Feeding method of raw material pellets for smelting fused magnesite

A feeding method and technology of fused magnesia are applied in the field of feeding raw material pellets, which can solve the problems of high energy consumption and poor quality of fused magnesia, and achieve the effects of improving the rate of high-quality products, ensuring economic operation, and improving overall quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

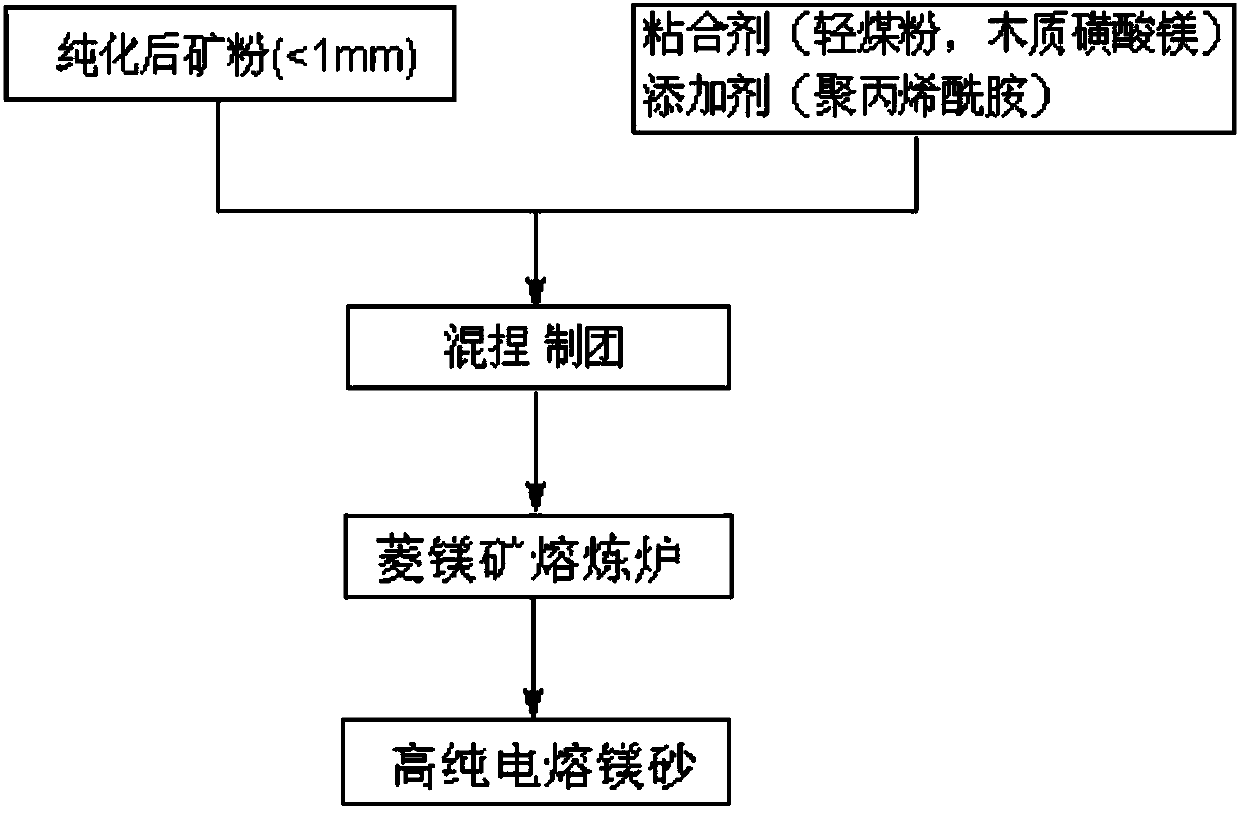

[0026] figure 1 It is a schematic flow chart of the electro-fused magnesium smelting method in Example 1.

[0027] This embodiment discloses a method for feeding raw material pellets for electric smelting magnesium smelting in a rotary magnesite smelting furnace with high-power automatic feeding, such as figure 1 As shown, the feeding method of the raw material pellets for electric fused magnesium smelting comprises the following steps:

[0028] (1), the magnesite is crushed, flotation to remove impurities to obtain magnesite concentrate (particle size <1mm); the magnesite concentrate, light coal powder, magnesium lignosulfonate and polyacrylamide are mixed and kneaded to produce group. The pellets are divided into large-diameter pellets and small-diameter pellets, and the particle diameter of the large-diameter pellets is greater than the particle diameter of the small-diameter pellets; specifically, the particle diameters of the large-diameter pellets in this embodiment ar...

Embodiment 2

[0034] This embodiment discloses a method for feeding raw material pellets for electro-fused magnesium smelting, which includes the following steps:

[0035] (1) Grinding the magnesite and removing impurities by flotation to obtain a magnesite concentrate (particle size < 1 mm); kneading the magnesite concentrate and a binder to make agglomerates. The pellets are divided into large-diameter pellets and small-diameter pellets; specifically, the particle diameters of the large-diameter pellets in this embodiment are: 55mm and 65mm. The particle size of small particle size pellets is: 35mm, 45mm.

[0036] (2) In the start-up stage of smelting, the use of large-size pellets for smelting can increase the gap between pellets, which is conducive to arcing between electrodes, accelerates the melting of materials, and shortens the formation time of molten pools.

[0037] (3) In the stable stage of smelting, large-sized pellets and small-sized pellets are used at the same time, and the...

Embodiment 3

[0041] This embodiment discloses a method for feeding raw material pellets for electro-fused magnesium smelting, which includes the following steps:

[0042] (1), the magnesite is crushed, flotation to remove impurities to obtain magnesite concentrate (particle size <1mm); the magnesite concentrate, light coal powder, magnesium lignosulfonate and polyacrylamide are mixed and kneaded to produce group. The pellets are divided into large-diameter pellets and small-diameter pellets, and the particle diameter of the large-diameter pellets is larger than the particle diameter of the small-diameter pellets; specifically, the particle diameter of the large-diameter pellets in this embodiment is: 60mm, 70mm. The particle size of small particle size pellets is: 30mm, 40mm.

[0043] (2) In the start-up stage of smelting, the use of large-size pellets for smelting can increase the gap between pellets, which is conducive to arcing between electrodes, accelerates the melting of materials,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com