Electrically controlled manual locking mechanism of sliding-plug door and sliding-plug door applying electrically controlled manual locking mechanism

A manual lock and electric control technology, which is applied in the field of sliding doors and electric control manual locking mechanisms of sliding doors, can solve the problems that the motor cannot work, the electric sliding doors cannot work normally, and cannot be unlocked and locked. To achieve the effect of stable locking function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

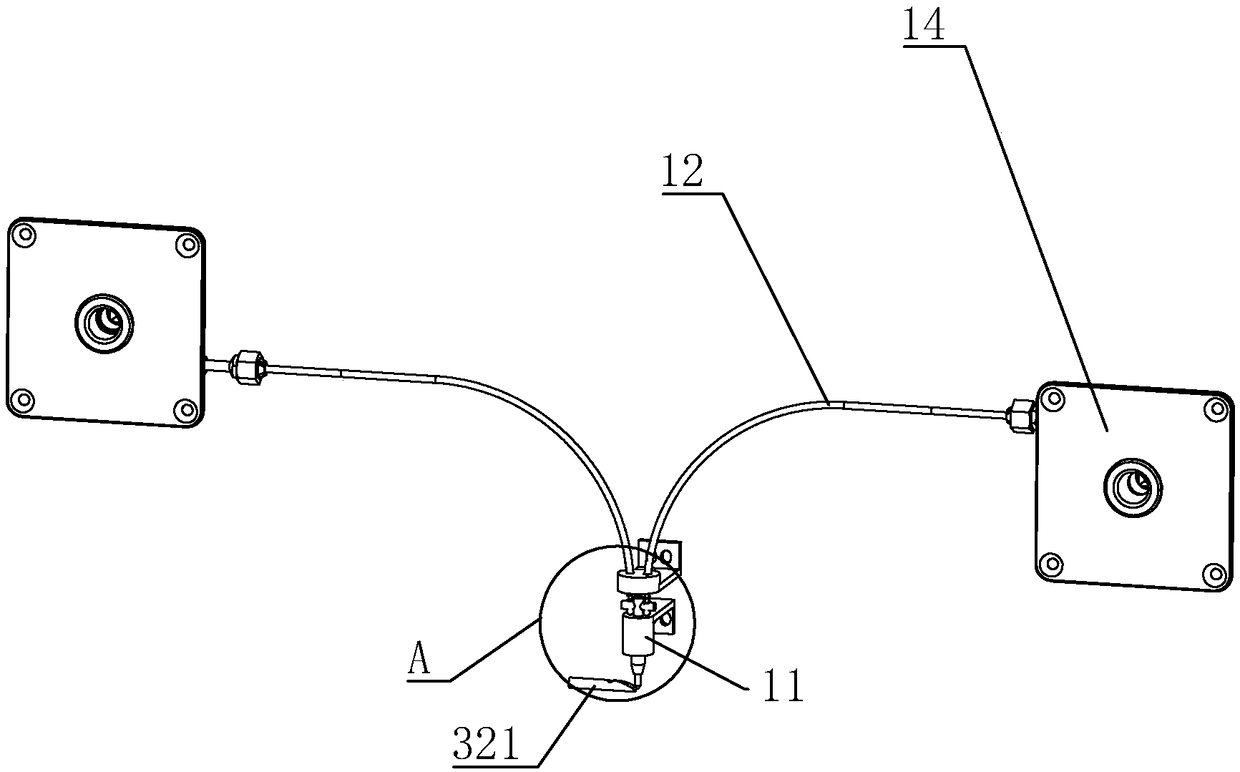

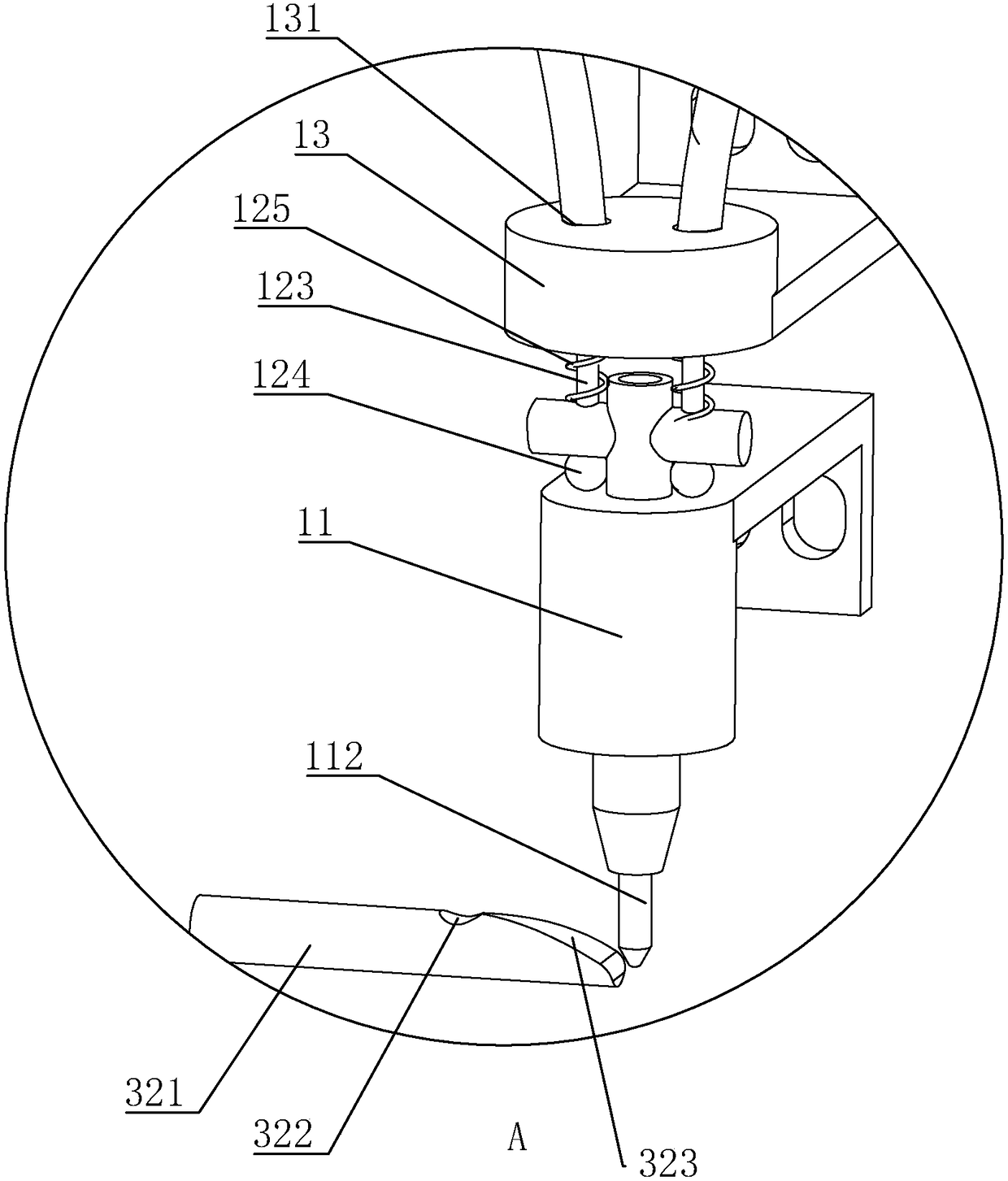

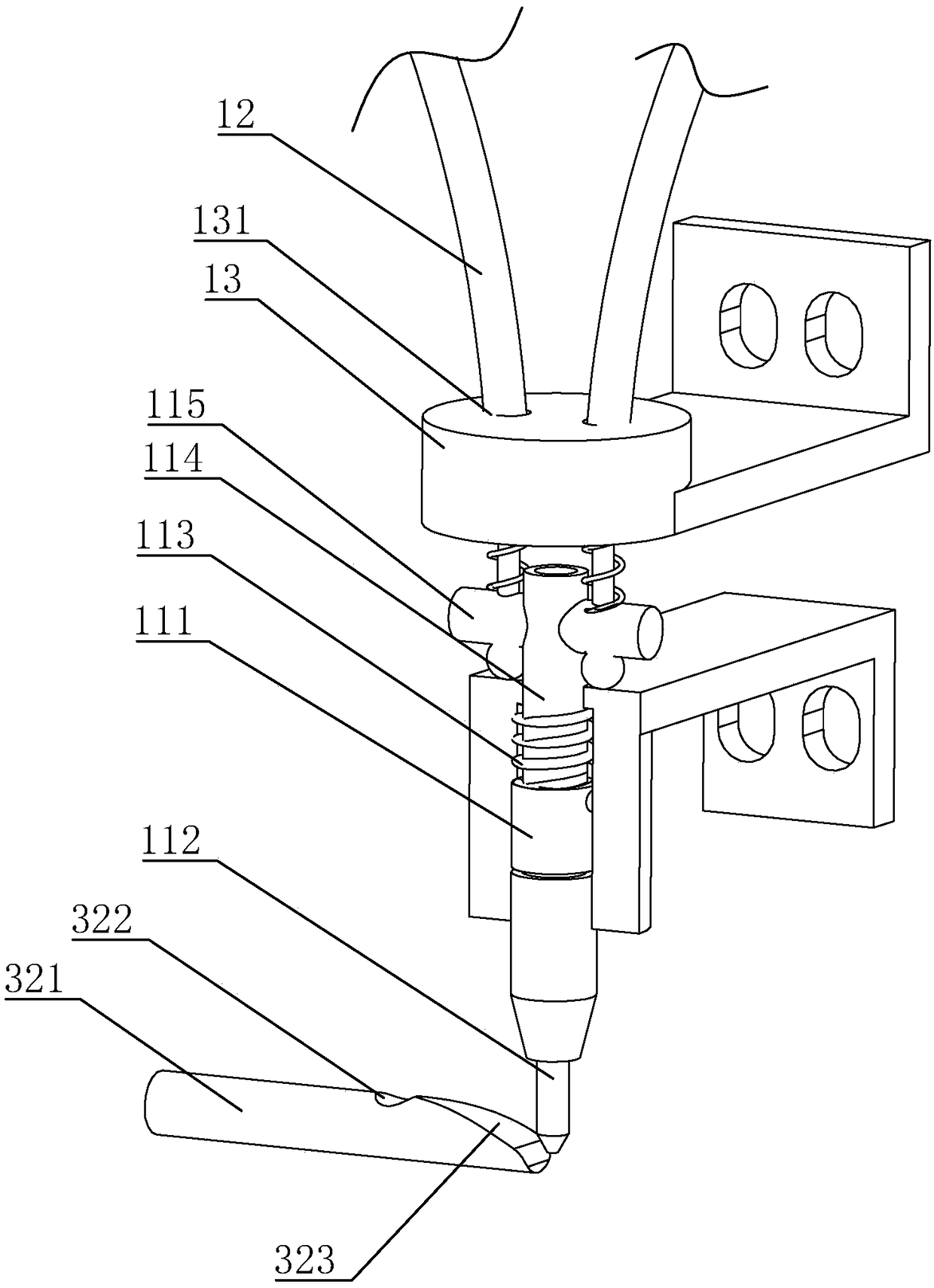

[0054] Embodiment 1: An electronically controlled manual locking mechanism for a plug door, such as figure 1 , 3 shown, including mounting on the mast 1 (as Figure 9 shown) on the electromagnet 11 and with the plug door 7 (such as Figure 9 As shown) the lock tongue 321 that acts together to control the moving state of the plug door 7 is fixedly connected to the armature 111 in the electromagnet 11 with a cylindrical locking rod 112, and the locking rod 112 passes through the bottom of the electromagnet 11 , a compression spring 113 is arranged inside the electromagnet 11, one end of the compression spring 113 is fixedly connected with the end of the armature 111 away from the locking rod 112, and the other end is fixedly connected with the inside of the electromagnet 11, and at the position where the armature 111 is away from the locking rod 112 One end is provided with a cylindrical connecting rod 114, the connecting rod 114 passes through the electromagnet 11 and is conn...

Embodiment 2

[0063] Embodiment 2: An electronically controlled manual locking mechanism for a plug door, the difference from Embodiment 1 is that, as Figure 5As shown, the connecting rod 114 is provided with a stroke hole 116 through which the driving rod 115 passes, and the stroke hole 116 extends along the axis of the connecting rod 114 . When the locking rod 112 was inserted into the locking hole 322 to limit the movement of the dead bolt 321, the driving rod 115 just collided with the side hole wall of the stroke hole 116 away from the armature 111; When the tongue 321 is unlocked, the driving rod 115 just or does not interfere with the side hole wall of the stroke hole 116 near the armature 111, that is, the stroke of the stroke hole 116 is greater than or equal to the depth of the locking rod 112 inserted into the locking hole 322.

[0064] Such as Figure 6 As shown, a fixed tube 15 is also arranged directly below the electromagnet 11 on the door frame 1, the axis of the fixed tub...

Embodiment 3

[0066] Embodiment 3: a kind of sliding door, such as Figure 7 , 8 As shown, it includes a driving wheel 21 installed on the door frame 1 , a driven wheel 22 and a motor 2 for driving the driving wheel 21 to rotate, and the driving wheel 21 and the driven wheel 22 are linked by a toothed belt 23 .

[0067] Such as Figure 8 As shown, a linear guide rail 3 with a U-shaped cross-section is fixedly connected to the door frame 1. The linear guide rail 3 is located below the toothed belt 23 and is parallel to the toothed belt 23. A slider is slidably connected to the linear guide rail 3. 31.

[0068] Such as Figure 8 and 10 As shown, a connecting plate 32 is fixedly connected to the side of the slider 31 away from the linear guide rail 3, and is fixedly connected to the toothed belt 23 through the belt clamp 231 above the connecting plate 32. On the side of the connecting plate 32 away from the linear guide rail 3 A self-lubricating radial joint bearing-411 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com