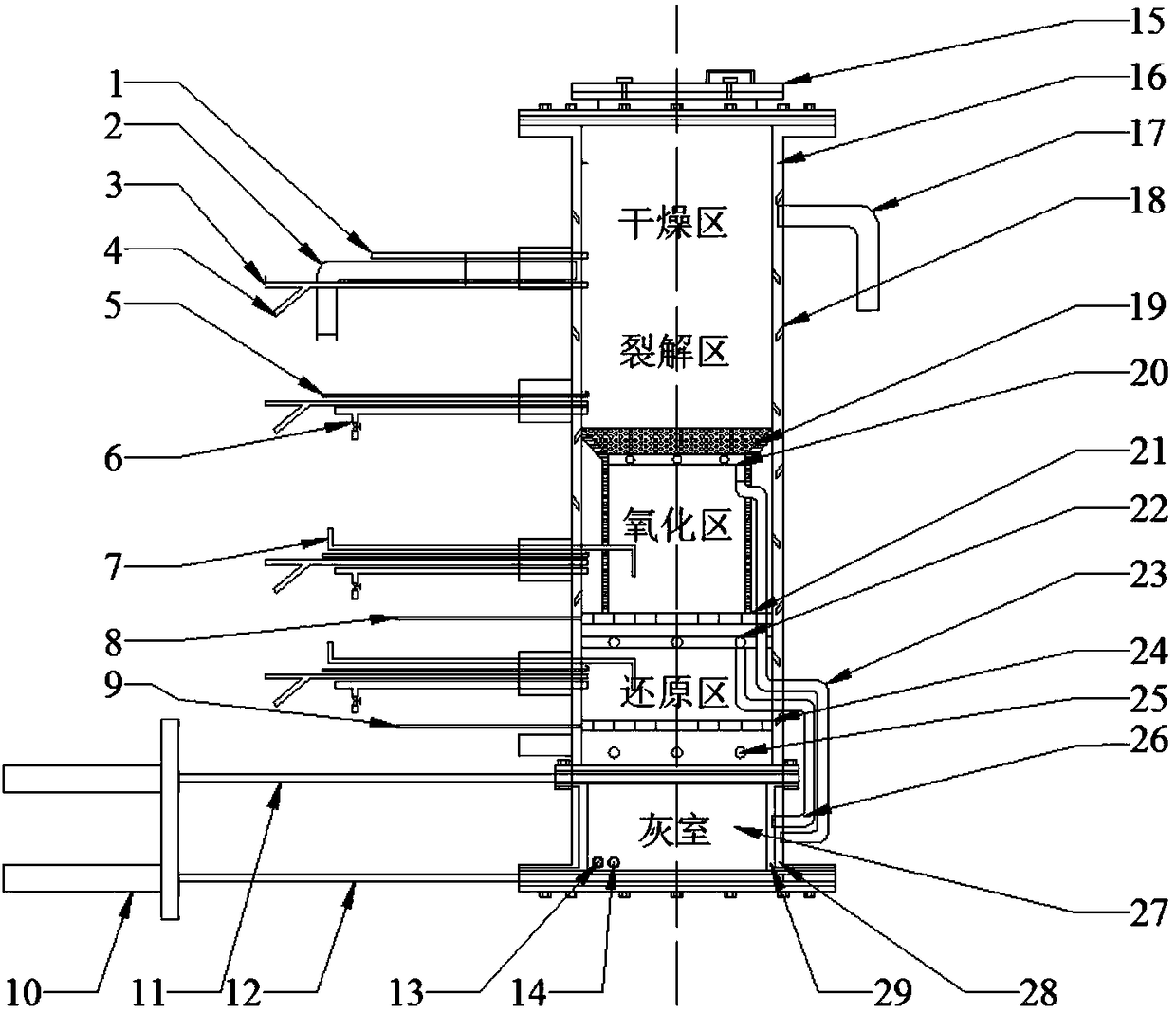

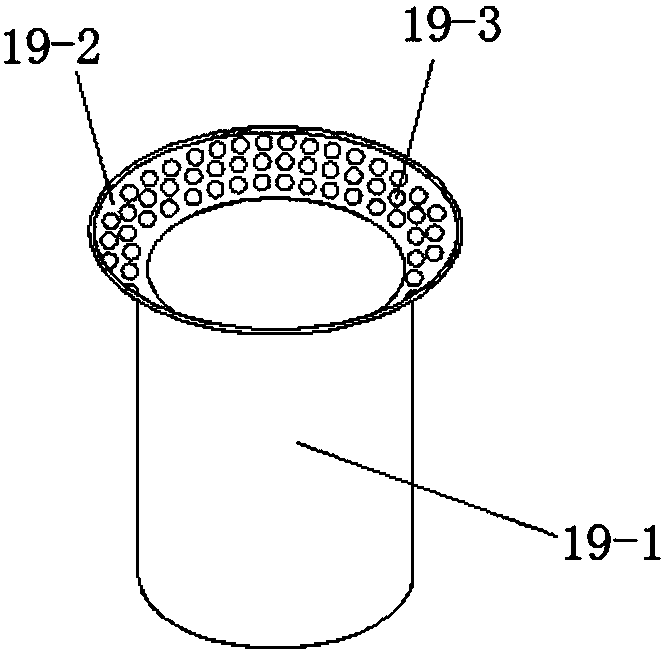

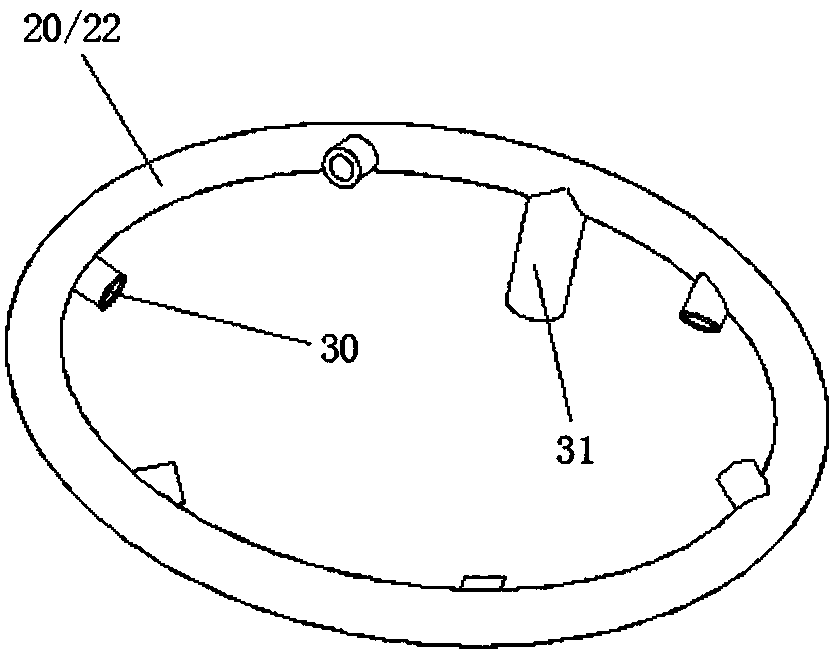

Biomass gasification furnace and gasification operation method thereof

ActiveCN108192667AHigh thermal efficiencyAvoid emissionsChemical industryGasification processes detailsReaction temperatureEngineering

The invention relates to a biomass gasification furnace and a gasification operation method thereof, and belongs to the technical field of energy conservation equipment. A drying area, a cracking area, an oxidation area, a reduction area and an ash chamber are arranged in a reaction furnace body sequentially from top to bottom; a Y-shaped cracking gas isolating flow dividing device is arranged inthe oxidation area; an oxidation area round tangential air supply device is arranged in the Y-shaped cracking gas isolating flow dividing device; an upper movable furnace bar is arranged at the bottomof the Y-shaped cracking gas isolating flow dividing device; a lower movable furnace bar is arranged at the bottom of the reduction area; a reduction area round tangential air supply device is arranged at the top of the reduction area; the ash chamber is formed by coiling three layers of heat-resistant steel plates and then is welded with upper and lower flanges, so that the gasification reactionis higher in controllability and more flexible in adjustment, the gasification working condition can be effectively improved, the gasification reaction is more uniform and complete, the problem of waste of heat caused by too high reaction temperature of the gasification furnace can be avoided, the heat efficiency of the reaction furnace is improved, the gasification efficiency is improved, the content of tar in fuel gas is reduced and the quality of the fuel gas is improved.

Owner:YANGZHOU UNIV

Moving desorptive equipment for activated coke

InactiveCN1132677CReduce resistance to movementLow running costDispersed particle separationCombustible gas purificationInlet valveAir pump

A flowing desorptive equipment for regenerating the activated coke which has adsorbed SO2 is composed of inlet storage cabin, inlet valve, inlet transition cabin, heating cabin with heating heat exchanger, reaction cabin, cooling cabin with cooling heat exchanger, outlet transition cabin and outlet valve in sequence. There is an insulating layer between the units above the outlet transition cabin. A heater is between the said two heat exchangers. Its advantages are simple structure, uniform reaction without dead corner, low flowing resistance, and low cost.

Owner:SHANGHAI CLEAR ENVIRONMENTAL PROTECTION SCI & TECH

Preparation method for high-bonding wearproof composite coating

ActiveCN105506716AHigh bonding strengthThe reaction is fully and evenlyElectrolytic coatingsUltrasonic oscillationDiamond

The invention discloses a preparation method for a high-bonding wearproof composite coating. The high-bonding wearproof composite coating is characterized in that diamond powder and silica powder are ball-milled and mixed according to a proportion of 1:(1-5); then electrophoretic liquid is added, wherein the electrophoretic liquid is prepared from water, absolute ethyl alcohol and acetone according to the mass part ratio of 1:8:1; and the mixture is subjected to ultrasonic oscillation for 10-15 minutes after being stirred with a glass rod. The prepared suspension liquid is placed on a magnetic stirrer; electrode materials are inserted, wherein the negative electrode material is graphite; an electrophoresis apparatus is connected, and then mixed powder starts to be electrophoretically deposited on the graphite; and the electrophoretic deposition time is 1-10 minutes. The revolving speed of the magnetic stirrer is 500-1200 r / min; after the electrophoretic deposition is finished, a deposited sample is taken out carefully, is dried for 1-2 h at 100-120 DEG C, and then is placed in a high-vacuum reacting furnace; the reacting furnace is heated to 1500-1600 DEG C at an inert atmosphere, and then the temperature is maintained for 1-2h; and reactive sintering is performed to obtain the composite coating. According to the preparation method, a carbide interface is formed between a substrate and diamond through metallurgical reaction, so that the bonding strength of the diamond is improved; electrophoretic deposition mixed powder particles are uniform and compact; the coating is reacted uniformly and thoroughly; the preparation cycle is short; and the cost is low.

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

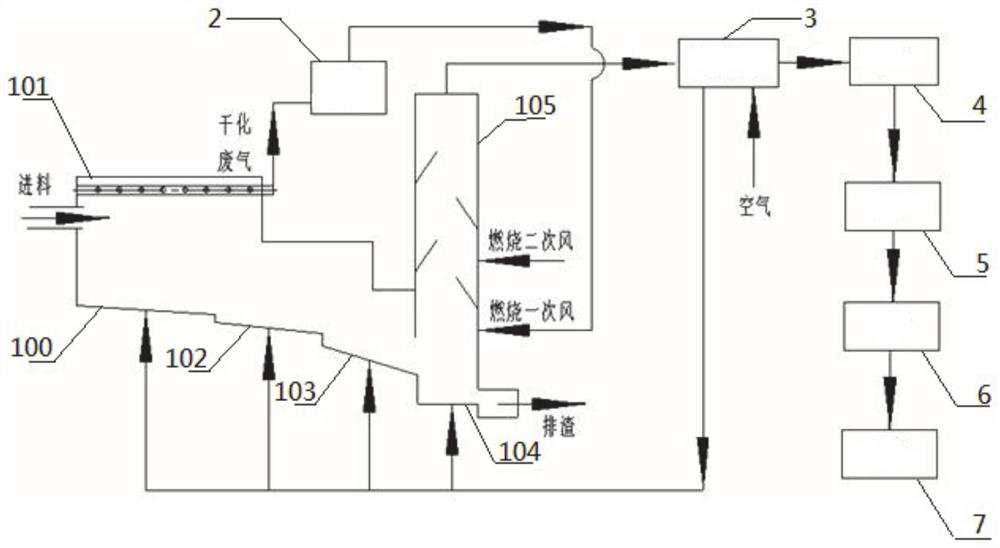

Garbage pyrolysis and gasification incineration system and process

InactiveCN111853801AImprove utilization efficiencyIncrease the low calorific valueCombustion technology mitigationIncinerator apparatusWater vaporDust collector

The invention particularly relates to a garbage pyrolysis and gasification incineration system and process. According to the garbage pyrolysis and gasification incineration system, a pyrolysis and gasification furnace, a high-temperature heat exchanger, a quench tower, a demister, a dust collector and an exhausting device are connected successively, and the pyrolysis and gasification furnace is provided with a drying area, a pyrolysis area, a gasification area, an ash after-combustion area and a gas combustion area which are integrally formed. The drying area is further provided with an exhaust gas recovery pipeline to extract water vapor generated in a garbage drying process on the one hand to improve the stability of garbage pyrolysis and gasification and combustion reaction processes, and on the other hand, the dried exhaust gas can be further taken as primary combustion air of gas combustion. Heat generated by garbage incineration is distributed again to enter an incineration furnace to assist garbage combustion. The system can operate stably by controlling an air distribution proportion without extra energy for supporting combustion. A low generation rate of pollutants such asdioxin, heavy metals, oxynitride and oxysulfide can be further guaranteed. The garbage pyrolysis and gasification incineration system and process have good popularization and application value.

Owner:山东百川同创能源有限公司

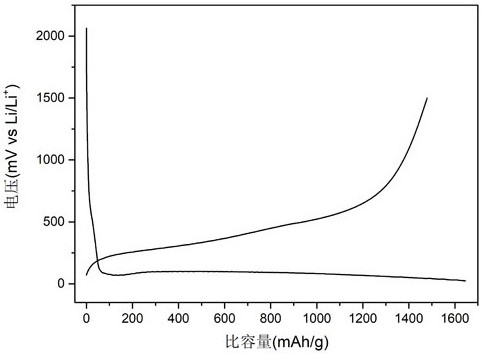

Method for pre-lithiation of silicon-based negative electrode material

InactiveCN112563457AImprove first-time efficiencyThe reaction is fully and evenlyCell electrodesFinal product manufacturePhysical chemistryAromatic hydrocarbon

The invention discloses a method for pre-lithiation of a silicon-based negative electrode material. The method comprises the following steps: dissolving aromatic hydrocarbon organic matters in organicether to prepare an aromatic hydrocarbon-containing solution, putting a lithium sheet into the solution, and reacting aromatic hydrocarbon with the lithium sheet to obtain a precursor solution of aromatic hydrocarbon lithium salt; then adding the silicon-based negative electrode material into the precursor solution to obtain a turbid liquid, and carrying out a pre-lithiation reaction; and standing for a period of time, drying the turbid liquid under the protection of an inert atmosphere, and calcining to obtain the pre-lithiated silicon-based negative electrode material. The method has the advantages that the preparation is simple, the silicon-based material can be effectively pre-lithiated, and the first efficiency is greatly improved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

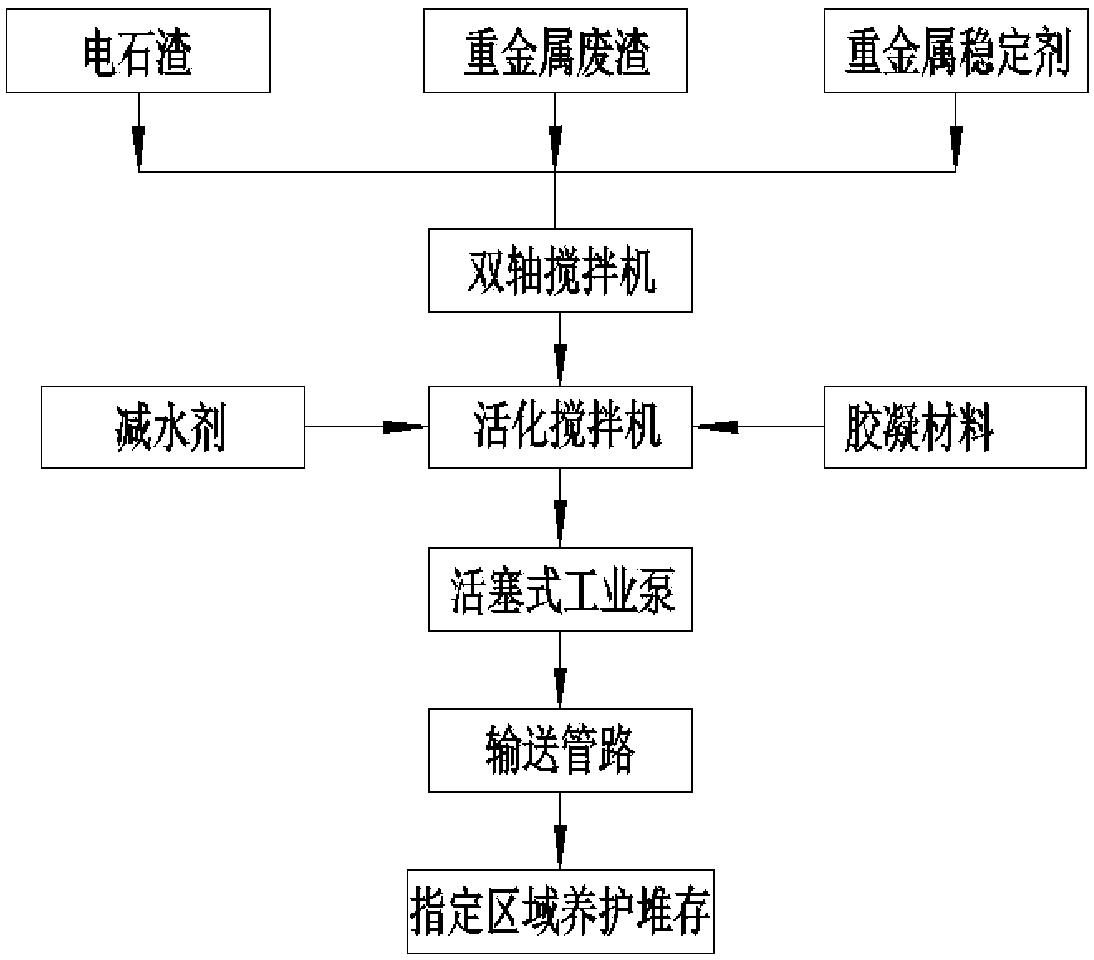

Stable curing continuous treatment process of heavy metal waste residues

A stable curing continuous treatment process of heavy metal waste residues comprises the following steps that the heavy metal waste residues, carbide slag and a heavy metal stabilizer are added into adouble-screw horizontal stirrer according to a certain metering proportion, discharging is carried out after even stirring is carried out, and the mixture enters an activating stirrer; meanwhile, a water reducing agent and a binding material are added into the activating stirrer, and the mixture is discharged into a piston type industrial pump after even stirring is carried out; finally, the product is conveyed to a specified area to be maintained and piled up. The process has the advantages of being large in treatment amount, capable of achieving continuous production, good in heavy metal waste residue stabilizing / curing effect and low in cost, and can be widely applied to the fields of the heavy metal waste residues, mining rehabilitation, waste and industrial waste incineration fly ashtreatment and the like.

Owner:HUNAN HENGKAI ENVIRONMENT TECH INVESTMENT CO LTD

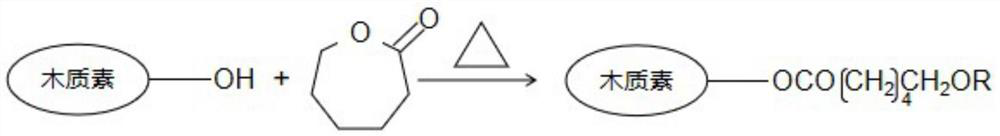

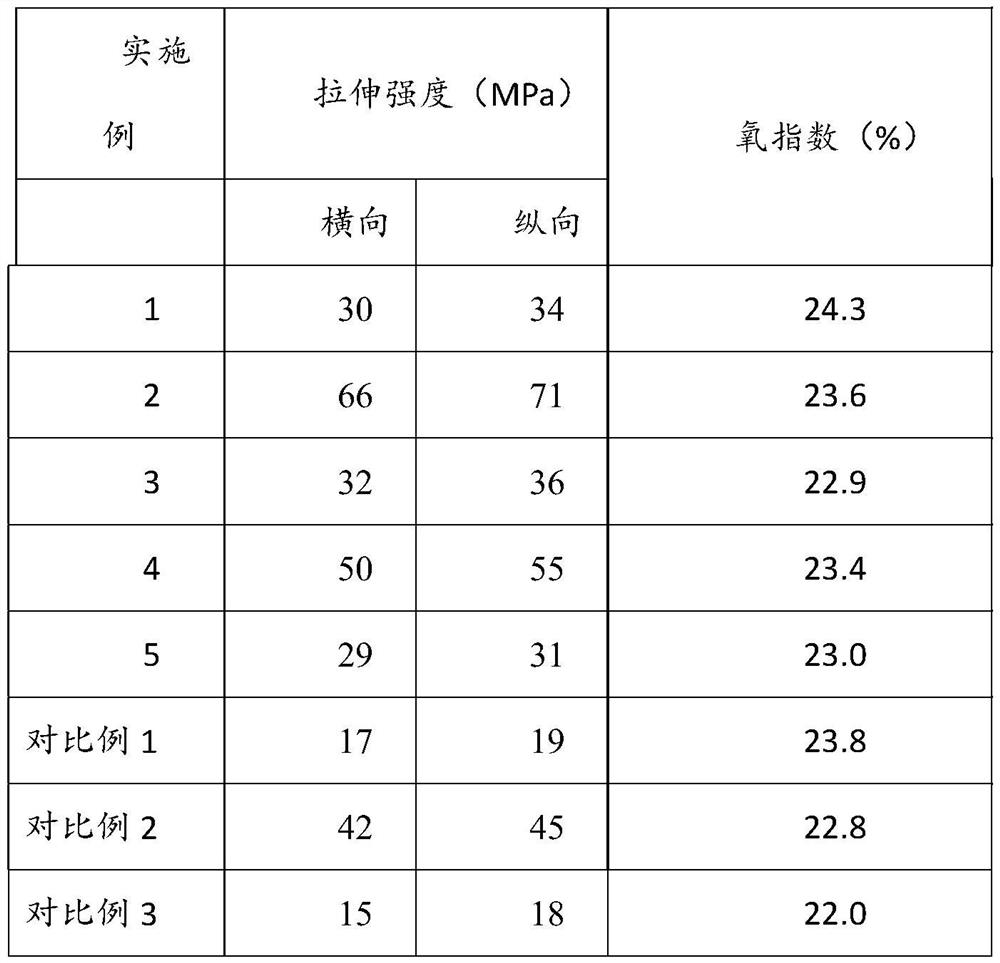

Lignin-based biodegradable polymer composite film and preparation method thereof

The invention discloses a lignin-based biodegradable polymer composite film which is prepared from the following raw materials in parts by weight: 100 parts of a biodegradable polymer material, 5-30 parts of lignin and 0.2-6 part of caprolactone. The invention also provides a preparation method of the lignin-based biodegradable polymer composite film. The preparation method has the advantages thatthe prepared lignin-based biodegradable polymer composite film is high in tensile strength and tear strength, resistant to ultraviolet radiation, flame-retardant, simple in preparation process, low-carbon, environment-friendly, high in production efficiency and easy to industrialize.

Owner:HUAIHUA UNIV

Defoaming and adding method and defoaming and adding device for wet-process phosphoric acid extraction reaction

ActiveCN108455543AUnobstructed ventilationImprove cooling effectLiquid solutions solvent extractionPhosphorus compoundsPhosphoric acidChemistry

The invention discloses a method for defoaming a wet-process phosphoric acid extraction reaction. The adding method comprises the following steps: firstly, adding phosphoric ore pulp into an extraction tank; secondly, adding sulfuric acid into the phosphoric ore pulp from the lower part of the extraction tank; adding the sulfuric acid into the extraction tank (1) from a liquid feeding device. By adopting a liquid feeding method, foams are greatly reduced so as to eliminate adverse influence in the extraction process.

Owner:SICHUAN MIANZHU PANLONG MINERALS CO LTD +1

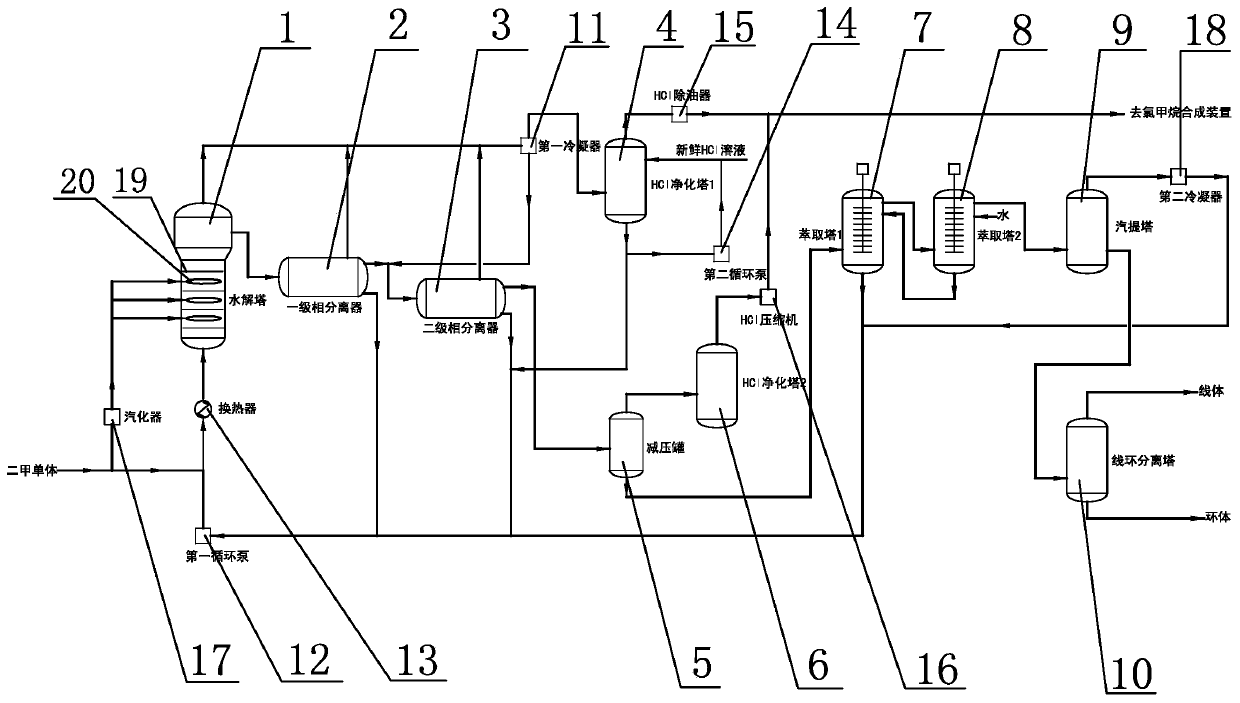

Organochlorosilane hydrolysis and hydrochloric acid refining system and method

ActiveCN110845734ARemove completelyInhibit aggregationChlorine/hydrogen-chloride purificationSpecific gas purification/separationPhysical chemistryHydrolysis

The invention discloses an organochlorosilane hydrolysis and hydrochloric acid refining system and a method. The organochlorosilane hydrolysis and hydrochloric acid refining system is characterized bycomprising a hydrolysis tower, a primary phase separator, a secondary phase separator, a first hydrochloric acid purification tower, a decompression tank, a second hydrochloric acid purification tower, a first extraction tower, a second extraction tower, a stripping tower and a line-loop separation tower; a plurality of sections of feeding holes are formed in the side part of the hydrolysis tower; an oil phase outlet at the upper end of the hydrolysis tower is connected with a feeding hole of the primary phase separator; an oil phase outlet of the primary phase separator is connected with a feeding hole of the secondary phase separator; a top gas phase outlet of the hydrolysis tower, a gas phase outlet of the primary phase separator and a gas phase outlet of the secondary phase separatorare respectively connected with a first condenser; a top gas phase outlet of the first condenser is connected with a lower end feeding hole of the first hydrochloric acid purification tower, the upperend of the first hydrochloric acid purification tower is provided with a fresh hydrochloric acid solution inlet, and the bottom of the first hydrochloric acid purification tower is provided with an oil phase outlet. The organochlorosilane hydrolysis and hydrochloric acid refining system has advantages of high reaction conversion rate and high product purity.

Owner:SEDIN NINGBO ENG

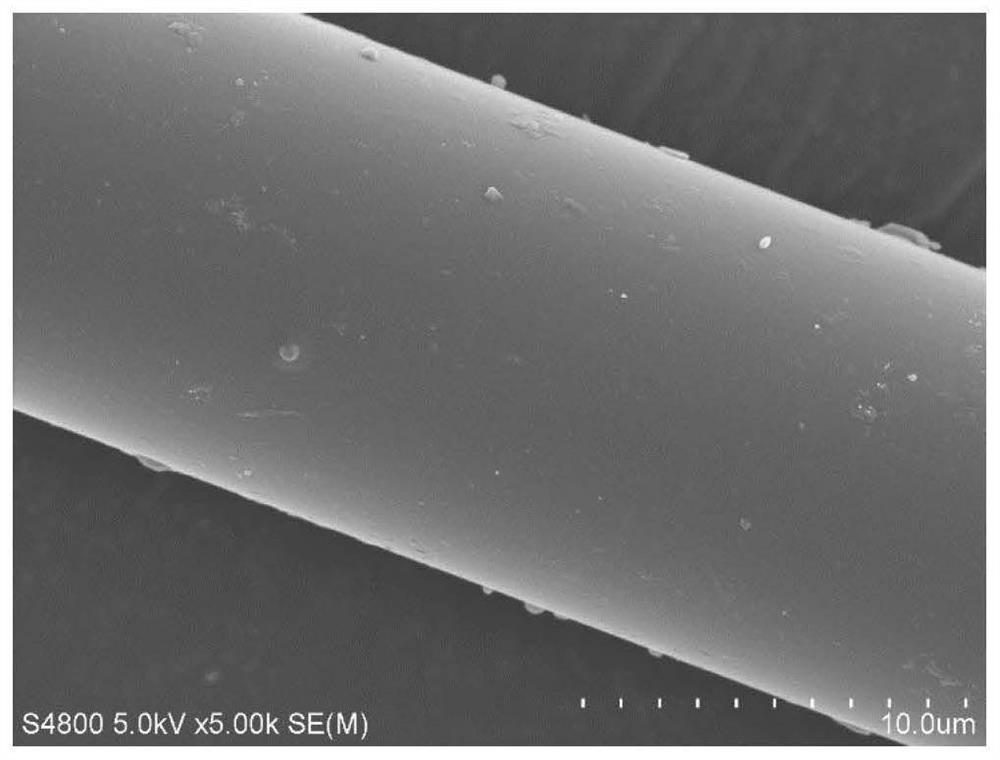

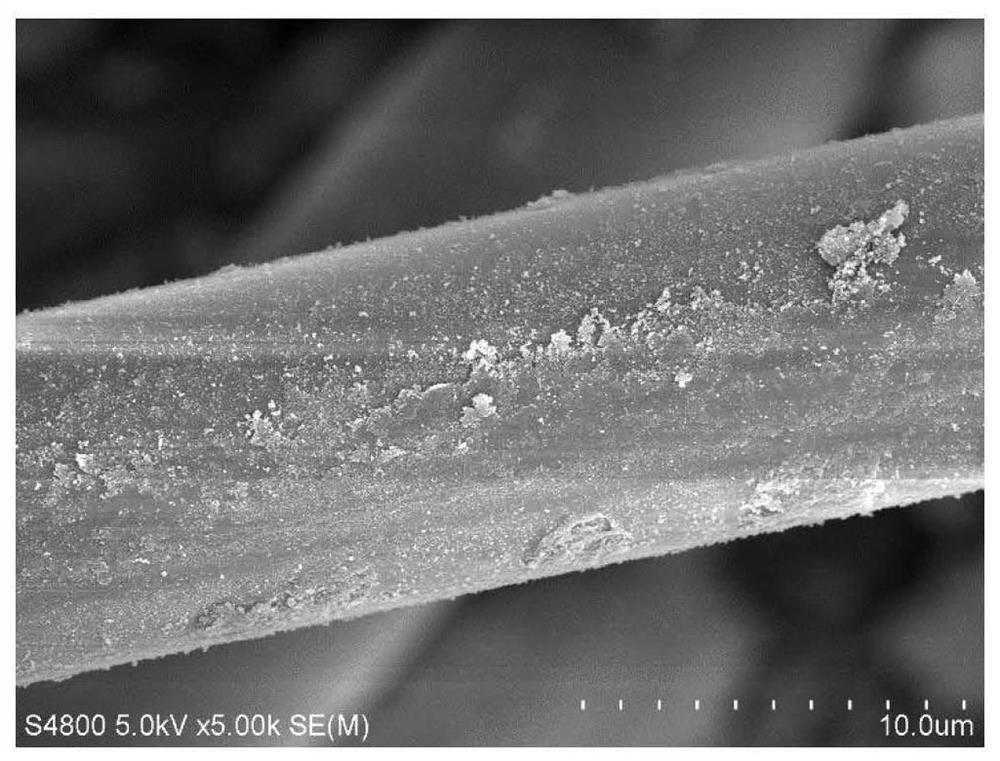

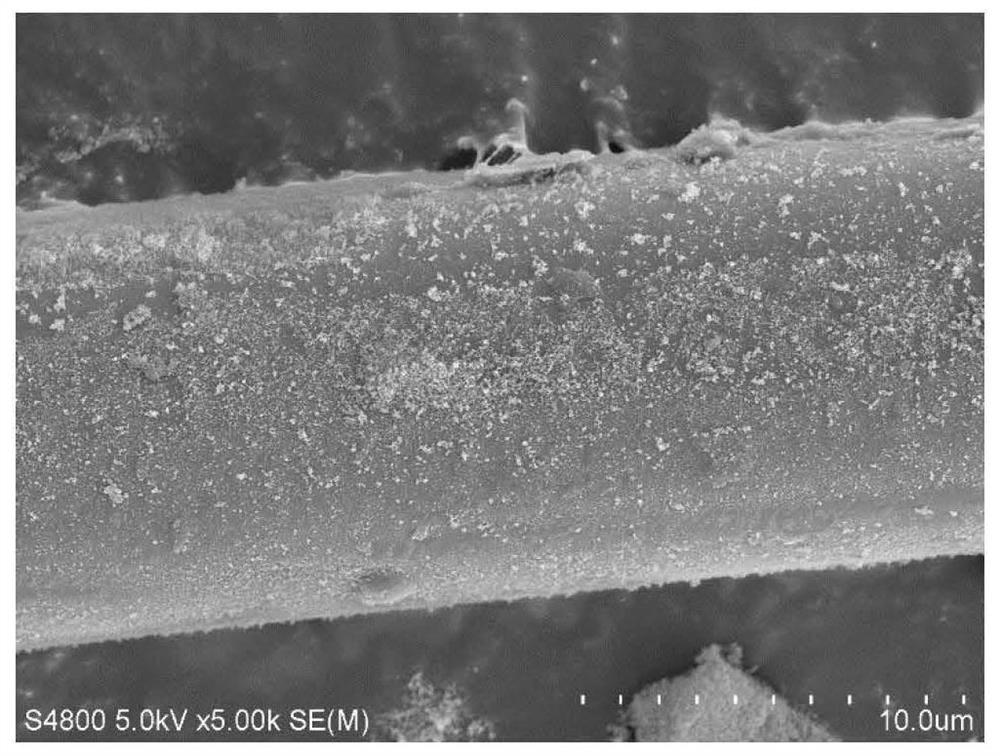

Chopped glass fiber silicon dioxide aerogel composite material and preparation method thereof

The invention discloses a preparation method of a chopped glass fiber silicon dioxide aerogel composite material and the obtained silicon dioxide aerogel composite material. The method comprises the following steps: mixing a silicon source, a solvent I, an acid catalyst, a chemical drying control additive, a basic catalyst, a solvent II and chopped glass fibers, preserving heat to form composite wet gel, putting the prepared composite wet gel into a reaction kettle, adding an aging solution for aging, and then sealing and preserving heat; adding an exchange solvent for at least two times, and keeping the temperature to enable the wet gel to form aerogel; adding a surface modifier and preserving heat for surface modification; adding an exchange solvent and preserving heat; and drying at normal pressure to obtain the silicon dioxide aerogel composite material. In the preparation process, the consumed solvent is less, the preparation speed is high, and the prepared silicon dioxide aerogel composite material is good in heat insulation property, small in density, high in hydrophobicity and high in mechanical strength.

Owner:北京蓝星清洗有限公司

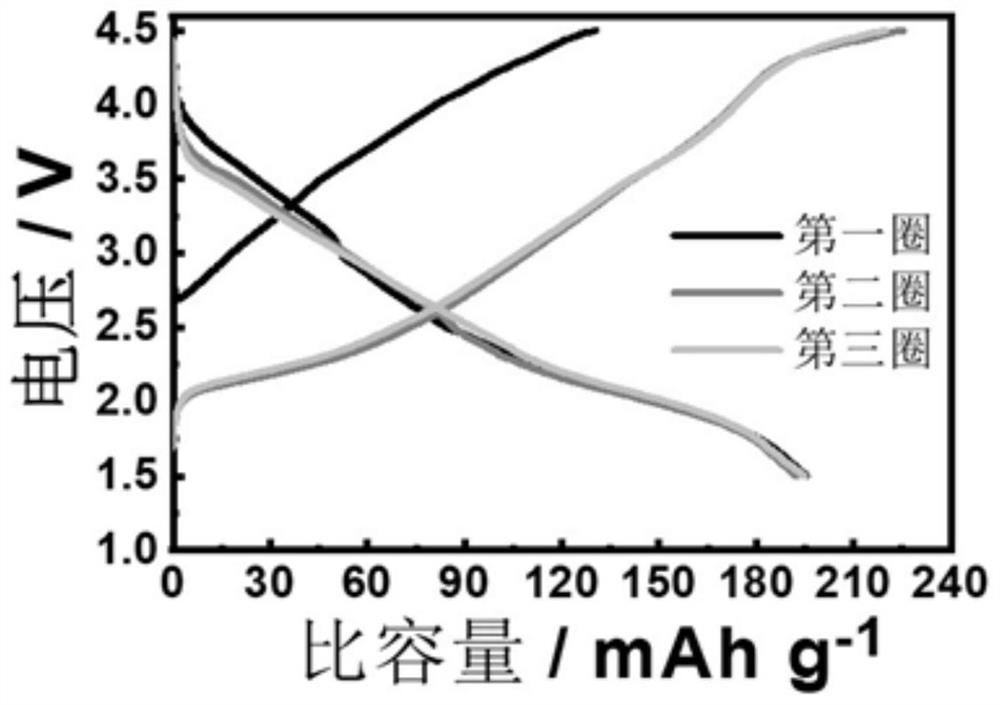

High-specific-energy sodium-ion battery manganese-based layered positive electrode material and preparation method thereof

ActiveCN113782714AImprove cycle stabilityImprove structural stabilityCell electrodesChemical physicsManganese

The invention relates to the field of electrochemistry, and especially relates to a high-specific-energy sodium-ion battery manganese-based layered positive electrode material. The general formula of the material is NaxLiyMn1-y-zMzO2, wherein M is Ru, Ni, Cu, Zn, Mg or Ti, x is more than or equal to 0.5 and less than or equal to 1, y is more than 0 and less than or equal to 0.33, and z is more than 0 and less than or equal to 0.33. In the positive electrode material, the Li element occupies the transition metal layer, and the Li-O-Na configuration triggers the non-hybrid energy level of oxygen and triggers the oxidation reduction of oxygen. According to the high-specific-energy sodium-ion battery manganese-based layered positive electrode material, a small amount of other metal M is uniformly doped, and a stronger covalent bond is formed relative to manganese and oxygen, so that the structural stability of lattice oxygen after electrons near oxygen are removed is improved, and the cycling stability of the sodium-ion battery is improved.

Owner:NANJING UNIV

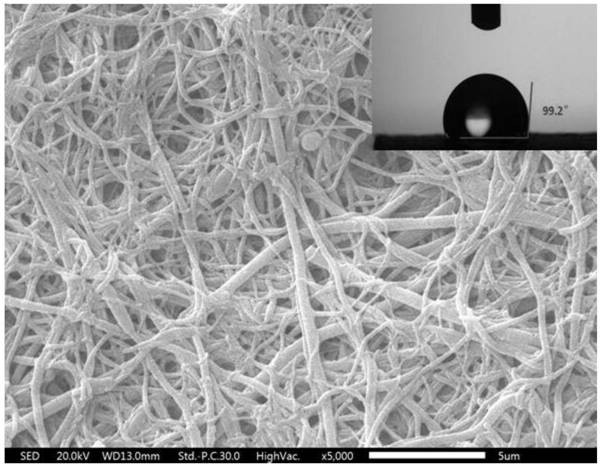

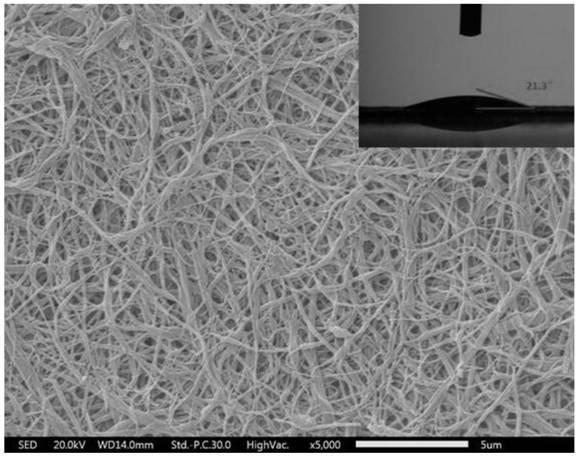

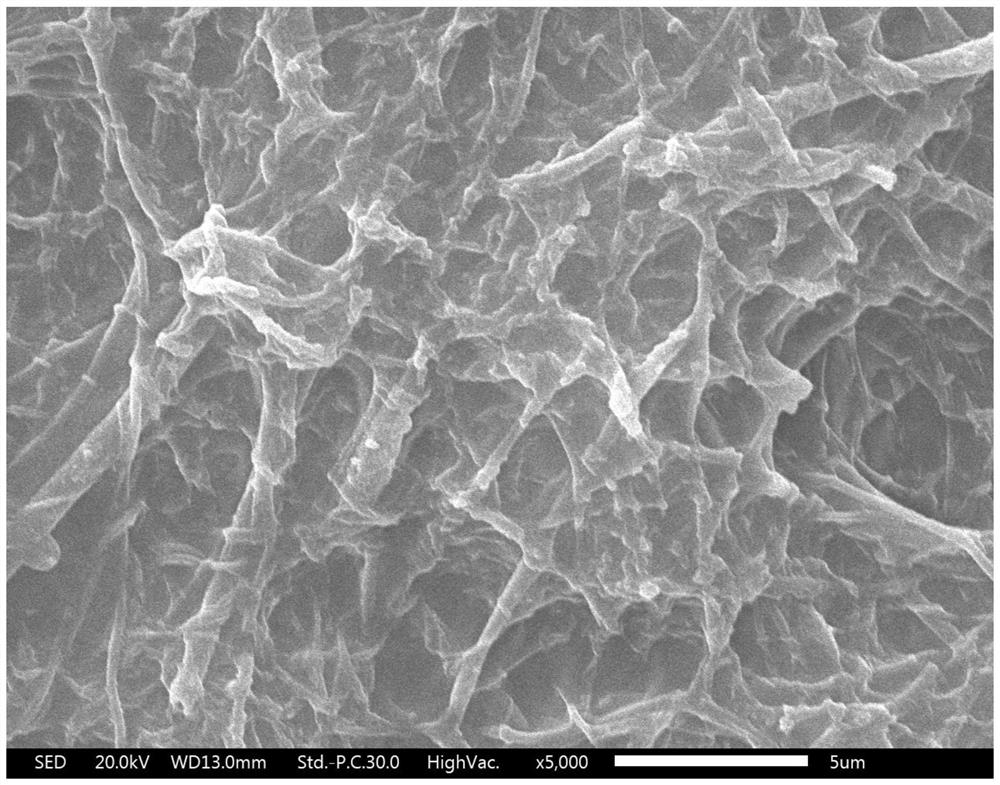

High-hydrophilicity nanofiber coating-based nanofiltration membrane and preparation method thereof

ActiveCN111644080AImprove hydrophilicityCompact structureMembranesSemi-permeable membranesPolymer scienceNanofiber

The invention provides a high-hydrophilicity nanofiber coating-based nanofiltration membrane and a preparation method thereof. The high-hydrophilicity nanofiber coating-based nanofiltration membrane is formed by compounding a high-hydrophilicity nanofiber coating base membrane and a nanofiltration separation layer loaded on the surface of the high-hydrophilicity nanofiber coating base membrane. The preparation method comprises the following steps: firstly, carrying out wet coating on an ethylene-vinyl alcohol copolymer nanofiber dispersion liquid on a non-woven fabric base layer to prepare a nanofiber coating base film; then carrying out alkali treatment and plasma treatment, and carrying out functional modification on the base membrane to obtain the high-hydrophilicity coating base membrane; and finally, carrying out interfacial polymerization to obtain the high-hydrophilicity nanofiber coating-based nanofiltration membrane. The composite nanofiltration membrane prepared by the invention is compact in structure, has high hydrophilicity, can realize synergistic improvement of flux and retention rate, and also has an excellent filtering effect. The preparation method provided by theinvention can optimize the interfacial polymerization process, and the preparation process is simple and controllable, green and pollution-free, and low in cost, and has a great industrial application prospect.

Owner:WUHAN TEXTILE UNIV

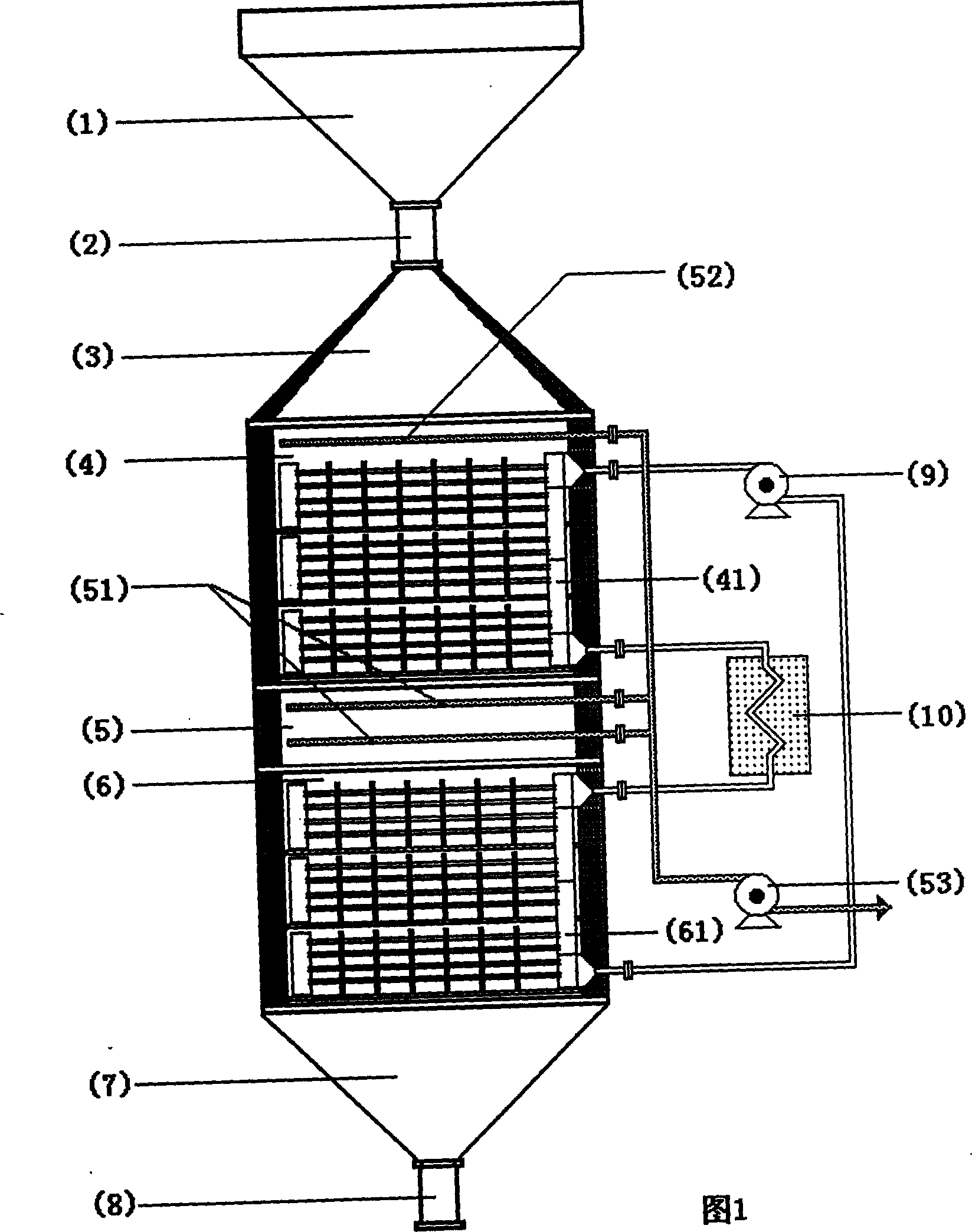

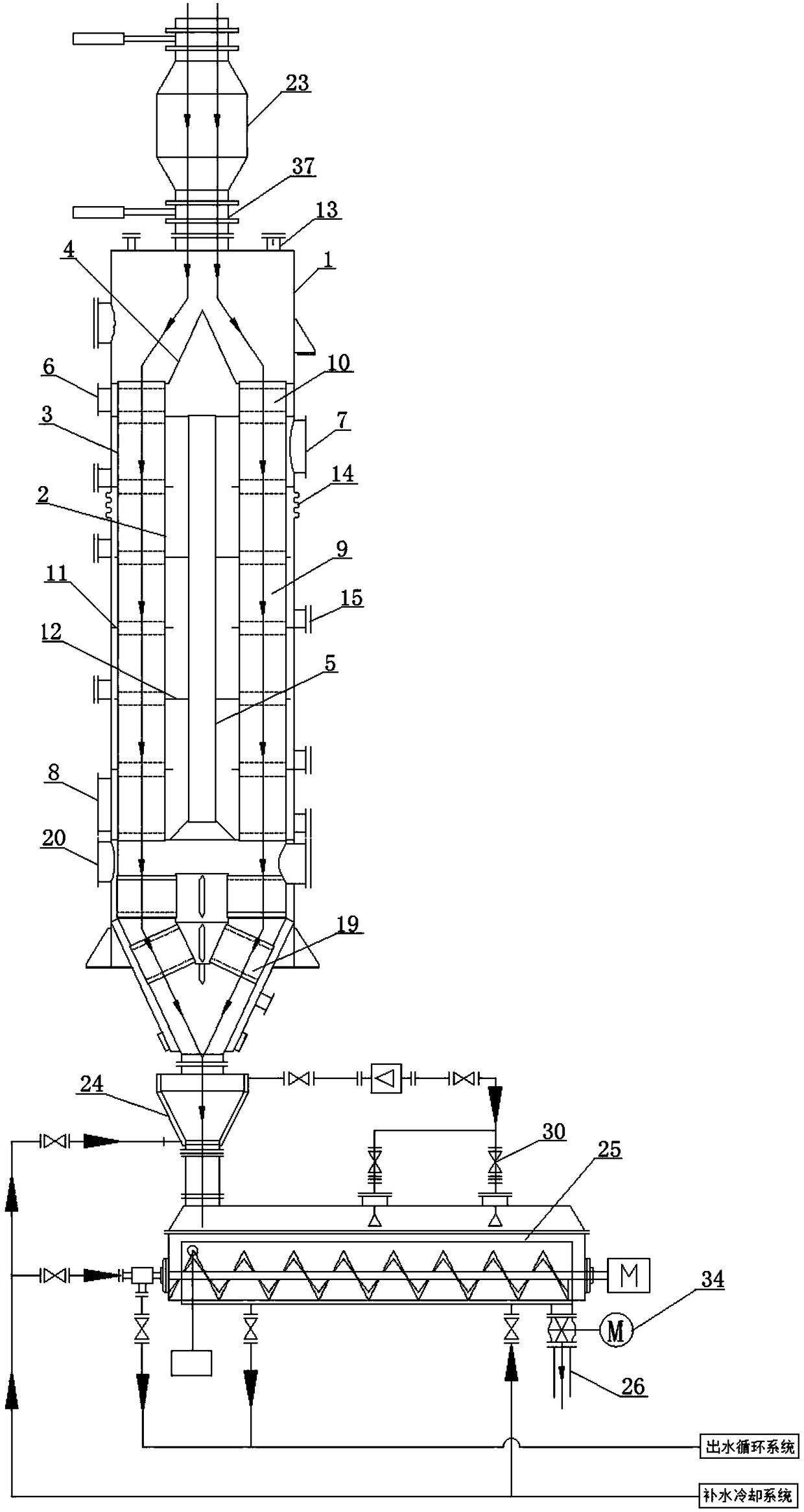

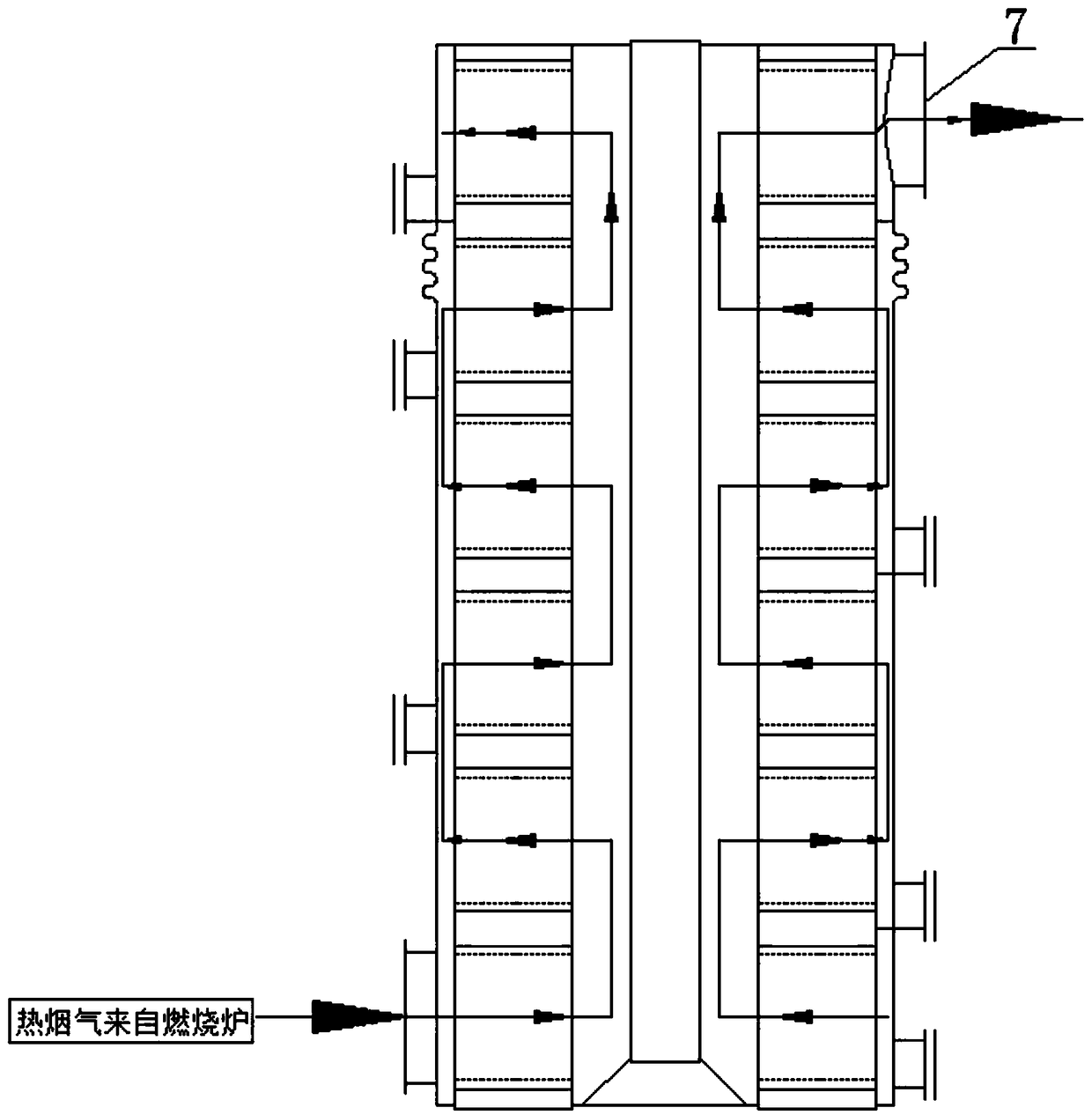

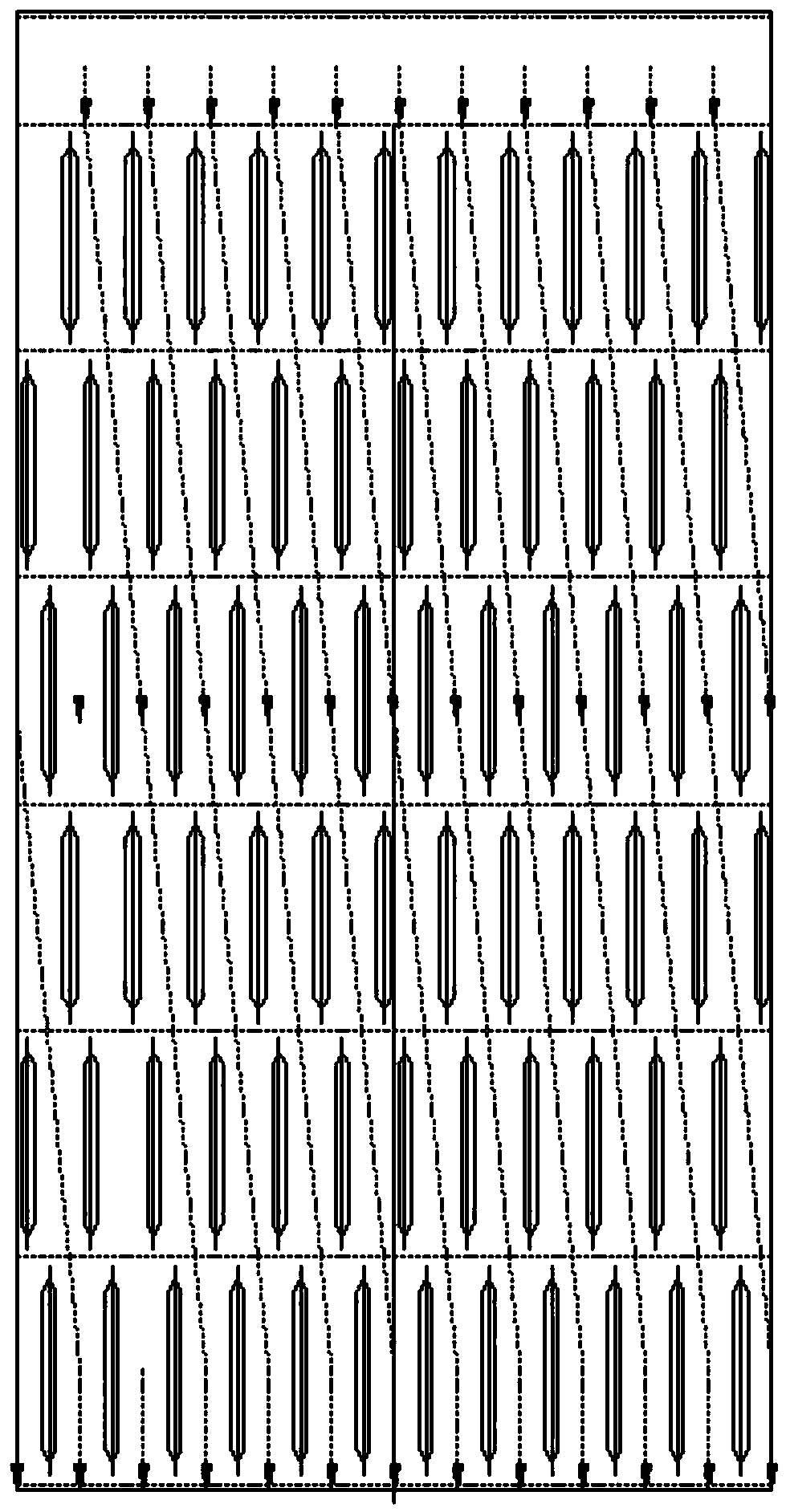

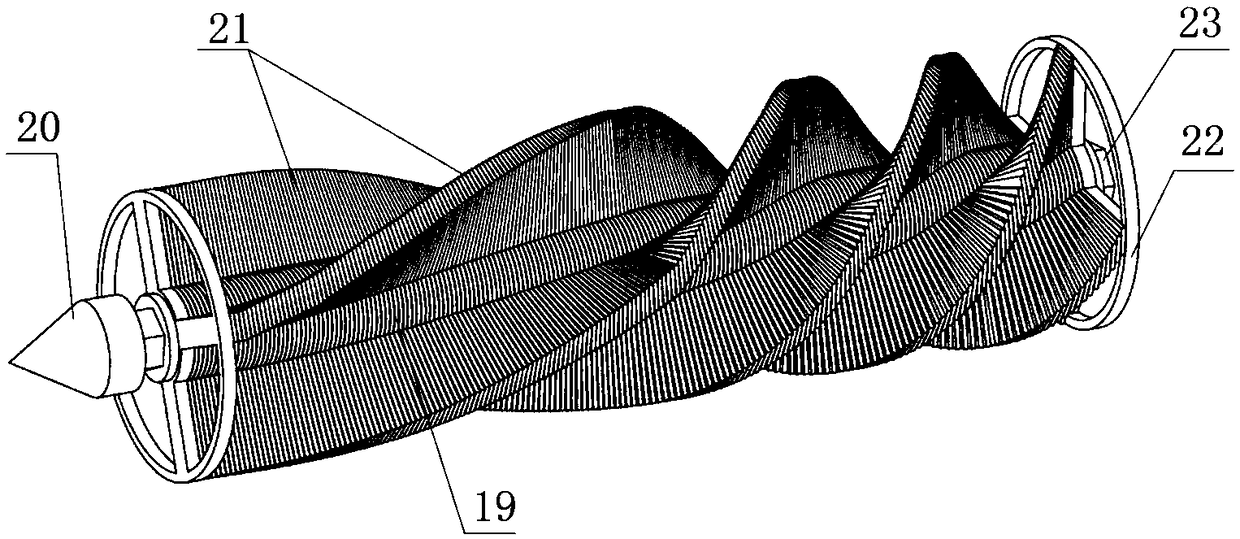

Efficient and energy-saving self-weight spiral progressive biomass pyrolysis system

PendingCN109161389AIncrease the heat exchange areaShorten pyrolysis timeBiofuelsSpecial form destructive distillationBiomassProcess engineering

The invention discloses an efficient and energy-saving self-weight spiral progressive biomass pyrolysis system which comprises a pyrolysis furnace, a material distribution tank (23), an air cooler anda water cooling system, wherein an outlet of the material distribution tank (23) communicates with the material feeding hole of the pyrolysis furnace; a biomass charcoal outlet in the bottom of the pyrolysis furnace communicates with a material inlet in the upper part of the air cooler; a material outlet in the lower part of the air cooler communicates with the material feeding hole of the watercooling system; an inner cylinder (2) and an outer cylinder (3) are arranged in the middle inside the furnace body (1) of the pyrolysis furnace; a conical material distributor (4) is arranged at the top, corresponding to the material feeding hole of the furnace body (1), of the inner cylinder (2); a pyrolysis gas secondary pyrolysis tube (5) is arranged in the inner cylinder (2); the outlet of thepyrolysis gas secondary pyrolysis tube (5) communicates with a pyrolysis gas outlet (6); both a flue gas outlet (7) and a hot flue gas inlet (8) communicate with an inner cavity of the inner cylinder(2). Mutual actions of heat conduction are achieved, high heat utilization efficiency is achieved, and gradient utilization of energy is achieved.

Owner:HUBEI NORMAL UNIV +1

Method and equipment for preparing electroplating-grade nickel sulfate using nickel-containing wastewater produced in surface treatment process

ActiveCN104229906BReduce carryoverReduce volumeMultistage water/sewage treatmentNickel sulfatesFiltrationSulfate

The invention discloses a method and equipment for preparing electroplating-grade nickel sulfate from nickel-containing wastewater produced in a surface treatment process, and belongs to the technical field of nickel-containing wastewater treatment process. The method is characterized by comprising the following steps: (1) collecting nickel-containing wastewater; (2) performing sedimentation and press filtration on nickel in the nickel-containing wastewater, and smashing nickel mud to obtain nickel slurry; (3) dissolving the nickel slurry into acid; (4) filtering a nickel sulfate solution; (5) removing impurities from the nickel sulfate solution for purification, and performing secondary filtration; (6) performing vacuum evaporative concentration, crystallization, filtration and centrifugal drying on the nickel sulfate solution to obtain nickel sulfate crystals. The invention aims to provide the method and the equipment which can reduce the waste of nickel resources, reduce potential hazard of nickel to the natural environment and realize recycling of the nickel resources and are used for preparing the electroplating-grade nickel sulfate from the nickel-containing wastewater produced in the surface treatment process. The method and the equipment are used for treating the nickel-containing wastewater.

Owner:MEIZHOU ENVIRONMENTAL EQUIP

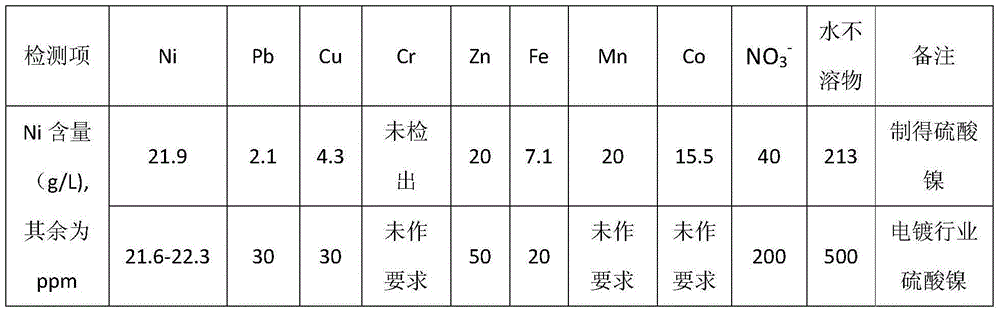

Reaction kettle

InactiveCN104941560AImprove the balance of temperature distributionImprove the mixing effectRotary stirring mixersMixer accessoriesReducerEngineering

The invention provides a reaction kettle comprising a kettle body. An external cooling jacket is arranged on the outer side of the kettle body. A variable-frequency motor is arranged on the upper portion of the kettle body. The variable-frequency motor is connected with a speed reducer. A stirring device is connected with the lower portion of the speed reducer and located in the kettle body. A flow guide cylinder is arranged between the kettle body and the stirring device. An internal cooling jacket is arranged outside the flow guide cylinder. The bottom and the top of the internal cooling jacket are connected with a cooling water inlet pipe and a cooling water outlet pipe respectively, and the cooling water inlet pipe and the cooling water outlet pipe extend out of the kettle body. The reaction kettle has the advantages that when the variable-frequency motor works, the turning radius of a horizontal sliding sleeve can be changed through centrifugal force, and therefore the stirring effect is better; the flow guide cylinder and the internal cooling jacket are additionally arranged in the kettle body, the balance of temperature distribution in the kettle body can be greatly improved, and especially the temperature balance on the peripheral area of a stirring shaft is improved; besides, the flow guide cylinder is designed to be in a waist drum shape, reactants can form turbulence, and the reaction is evener and more complete.

Owner:姚旺东

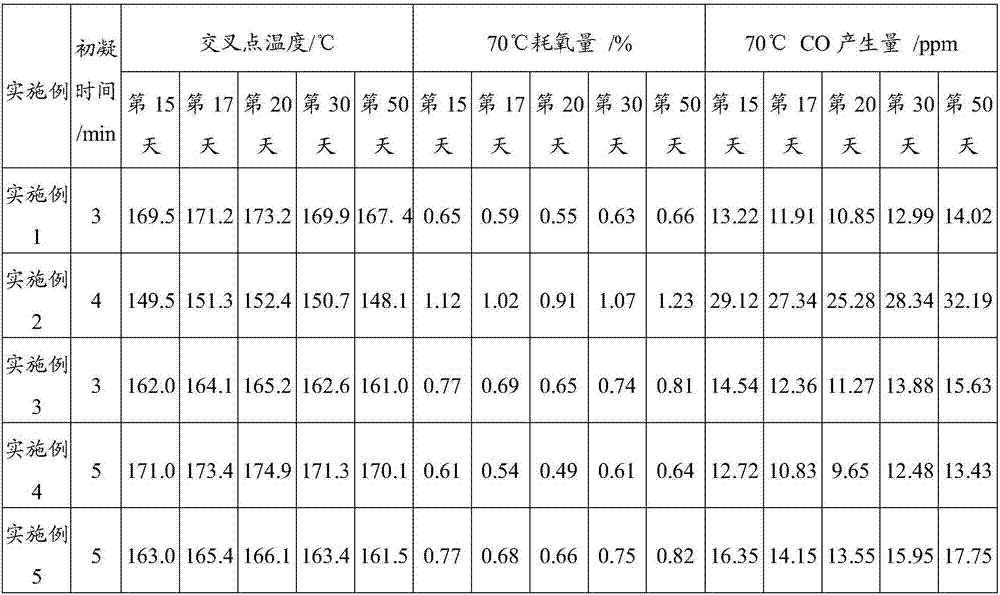

Mine inhibition type ultra-high water fire preventing and extinguishing material based on coal spontaneous combustion mechanism and preparation method thereof

InactiveCN106880919ALow costImprove the blocking effectFire extinguisherCoal spontaneous combustionPEG 400

The invention discloses a mine inhibition type ultra-high water fire preventing and extinguishing material based on the coal spontaneous combustion mechanism and a preparation method thereof and relates to the field of spontaneous combustion inhibition of fire preventing and extinguishing of coal mines. The mine inhibition type ultra-high water fire preventing and extinguishing material is composed of materials A, materials B and water. The materials A comprise, by mass, 60%-85% of sulphoaluminate cement, 0.5%-5% of calcium formate, 2%-10% of polyethylene glycol 400, 5%-18.5% of calcium sulfate, 1.5%-7% of calcium oxide and 2%-5% of calcium chloride. The materials B comprise, by mass, 0.3%-2% of ascorbic acid, 15%-25% of sodium aluminate, 33%-50% of calcium oxide, 3%-10% of sodium sulfate and 13%-30% of calcium sulfate. The mass ratio of the materials A to the materials B is 5-7:1. The mass ratio of the total mass of the materials A and the materials B to the mass of the added water is 1: (8-11). The cost is low, environmental friendliness is achieved, the sources of the raw materials are abundant, the mine inhibition type ultra-high water fire preventing and extinguishing material has the functions of rapid cooling and chemical inhibition extinguishing and can regionally prevent and treat coal spontaneous combustion, and reburning and occurrence of new peripheral combustion sources are prevented while the coal spontaneous combustion disaster is treated efficiently.

Owner:CHINA UNIV OF MINING & TECH

Manufacturing method of corrosion-resistant high-flame-retardant silicon core pipe

The invention discloses a corrosion-resistant high-flame-retardant silicon core pipe which is prepared from, by weight, 230-320 parts of n-paraffin hydrocarbon, 195-225 parts of high-density polyethylene, 35-45 parts of dodecene, 135-145 parts of methyl hydrogen silicone oil, 25-30 parts of hydroxy stearic acid, 75-85 parts of polyolefin resin, 10-12 parts of color master batches, 6-8 parts of graphene, 3-5 parts of sodium-based bentonite, 2-4 parts of polyvinyl alcohol, 1-2 parts of zinc naphthenate, 2-4 parts of nano-boride, 3-4 parts of polyurethane, 1-2 parts of polyacrylic acid, 3-5 partsof triethyl phosphate, 2-3 parts of chlorinated paraffin, 1-2 parts of antioxidants, 5-7 parts of glycerol and 7-9 parts of deionized water. By the aid of the formula, the corrosion-resistant high-flame-retardant silicon core pipe has high wear resistance, high flame resistance and high reliability, overall consistency is improved, and the problem of delaminating is avoided. In addition, variousreactants with different functions are added, so that reaction is sufficient, various composition effects of the pipe are maximally achieved, and finally, the pipe is quite high in overall performance.

Owner:RONGCHENG PIPE IND

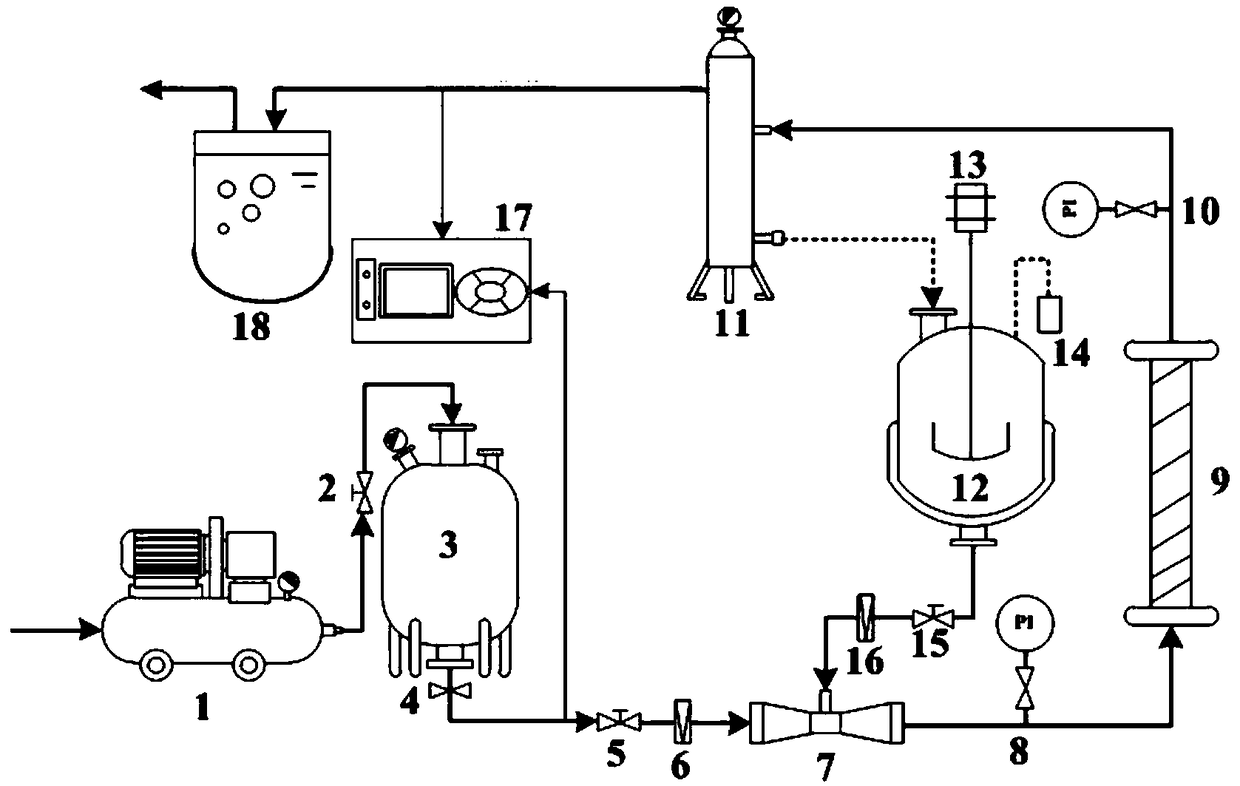

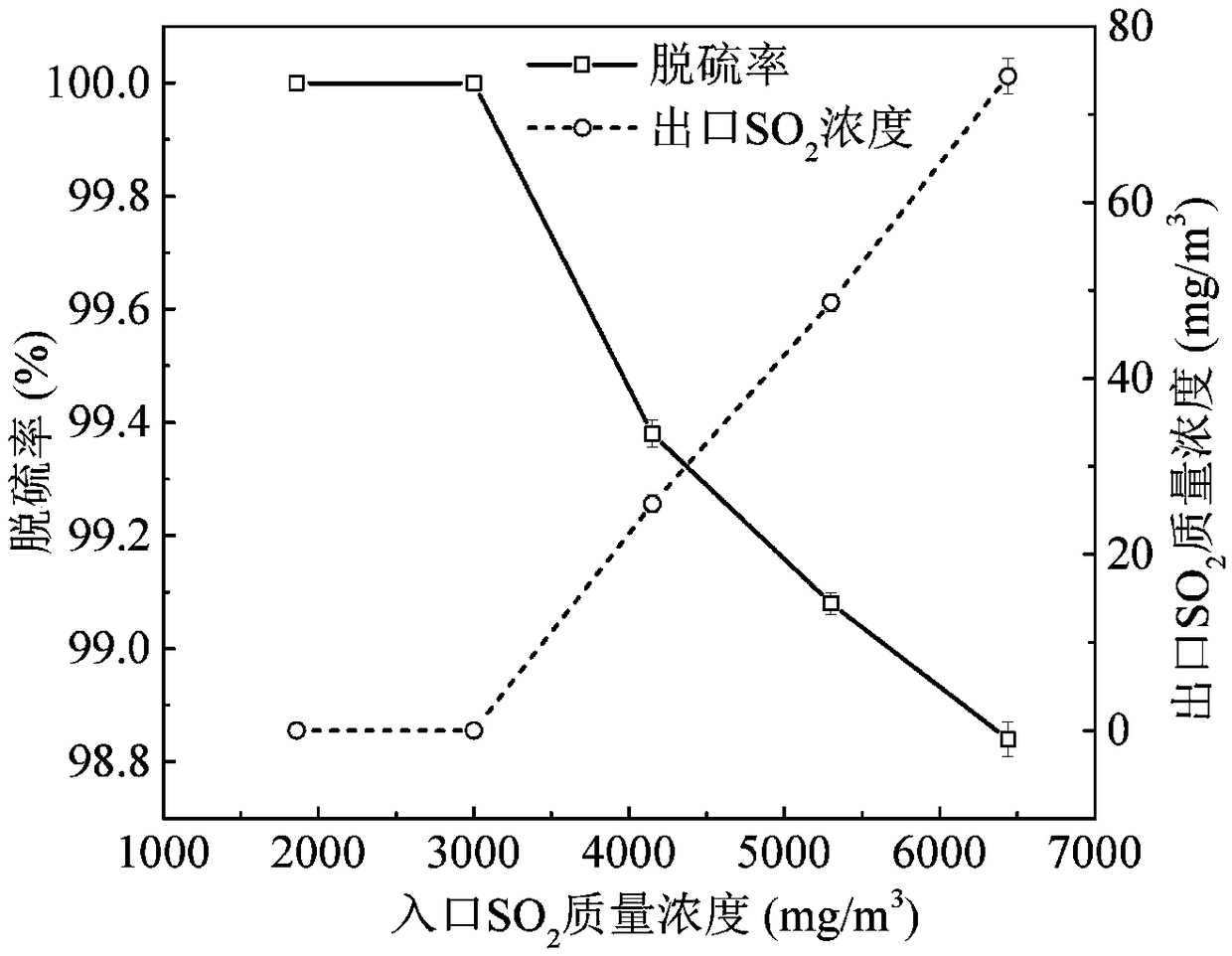

Wet flue gas desulfurization device and method for enhancing gas-liquid mass transfer reaction

ActiveCN109173633AEnhanced mass transferFacilitate chemical reactionsGas treatmentDispersed particle separationRefluxGas compressor

The invention relates to a wet flue gas desulfurization device and method for enhancing a gas-liquid mass transfer reaction. The device comprises a gas compressor, an inlet end of the gas compressor is connected to a flue gas conveying pipe, an outlet end of the gas compressor is orderly connected to a gas storage tank and a Venturi jet device, an upper inlet of the Venturi jet device is connectedto a discharge port at the lower end of a desulfurizer liquid storage tank, an outlet end of the Venturi jet device is connected to a static spiral cutter, an outlet of the static spiral cutter is connected to a gas / liquid inlet at the middle of a gas-liquid separation tank, a desulfurizer reflux inlet at the lower part of the gas-liquid separation tank is connected to the top of the desulfurizerliquid storage tank so that desulfurizer circulation is realized, a gas outlet at the upper part of the gas-liquid separation tank is connected to an exhaust gas absorption tank through a pipe, and the device also comprises a flue gas analyzer. The device has high efficiency, saves energy, realizes micro-nanoization and high-dispersion mixing of the desulfurizer droplets under a small liquid-gasratio, finishes the ultra-purification treatment for flue gas desulfurization and realizes miniaturization and economy of flue gas desulfurization equipment.

Owner:JIANGNAN UNIV

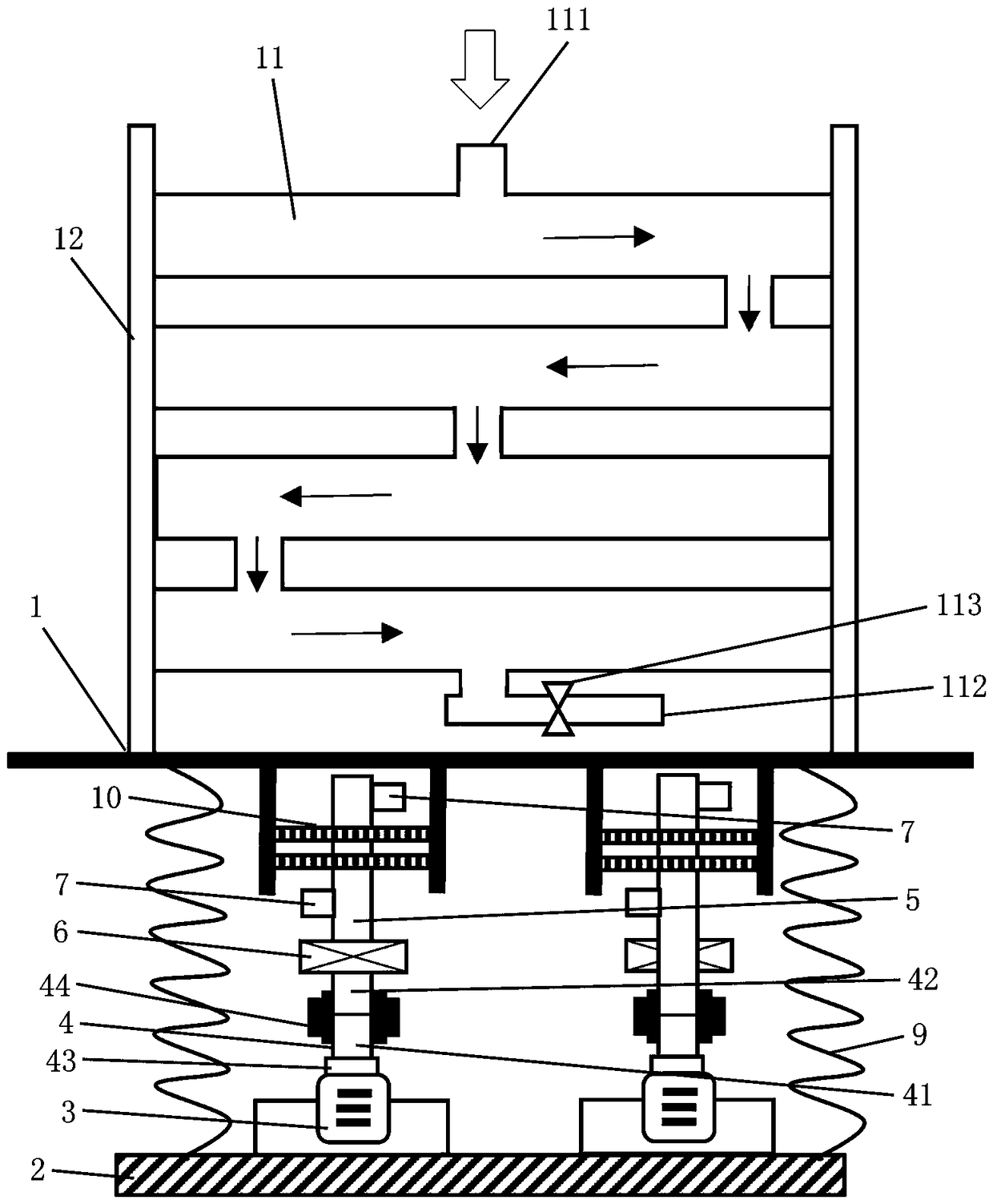

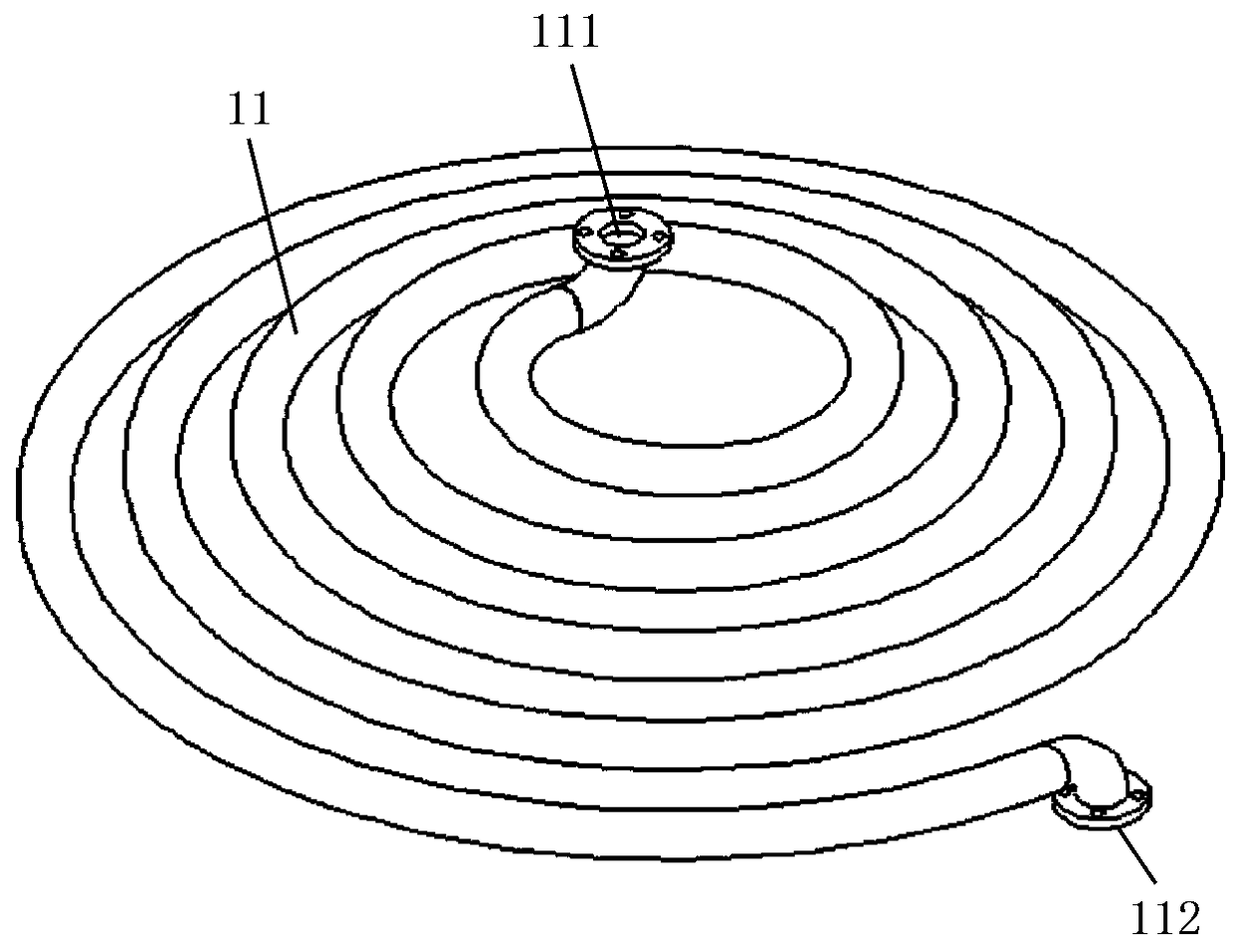

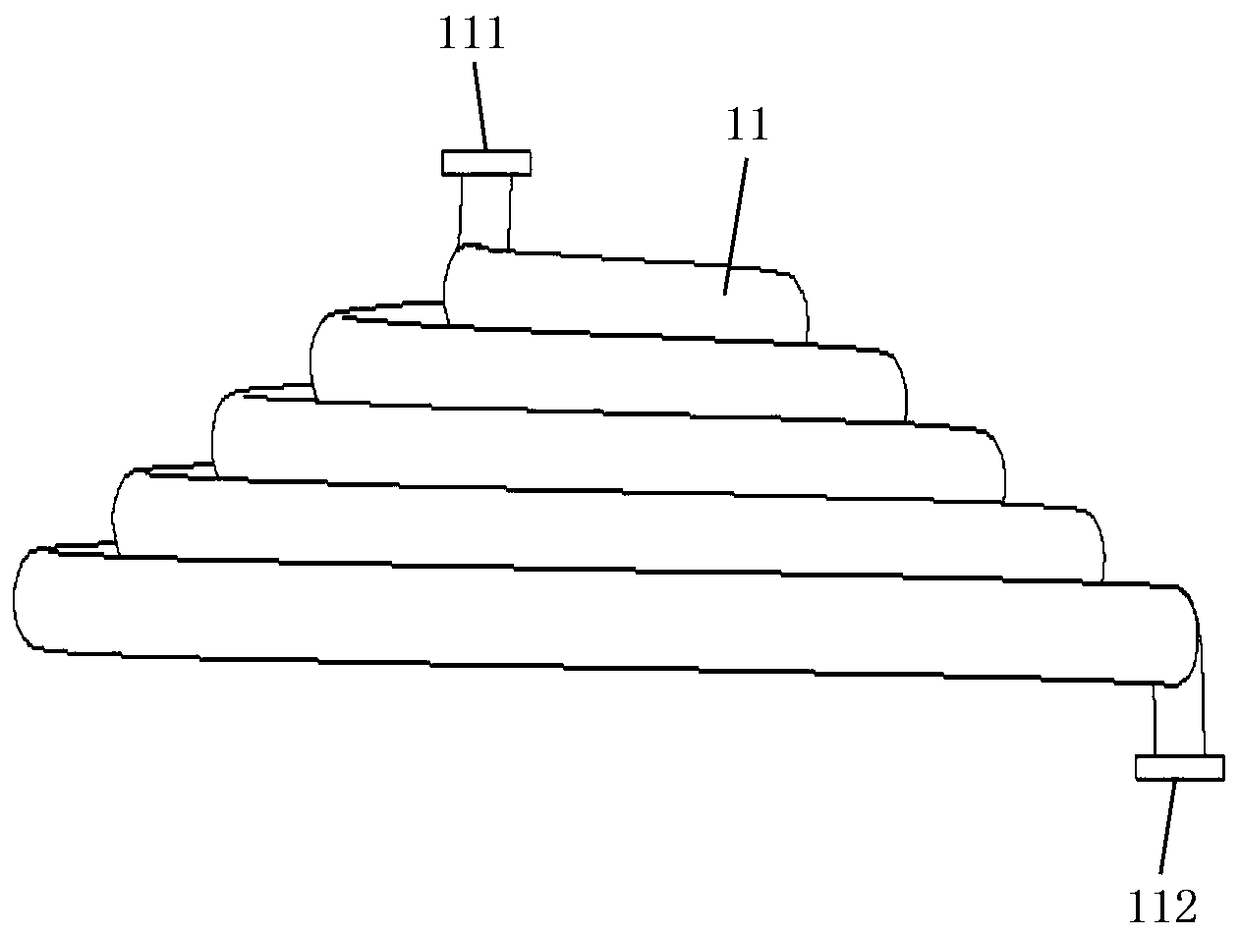

Pipeline vibration type material reaction device

PendingCN109126681AThe reaction is fully and evenlyFully contactedChemical/physical/physico-chemical moving reactorsEngineeringProcess engineering

The invention discloses a pipeline vibration type material reaction device. The pipeline vibration type material reaction device comprises a reactor and a vibration assembly; the vibration assembly isconnected with the reactor and drives the reactor to vibrate; the reactor is provided with a reaction channel for materials to pass through; and the reaction channel is provided with a feeding port and a discharging port. The pipeline vibration type material reaction device has the advantages of high production efficiency, high environmental friendliness, low production cost, capability of enabling the materials to react completely and uniformly and the like.

Owner:海南行者新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com