Biomass gasification furnace and gasification operation method thereof

A biomass and gasifier technology, applied in gasification process, fixed bed gasification, chemical industry, etc., can solve the problems of unstable system operation, complex post-processing system, and low utilization efficiency, and achieve novel structure and reduce Tar content, the effect of improving gasification conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing:

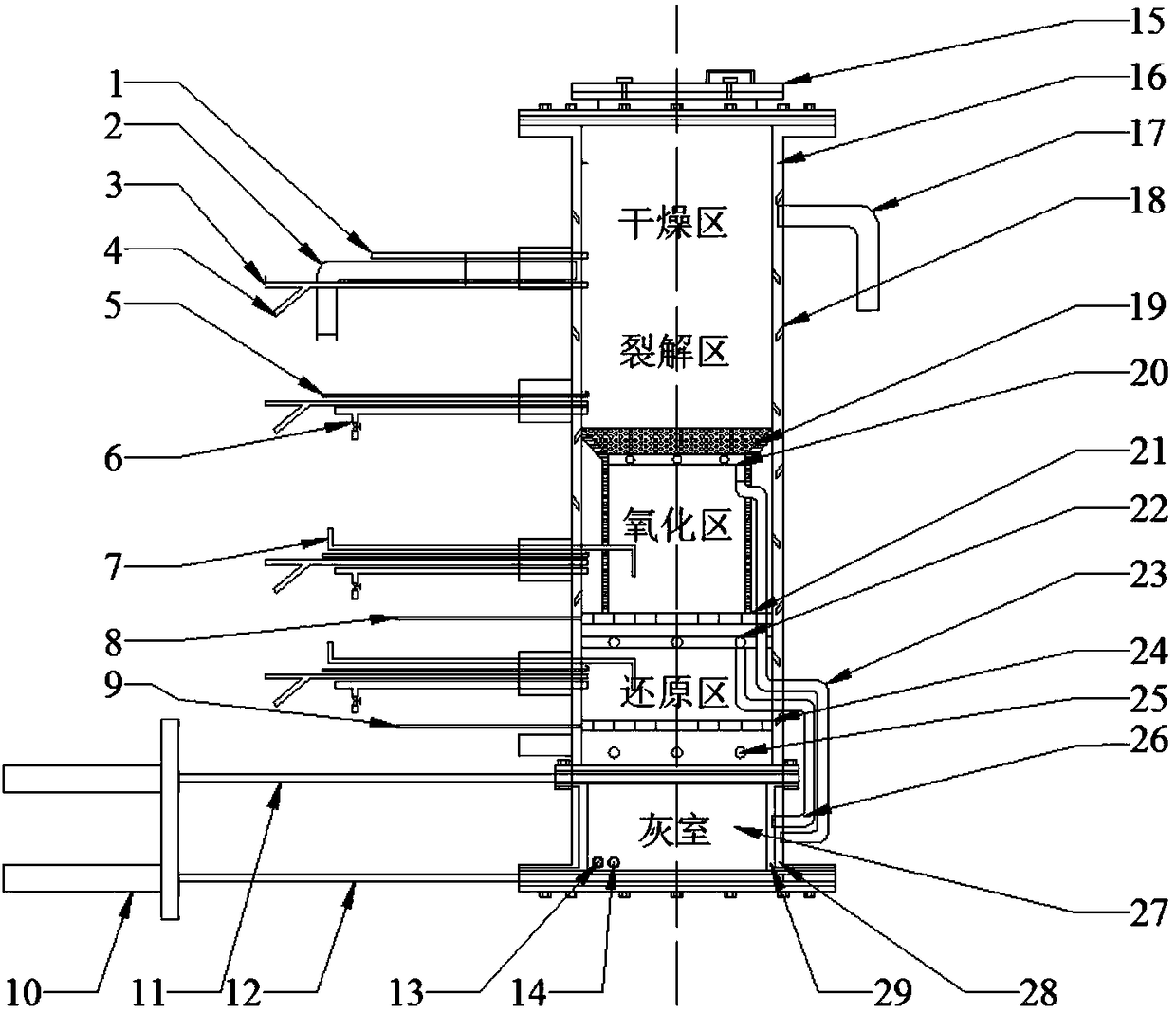

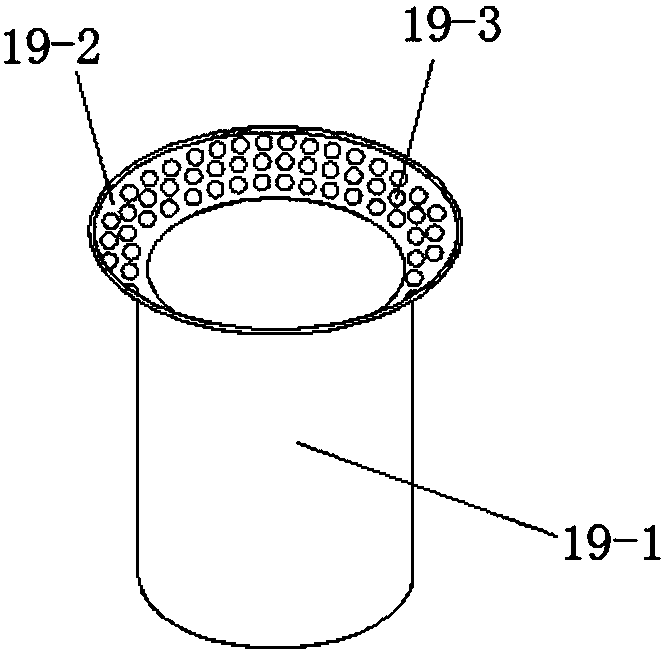

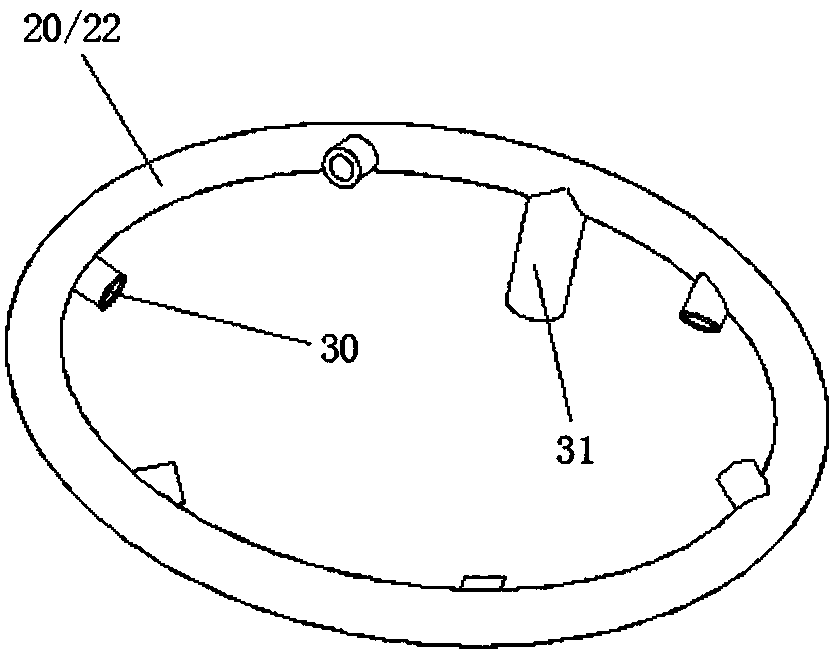

[0025] Such as Figure 1-3As shown, a biomass gasification furnace includes a reaction furnace body, a feed port 15 arranged on the top of the reaction furnace body and a base arranged at the bottom of the reaction furnace body; the reaction furnace body is made of double-layer coaxial heat-resistant steel pipes, The double-layer coaxial heat-resistant steel pipe forms a hollow furnace wall jacket 16, and several irregular stoppers 18 are arranged in the furnace wall jacket 16 from top to bottom, and the reaction furnace body is sequentially provided with drying areas, cracking Zone, oxidation zone, reduction zone and ash chamber 27; in the oxidation zone, a Y-type cracked gas isolation and diversion device 19 is arranged, and the lower part of the Y-type cracked gas isolation and diversion device 19 is an equal-diameter heat-resistant steel pipe 19-1, and the upper part is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com