Movable desorption device of activated coke

An active coke and desorption technology, which is applied in filter regeneration, filtration separation, petroleum industry, etc., can solve the problems of incomplete pumping of the device, large overall device, wear and tear of active coke, and achieve convenient, flexible and reasonable energy for heating , the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

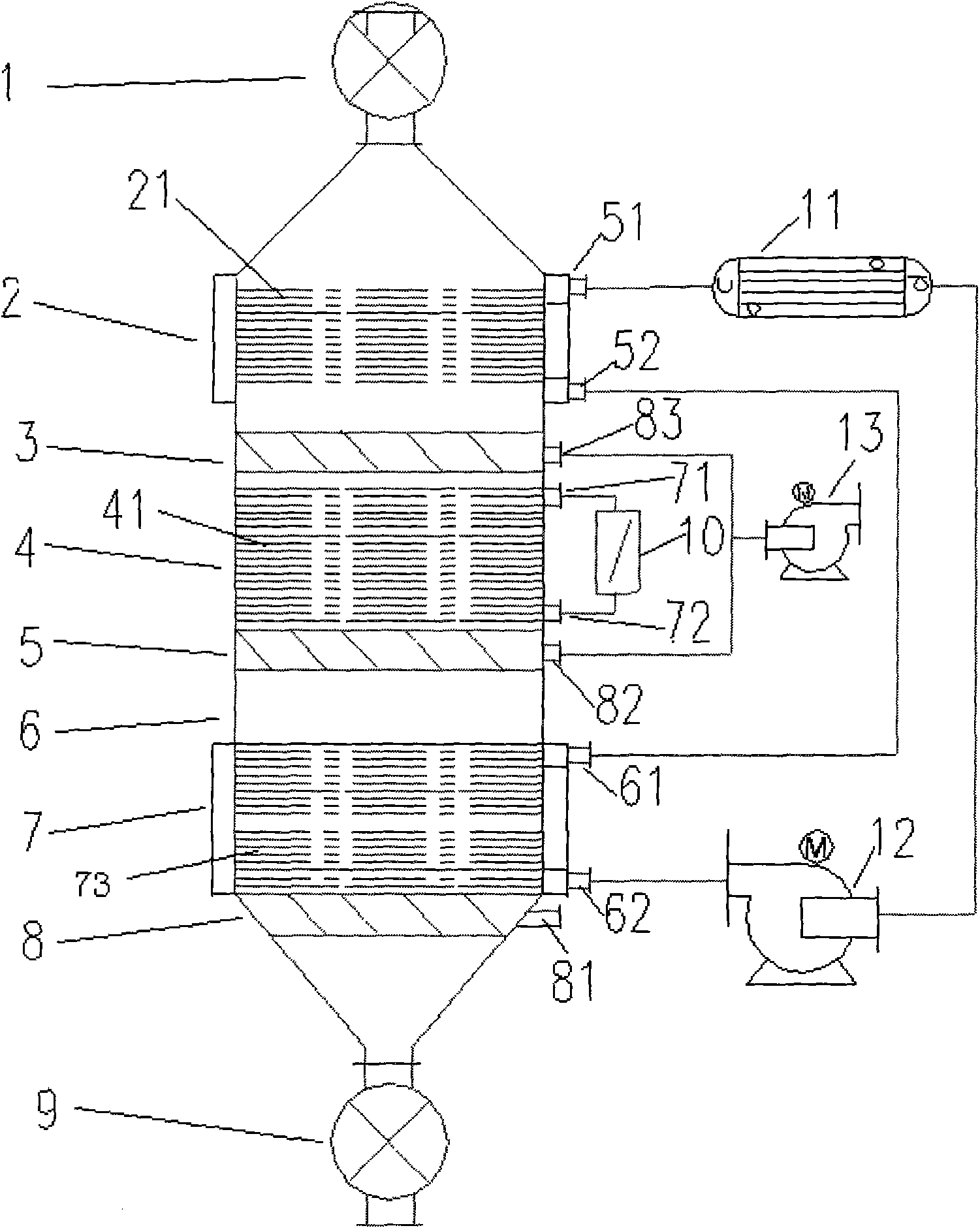

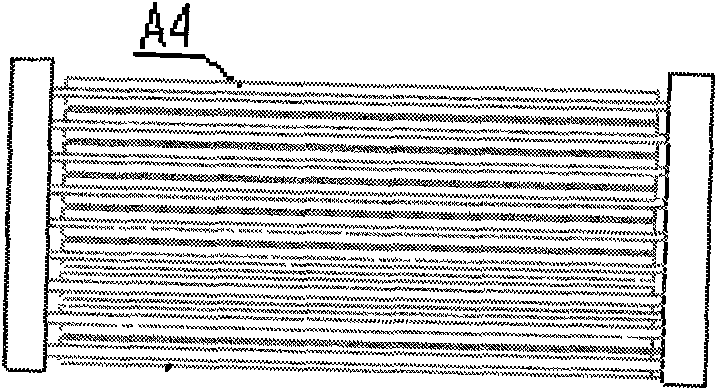

[0051] Steam is used as the desorption heat source, that is, the heat source system 10 is heated by steam. The heating heat exchanger 41 adopts Image 6 In the shown structure, the steam in the heating chamber 4 enters directly from the inlet 72 of the heating heat exchanger, and goes out from the outlet 71 of the heating heat exchanger. The used steam is medium-pressure steam, which is used for industrial production according to the actual needs of the project. The cooling medium in the cooling chamber 7 is heated when cooling the active coke, and enters the air inlet 52 of the preheating heat exchanger from the outlet 61 of the cooling heat exchanger, and the active coke is preheated in the preheating chamber 2, and the medium is cooled at the same time. The external circulating medium heat exchanger 11 is further cooled to obtain a lower temperature, and circulates into the cooling chamber 7 through the circulation pump 12 . In thermal cycling, the medium can be inert gas ...

Embodiment 2

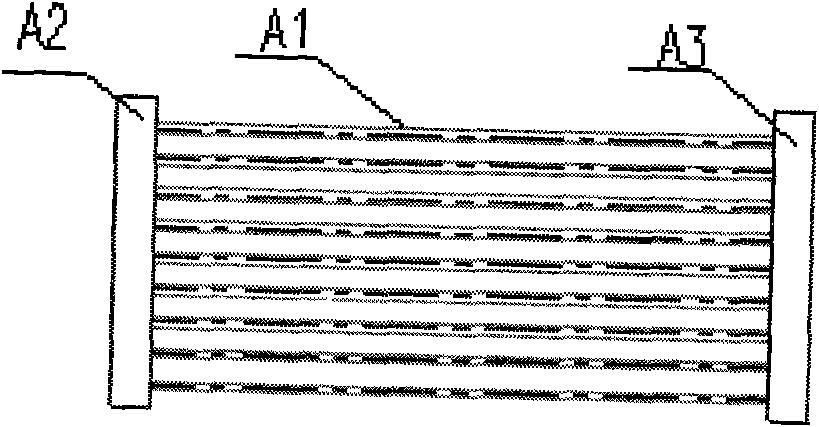

[0056] Electricity is used as the desorption heat source, that is, the heat source system 10 is electric heating, and the heating chamber heat exchanger 41 adopts image 3 The structure shown is the same as that of Embodiment 1. In this way, the heat exchange medium coming out of the outlet 71 of the heating heat exchanger of the heating chamber 4 directly enters the heat source system 10 for electric heating, and the temperature is raised to about 500° C. by the electric heater. The gas outlet 72 of the heating heat exchanger enters the heating chamber 4 to heat the active coke to reach the desorption temperature. The heat exchange medium can be air or inert gas. The sealing of the device and the extraction of the desorption gas are the same as in Example 1.

[0057] In this patent, if the corresponding heat exchangers (preheating heat exchanger 21, heating heat exchanger 41, and cooling chamber heat exchanger 73) in the preheating chamber 2, heating chamber 4, and cooling c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com