Stable curing continuous treatment process of heavy metal waste residues

A heavy metal stabilizer and treatment process technology, which is applied in the field of environmental protection, can solve the problems of not much research on stabilization/curing process, small processing capacity of treatment process, and non-continuous treatment, etc., to achieve major pollution control significance, good stabilization effect, The effect of increasing mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

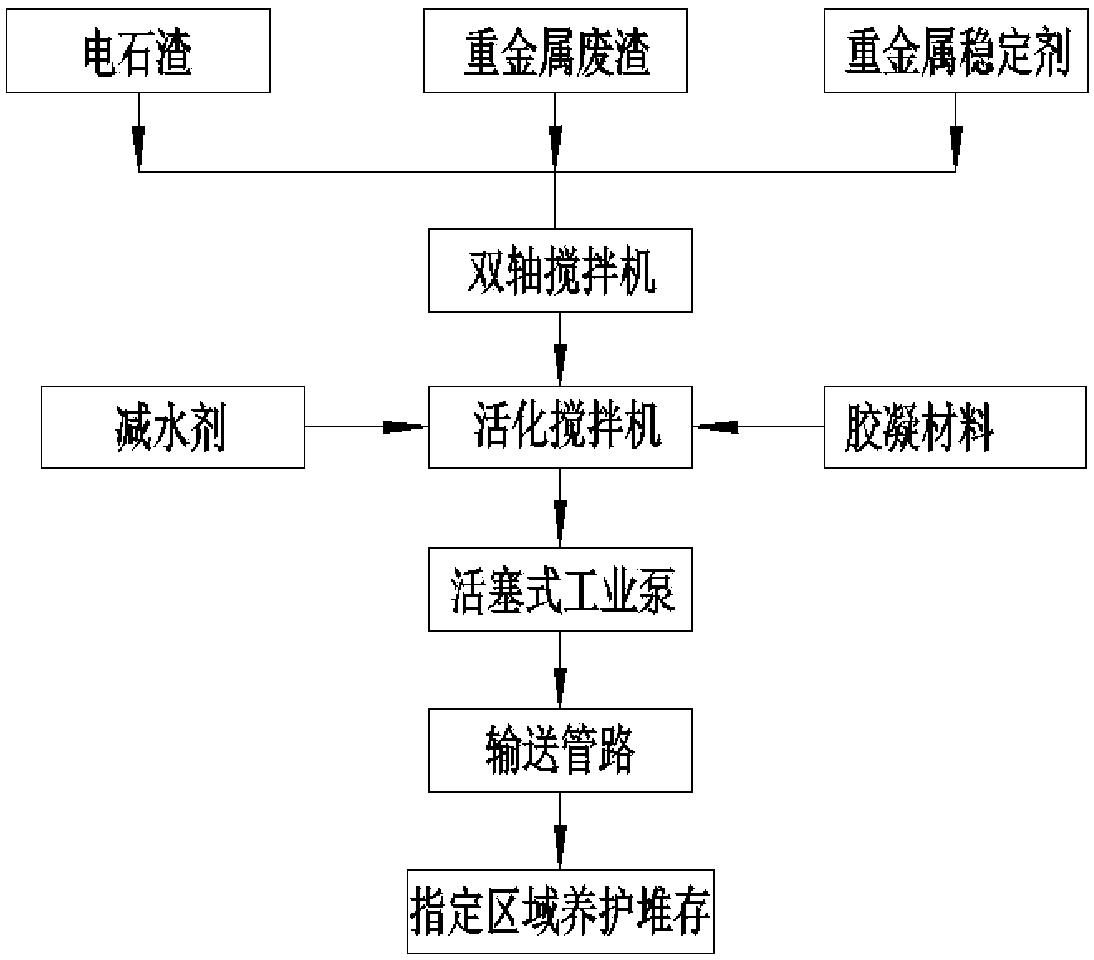

Method used

Image

Examples

Embodiment 1

[0044] The heavy metal waste slag produced by a smelter in the south has a gray-black appearance, mixed with some soil, stones, sand and other sundries, and the main metal pollution factors are Pb, Cd, Zn, Mn, among which the average content of Pb is 2210mg / kg, Cd The average content is 123mg / kg, the average Zn content is 2323mg / kg, and the average Mn content is 521mg / kg.

[0045]After the heavy metal waste slag is crushed, sieve through a 16mm sieve, take the undersieve, add calcium carbide slag and a solution containing sodium dihydrogen phosphate to a double-helix horizontal mixer according to a certain metering ratio, and stir evenly to obtain slurry A; the stirring time is 1min , the stirring speed is 150r / min,

[0046] The addition of the calcium carbide slag is added according to 5% of the quality of the heavy metal waste residue. In the solution containing sodium dihydrogen phosphate, the mass fraction of the sodium dihydrogen phosphate is 0.01%, and the addition of th...

Embodiment 2

[0055] The heavy metal waste slag produced by a copper mine tailings pond has a gray appearance and a particle size of less than 1mm. The main metal pollution factors are Pb, Cu, Zn, and Ni. The average content of Pb is 870mg / kg, and the average content of Cu is 1023mg / kg. The average content of Zn is 753mg / kg, and the average content of Ni is 821mg / kg.

[0056] Add the above-mentioned heavy metal waste slag, calcium carbide slag and sodium dihydrogen phosphate-containing solution into a double-helix horizontal mixer and stir evenly to obtain slurry A; the stirring time is 45s, and the stirring speed is 200r / min.

[0057] The addition amount of the calcium carbide slag is 4% of the weight of the heavy metal waste residue. In the solution containing sodium dihydrogen phosphate, the mass fraction of sodium dihydrogen phosphate is 0.02%, and the addition amount is 3% of the weight of the heavy metal waste residue.

[0058] After the slurry A is stirred, it is unloaded into the ac...

Embodiment 3

[0064] Adopt the same heavy metal waste slag of embodiment 1. After the heavy metal waste slag is crushed, sieve through a 16mm sieve, take the undersieve, add calcium carbide slag and a solution containing potassium dihydrogen phosphate to a double-helix horizontal mixer according to a certain metering ratio, and stir evenly to obtain slurry A; the stirring time is 1min , the stirring speed is 150r / min,

[0065] The addition of the calcium carbide slag is added according to 3% of the mass of the heavy metal waste residue. In the solution containing potassium dihydrogen phosphate, the mass fraction of potassium dihydrogen phosphate is 0.01%, and the addition of the heavy metal stabilizer is 2.5% of the mass of the heavy metal waste residue. %join in.

[0066] After the slurry A is stirred, it is discharged into the activated mixer, and the lignosulfonate early-strength water reducer and fly ash are added at the same time, and the slurry B is obtained by stirring evenly. The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com