Moving desorptive equipment for activated coke

An activated coke and desorption technology, which is applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of uneven heating of active coke, high energy consumption, and non-recycling, so as to achieve convenient, flexible and full utilization of heating energy Waste heat, uniform and sufficient effect of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

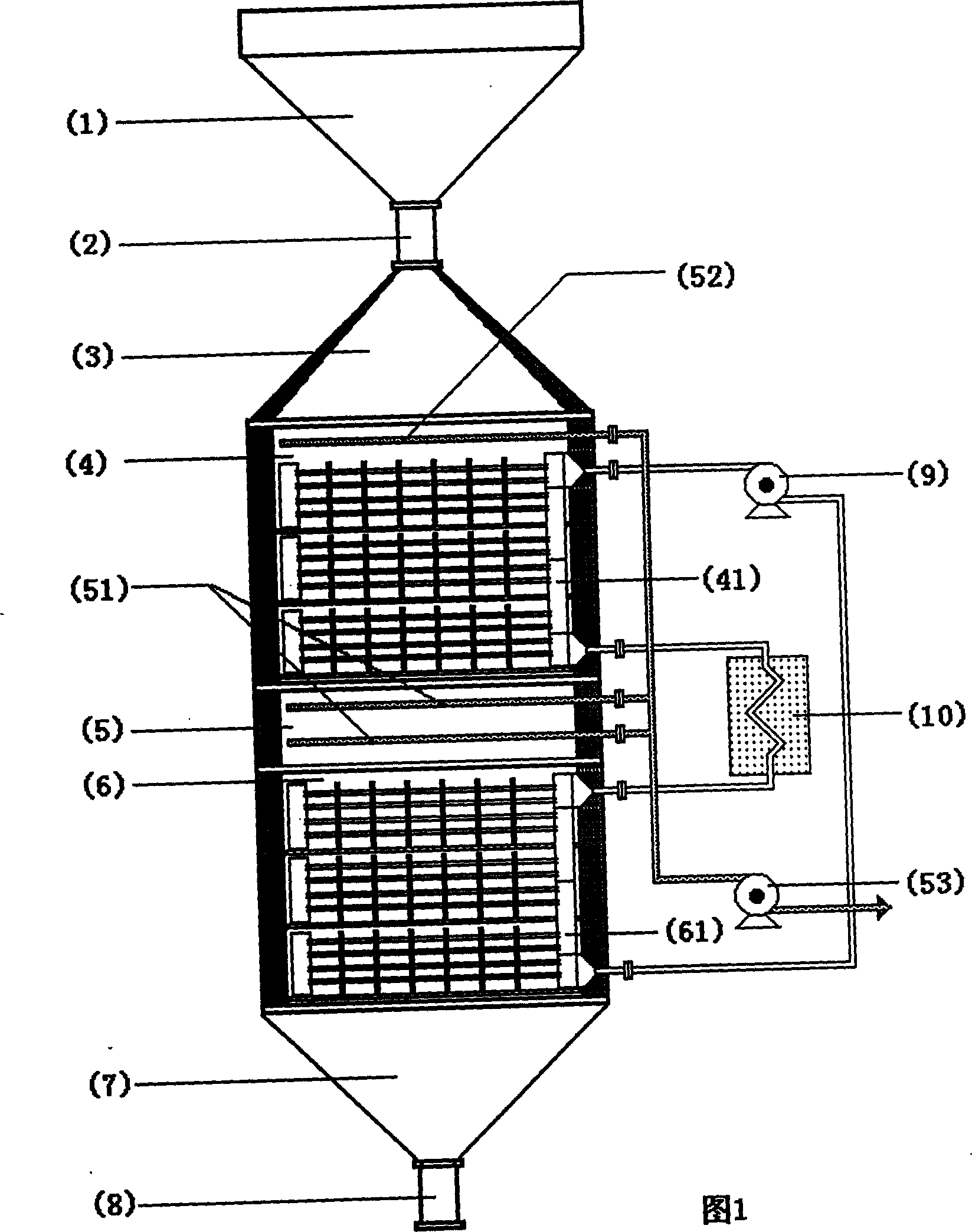

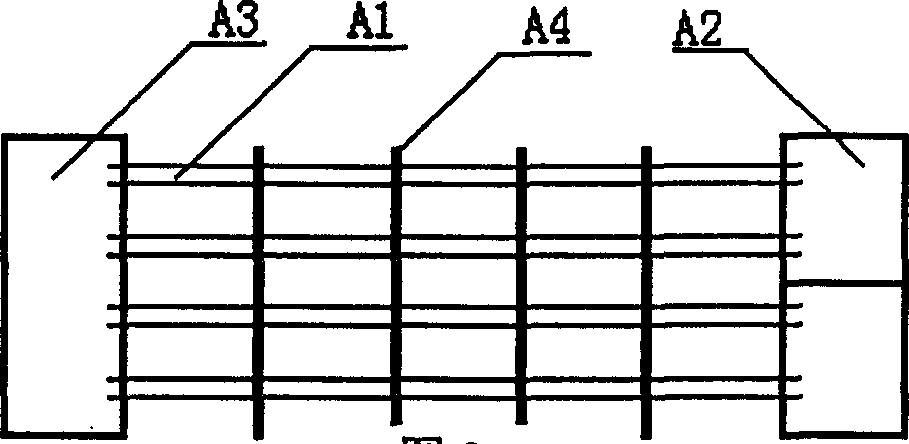

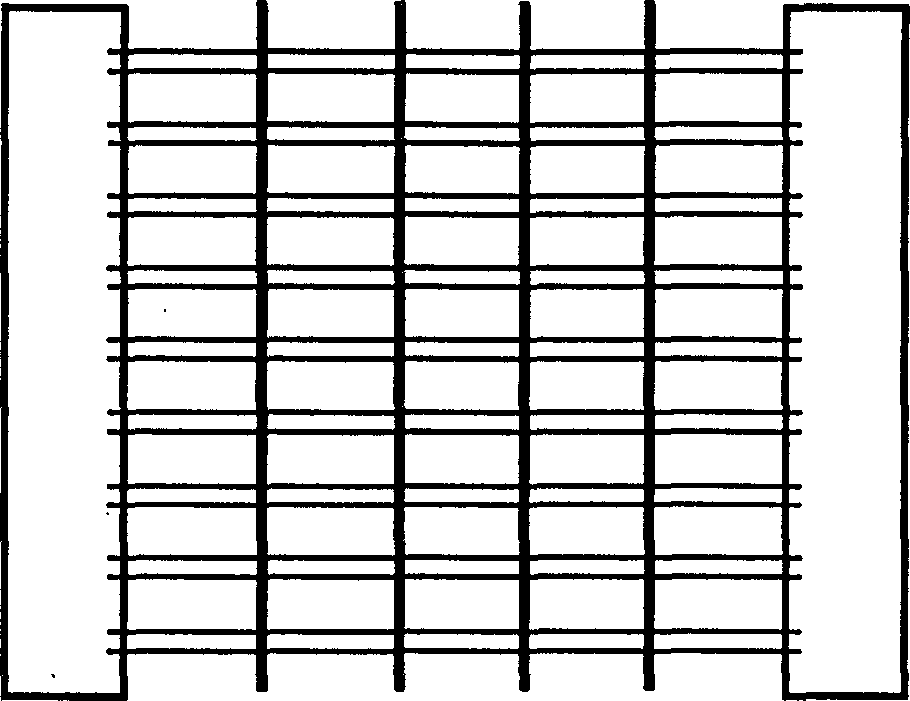

[0018]In the active coke mobile desorption device of the present invention, the main body of the active coke desorption device and the internal heat transducer can be made of corrosion-resistant stainless steel, or only the transducer tube in the high temperature section can be made of stainless steel and other parts can be made of carbon. Made of steel. The device is connected from top to bottom by the inlet storage bin 1, the inlet valve 2, the inlet transition bin 3, the heating bin 4, the reaction bin 5, the cooling bin 6, the outlet transition bin 7, and the outlet valve 8. Between the outer walls of the above parts, heat insulating materials are provided to isolate the outer walls of the upper and lower parts from each other. In the heating chamber 4, a heating heat exchanger 41 is provided, and in the cooling chamber 6, a cooling heat exchange is provided. 61, the upper part of the heating heat exchanger 41 is communicated with the lower part of the cooling heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com