Method and equipment for preparing electroplating-grade nickel sulfate using nickel-containing wastewater produced in surface treatment process

A technology for surface treatment and nickel wastewater, applied in nickel sulfate, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve the problems of high safety treatment cost, complicated process, secondary pollution, etc., and achieve saving manpower and material resources, The effect of improving economic benefits and eliminating potential harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

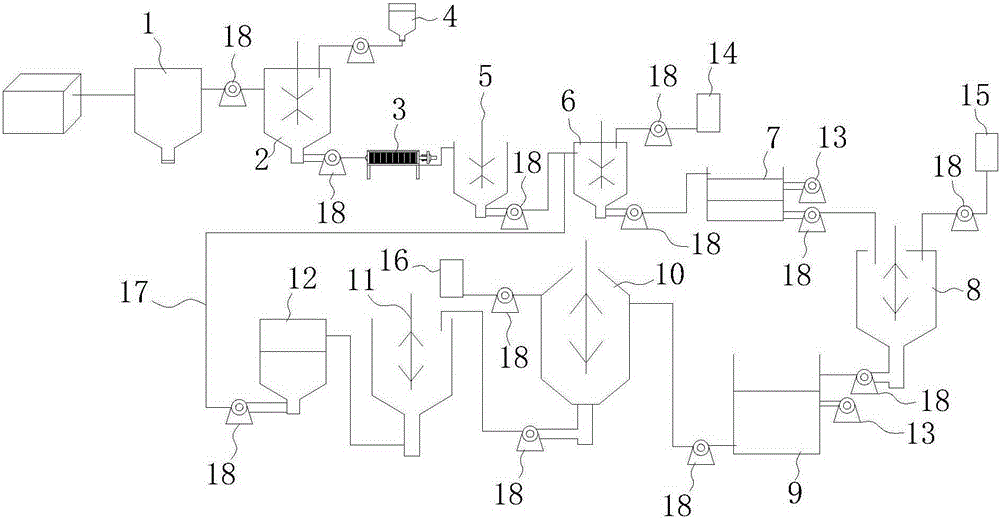

Method used

Image

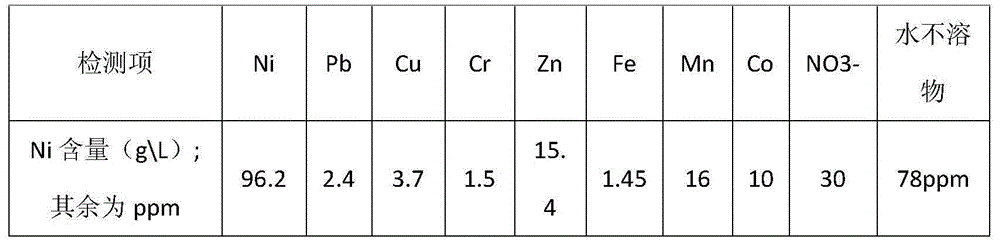

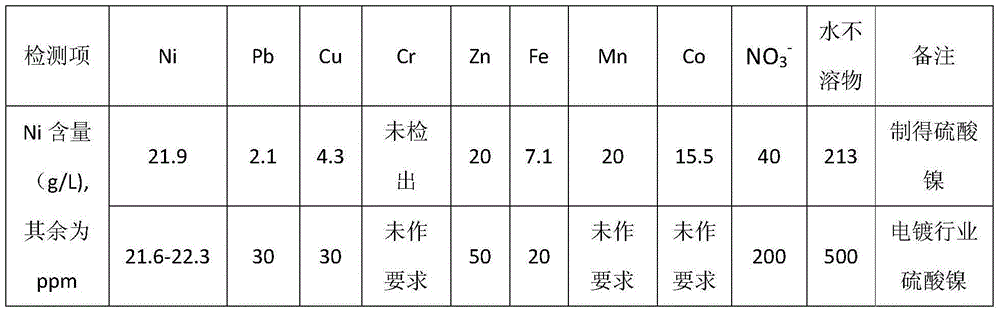

Examples

Embodiment 1

[0034] A kind of method that utilizes the nickel-containing waste water that surface treatment process produces to prepare electroplating grade nickel sulfate, this method comprises the following steps:

[0035] (1) The nickel-containing waste water produced in the surface treatment process is separately collected by a collection tank;

[0036] (2) Pump the nickel-containing waste water into the sedimentation tank, pump the soluble lye or carbonate solution in the first liquid storage tank into the sedimentation tank for mixed reaction, and the pH value range of the solution after the reaction is 8.3-8.5 to obtain a nickel-containing water-insoluble solid compound, which is separated by pressure filtration with a filter press to obtain a nickel slime solid with a water content of 70-90%.

[0037] (3) The nickel mud solid containing moisture is broken into nickel mud by a beating tank with a stirrer; the particle size of the nickel mud is more than 70 mesh.

[0038] (4) Nickel...

Embodiment 2

[0042] A kind of method that utilizes the nickel-containing waste water that surface treatment process produces to prepare electroplating grade nickel sulfate, this method comprises the following steps:

[0043] (1) The nickel-containing waste water produced in the surface treatment process is separately collected by a collection tank;

[0044] (2) Nickel-containing wastewater is pumped into the sedimentation tank, and the soluble carbonate in the first liquid storage tank is pumped into the sedimentation tank for mixed reaction. The pH value range of the solution after the reaction is 8.3-10, and nickel-containing wastewater is obtained. The water-insoluble solid compound is separated by pressure filtration with a filter press to obtain nickel slime solid with a water content of 70-90%.

[0045] (3) The nickel mud solid containing moisture is broken into nickel mud by a beating tank with a stirrer; the particle size of the nickel mud is more than 70 mesh.

[0046] (4) Pump t...

Embodiment 3

[0050] A kind of method that utilizes the nickel-containing waste water that surface treatment process produces to prepare electroplating grade nickel sulfate, this method comprises the following steps:

[0051] (1) The nickel-containing waste water produced in the surface treatment process is separately collected by a collection tank;

[0052] (2) Pump nickel-containing wastewater into the sedimentation tank, pump the mixture of soluble alkali and soluble carbonate in the first liquid storage tank into the sedimentation tank for mixed reaction, and the pH value range of the solution after the reaction is 8.3- 10. A nickel-containing water-insoluble solid compound is obtained, which is separated by pressure filtration with a filter press to obtain a nickel slime solid with a water content of 70-90%.

[0053] (3) The nickel mud solid containing moisture is broken into nickel mud by a beating tank with a stirrer; the particle size of the nickel mud is more than 70 mesh.

[0054...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com