Chopped glass fiber silicon dioxide aerogel composite material and preparation method thereof

A technology of chopped glass fiber and silica, which is used in the preparation of chopped glass fiber and silica aerogel composite materials, and the field of chopped glass fiber and silica aerogel composite materials can solve the problem of hindering aerogel Problems such as industrialization, aerogel cannot be produced continuously, and it takes a long time and solvent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

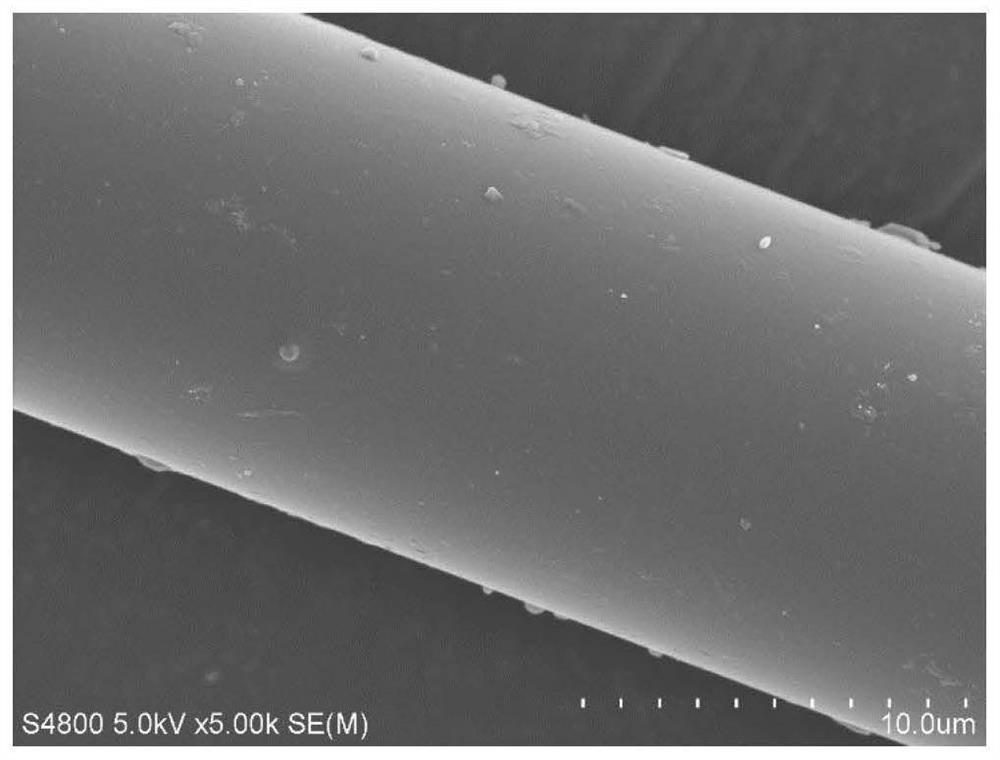

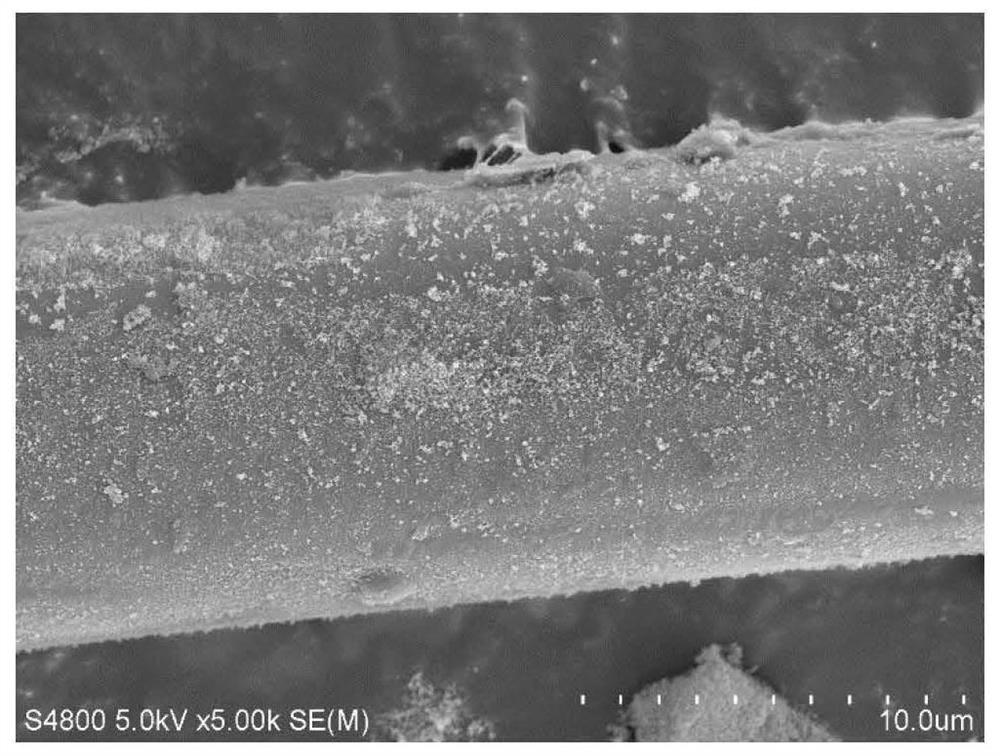

[0058] A method for preparing a silica airgel composite material, comprising the steps of:

[0059] 1) Silica wet gel preparation: According to the mass ratio of 45:60:1:3:8:50:5, take silicon source, solvent 1, acid catalyst, chemical drying control additive, basic catalyst, solvent 2, short Cut glass fiber; first stir the silicon source, acidic catalyst and part of the solvent-(ethanol) at a stirring speed of 100r / min for 30min, then hold at a holding temperature of 35°C for 12h; then add chemical drying Additives, basic catalysts, and remaining ethanol are controlled to stir, the stirring speed is 100r / min, and the stirring time is 30min; 6mm chopped glass fibers are ultrasonically treated in the ethanol solution, and the conditions are set at a temperature of 35°C, a water level of 10cm, The time is 10 minutes and the power is 100%, and the chopped glass fibers are soaked in hydrogen peroxide for 6 hours. Then dry the chopped glass fiber after ultrasonic treatment, add so...

Embodiment 2

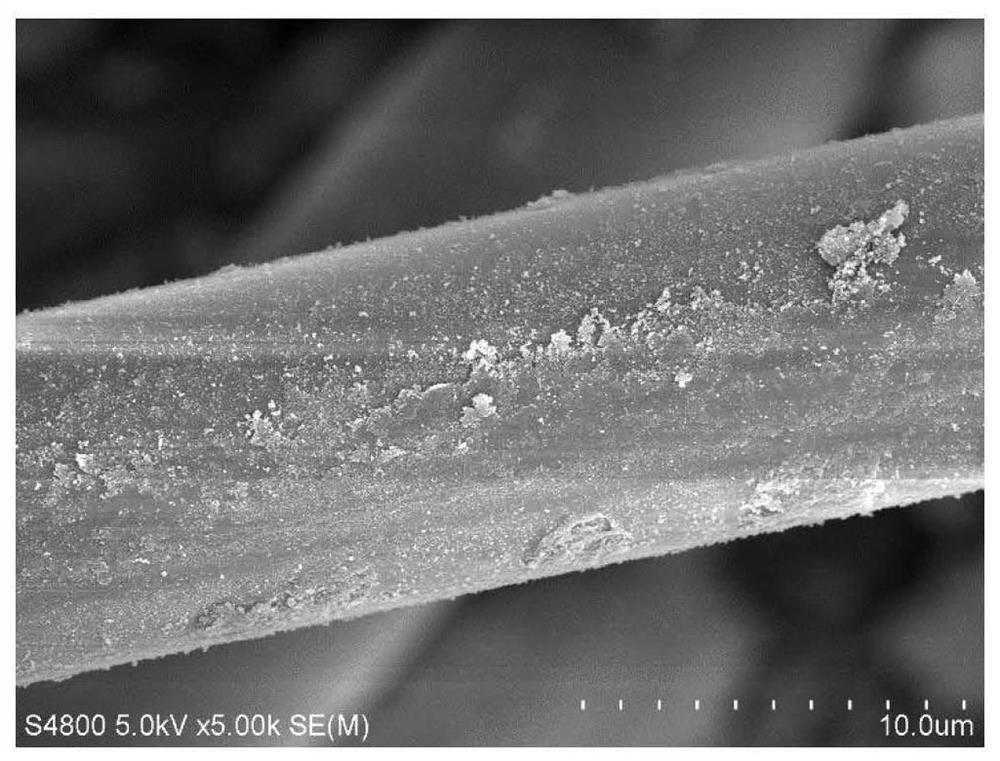

[0075] A method for preparing a silica airgel composite material, comprising the steps of:

[0076]1) Silica wet gel preparation: According to the mass ratio of 45:60:1:3:8:50:5, take silicon source, solvent 1, acid catalyst, chemical drying control additive, basic catalyst, solvent 2, short Cut glass fiber; firstly stir the silicon source, acidic catalyst and part of the solvent (ethanol), the stirring speed is 100r / min, the stirring time is 30min, and then the holding time is 12h at the holding temperature of 35°C; then add the chemical drying control Stir the additive, alkaline catalyst and remaining ethanol at a stirring speed of 100r / min and a stirring time of 30 minutes; ultrasonically treat 6mm chopped glass fibers in an ethanol solution, the conditions are set at a temperature of 35°C, a water level of 10cm, and a time of 10 minutes And the power is 100%, and the chopped glass fiber is soaked in hydrogen peroxide for 3 hours. Then dry the chopped glass fibers after ul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com