High-temperature atmosphere revolving furnace and application thereof in preparation of AION (Anterior Ischemic Optic Neuropathy) powder

A rotary furnace and atmosphere technology, applied in high temperature atmosphere rotary furnace and its application in the preparation of A1ON powder, can solve the problems of poor uniformity of A1ON powder, achieve small grain size, sufficient and uniform reaction, high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

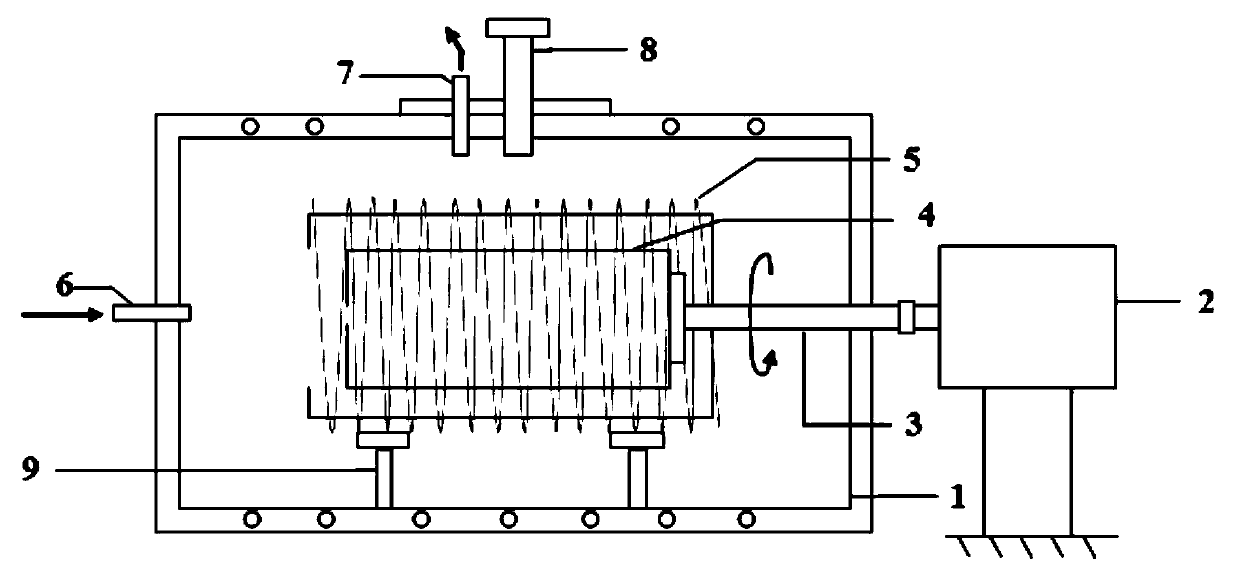

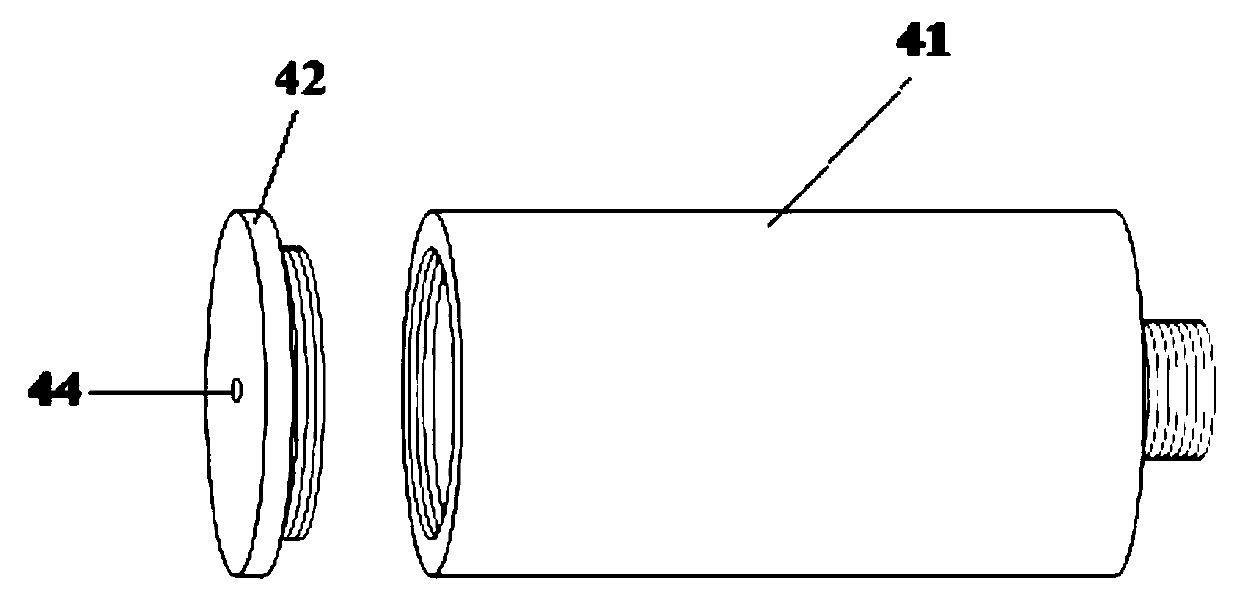

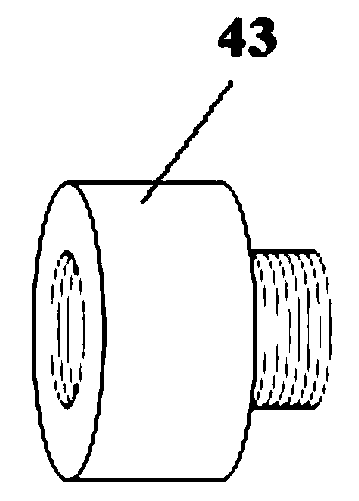

[0029] The structure of the high-temperature atmosphere rotary furnace described in this embodiment is as follows: figure 1 As shown, it includes a furnace body 1, a crucible 4, a connecting body 43, a heating and heat preservation assembly 5, and a motor 2 that drives the crucible to rotate; The structure is as figure 2 As shown, it is composed of a crucible main body 41 and an end cover 42. The crucible main body 41 and the end cover 42 are both made of graphite, and its shape is a cylinder with one end closed and one end open. The internal thread section is provided with an external thread section connected to the connecting body on the closed end face, and the end cover 42 is provided with an external thread section matching the open end of the crucible main body and a vent hole 44 with a diameter of 2 mm; the connecting body 43 is made of graphite , whose structure is as image 3 As shown, it consists of a conical body with an internal thread section at one end and an ...

Embodiment 2

[0032] The structure of the high-temperature atmosphere rotary furnace described in this embodiment is as follows: figure 1As shown, it includes a body of furnace 1, a crucible 4, a heating and heat preservation assembly 5 and a motor 2 that drives the rotation of the crucible; the body of furnace is provided with an intake pipe 6, an air discharge pipe 7 and a vacuum valve 8, and the structure of the crucible is as follows figure 2 As shown, it is composed of a crucible main body 41 and an end cover 42. The end cover 42 is made of graphite. The crucible main body 41 uses graphite as a matrix, and the surface of the inner cavity of the matrix is covered with a tantalum layer. The inner hole of the open end is provided with an internal thread section connected to the end cap, and the end face of the closed end is provided with an external thread section connected with the connecting body. The end cover 42 is provided with an external thread section matching the open end of th...

Embodiment 3

[0035] In this example, the A10N powder was prepared by using the high-temperature atmosphere rotary furnace described in Example 1.

[0036] Nanoscale γ-A1 2 o 3 powder and nano-scale high-purity carbon black as raw materials, according to γ-A1 2 o 3 The content of the powder is 94.4wt%, the content of carbon black is 5.6wt% to carry out batching, 50g of mixed powder is added in the polyurethane tank, according to powder-ball ratio=1:12, add zirconium dioxide grinding balls in the polyurethane tank, with no Water and ethanol are used as the ball milling medium, and the rotating speed is 300r / min. The mixed powder is mixed by wet ball milling, and the ball milling time is 24h. The slurry obtained by ball milling was stirred and dried at 75°C, and the dried powder was passed through a 140-mesh sieve, and 20 g of the sieved powder was placed in an alumina crucible matching the size of the crucible main body 41, and the oxidized Put the aluminum crucible into the crucible mai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com