Patents

Literature

35results about How to "Reasonable energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

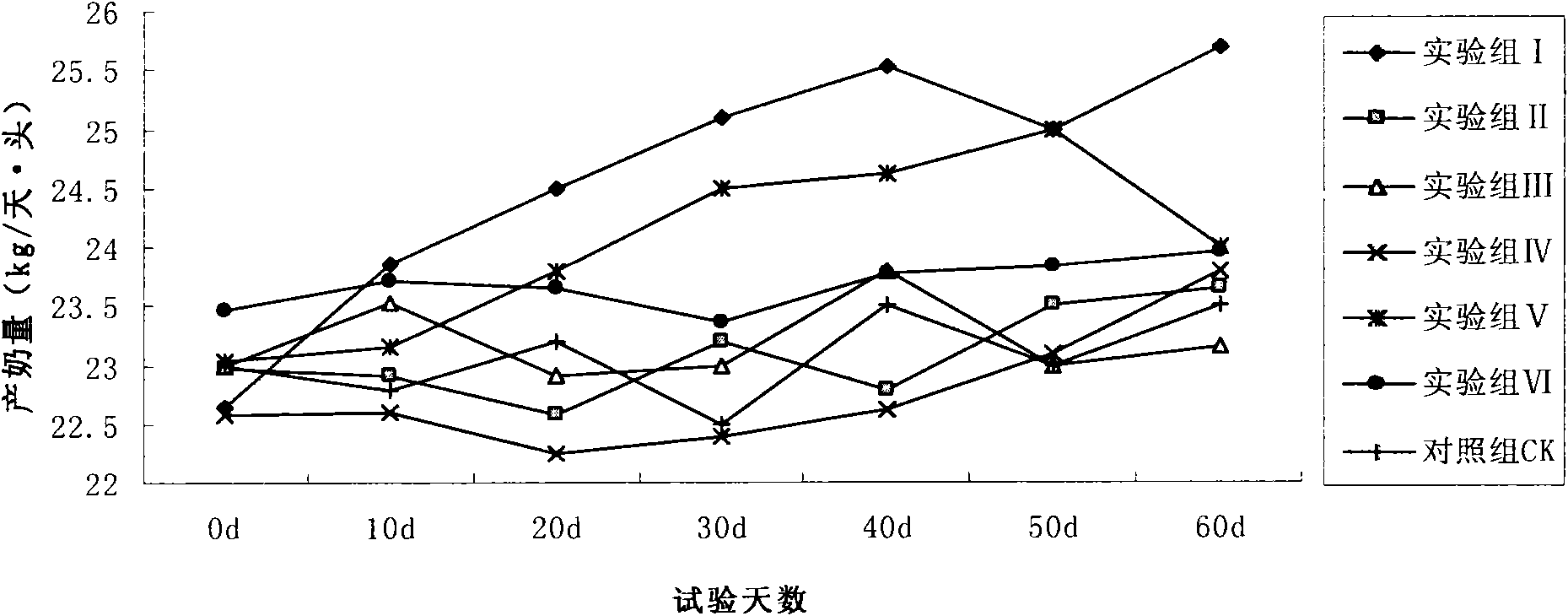

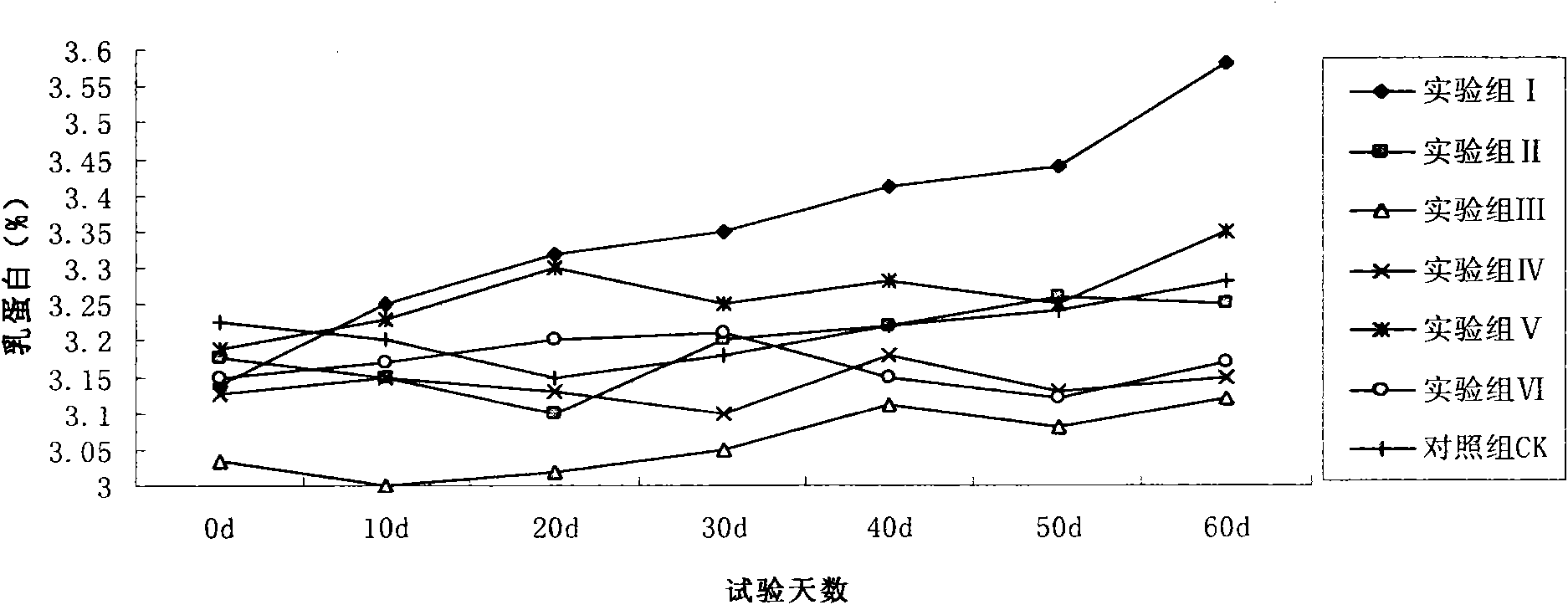

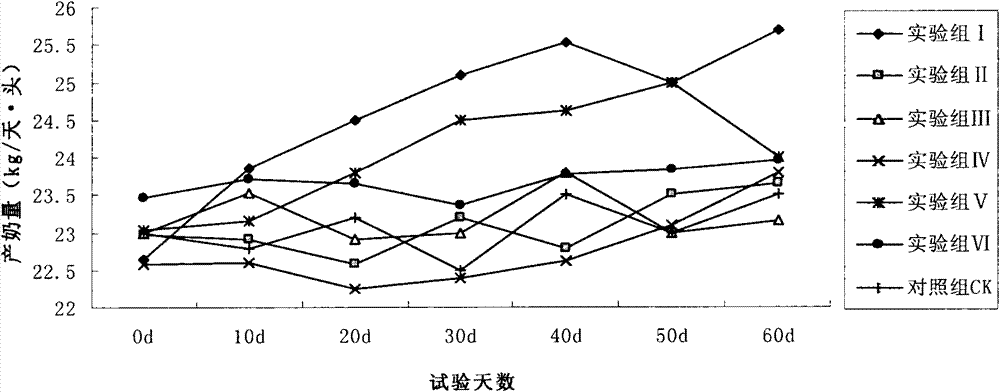

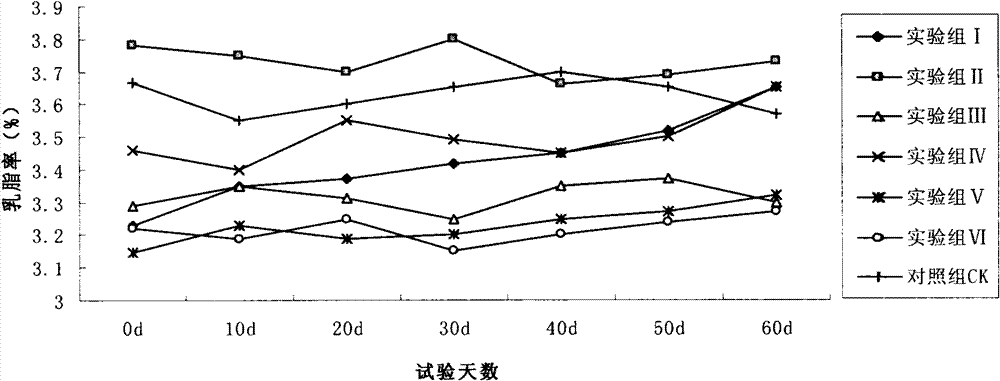

Milch cow feed capable of improving milk quality and preparation method and application thereof

ActiveCN102113628AAddressing chronic rumen acidosisFully absorbedFood processingAnimal feeding stuffYeastRumen

The invention relates to a milch cow feed and a preparation method and application thereof, in particular to a functional milch cow feed capable of improving the nutrition of milch cow and enhancing the milk quality and a preparation method and application of the feed. The milch cow feed is prepared from the following components in a special proportion: rumen-protected lysine, rumen-protected methionine, rumen-protected dextrose, active dry yeast, trace mineral vitamin premix and bean pulp. The milch cow feed provided by the invention is fed to milch cows to supplement the energy and nutritional inadequacy of the milch cow on a basis of original concentrated supplementation feed so as to achieve the effects of improving milk yield and milk quality.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

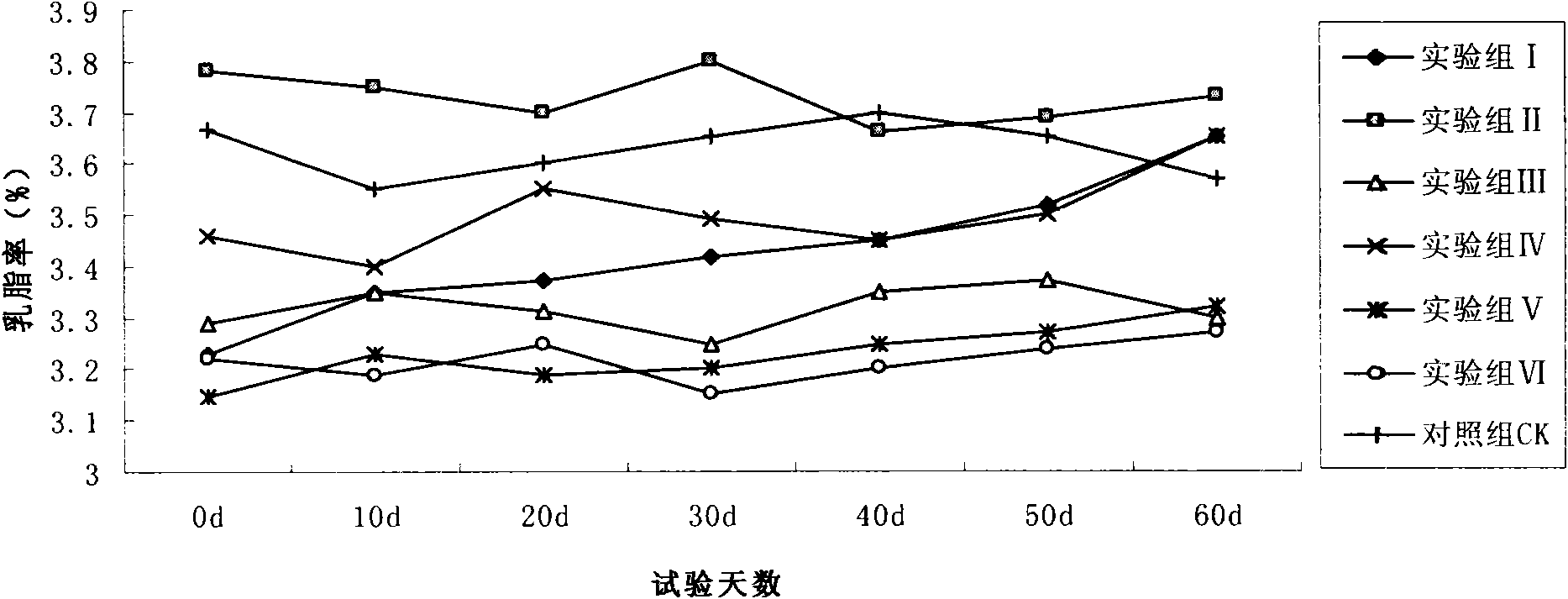

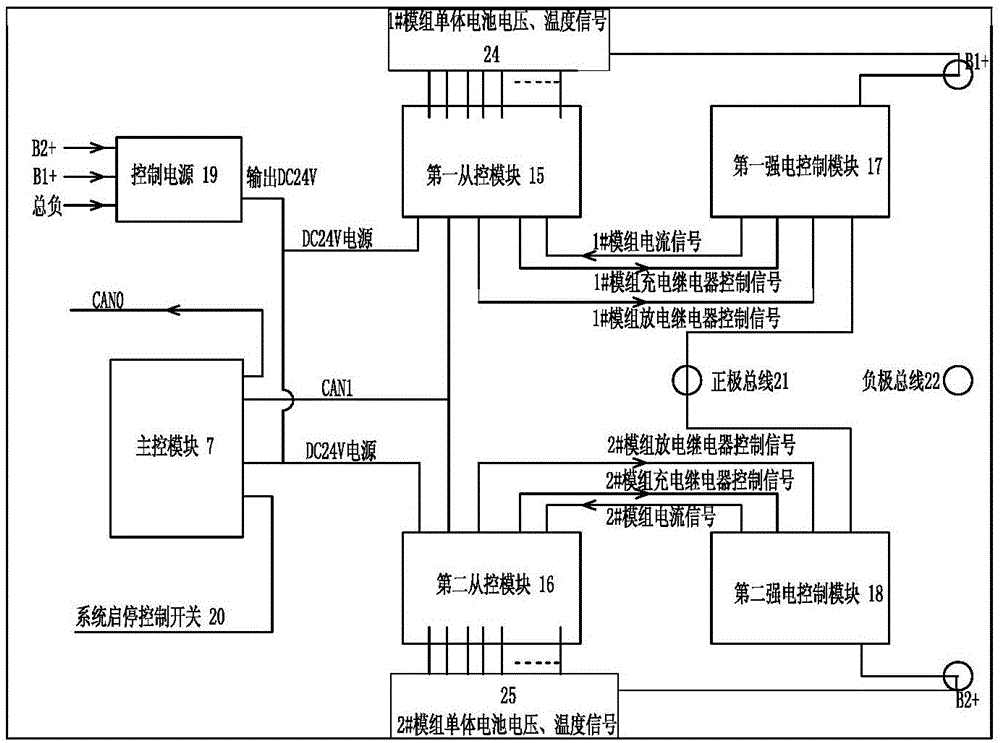

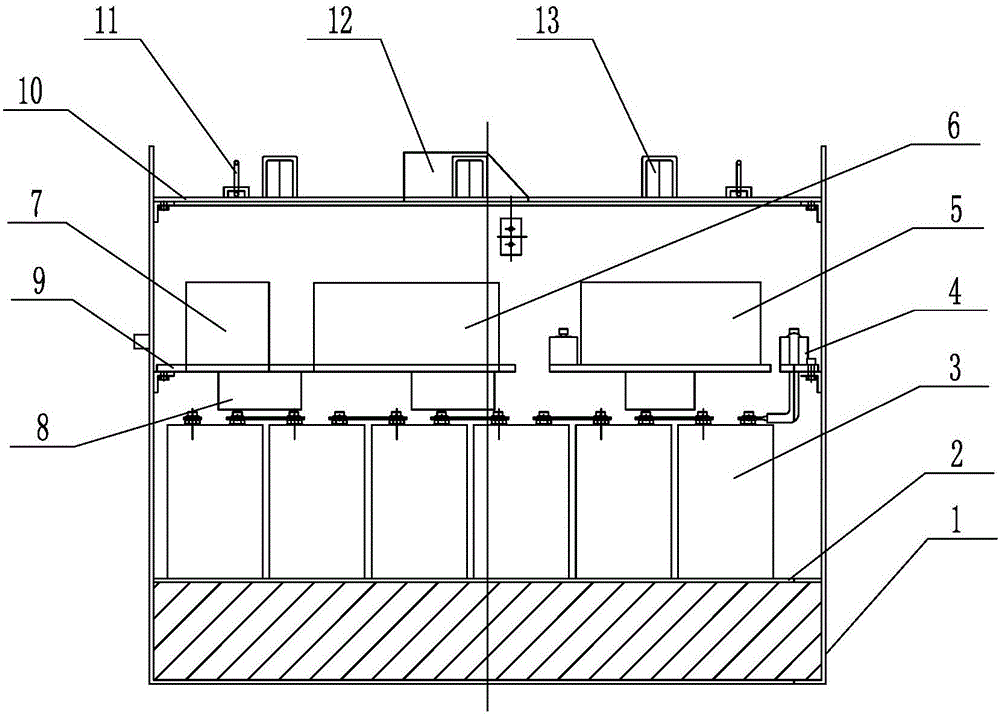

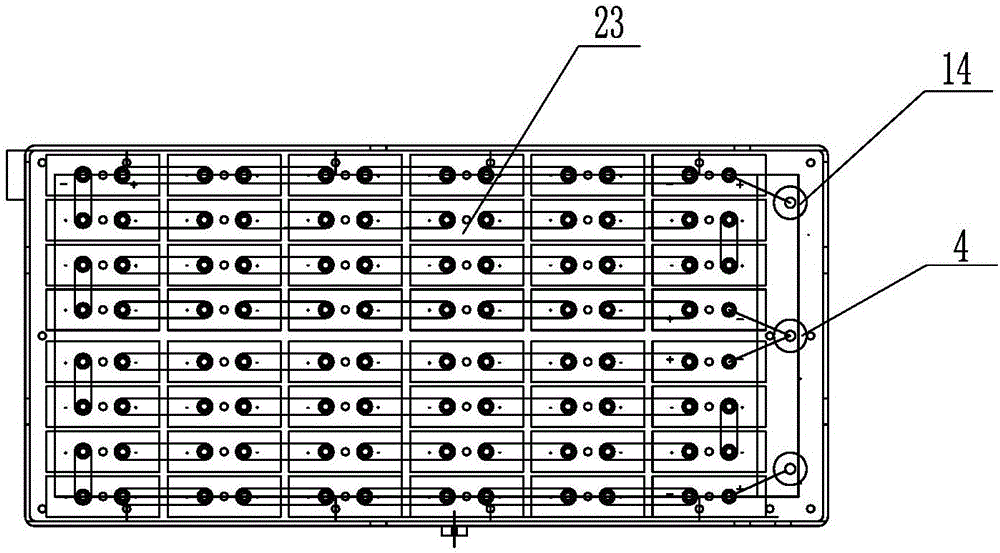

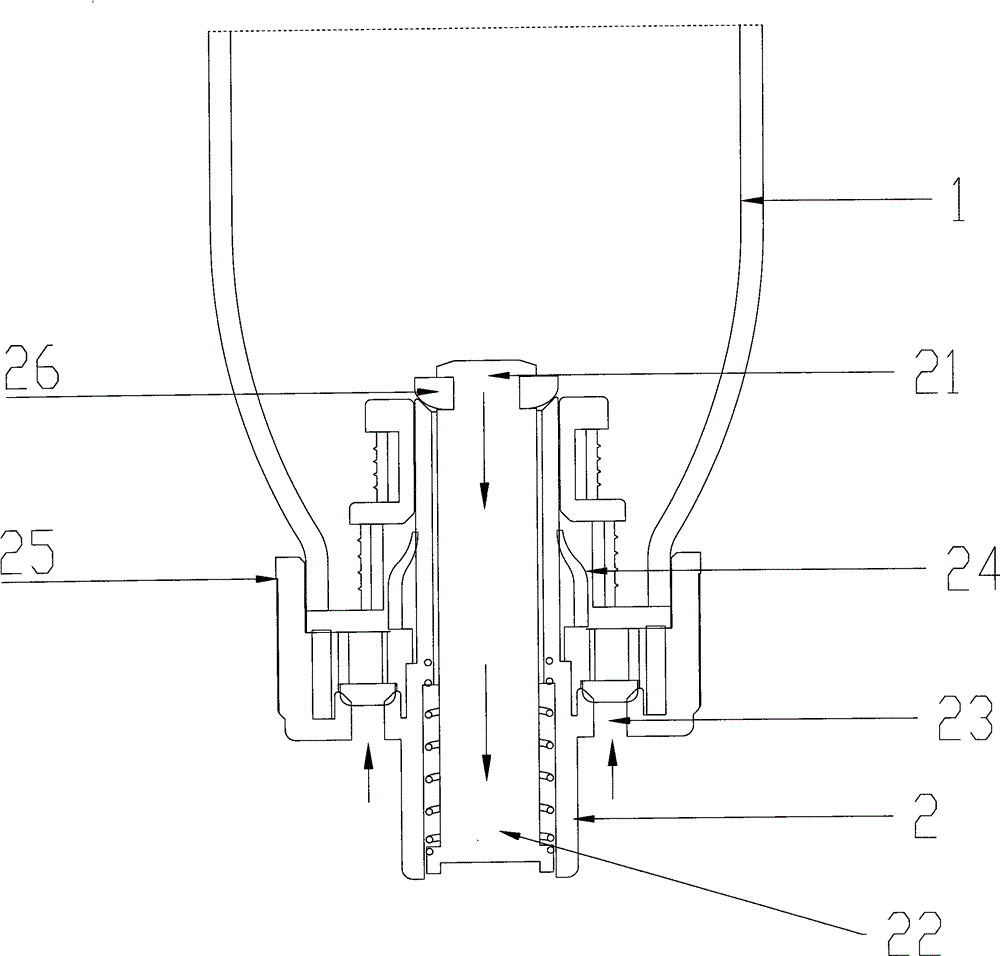

Lithium ion battery pack for forklift

ActiveCN106129457AMeet the power supplySimple structureSecondary cellsCell component detailsDischarge efficiencyElectrical battery

The invention relates to a lithium ion battery pack for a forklift, and belongs to the technical field of a lithium ion battery. The lithium ion battery pack comprises a power supply box. A power supply box cover is arranged on the top of the power supply box. A first insulation plate is arranged at the lower part of the power supply box. Multiple single batteries are arranged on the first insulation plate. A second insulation plate is above the single batteries. Damping rubber blocks are fixed on the bottom of the second insulation plate. A main control module, a slave control module and a strong electric control module are arranged on the top of the second insulation plate. The single batteries are connected in series to form the battery pack. An anode bus and a cathode bus are leaded out from the battery pack. Voltage signal lines and temperature sensor connection lines on the single batteries are connected with the slave control module. The strong electric control module is connected with the slave control module. The slave control module is connected with the main control module. The battery packet has the advantages of simple and reasonable structure, saving electric energy, long service life, short charging time and high charging / discharging efficiency.

Owner:ZIBO TORCH ENERGY

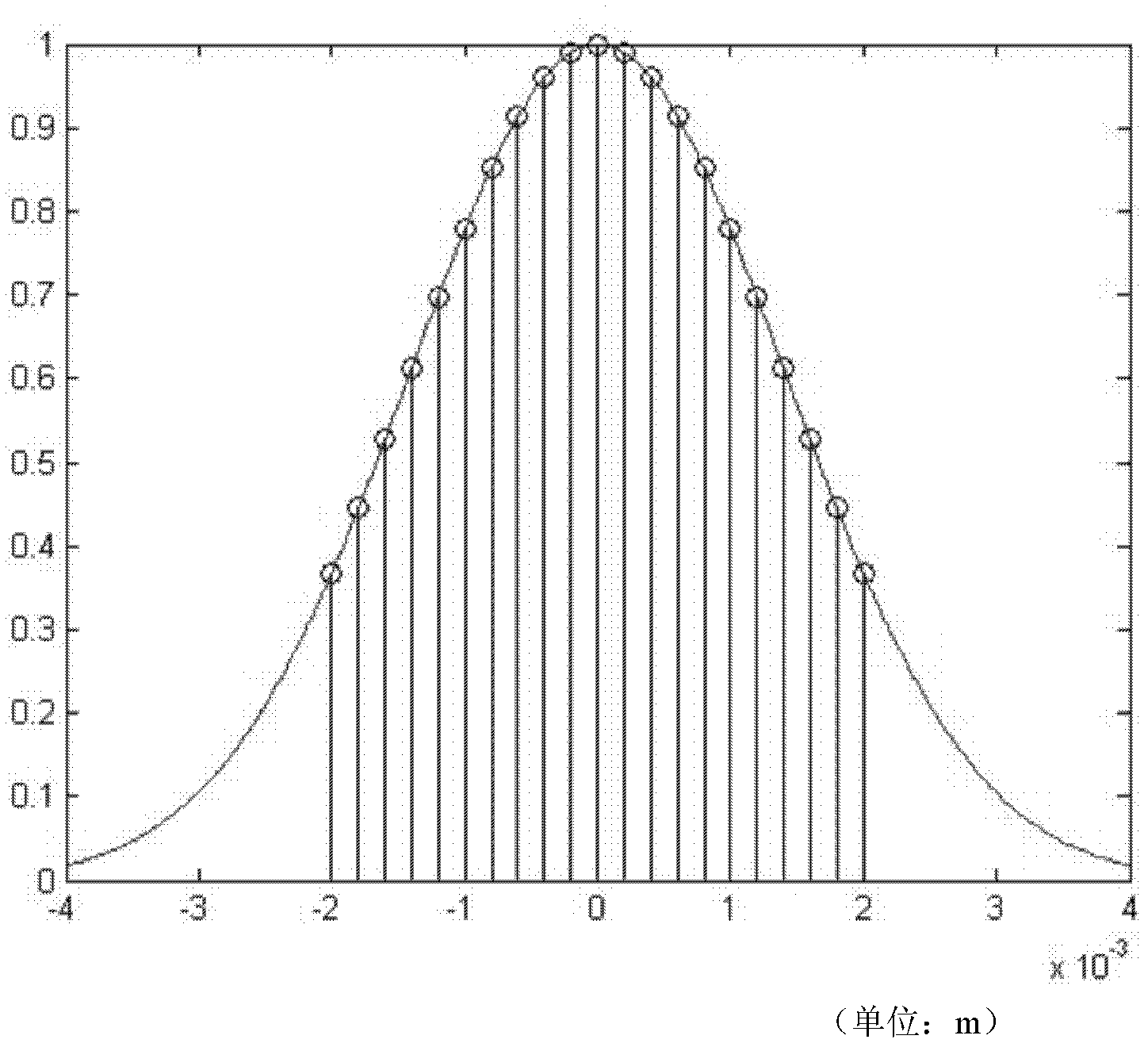

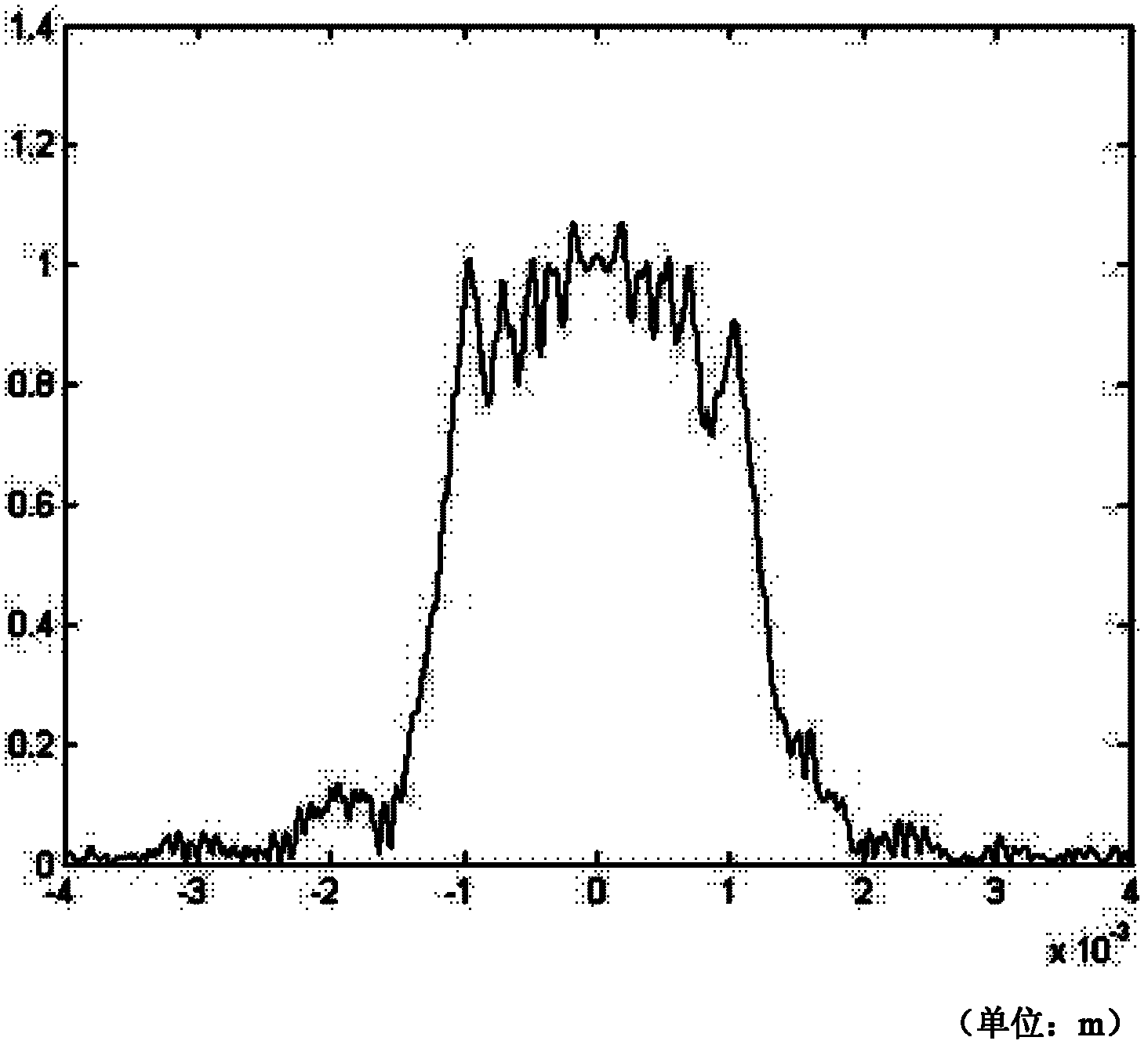

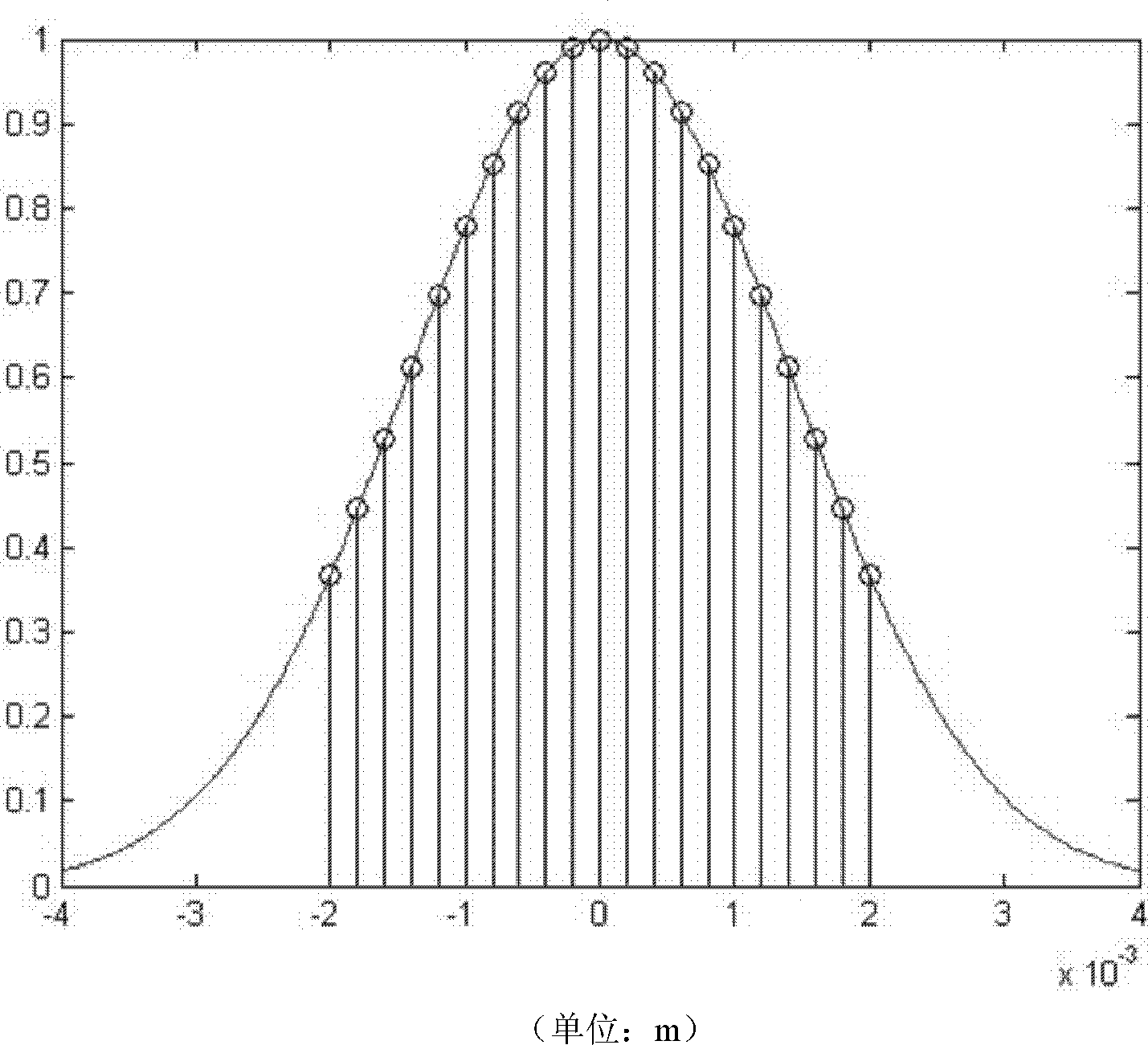

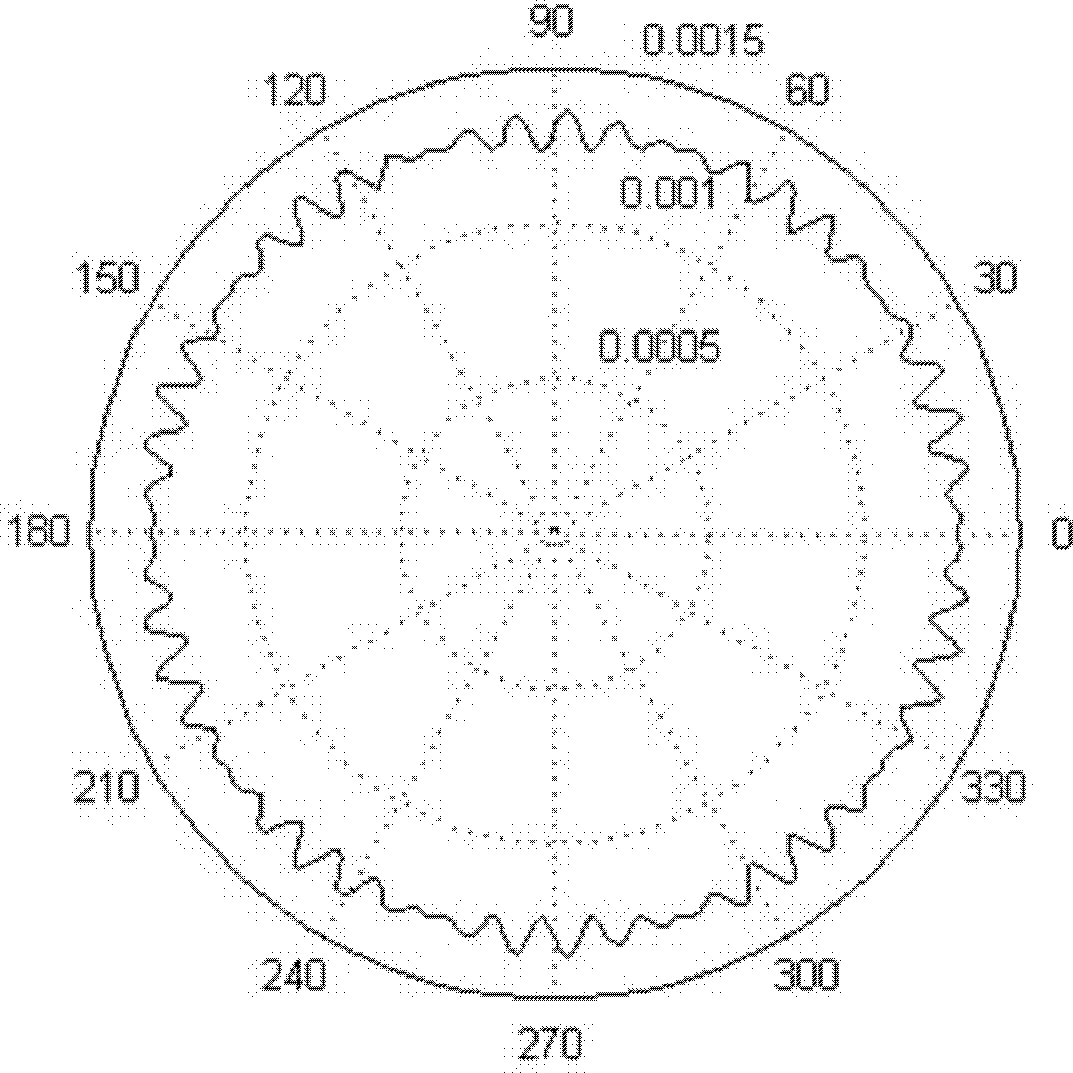

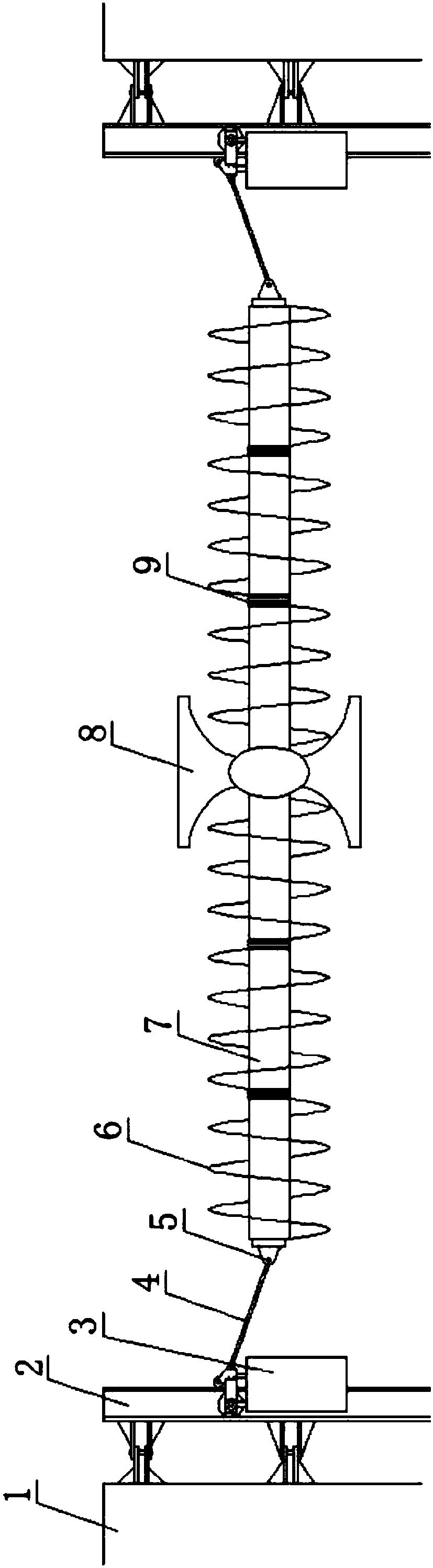

Determination method of average radius of ripple serrated aperture for realizing Gaussian beam shaping

InactiveCN102540461AAchieve shapingAchieve homogenizationLaser detailsOptical elementsGaussian beamLight beam

The invention discloses a determination method for an average radius of a ripple serrated aperture for realizing Gaussian beam shaping, and belongs to the field of laser. The method comprises the following steps of: determining aperture radius r, namely r is equal to a*(1+a1*sin (5 theta) sin (50 theta)), wherein a is the average radius which is 0.001-0.003 m, and a1 is modulation width which is 0.05; then manufacturing apertures r of different radiuses to perform experiments and calculating characteristic parameters: filling factor, modulation intensity and light intensity contrast; and finally determining the optimal range of the average radius a to be between 60 percent and 65 percent of beam width of an emitted Gaussian beam from the characteristic parameters. By using the method, a part of energy of the Gaussian beam is intercepted to improve the filling ratio through the aperture; the modulation strength is reduced through irregularity of the edge of the aperture; the optimal ratio of the average radius of the serrated aperture to the Gaussian beam width is determined through calculation of the characteristic parameters; and thus, an output beam with better light intensity distribution is obtained. The method can be widely used in a high-power solid laser for shaping and homogenizing the Gaussian beam, and is easy to operate and easy for engineering application.

Owner:BEIJING UNIV OF TECH

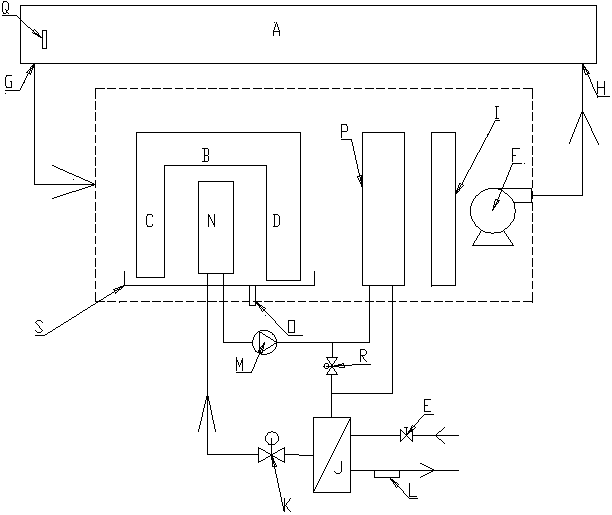

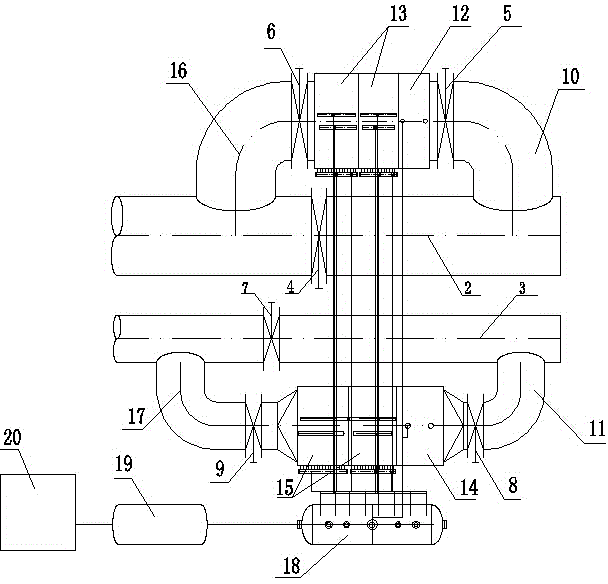

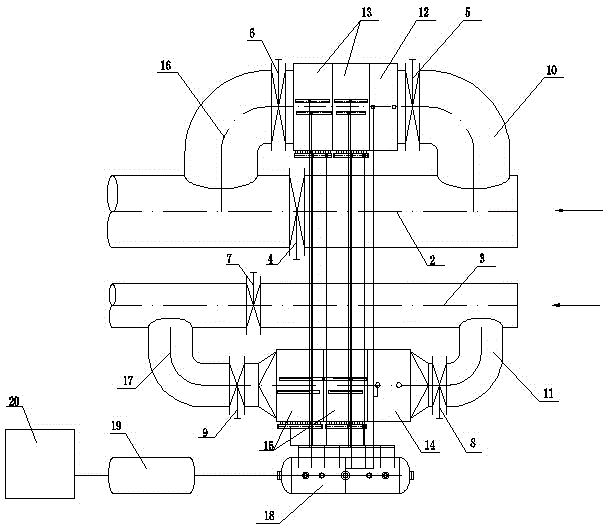

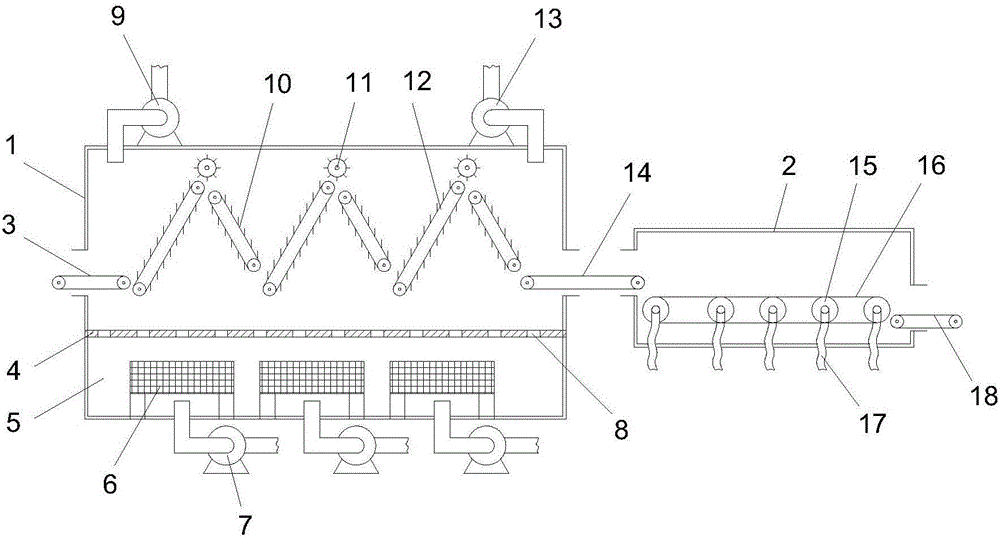

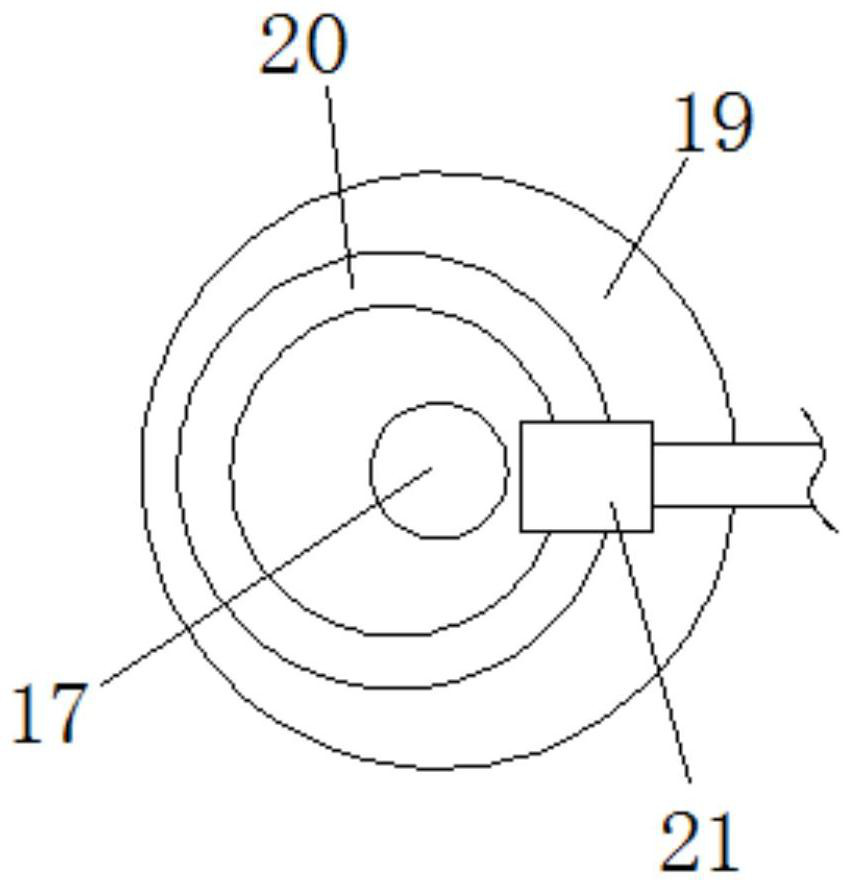

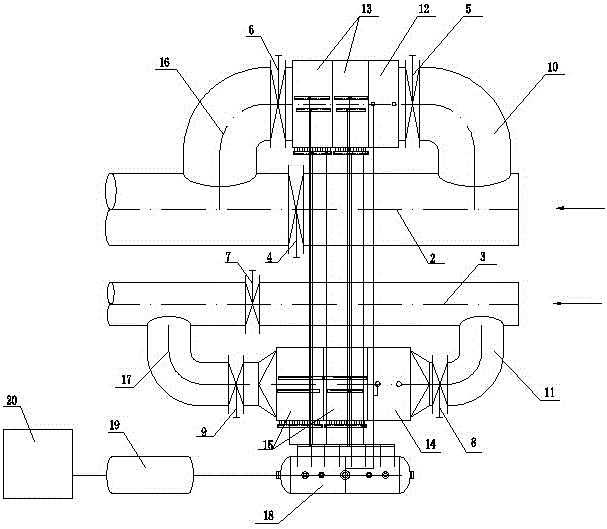

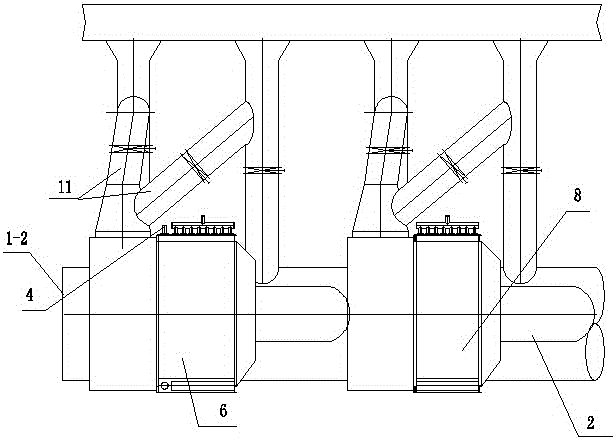

Cool storage energy-saving dehumidification air conditioner and dehumidification control method

PendingCN108119973AReasonable energyReduce energy consumptionMechanical apparatusCondensate preventionCool storageProcess engineering

The invention provides a cool storage energy-saving dehumidification air conditioner and a dehumidification control method. The cool storage energy-saving dehumidification air conditioner is characterized in that a heat recovery dehumidification air duct, which is formed between a return air inlet and an air supply opening in the cool storage by the driving of a fan , sequentially comprises a precooler, an evaporator, a reheater, a first stage condenser and an auxiliary heater from entrance to exit; heaters are communicated with each other forming a closed cycle path of temperature differencepower energy; an air outlet of the evaporator is communicated with an air inlet of the first stage condenser through a compressor and a corresponding pipeline; a liquid outlet of the first condenser is communicated with a liquid outlet of the evaporator through a two stage plate condenser and a corresponding pipeline. The cool storage energy-saving dehumidification air conditioner has the advantages of making full use of various heat sources in dehumidification process for system cooling, dehumidification, or heating, having reasonable and effective use of energy, and meeting constant temperature and humidity requirements of the cool storage with the lowest energy consumption.

Owner:苏州海派特热能设备有限公司

Clean recovery and production method for waste copper and copper-containing waste

ActiveCN102618722AIncrease profitRealize added valueProcess efficiency improvementSlagPollutant emissions

The invention discloses a clean recovery and production method for waste copper and copper-containing waste. The method comprises the following steps of: sorting and classifying the copper-containing waste, and cleaning the sorted waste copper by adopting a sulfuric acid solution to obtain qualified copper and a low-grade copper sulfate solution; dissolving the qualified copper into a copper sulfate solution to obtain a high-grade copper sulfate solution; processing and granulating the sorted copper-containing material or electronic garbage, and dissolving the granulated copper-containing material into a sulfuric acid solution to obtain a low-grade copper sulfate solution and waste slag; sequentially performing extraction and back extraction on the low-grade copper sulfate solution to obtain a high-grade copper sulfate solution; and performing electro-deposition on the high-grade copper sulfate solution to produce a cathode copper or copper product blank, and processing the copper product blank into various copper products. By the method, the high-content waste copper material can be effectively recovered, the waste copper material with low copper content can also be effectively recovered, and the recovery rate reaches 99 to 100 percent. According to the method, pollutants are not discharged, and any fuel is not adopted; and the method is reasonable in design, simple in process, strong in practicability and easy to popularize and implement.

Owner:河南萃海再生资源有限公司

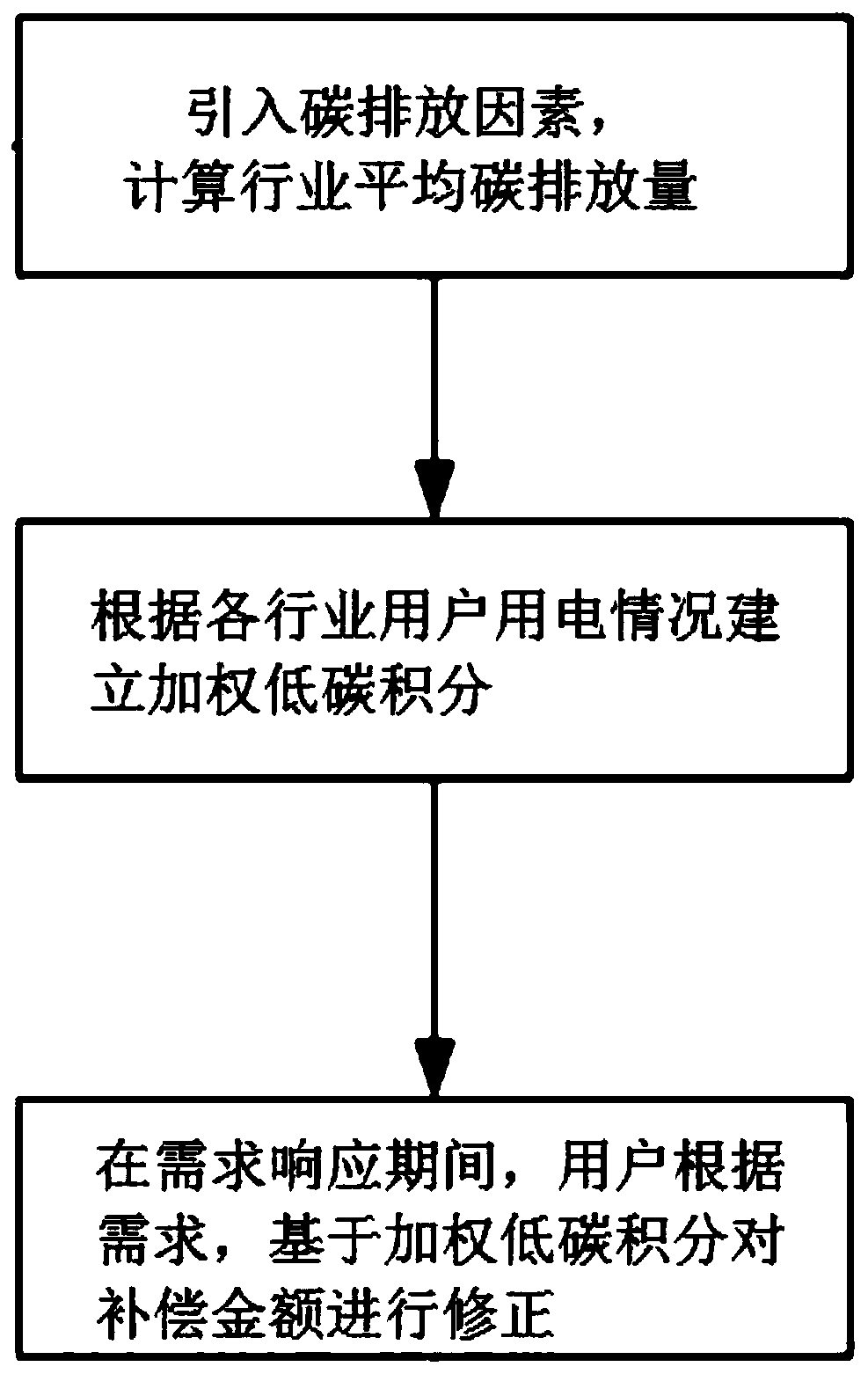

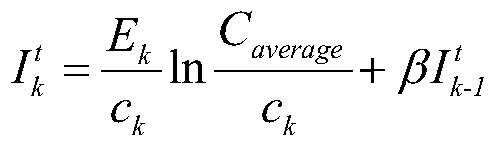

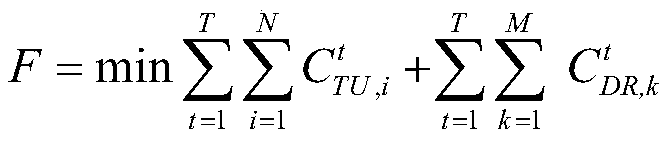

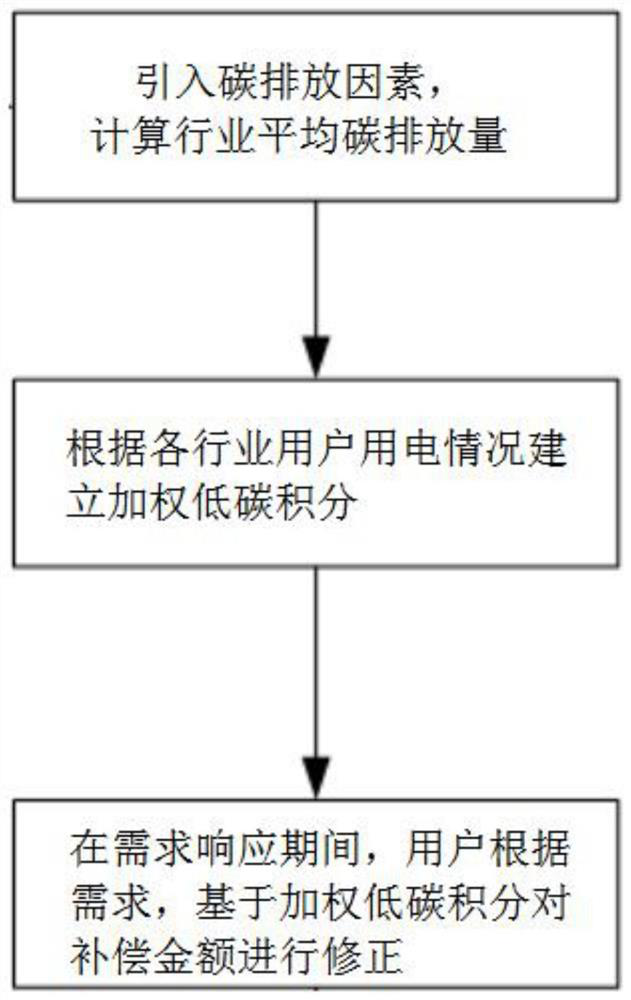

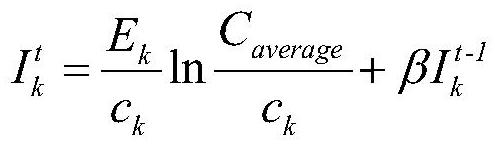

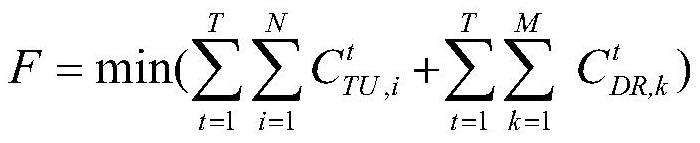

Demand response control method based on weighted low carbon integration

ActiveCN110535127AReasonable energyEmission reductionTechnology managementResourcesRational useDemand side

The invention discloses a demand response control method based on weighted low carbon integration. The demand response control method comprises the following steps: step 1, introducing carbon emissionfactors to calculate the average carbon emission of the industry; step 2, establishing weighted low carbon integration according to the electricity consumption situation of users in various industries; and step 3, the user corrects the compensation amount based on the weighted low carbon integration according to the demand during the demand response period. The carbon emission of each user is considered, the weighted low carbon integration for the users in various industries is established. The users with higher low carbon integration are rewarded and the users with lower low carbon integration are punished. Demand response scheduling management is implemented on the basis of the weighted low carbon integration so as to improve the effectiveness and the standardization of users' rationaluse of electricity, protect the environment and reduce the carbon emission. The invention demand side management and the low carbon emission power generation are simultaneously considered, the carbonemission is reduced, the users are enabled to reasonably use electric energy and the power consumption cost is reduced.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO +1

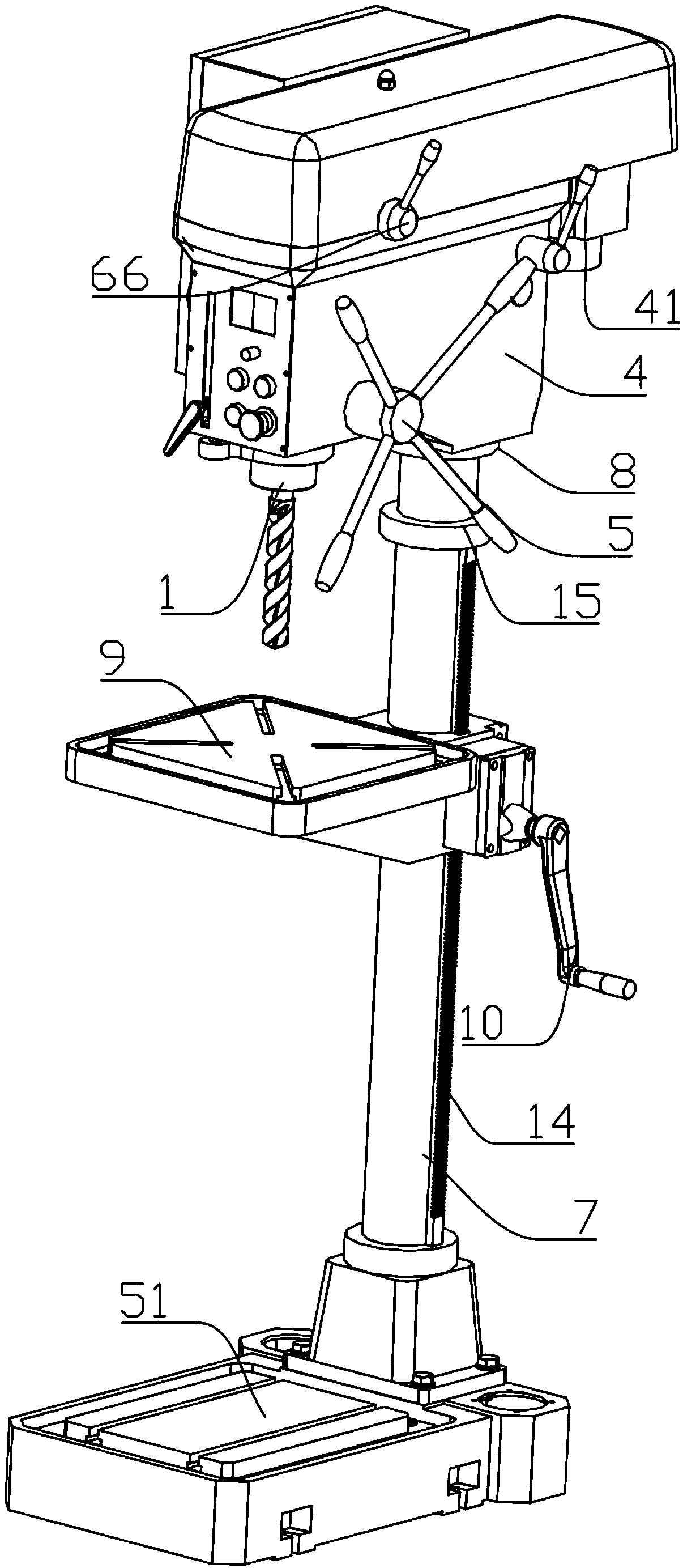

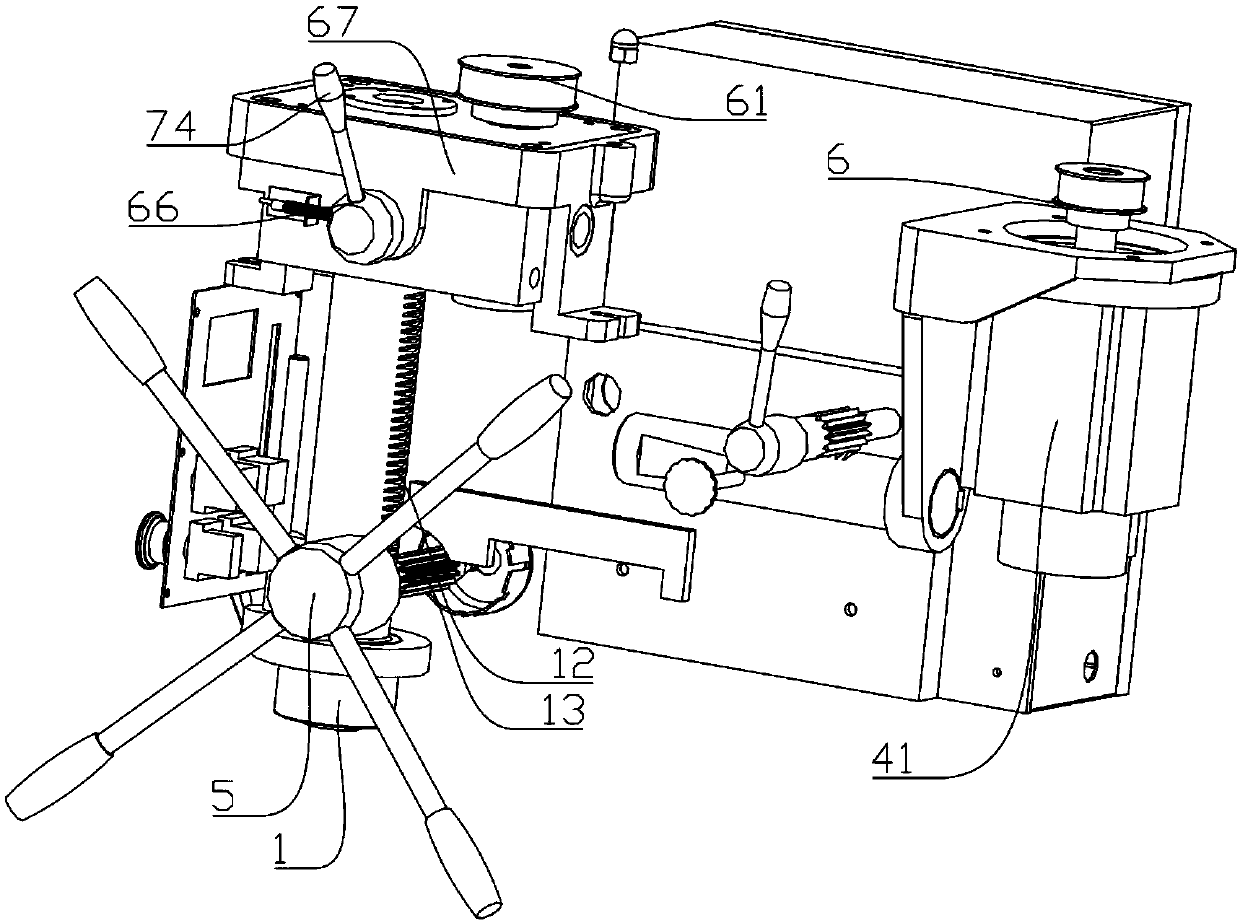

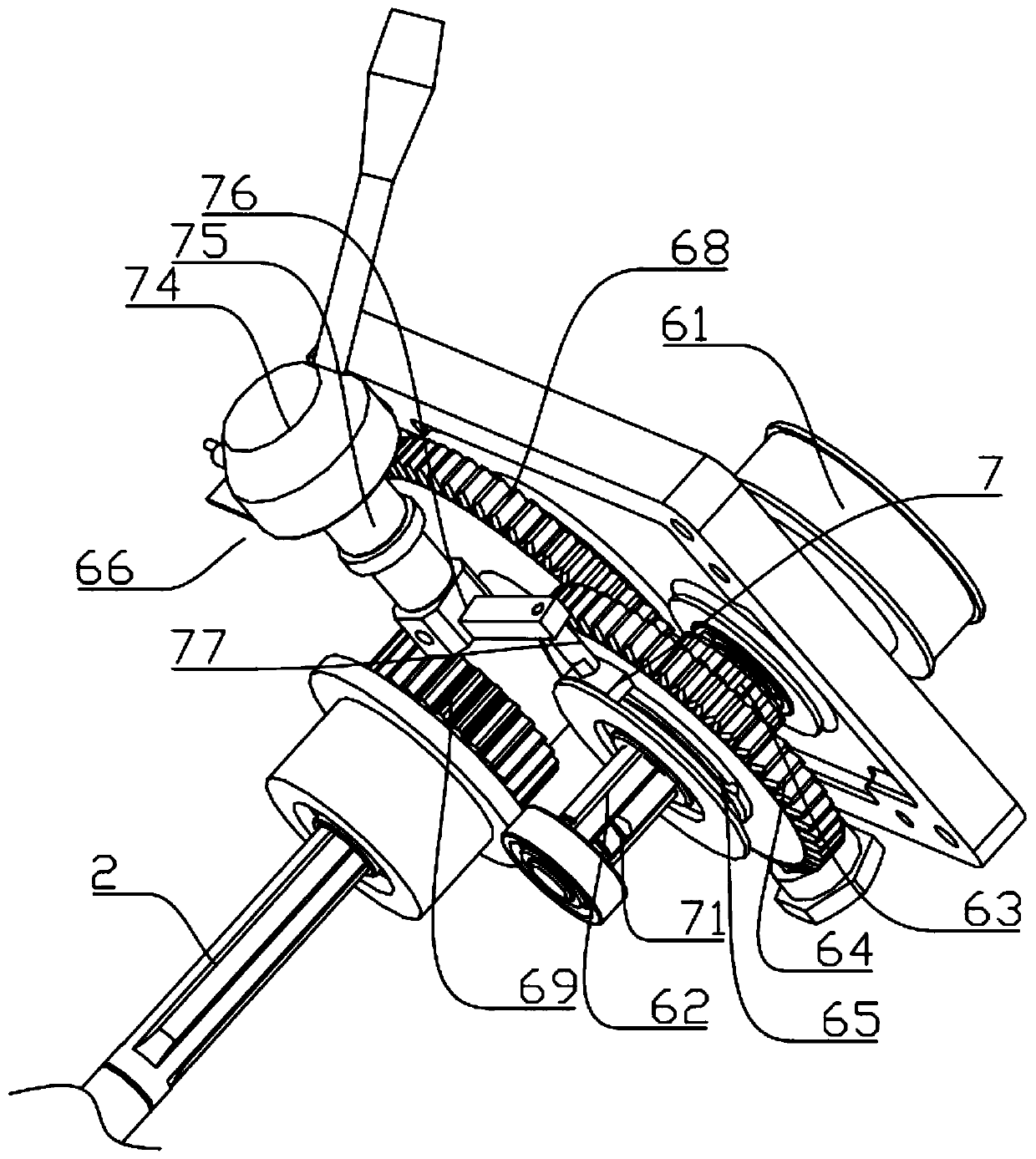

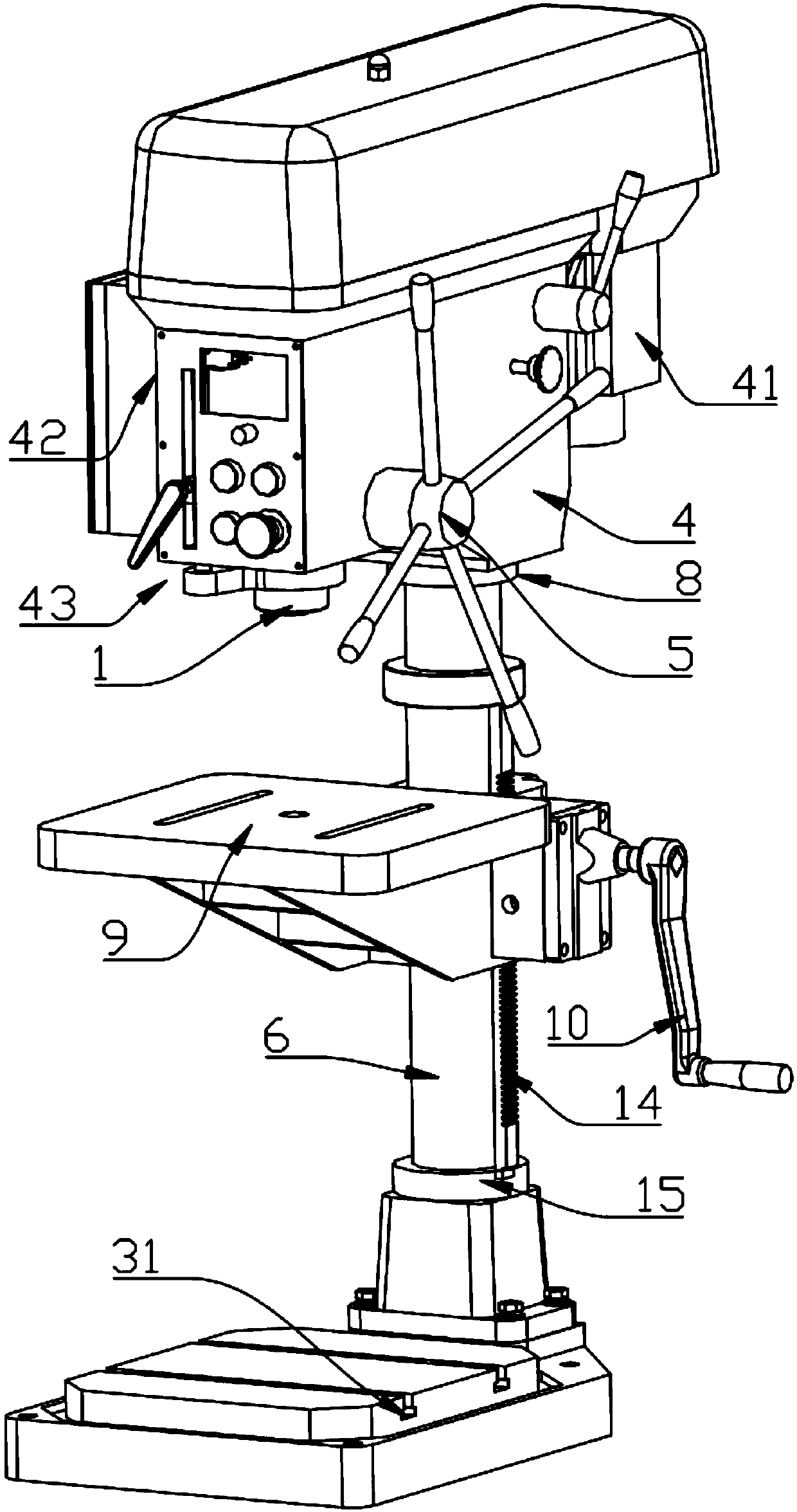

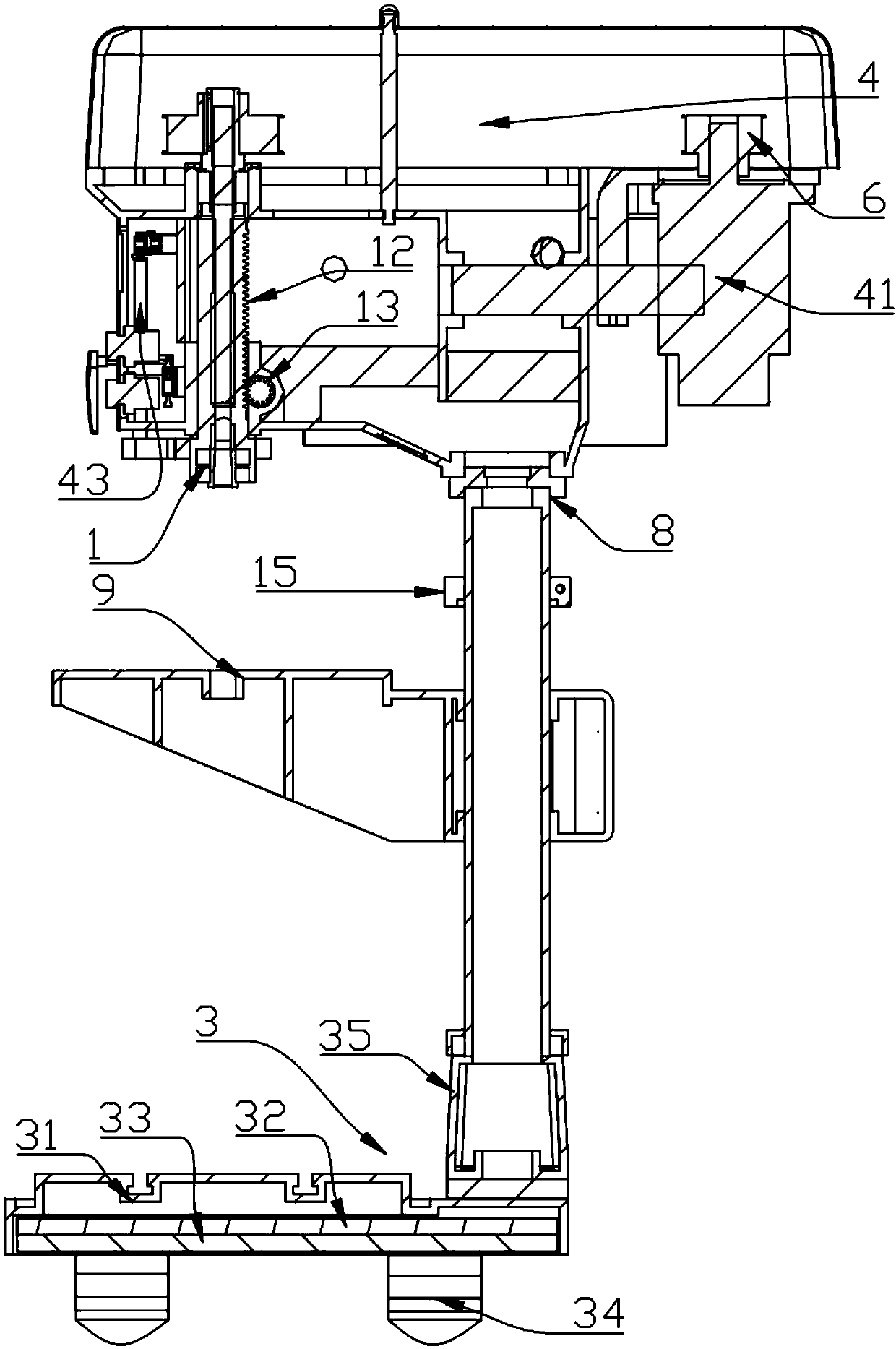

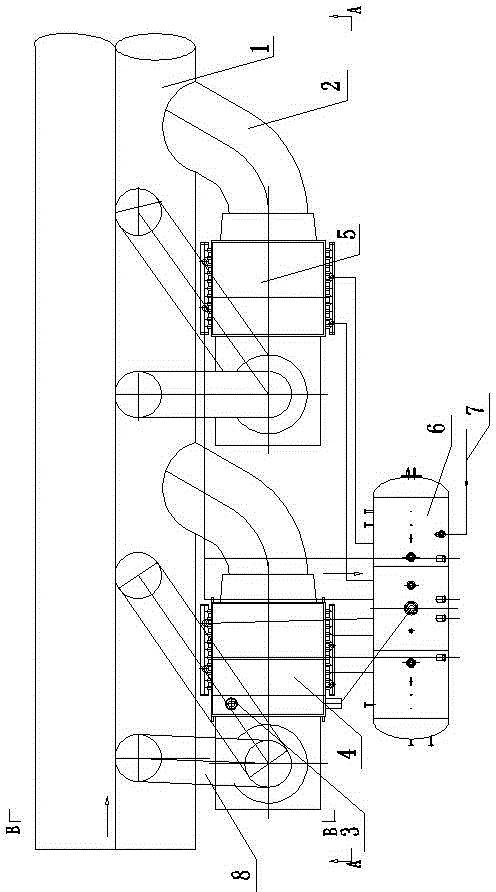

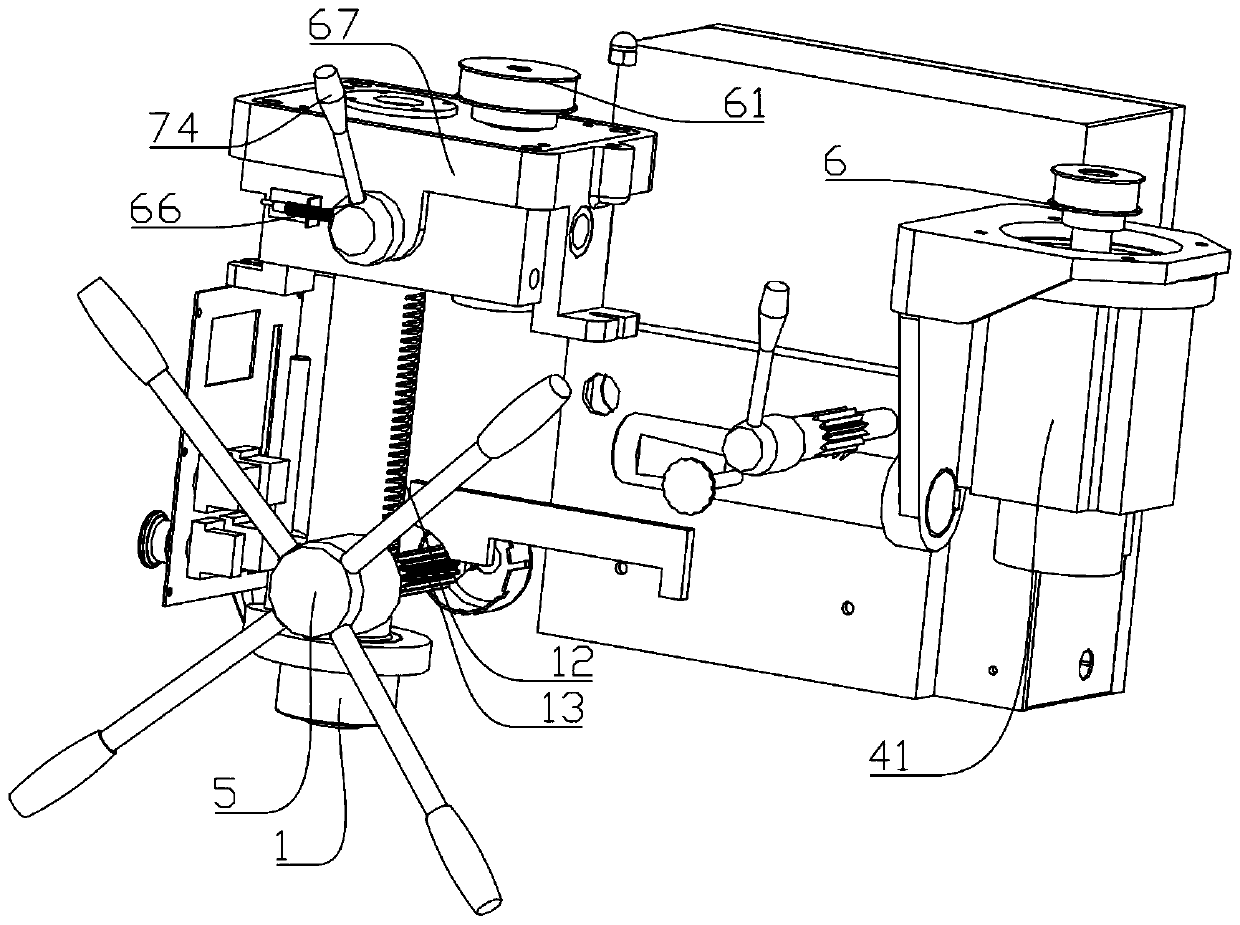

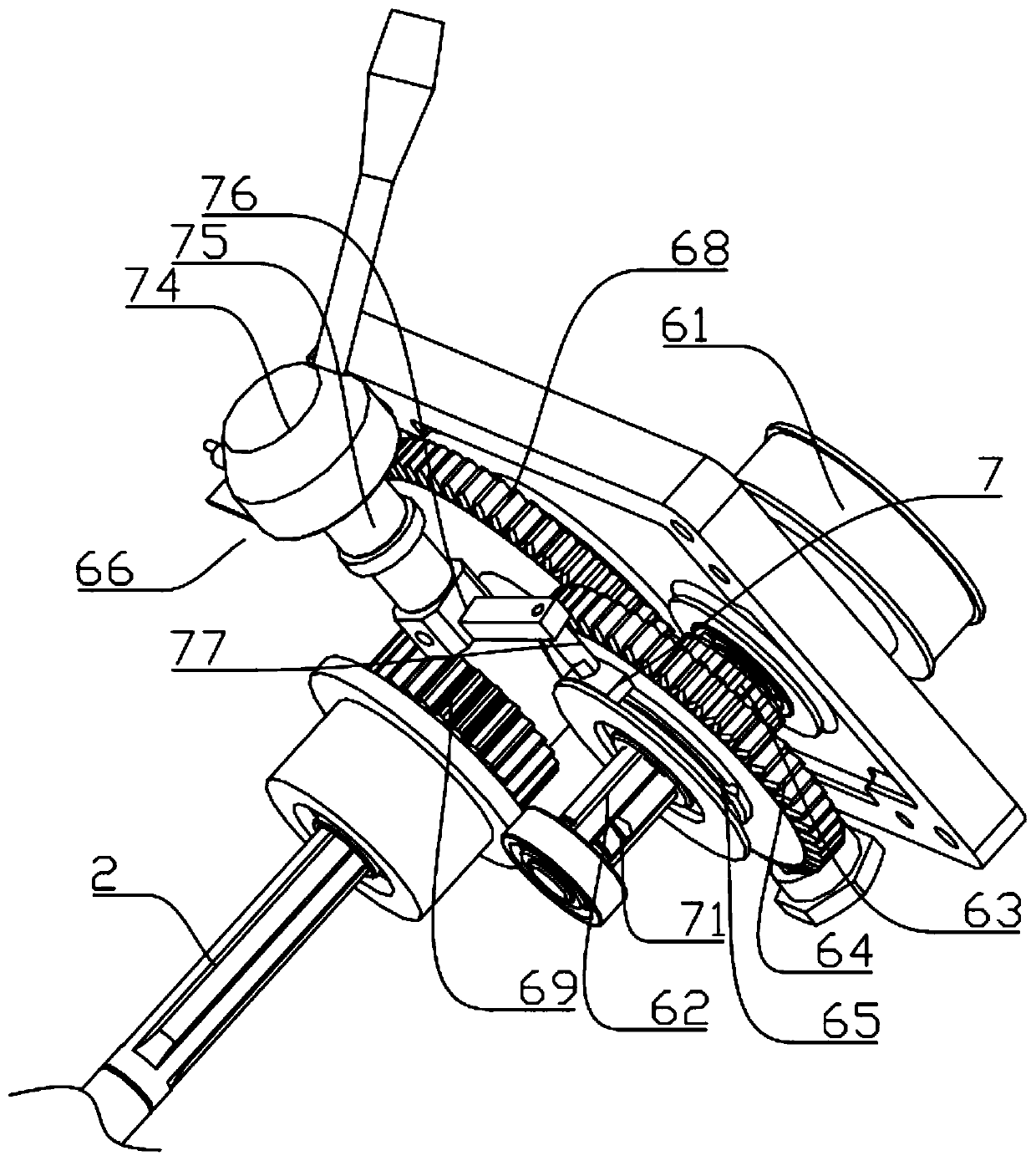

Novel drilling machine

ActiveCN109604666AEasy to operateImprove processing efficiencyDriving apparatusBoring/drilling componentsRocker armEngineering

The invention belongs to the technical field of machinery, and particularly relates to a novel drilling machine. The novel drilling machine comprises a base, a supporting rod, a working table and a machine head, the base is provided with the supporting rod, the supporting rod is provided with the working table in a sleeved mode, a rotary rocker arm is arranged on one side of the working table, themachine head is arranged at the upper end of the supporting rod in a penetrating mode, the machine head comprises a head frame, a rotary plate, a gear box and a motor, a first belt pulley is arrangedon an output shaft of the motor, one side of the first belt pulley is provided with a second belt pulley through a synchronous belt, the second belt pulley is internally provided with a rotary shaftin a penetrating mode, the rotary shaft is slidably provided with a first small gear and a first large gear from top to bottom in sequence, a stirring groove is formed in the lower part of the first large gear, andan adjusting device is mounted inside the stirring groove; the gear box is provided with a main shaft in a penetrating mode, the upper end of the main shaft is provided with a second large gear and a second small gear from top to bottom in sequence, when the adjusting device is anticlockwise rotated, the second large gear is engaged with the first small gear, when the adjusting device is clockwise rotated, the second small gear is engaged with the first large gear.

Owner:ZHEJIANG XILING

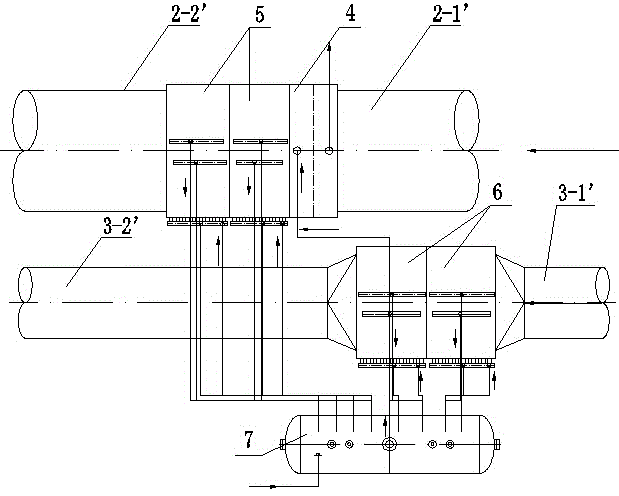

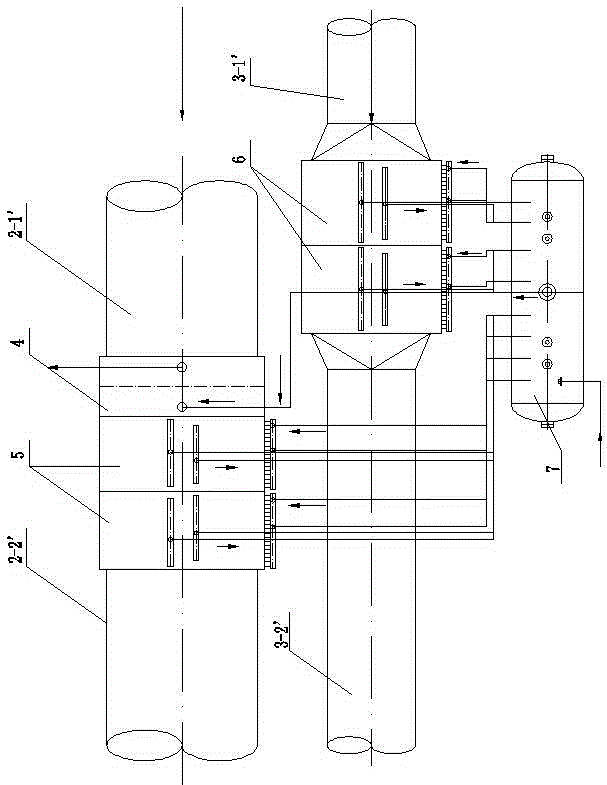

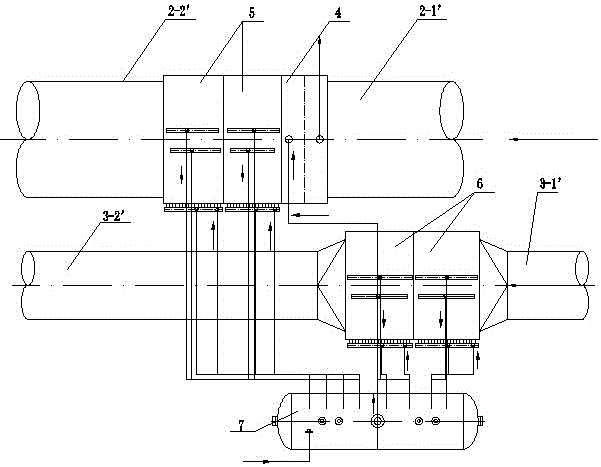

Water pipe heating pipe residual heat boiler system arranged in sintering machine flue

ActiveCN104832899AReasonable energyLess investment in equipmentIncreasing energy efficiencySteam generation using hot heat carriersFlueProcess engineering

The invention provides a water pipe heating pipe residual heat boiler system arranged in a sintering machine flue and relates to the technical field of steel smelting equipment. The water pipe heating pipe residual heat boiler system comprises a large flue and a small flue of a sintering machine, a large flue heat pipe type evaporator, a small flue heat pipe type evaporator, a large flue primary water pipe type evaporator, a large flue secondary water pipe type evaporator, a small large flue primary water pipe type evaporator, a small flue secondary water pipe type evaporator, a steam pocket and a water feeding system, wherein the large flue and the small flue are provided with a plurality of gas guide pipes respectively. According to the water pipe heating pipe residual heat boiler system, the water pipe type evaporators and the heat pipe type evaporators are divided into a plurality of heat exchange modules to be directly arranged on the large flue and the small flue of the sintering machine, so that the reasonable and effective gradient utilization of energy sources is realized; equipment investment is saved and an occupied area is small; respective advantages of the water pipe type evaporators and the heat pipe type evaporators are fully played in a use process; the flue gas residual heat is recycled to the greatest extent; meanwhile, the production of the sintering machine is not influenced and the water pipe heating pipe residual heat boiler system can be widely applied to the industry of a steel enterprise sintering machine.

Owner:江苏中天能源设备有限公司

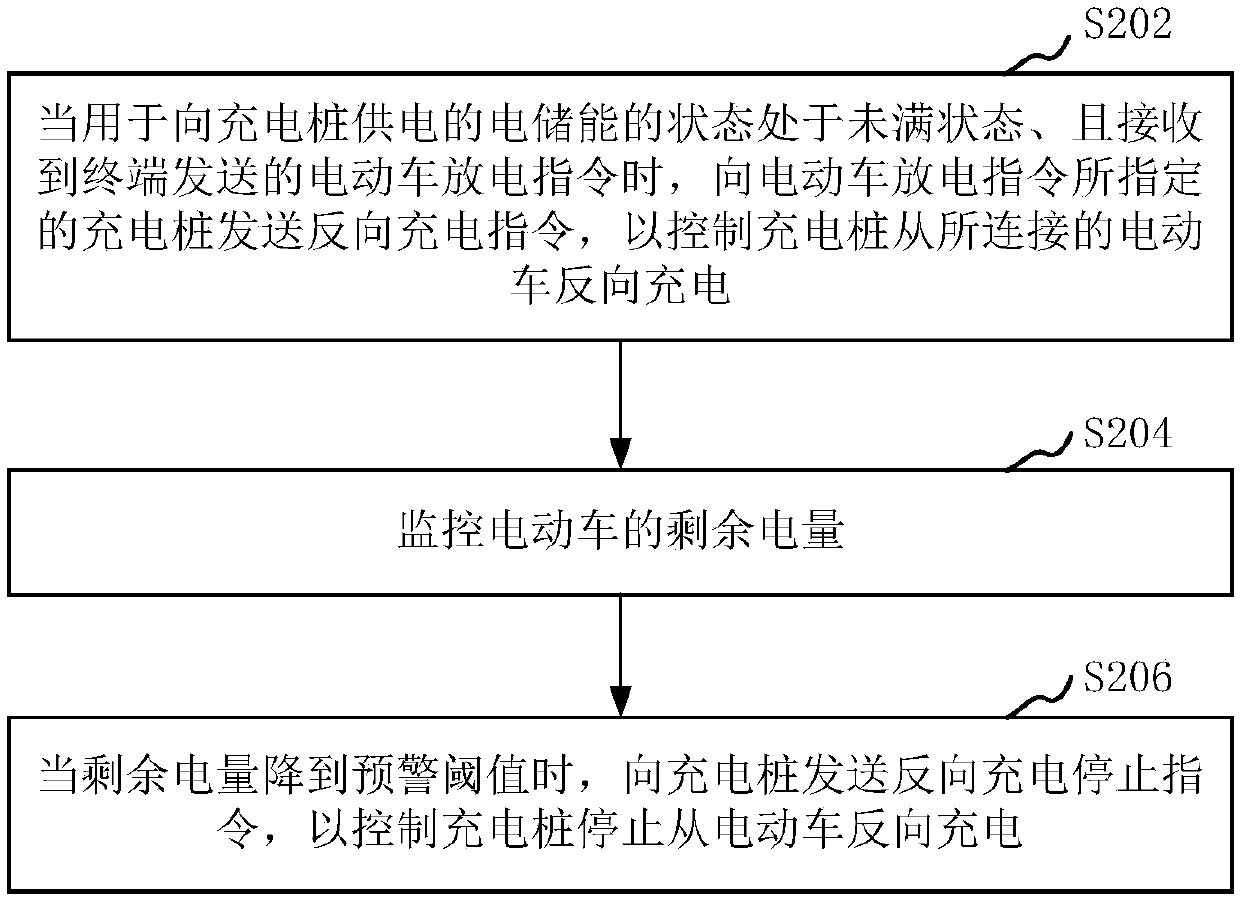

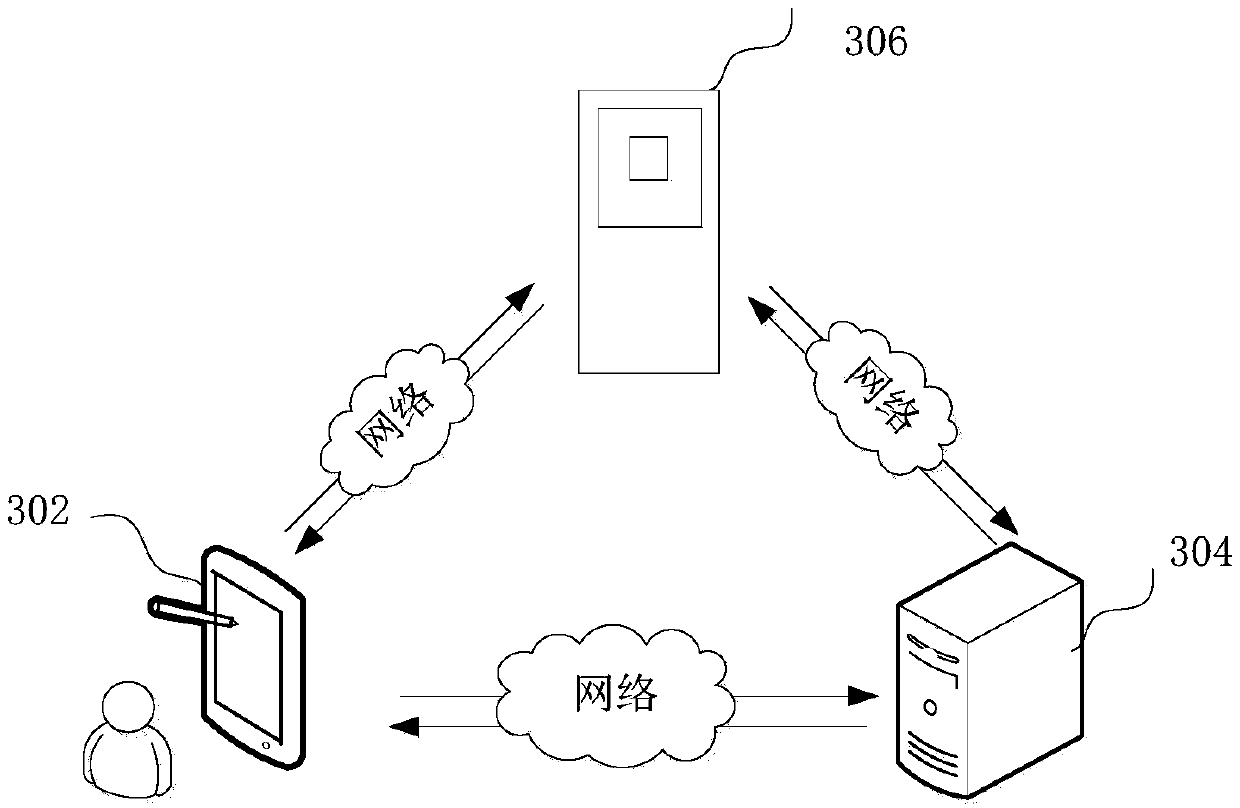

Power supply control method, device, computer equipment and storage medium

ActiveCN109606191AReasonable schedulingReasonable energyElectric powerElectric energyComputer equipment

The invention relates to a power supply control method, a device, computer equipment and a storage medium. The method comprises the following steps: when electric energy accumulator for supplying power to a charge post is at an unfull state, and an electronic vehicle discharge instruction transmitted from a terminal is received, transmitting a reverse charge instruction to a charge post appointedby the electronic vehicle discharge instruction to control that power is supplied to the charge post from a connected electronic vehicle reversely; monitoring residual power of the electronic vehicle;when the residual power is reduced to an early-warning threshold, transmitting a reverse charge stop instruction to the charge post to control the charge post to stop being reversely supplied by power from the electronic vehicle. Due to adoption of the method, power discharge of the electronic vehicle can be achieved, electric power can be scheduled reasonably, and the utilization rate of electric resources can be increased.

Owner:SHENZHEN POWER SUPPLY BUREAU +1

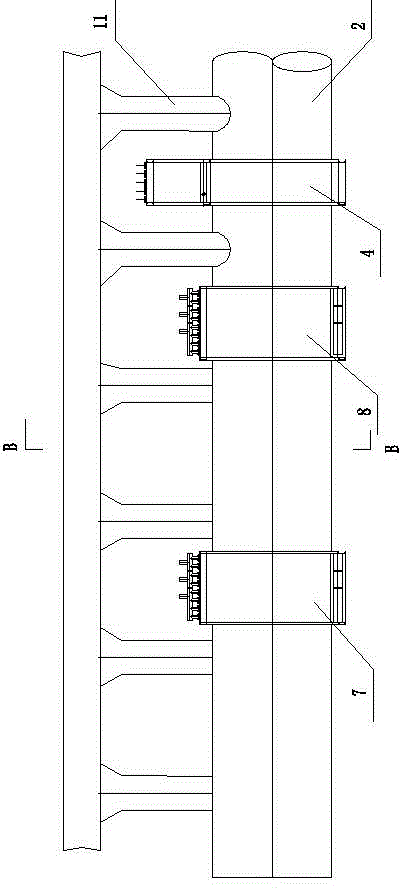

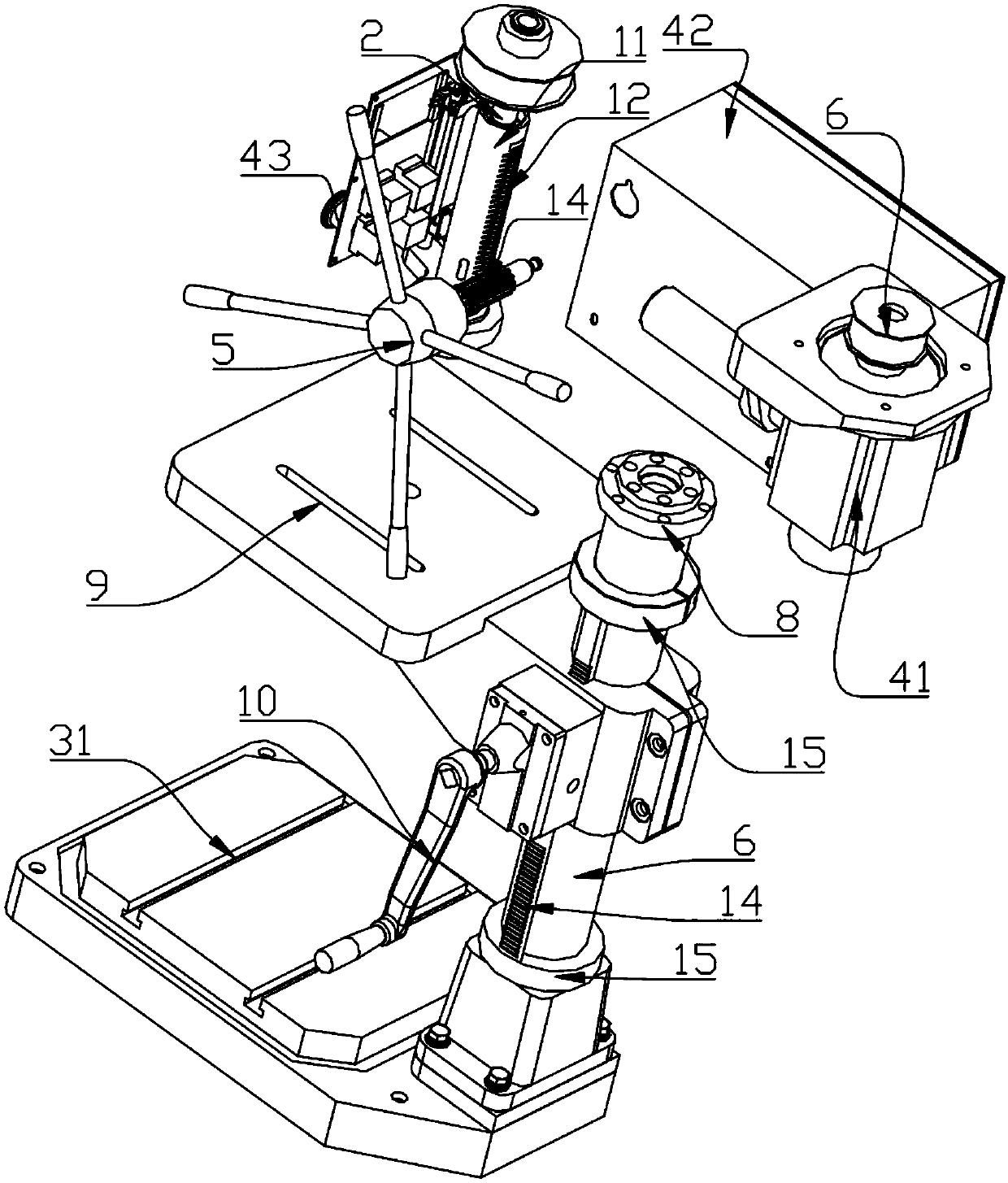

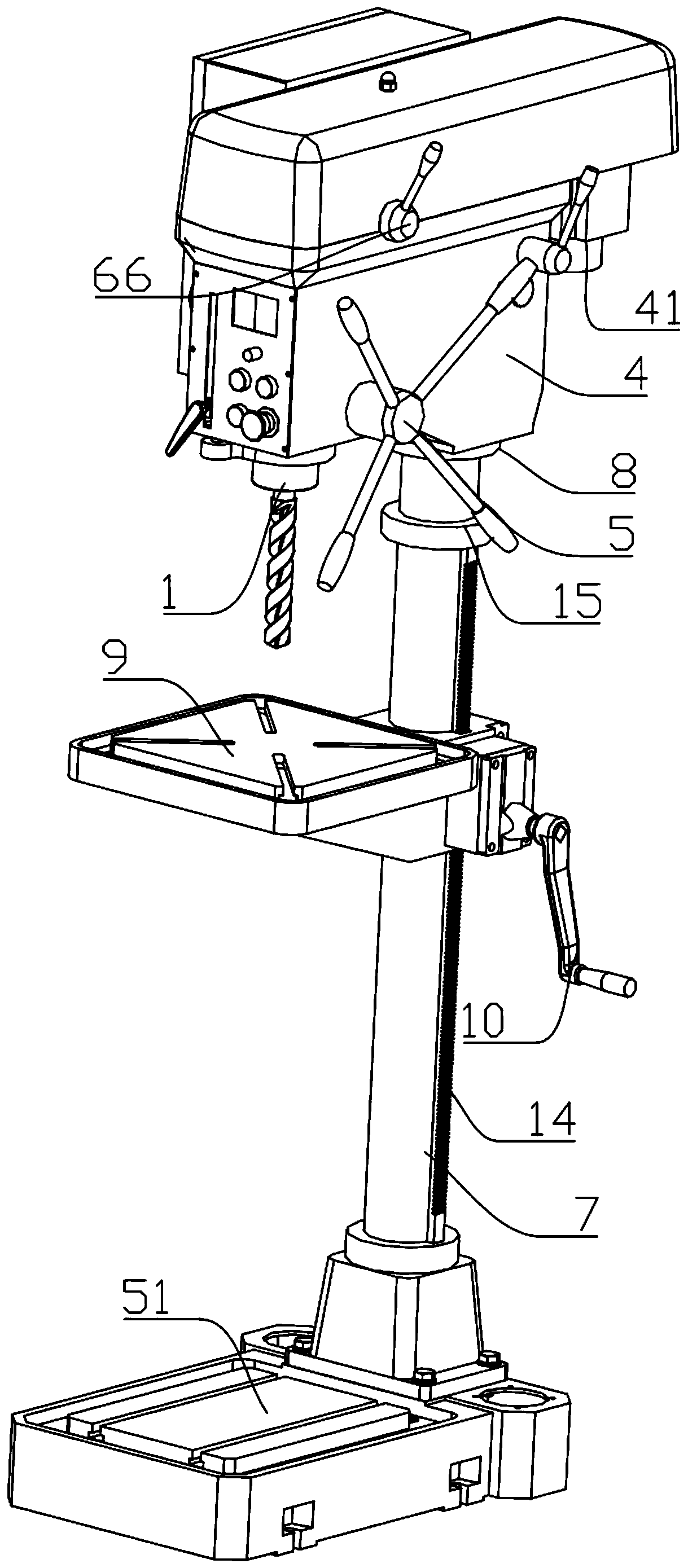

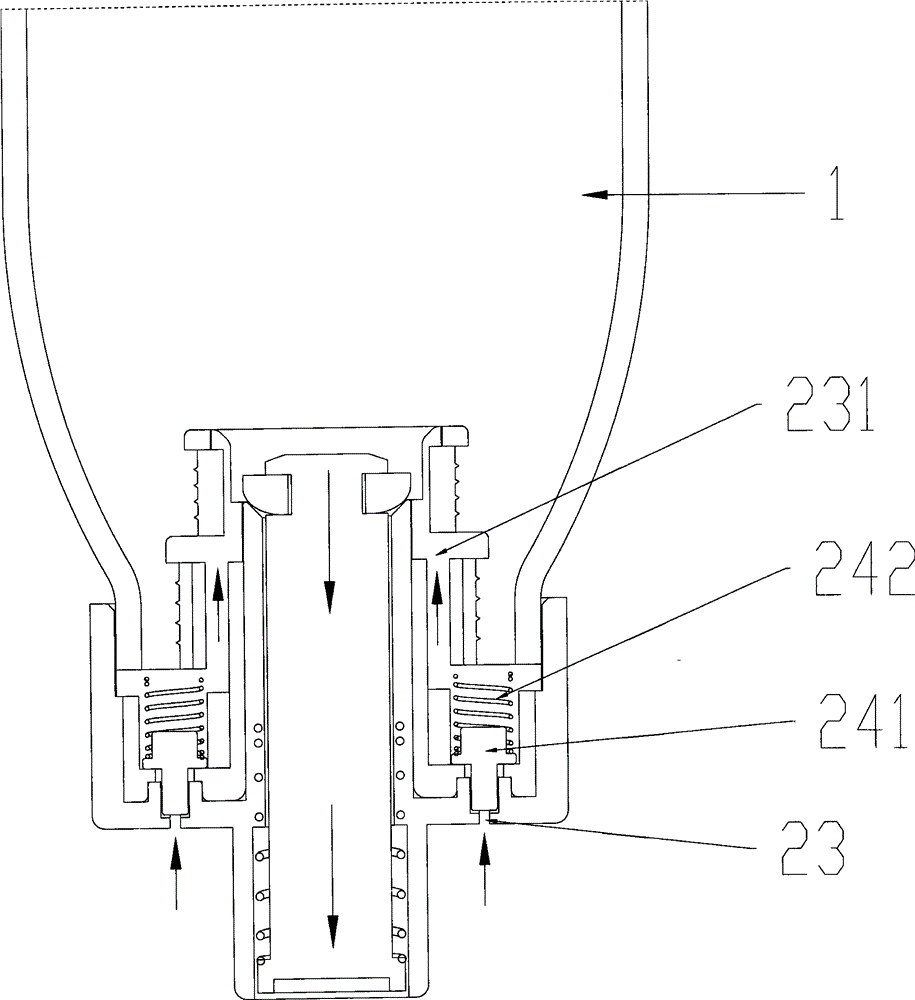

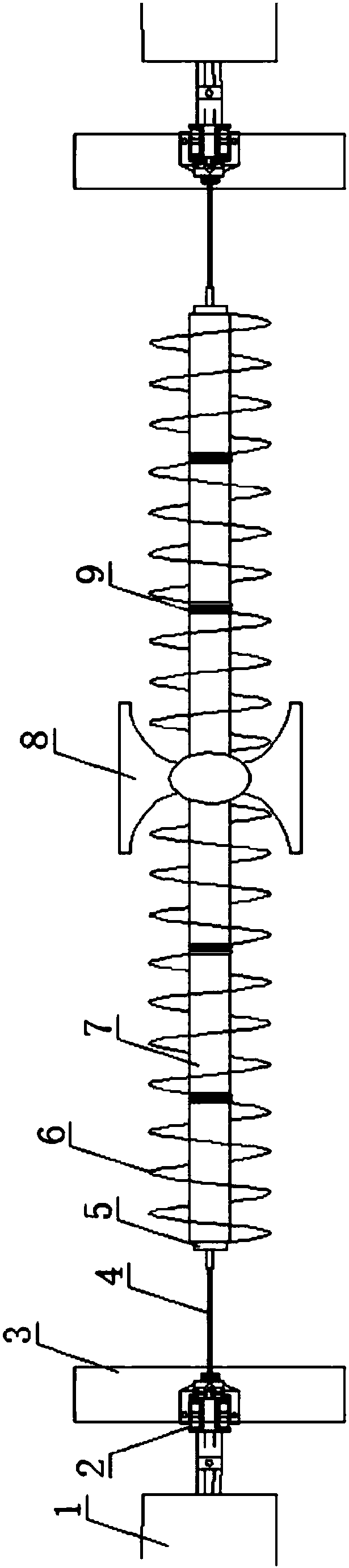

Drilling machine

InactiveCN109604664AOutstanding and Beneficial Technical EffectsEasy to operateBoring/drilling componentsMaintainance and safety accessoriesFrequency changerEngineering

The invention belongs to the technical field of machinery, in particular to a drilling machine. The drilling machine comprises a drill bit, a main shaft arranged above the drill bit and driving the drill bit to rotate, a head frame, a rotary disc rotatably arranged on one side of the head frame, a belt wheel arranged on the head frame, a base, a supporting column arranged on the base, a connectingflange sleeving on the supporting column, a working table and a rotary shaking arm, wherein the rotary shaking arm is arranged on one side of the working table and can control the working table to slide on the supporting column, and the rotary shaking arm is movably connected with the drilling machine working table; and a permanent magnet motor with a frequency changing function is arranged on one side of the head frame, an output shaft of the permanent magnet motor is connected with the belt wheel, a frequency changer is arranged on one side of the permanent magnet motor and connected with the permanent magnet motor through a wire, the frequency changer is mounted on the head frame, and a plurality of control devices used for adjusting speed and starting and stopping are arranged on thefrequency changer. The drilling machine has stable structure, stepless speed adjustment and long service life.

Owner:ZHEJIANG XILING

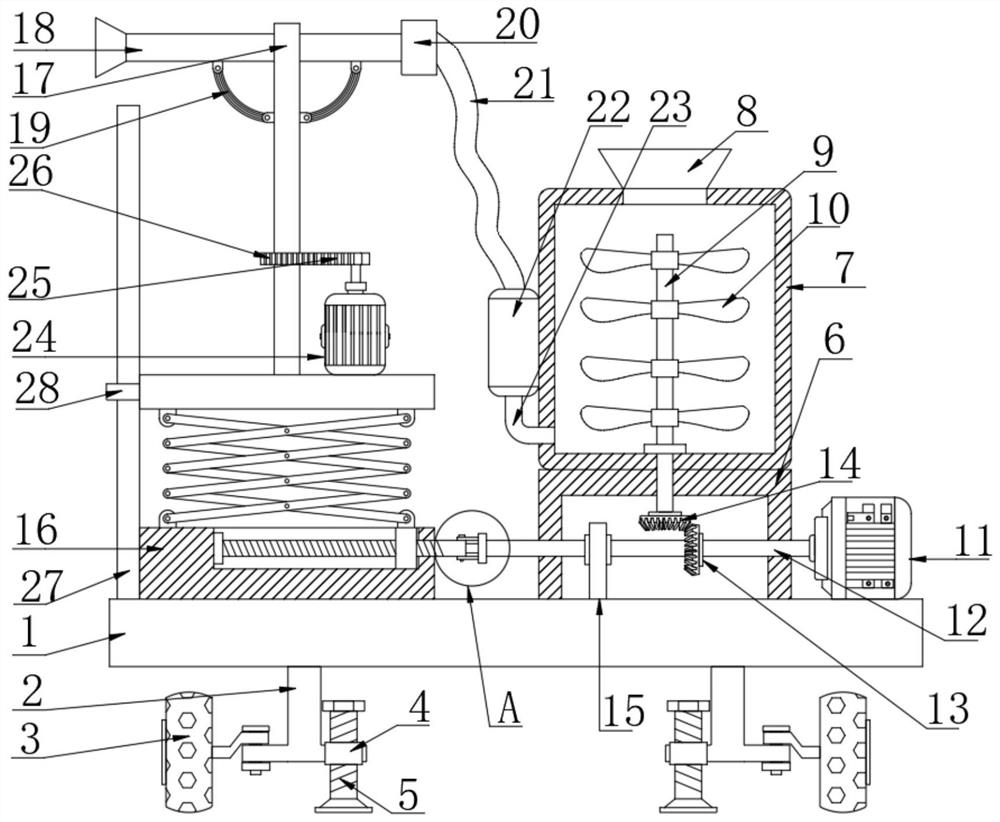

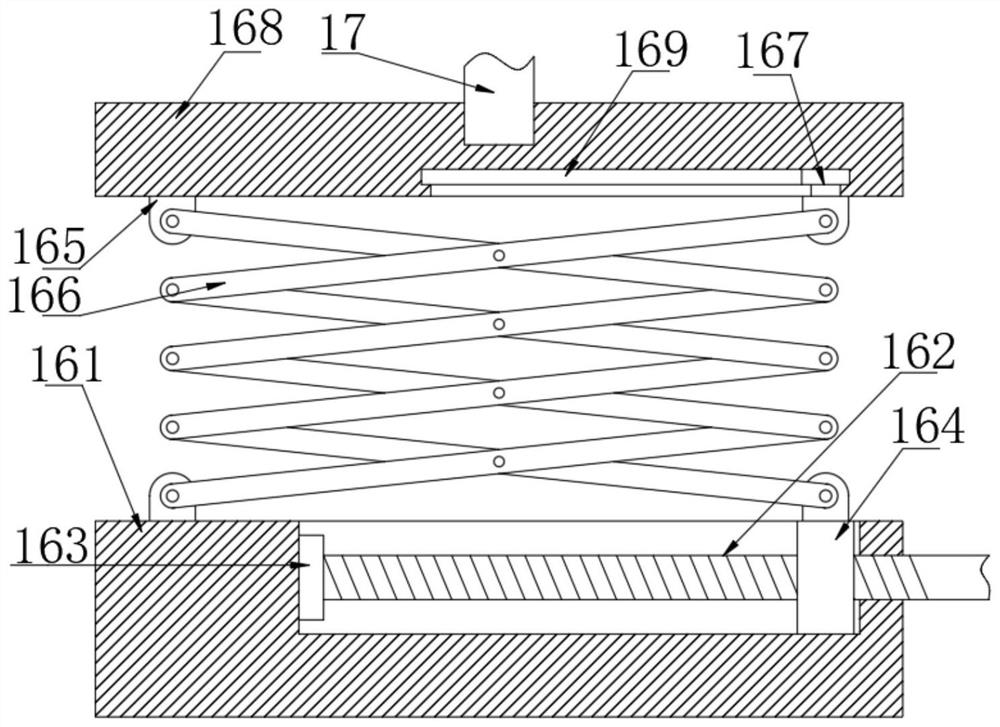

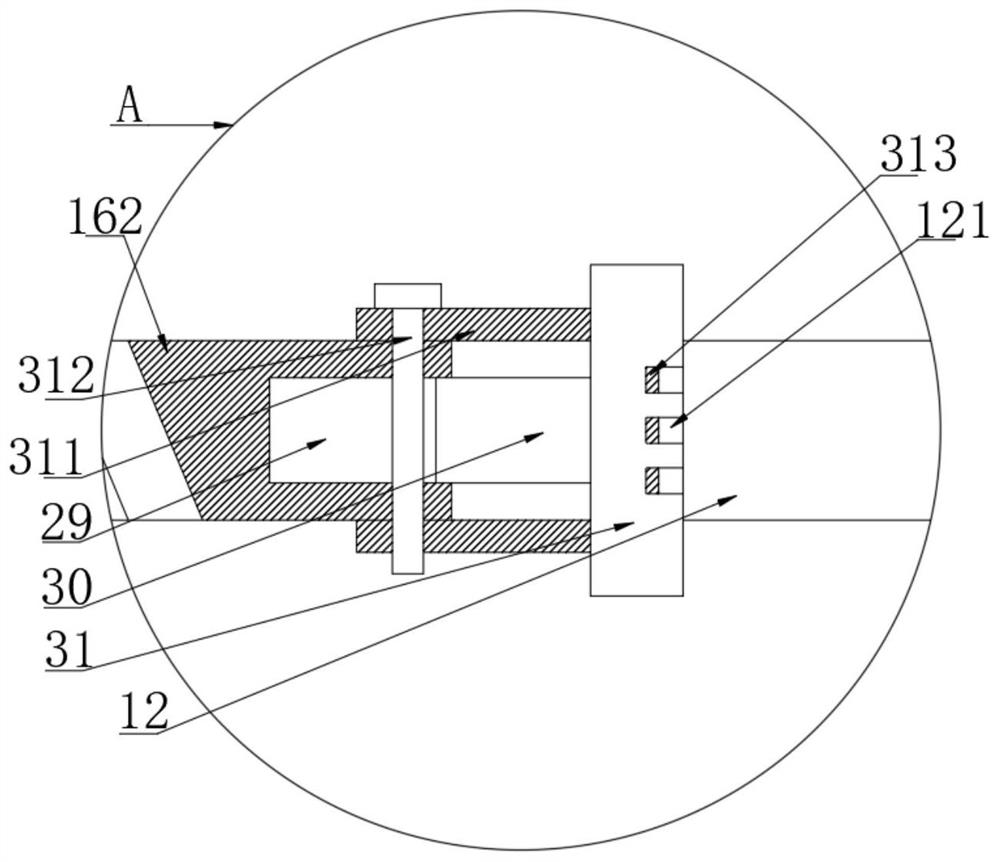

Paint spraying equipment and method used in crane production process

The invention discloses paint spraying equipment used in a crane production process, and belongs to the technical field of crane paint spraying equipment. The paint spraying equipment comprises a bottom plate, wherein the right side of the top end of the bottom plate is fixedly connected to a supporting frame; the top end of the supporting frame is fixedly connected to a mixing box; the bottom endof the mixing box is connected to a driving mechanism; the left side of the driving mechanism is connected to a lifting mechanism through a connecting piece; the lifting mechanism is arranged at theleft side of the top end of the bottom plate; the top end of the lifting mechanism is connected to a vertical rod; the top end of the vertical rod is transversely connected to a spraying gun; the right side of the spraying gun is connected to a booster pump; the right side of the booster pump is connected to a material guide pipe; the other end of the material guide pipe is connected to a liquid pump; the liquid pump is fixedly arranged at the left side of the mixing box; the bottom end of the liquid pump is connected to a material pumping pipe; and the other end of the material pumping pipe penetrates through the bottom end of the left side of the mixing box and is provided with a half gear and a gear, so that the vertical rod can rotate, areas on the two sides of a spraying area can be sprayed, and the spraying efficiency is improved.

Owner:SHANDONG LONGHUI HOISTING MACHINERY

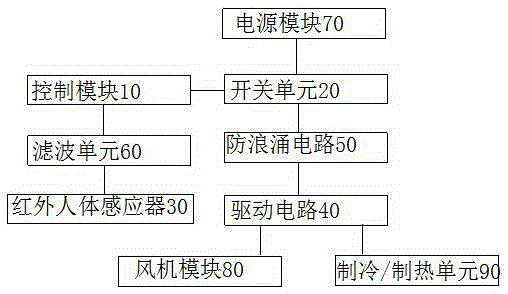

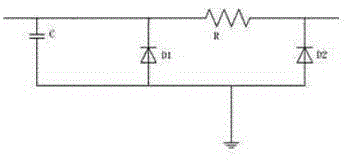

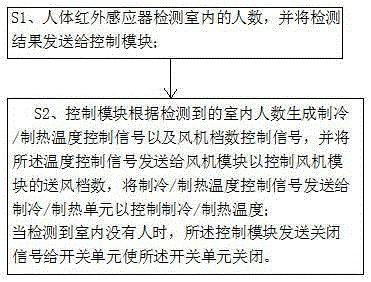

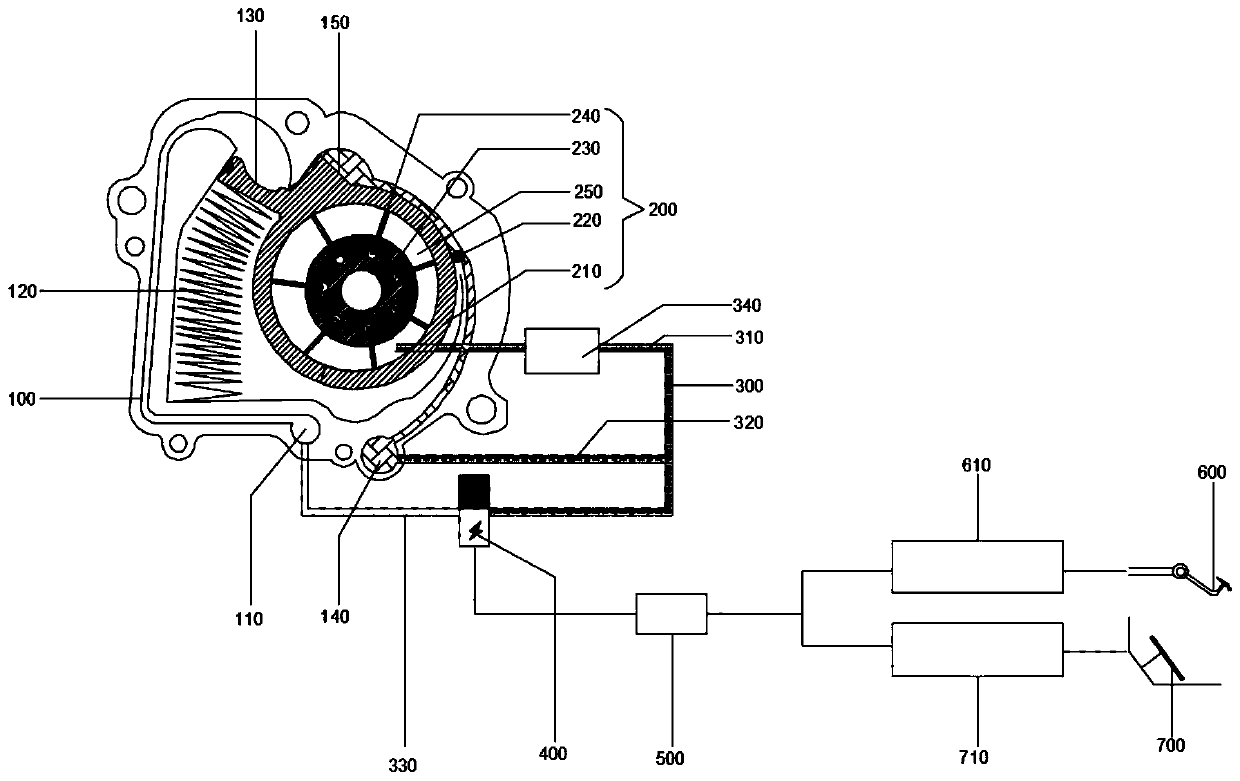

Infrared human body sensing intelligent air-conditioner and control method thereof

InactiveCN105402865AImprove experienceConducive to saving electricityMechanical apparatusSpace heating and ventilation safety systemsRefrigerationHeating temperature

The invention provides an infrared human body sensing intelligent air-conditioner and a control method thereof. The infrared human body sensing intelligent air-conditioner comprises a power module, a human body infrared sensor, a filtering unit, a control module, a switching unit, a driving circuit, a draught fan module and a refrigeration / heating unit; the human body infrared sensor is used for detecting the number of people in a detecting chamber, and the filtering unit is used for filtering out noise jamming; when the human body infrared sensor senses that no people exists in the chamber, the control module transmits a closing signal to the switching unit to close the switching unit; and the control module is further used for controlling the air feeding gear number of the draught fan module and the refrigeration / heating temperature of the refrigeration / heating unit according to the number of people detected by the human body infrared sensor. The infrared human body sensing intelligent air-conditioner and the control method have the beneficial effects that the power energy is saved, and the user experience is improved.

Owner:HUIZHOU UNIV

Milch cow feed capable of improving milk quality and preparation method and application thereof

ActiveCN102113628BAddressing chronic rumen acidosisFully absorbedFood processingAnimal feeding stuffRumenTrace Minerals

The invention relates to a milch cow feed and a preparation method and application thereof, in particular to a functional milch cow feed capable of improving the nutrition of milch cow and enhancing the milk quality and a preparation method and application of the feed. The milch cow feed is prepared from the following components in a special proportion: rumen-protected lysine, rumen-protected methionine, rumen-protected dextrose, active dry yeast, trace mineral vitamin premix and bean pulp. The milch cow feed provided by the invention is fed to milch cows to supplement the energy and nutritional inadequacy of the milch cow on a basis of original concentrated supplementation feed so as to achieve the effects of improving milk yield and milk quality.

Owner:INNER MONGOLIA YOURAN ANIMAL HUSBANDRY CO LTD

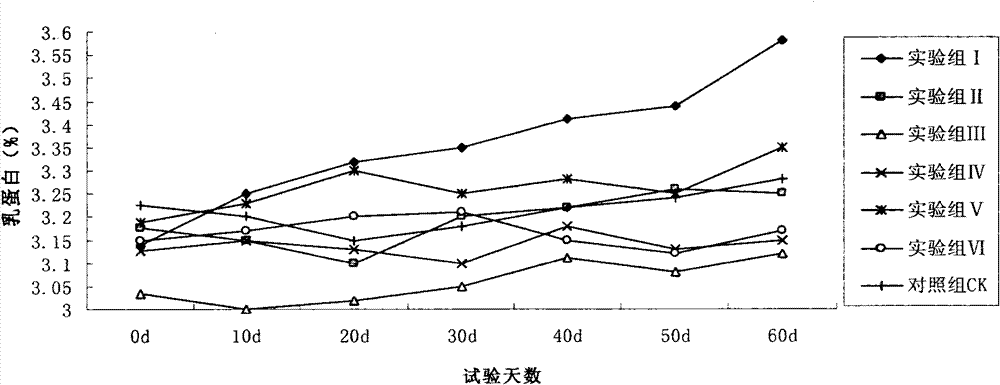

Enterprise energy consumption monitoring system

InactiveCN103900633AReasonable useReasonable energyElectrical measurementsAutomotive engineeringElectric energy

The invention discloses an enterprise energy consumption monitoring system for monitoring enterprise electric energy consumption. The enterprise energy consumption monitoring system comprises at least one electric energy meter for monitoring the electric energy consumption, a data acquisition module for acquiring data measured by the electric energy meter, and a monitoring system for monitoring the data acquisition module. Compared with the prior art, the enterprise energy consumption monitoring system of the invention can be used to acquire accurate electric energy consumption parameters so as to provide a basis for enterprise decisions to make an enterprise capable of utilizing the electric energy more reasonably and reducing the unnecessary spending.

Owner:SUZHOU IND PRAK NEW HONGBO COMM TECH

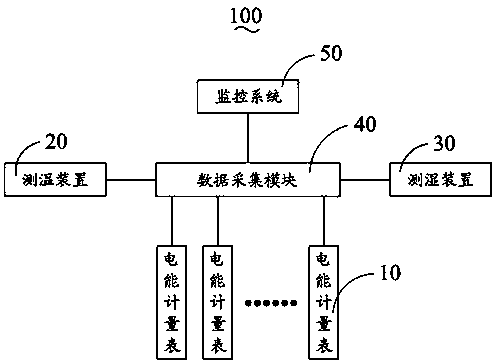

Feeding method of raw material pellets for smelting fused magnesite

The invention provides a feeding method of raw material pellets for smelting fused magnesite. The method comprises the following steps: (1) carrying out crushing and floatation impurity removal on magnesite to prepare pellets, wherein the pellets are divided into large pellets and small pellets; and the large pellets are greater than the small pellets in particle size; (2) at a smelting starting stage, smelting by using the large pellets; (3) at a stable smelting stage, smelting by using the large pellets and the small pellets simultaneously, wherein the mass ratio of the large pellets to the small pellets is (3:7) to (6:4); and (4) at a smelting shutdown stage, smelting by using the small pellets. The invention discloses the particle sizes of the pellets in smelting of the fused magnesite and the particle size ratio of the pellets at all stages; therefore, economical operation of a high-power rotary smelting furnace is ensured and the overall quality of the fused magnesite product is improved.

Owner:NORTHEASTERN UNIV +1

Heat tube type waste heat boiler system externally arranged beside large flue of sintering machine

InactiveCN106287626AReasonable energyLess investment in equipmentEnergy industryIncreasing energy efficiencySuperheaterEvaporator

The invention relates to the technical field of steel smelting equipment, in particular to a heat tube type waste heat boiler system externally arranged beside a large flue of a sintering machine. The heat tube type waste heat boiler system externally arranged beside the large flue of the sintering machine comprises the large flue of the sintering machine, bypass flues, steam superheaters, a primary heat tube type evaporator, a secondary heat tube type evaporator, a steam pocket and a water feeding system. A plurality of steam guide tubes are arranged on the large flue. According to the heat tube type waste heat boiler system externally arranged beside the large flue of the sintering machine, because the heat tube type waste heat boiler is directly arranged beside the large flue of the sintering machine, an existing site of the sintering machine is fully utilized to recycle waste heat resources of the sintering machine, reasonable, effective and gradient utilization of energy is achieved, the equipment investment is small, and the occupied area is small; and generated superheated steam is used for power generation, and remarkable economic and social benefits are achieved. Meanwhile, the heat tube type waste heat boiler system externally arranged beside the large flue of the sintering machine cannot influence production of the sintering machine and can be widely applied to the industry of sintering machines of steel enterprises.

Owner:江苏中天能源设备有限公司

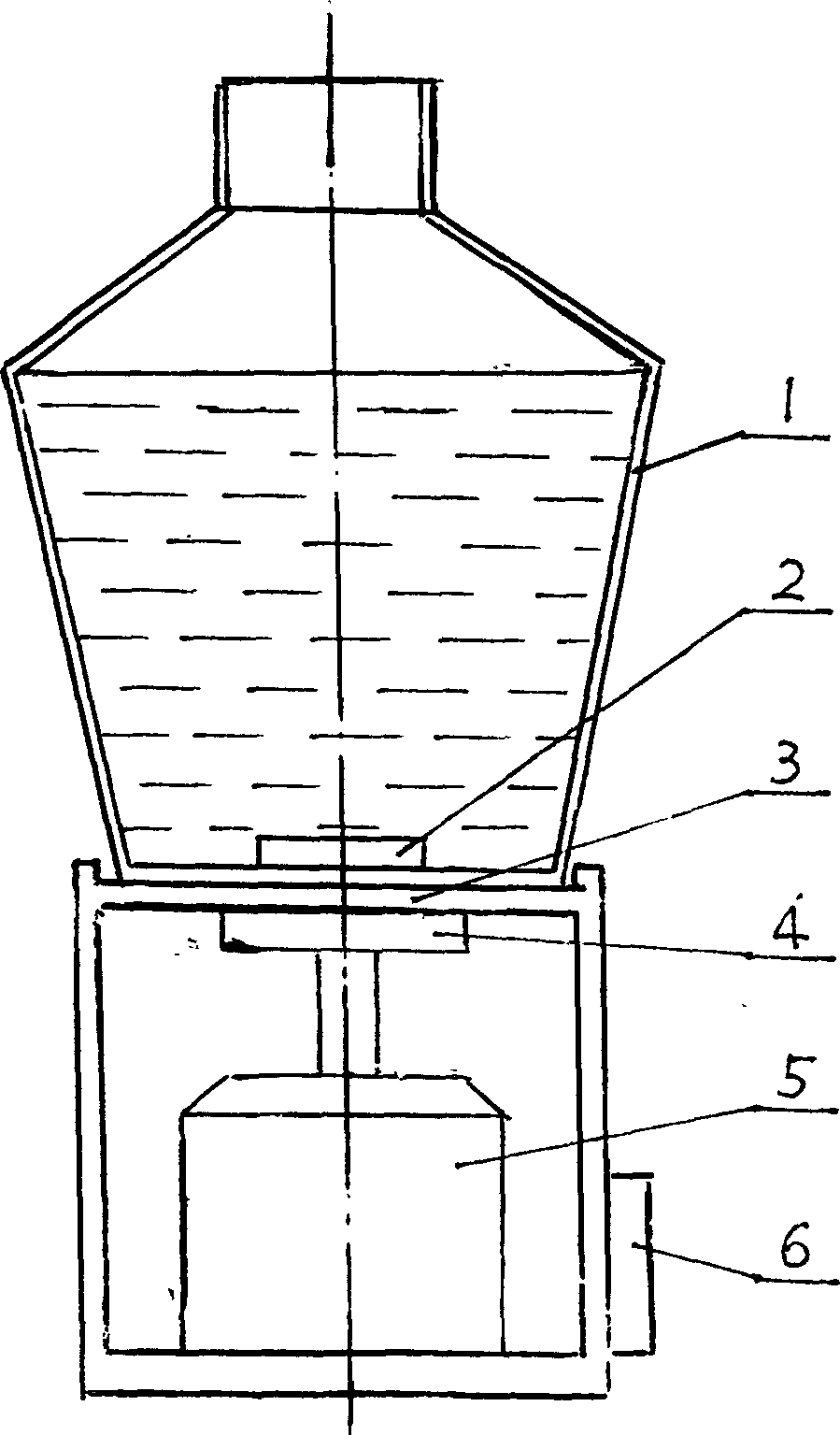

Equipment for breeding seed monadian algae

The invention relates to a reproducing of an animalcule especially single-cell algae seed algae. The feature is that the reproducing device includes a hyaline reproducing bottle that is non-magnetism vessel and a magnetism whisking stick is put on the bottom of the inner cavity, and the bottle is put on the flat of non-magnetism support, electromotor is fixed under the support, the output of the electromotor is connected to magnetism rotating disc, and the upper flat connecting to the back of the upper flat of the support without support.

Owner:孙建明

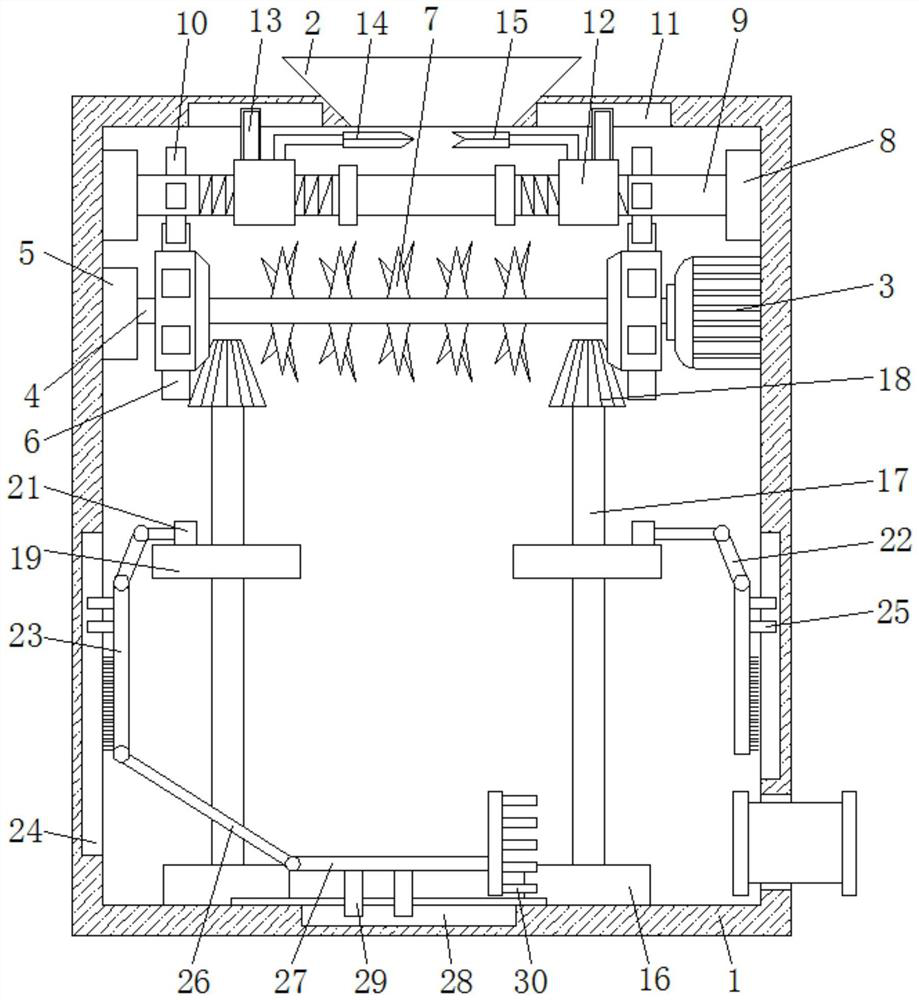

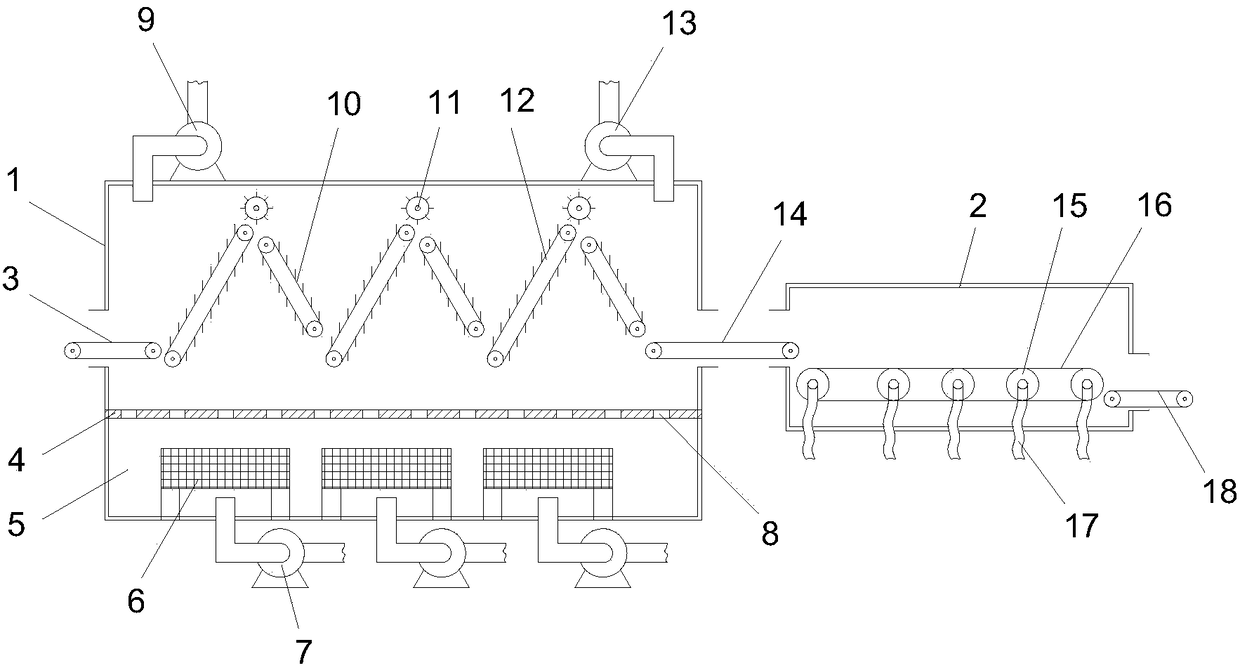

Cotton fiber drying and cooling system

The invention discloses a cotton fiber drying and cooling system which comprises a drying box body and a cooling box body, wherein the drying box body is internally provided with a transverse clapboard; the transverse clapboard divides the interior of the drying box body into a drying chamber at the upper end and a heating chamber at the lower end; multiple vent holes are uniformly distributed in the transverse clapboard; the side walls of two ends of the drying chamber are respectively provided with an inlet and an outlet which are corresponding to each other; the inlet end of the drying chamber is provided with an inlet cotton conveying curtain, and the outlet end of the drying chamber is provided with a middle conveying curtain; the drying chamber is internally provided with multiple groups of oblique upward conveying curtains and oblique downward conveying curtains, which are matched with each other; the oblique upward conveying curtains and the oblique downward conveying curtains constitute inverted V-shaped drying channels; the inner wall, positioned at the tops of the oblique upward conveying curtain and oblique downward conveying curtain in each group, of the drying box body is rotatably provided with a stripping roller; the other end of the middle conveying curtain extends into the inlet end of the cooling box body. The cotton fiber drying and cooling system is simple in structure, uniform and full in drying, small in equipment size, improved in drying stroke and high in cooling efficiency.

Owner:GUANGDE TIANYUN NEW TECH

a drill press

ActiveCN109604666BEasy to operateReduce volumeDriving apparatusBoring/drilling componentsHeadframeGear wheel

The invention belongs to the technical field of machinery, and particularly relates to a novel drilling machine. The novel drilling machine comprises a base, a supporting rod, a working table and a machine head, the base is provided with the supporting rod, the supporting rod is provided with the working table in a sleeved mode, a rotary rocker arm is arranged on one side of the working table, themachine head is arranged at the upper end of the supporting rod in a penetrating mode, the machine head comprises a head frame, a rotary plate, a gear box and a motor, a first belt pulley is arrangedon an output shaft of the motor, one side of the first belt pulley is provided with a second belt pulley through a synchronous belt, the second belt pulley is internally provided with a rotary shaftin a penetrating mode, the rotary shaft is slidably provided with a first small gear and a first large gear from top to bottom in sequence, a stirring groove is formed in the lower part of the first large gear, andan adjusting device is mounted inside the stirring groove; the gear box is provided with a main shaft in a penetrating mode, the upper end of the main shaft is provided with a second large gear and a second small gear from top to bottom in sequence, when the adjusting device is anticlockwise rotated, the second large gear is engaged with the first small gear, when the adjusting device is clockwise rotated, the second small gear is engaged with the first large gear.

Owner:ZHEJIANG XILING

A straw crushing device that saves energy and improves work efficiency

The invention relates to the technical field of straw crushing, and discloses a straw crushing device that is convenient for saving energy and improving work efficiency, including a body, the top of the body is fixedly connected with a feeding hopper, and the inner wall on the right side of the body is fixed A drive motor is connected, the output end on the left side of the drive motor is fixedly connected with a rotating shaft, the inner wall on the left side of the body is fixedly connected with a mounting bearing seat, and the left end of the rotating shaft is fixedly connected to the inner surface of the right side of the mounting bearing seat superior. The straw crushing device, which is convenient for saving energy and improving work efficiency, crushes the straw by setting the driving motor, installing the bearing seat and the crushing rod, and then setting the transmission gear, the traction tooth block, the positioning bearing seat, The threaded rod, the limiting rod, the shearing knife plate and the shearing groove plate play the role of using the power source of the crushing structure to shear the straw, so as to achieve the effect of saving energy and improving efficiency.

Owner:广西梧州伟创植物纤维科技有限公司

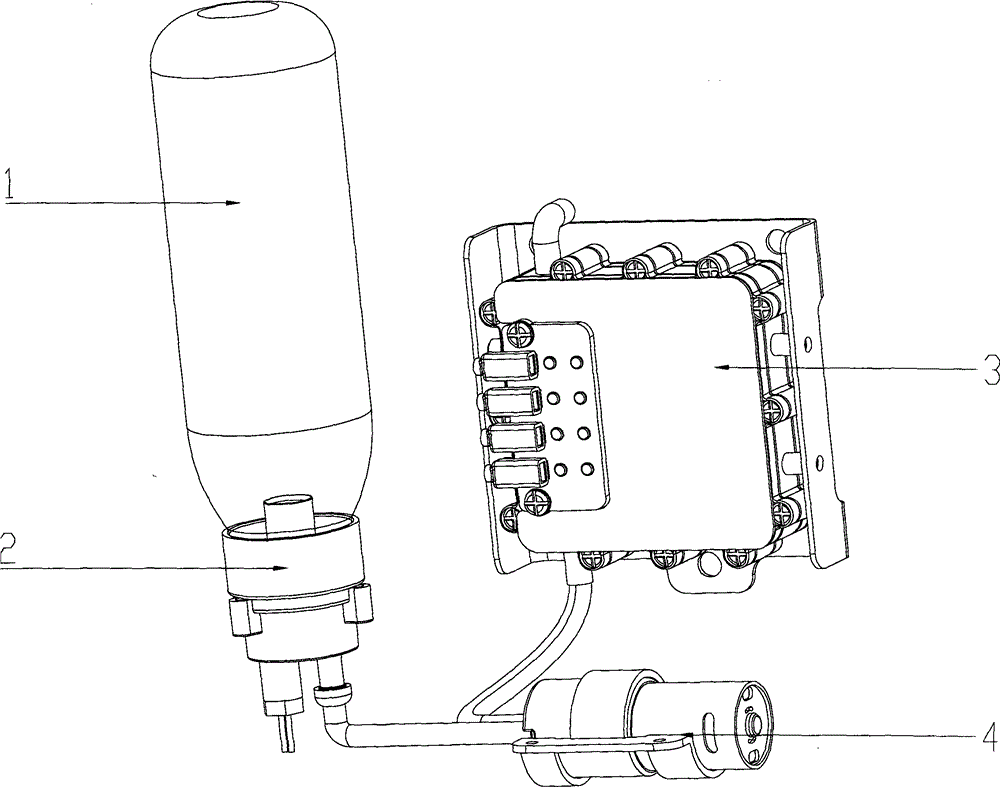

Novel instant-heating type drinking water dispenser

The invention relates to a novel instant-heating type drinking water dispenser. The novel instant-heating type drinking water dispenser comprises a dispenser body and a raw water container, wherein a water feeding valve is arranged between the dispenser body and the raw water container; a water pump and a heating tube are arranged in the dispenser body; the water pump is correspondingly connected with the water feeding valve and the heating tube; a through hole is formed in the center of the water feeding valve, and two ends of the water feeding valve are correspondingly connected with the raw water container and the water pump; an air inlet which is communicated with the outside is formed in the side surface of the water feeding valve; the air inlet is connected with the raw water container, and an elastic stopping part is arranged in the water inlet; the elastic stopping part in an air feeding channel can be deformed in the working process, and the air feeding channel can be opened when the elastic stopping part is deformed, so that air can enter the raw water container, and the raw water container can be prevented from entering a vacuum state. According to the novel instant-heating type drinking water dispenser, the water feeding valve is arranged to replace a water storing container in the existing technology, so that drinking water can directly enter the heating tube, and as a result, the sanitation and the safety can be improved; in addition, people can drink the water instantly while the water is boiled, and repeated heating is avoided, so that the energy can be saved, and people can drink healthily. In conclusion, the novel instant-heating type drinking water dispenser is reasonable in design, simple in structure, and suitable for wide popularization.

Owner:宁波必博母婴科技有限公司

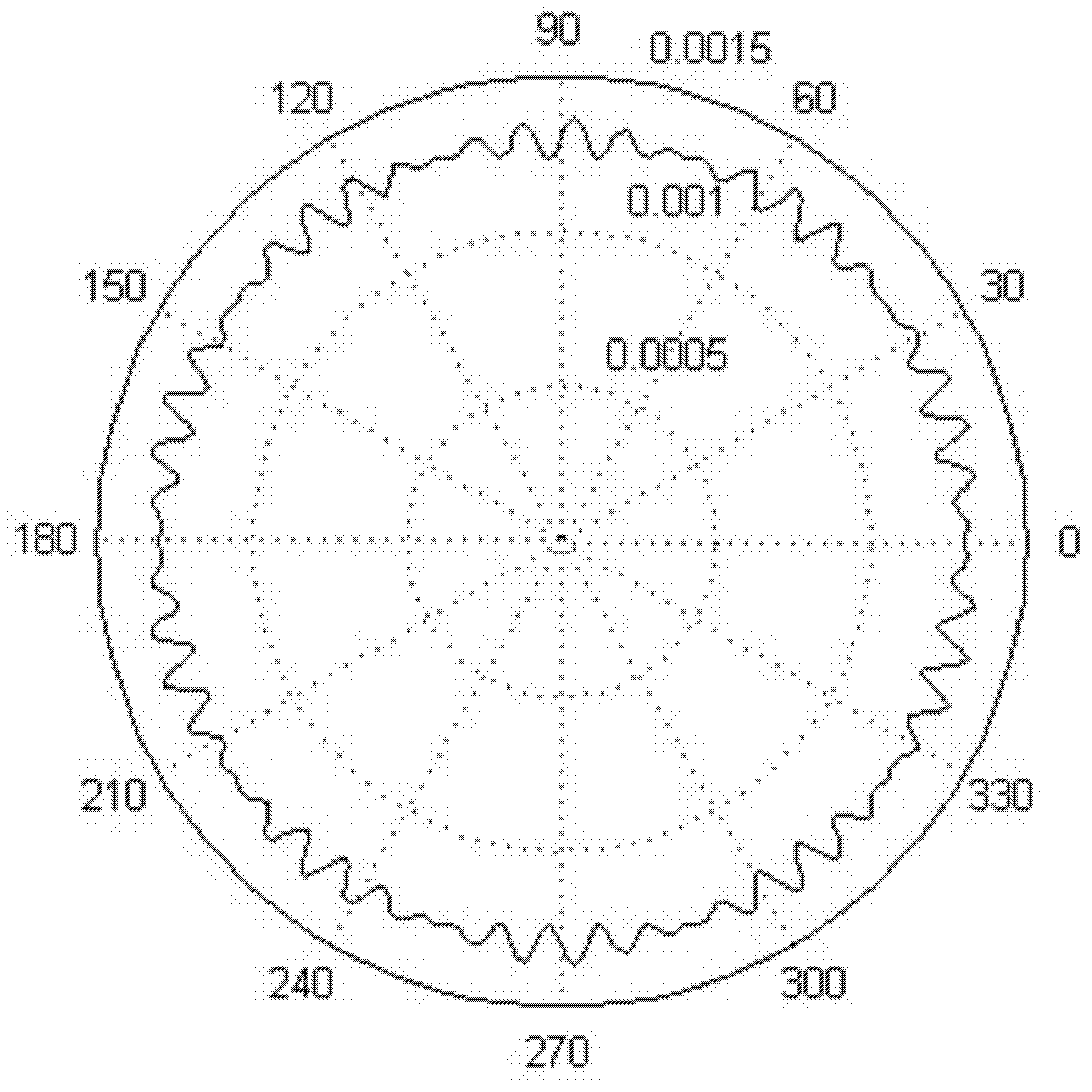

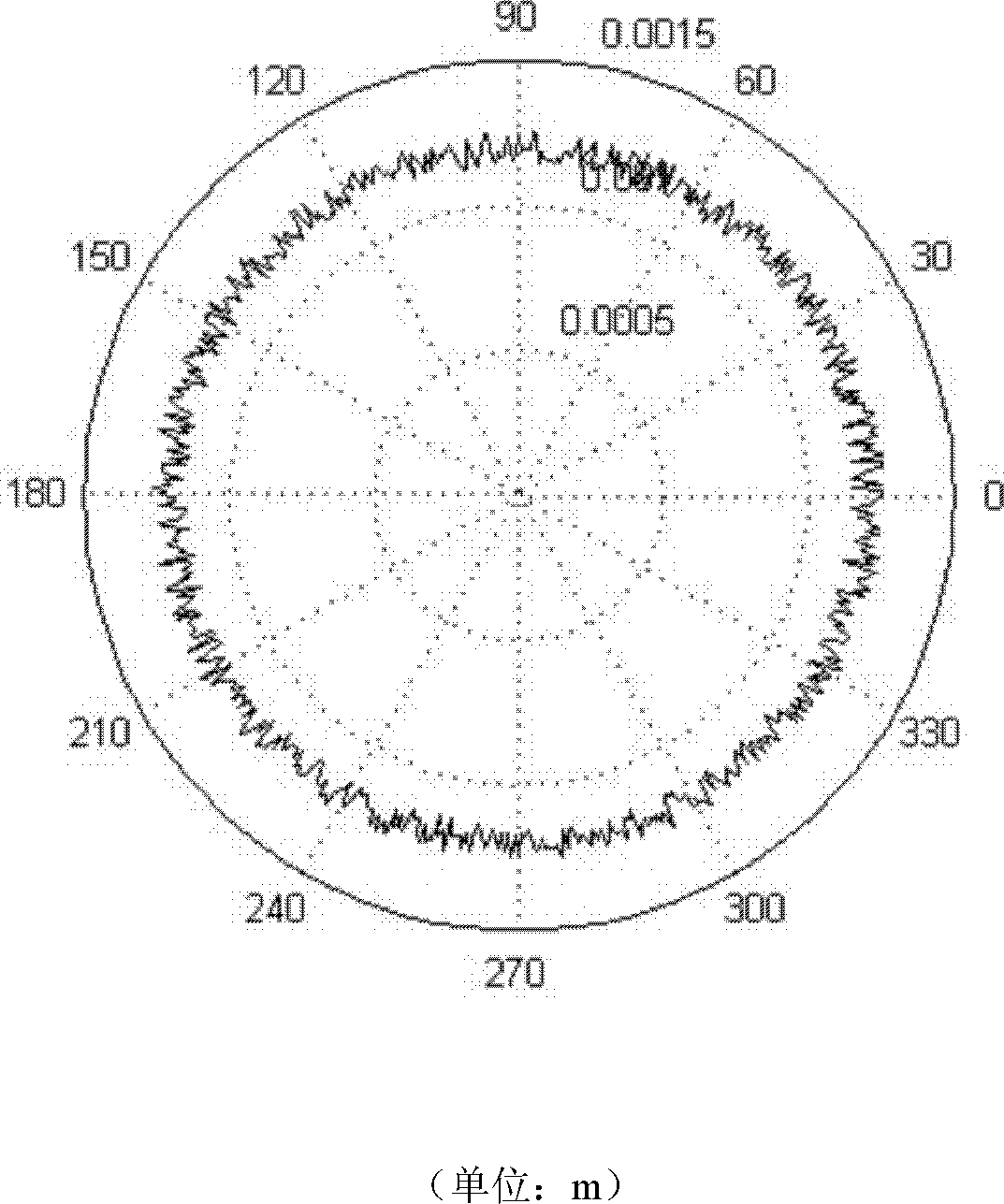

Method for realizing Gaussian beam shaping and determining average radius of serrated aperture with random radius

InactiveCN102540473BImprove fill rateReduce modulation strengthOptical elementsGaussian beamFeature parameter

The invention relates to a method for realizing Gaussian beam shaping and determining average radius of a serrated aperture with random radius and belongs to the field of laser. The method comprises the following steps of: determining the radius r of the aperture, namely r=a*(1+a1*rand(theta)), wherein a is average radius and equal to 0.001 to 0.003 m and a1 is modulation depth and equal to 0.05; manufacturing the apertures with different average radiuses; performing tests and calculating characteristic parameters such as the filling factor, the modulation intensity and the optical intensity contrast; and determining the optimal average radius, wherein the obtained a is 60 percent of the width of the incident Gaussian beam. Compared with the traditional amplitude modulation ripple serrated aperture, the serrated aperture with the radius randomly changed along with the change of the angle is used together with a space filter, so that the radial beam filling factor is improved and the modulation intensity is reduced. The method can be widely applied to beam shaping and light intensity homogenization of a laser. By the method, the high filling factor can be achieved and the utilization ratio, the stability and the output power of the energy storage substances of the laser can be improved obviously.

Owner:BEIJING UNIV OF TECH

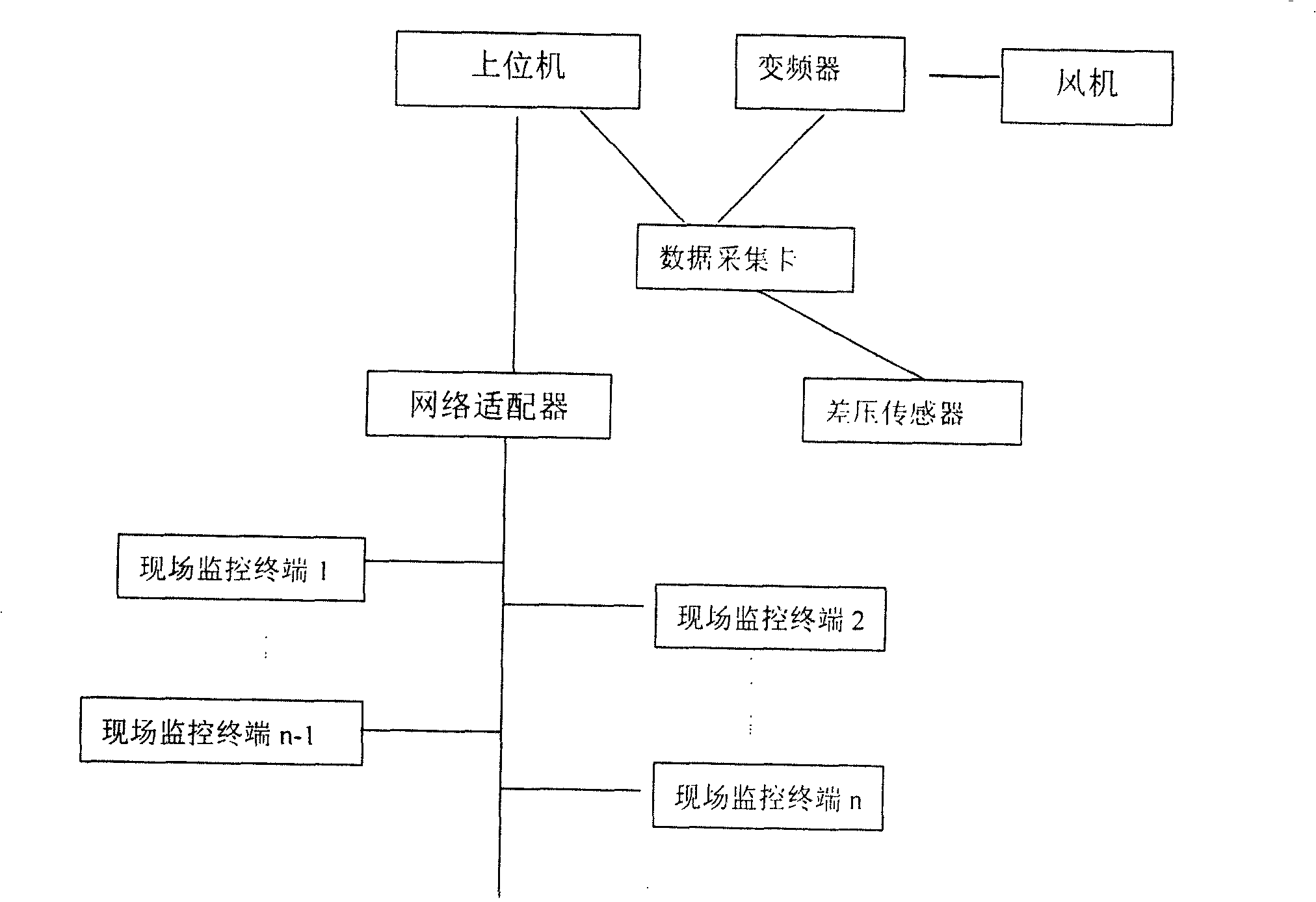

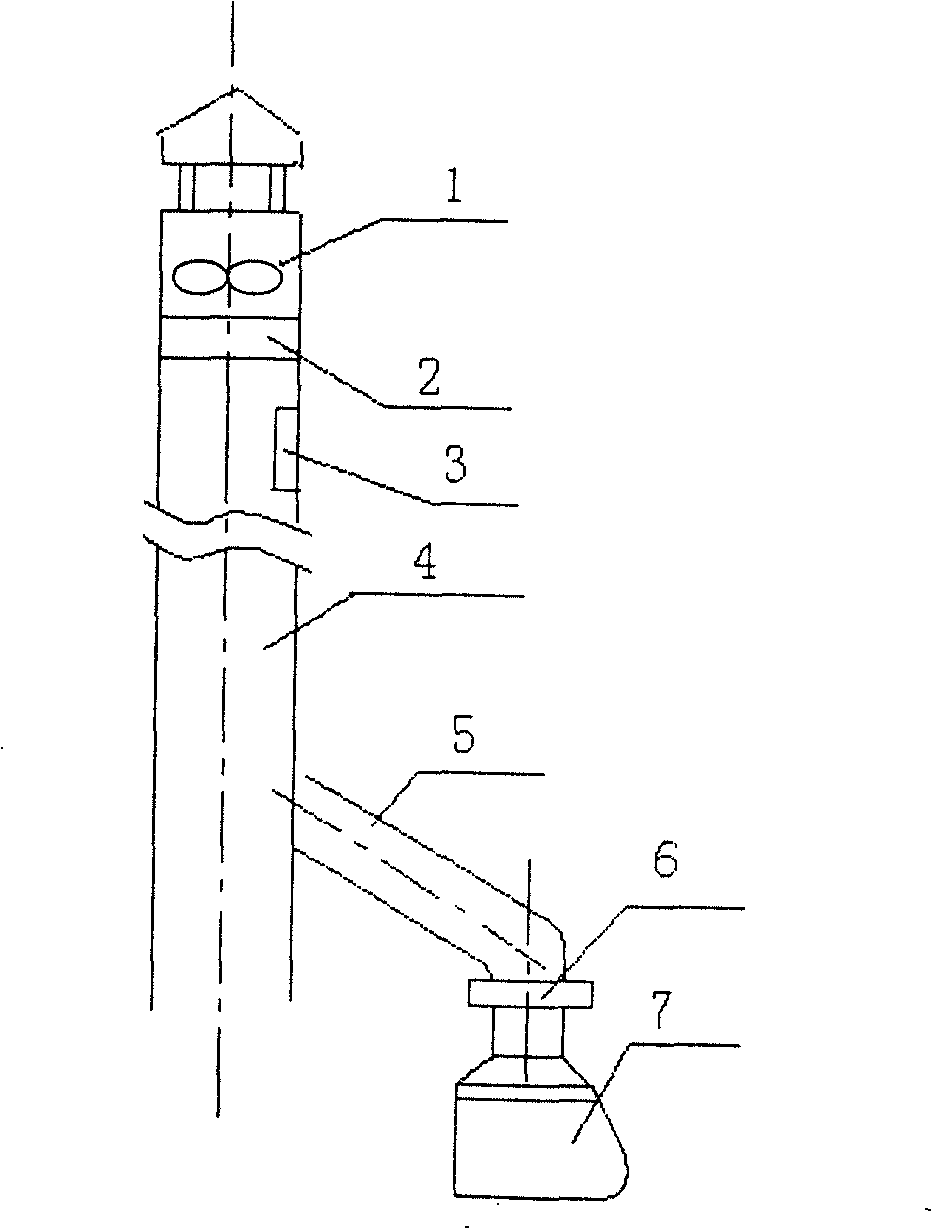

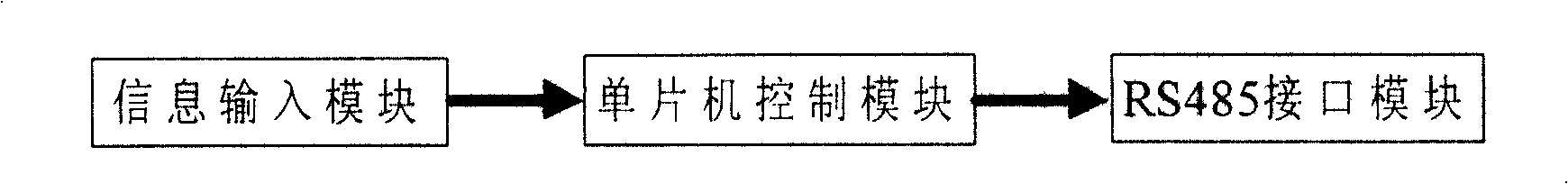

Storied building fume centralized discharge monitoring system and method thereof

InactiveCN100451271CLow costSave spaceComputer controlSimulator controlTransverterArchitectural engineering

The invention provides a central discharge monitoring system for building smoke and the discharge monitoring method. According to the each floor information and the air pressure value of present main pipe, the host computer of system can change the output frequency and voltage of inverter to realize the adjustment for fan speed so as to achieve the purpose of reasonable smoke exhaust and guarantee air quality of each user cell by stabilizing the air pressure value of main pipe. The system is provided with low equipment cost, small noise, good smoke exhaust performance, energy saving and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Hydraulic drive spin type trash drift

The invention discloses a hydraulic drive spinning type sewage intercepting floater, and belongs to environmental protection sewage removing equipment. Vertical tracks are oppositely and fixedly arranged on the inner sides of dams on two opposite sides respectively, buoyancy tank assemblies are installed on the vertical tracks on the two sides in a vertically moving mode respectively, a hollow sealing shaft assembly is rotationally installed on two oppositely-arranged bearing pedestal assemblies, a water impeller assembly is fixedly installed on the hollow sealing shaft assembly, anger blades opposite in spiral direction are fixedly installed at the portions, on the two sides of the water impeller assembly, of the hollow sealing shaft assembly respectively, the two ends of each inhaul cable are connected with the corresponding buoyancy tank assembly and the corresponding bearing pedestal assembly respectively, and the hollow sealing shaft assembly is connected on the buoyancy tank assemblies on the two opposite sides in a hung mode through the inhaul cables on the two opposite sides. The sewage intercepting floater is novel, simple and reasonable in structure, capable of saving energy, good in working effect, capable of bringing convenience to manual sewage salvage and saving labor, good in safety and high in applicability.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A variable displacement oil pump control device and method thereof under braking conditions

InactiveCN110056758BIncrease the power of auxiliary brakingReduce wearLubricating pumpsVehicle componentsEngineeringElectromagnetic valve

The invention belongs to the technical field of engines, and particularly relates to a variable-displacement engine oil pump control device and method under the brake working condition. The variable-displacement engine oil pump control device comprises a shell, an engine oil pump inner core, a main oil circuit, a control electromagnetic valve, an electronic control unit, a clutch pedal and an accelerator pedal. A controllable feedback oil circuit is formed on the left side of the inner wall of the shell. A first flow allocation surface is formed at the top end of the controllable feedback oilcircuit. A return spring is fixedly installed on the right side wall of the controllable feedback oil circuit. A normally-open feedback oil circuit is formed on the right side of the inner wall of theshell. A second flow allocation surface is formed at the top end of the normally-open feedback oil circuit. The engine oil pump inner core is fixedly installed in the middle of the inner wall of theshell and further comprises a regulating ring, a bearing, a rotor, blades and an oil supply cavity. The blades are evenly connected to the outer wall of the rotor in an inserting mode, and the oil supply cavity is formed among the multiple blades. By means of the variable-displacement engine oil pump control device and method under the brake working condition, abrasion to a brake is reduced and meanwhile the comprehensive effect of the braking effect is improved.

Owner:JILIN UNIV

Clean recovery and production method for waste copper and copper-containing waste

ActiveCN102618722BIncrease profitRealize added valueProcess efficiency improvementSlagPollutant emissions

Owner:河南萃海再生资源有限公司

Demand response control method based on weighted low-carbon credits

ActiveCN110535127BReasonable energyEmission reductionTechnology managementResourcesEnvironmental resource managementEnvironmental engineering

The invention discloses a demand response control method based on weighted low-carbon points, which includes the following steps: 1. Introducing carbon emission factors to calculate the average carbon emission of the industry; Step 2: Establishing weighted low-carbon points according to the electricity consumption conditions of users in various industries ; Step 3. During the demand response period, the user corrects the compensation amount based on the weighted low-carbon points according to the demand. The present invention considers the carbon emissions of each user, establishes weighted low-carbon points for users in various industries, rewards users with higher low-carbon points, and punishes users with lower low-carbon points, and implements demand response scheduling on the basis of weighted low-carbon points management, which improves the effectiveness and standardization of users’ rational use of electric power, protects the environment, and reduces carbon emissions; the present invention simultaneously considers demand-side management and low-carbon emission power generation, reduces carbon emissions, and enables users to use electric energy reasonably, reducing electricity cost.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ZHENJIANG POWER SUPPLY CO +1

A cotton fiber drying and cooling system

The invention discloses a cotton fiber drying and cooling system which comprises a drying box body and a cooling box body, wherein the drying box body is internally provided with a transverse clapboard; the transverse clapboard divides the interior of the drying box body into a drying chamber at the upper end and a heating chamber at the lower end; multiple vent holes are uniformly distributed in the transverse clapboard; the side walls of two ends of the drying chamber are respectively provided with an inlet and an outlet which are corresponding to each other; the inlet end of the drying chamber is provided with an inlet cotton conveying curtain, and the outlet end of the drying chamber is provided with a middle conveying curtain; the drying chamber is internally provided with multiple groups of oblique upward conveying curtains and oblique downward conveying curtains, which are matched with each other; the oblique upward conveying curtains and the oblique downward conveying curtains constitute inverted V-shaped drying channels; the inner wall, positioned at the tops of the oblique upward conveying curtain and oblique downward conveying curtain in each group, of the drying box body is rotatably provided with a stripping roller; the other end of the middle conveying curtain extends into the inlet end of the cooling box body. The cotton fiber drying and cooling system is simple in structure, uniform and full in drying, small in equipment size, improved in drying stroke and high in cooling efficiency.

Owner:GUANGDE TIANYUN NEW TECH

A finned tube waste heat boiler system placed outside the large flue of the sintering machine

ActiveCN104832900BWill not affect productionReasonable energyEnergy industryIncreasing energy efficiencySuperheaterSmall footprint

The invention relates to a finned tube type residual heat boiler system besides a large flue of a sintering machine, and relates to the technical field of steel and iron smelting equipment. The finned tube type residual heat boiler system comprises the large flue of the sintering machine, a bypass flue, a first large flue steam overheater, a second large flue steam overheater, a first large flue first-stage finned tube evaporator, a second large flue first-stage finned tube evaporator, a first large flue second-stage finned tube evaporator, a second large flue second-stage finned tube evaporator, a steam drum and a water supply system, wherein the large flue of the sintering machine comprises a first large flue and a second large flue; a plurality of air guide tubes are arranged on the first large flue and the second large flue. The finned tube type residual heat boiler system has the advantages that the finned tube type residual heat boiler system is directly arranged besides the large flue of the sintering machine, so the existing site of the sintering machine is sufficiently utilized, the residual heat resource of the sintering machine is recycled, and the energy source is reasonably and effectively used in a gradient way; the investment of equipment is saved, and the land occupation area is small; the generated overheat steam is used for generating power, the economic benefits and social benefits are obvious, and the finned tube type residual heat boiler system is widely applied to the sintering machine industry of steel and iron enterprises.

Owner:江苏中天能源设备有限公司

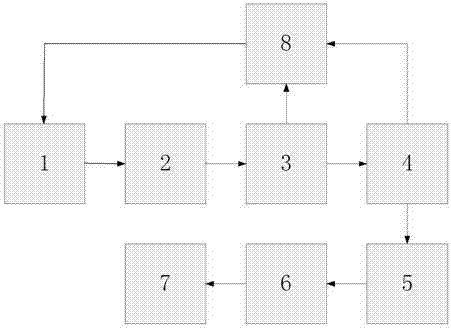

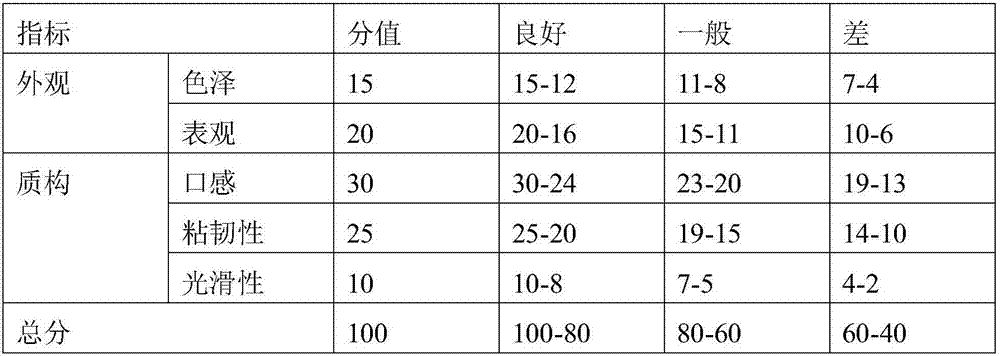

Processing apparatus and method of instant dry noodles eaten after mixing with water

InactiveCN107095151ARich in nutrientsIncrease contentDough-sheeters/rolling-machines/rolling-pinsDough mixing/kneading machinesNutrient contentHigh absorption

The invention discloses a processing apparatus of instant dry noodles eaten after mixing with water. The apparatus comprises a vacuum dough kneading machine, a pressing cutting machine, a boiling water tank, a spraying device, an acid leaching device, a dryer and a sterilization packing device. The above parts are orderly connected. Discharge ports of the boiling water tank and the spraying device are directly connected to a concentration tank. A water outlet of the concentration tank is connected to the vacuum dough kneading machine. A removable stainless steel grid is arranged in the boiling water tank. The invention also discloses a method of the instant dry noodles eaten after mixing with water. The instant dry noodles obtained by the method and apparatus are rich in nutrients and have high nutrient content. Most of the nutrients are small molecular substances easy to digest and absorb and have a high absorption and utilization degree. The instant dry noodles can be easily and fast eaten and are easy to store. The apparatus has a reasonable design, saves energy, reduces a cost and produces a product rich in nutrients and having a small nutrient loss.

Owner:江苏新顺福食品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com