Mine inhibition type ultra-high water fire preventing and extinguishing material based on coal spontaneous combustion mechanism and preparation method thereof

A fire prevention and ultra-high water technology, applied to fire prevention equipment, etc., can solve the problems of short fire prevention time period, easy to cause underground pollution, limited coverage, etc., achieve low material cost, significant chemical resistance effect, and convenient application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

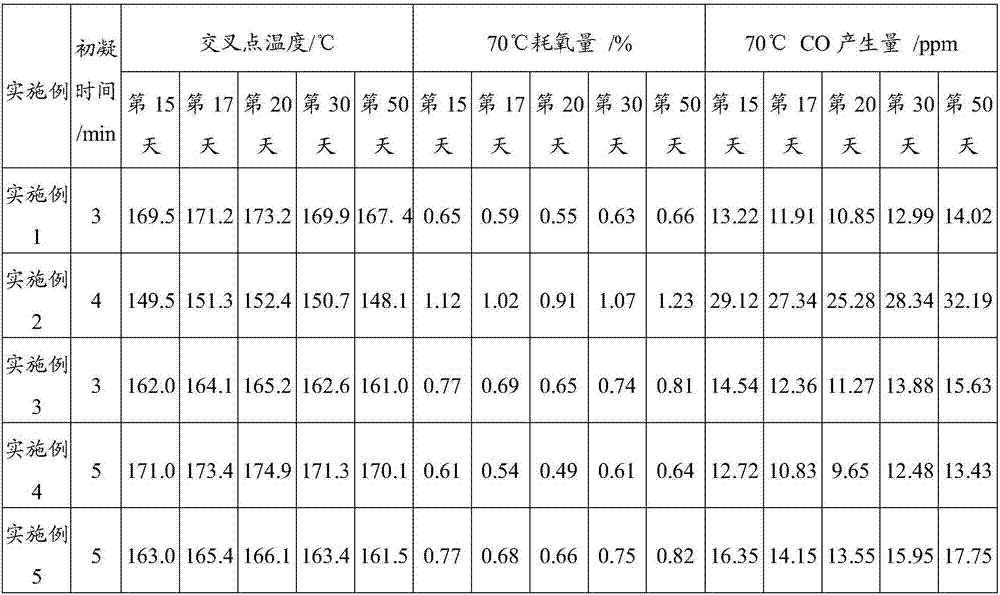

Embodiment 1

[0026] A mine-used chemical-resistance ultra-high water-proof and fire-extinguishing material based on the mechanism of spontaneous combustion of coal is composed of material A and material B. Wherein A material composition and mass ratio (kg) are: sulfoaluminate cement 60%, calcium formate 5%, polyethylene glycol 400 4.5%, calcium sulfate 18.5%, calcium oxide 7%, calcium chloride 5%; B The material composition and mass ratio (kg) are: 2% ascorbic acid, 15% sodium aluminate, 50% calcium oxide, 3% sodium sulfate, and 30% calcium sulfate. When in use, the mass ratio of material A to material B is 7:1, and the water-cement ratio is 8:1. The specific preparation process is: prepare material A and material B according to the above mass ratio, firstly mix the components of material A and material B evenly, then add water to material A and material B respectively to make slurry and stir evenly, wherein material A is mixed with water The quality is 5 times that of material A, and the...

Embodiment 2

[0029]A mine-used chemical-resistance ultra-high water-proof and fire-extinguishing material based on the mechanism of spontaneous combustion of coal is composed of material A and material B. Wherein A material composition and mass ratio (kg) are: sulfoaluminate cement 81%, calcium formate 0.5%, polyethylene glycol 400 10%, calcium sulfate 5%, calcium oxide 1.5%, calcium chloride 2%; B The material composition and mass ratio (kg) are: 0.3% of ascorbic acid, 25% of sodium aluminate, 34.7% of calcium oxide, 10% of sodium sulfate, and 30% of calcium sulfate. When in use, the mass ratio of material A to material B is 5:1, and the water-cement ratio is 9:1. The specific preparation process is: prepare material A and material B according to the above mass ratio, firstly mix the components of material A and material B evenly, then add water to material A and material B respectively to make slurry and stir evenly, wherein material A is mixed with water The quality is 5 times that of ...

Embodiment 3

[0032] A mine-used chemical-resistance ultra-high water-proof and fire-extinguishing material based on the mechanism of spontaneous combustion of coal is composed of material A and material B. Wherein A material composition and mass ratio (kg) are: sulfoaluminate cement 85%, calcium formate 3%, macrogol 400 2%, calcium sulfate 5%, calcium oxide 3%, calcium chloride 2%; B The material composition and mass ratio (kg) are: 1% ascorbic acid, 20% sodium aluminate, 47% calcium oxide, 7% sodium sulfate, and 25% calcium sulfate. When in use, the mass ratio of material A to material B is 6.5:1, and the water-cement ratio is 8:1. The specific preparation process is: prepare material A and material B according to the above mass ratio, firstly mix the components of material A and material B evenly, then add water to material A and material B respectively to make slurry and stir evenly, wherein material A is mixed with water The quality is 5 times that of material A, and the quality of ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com