Drilling machine

A drilling machine and worktable technology, which is applied to the components of the boring machine/drilling machine, boring/drilling, drilling/drilling equipment, etc. Achieve the effect of improving processing efficiency, convenient operation and small vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

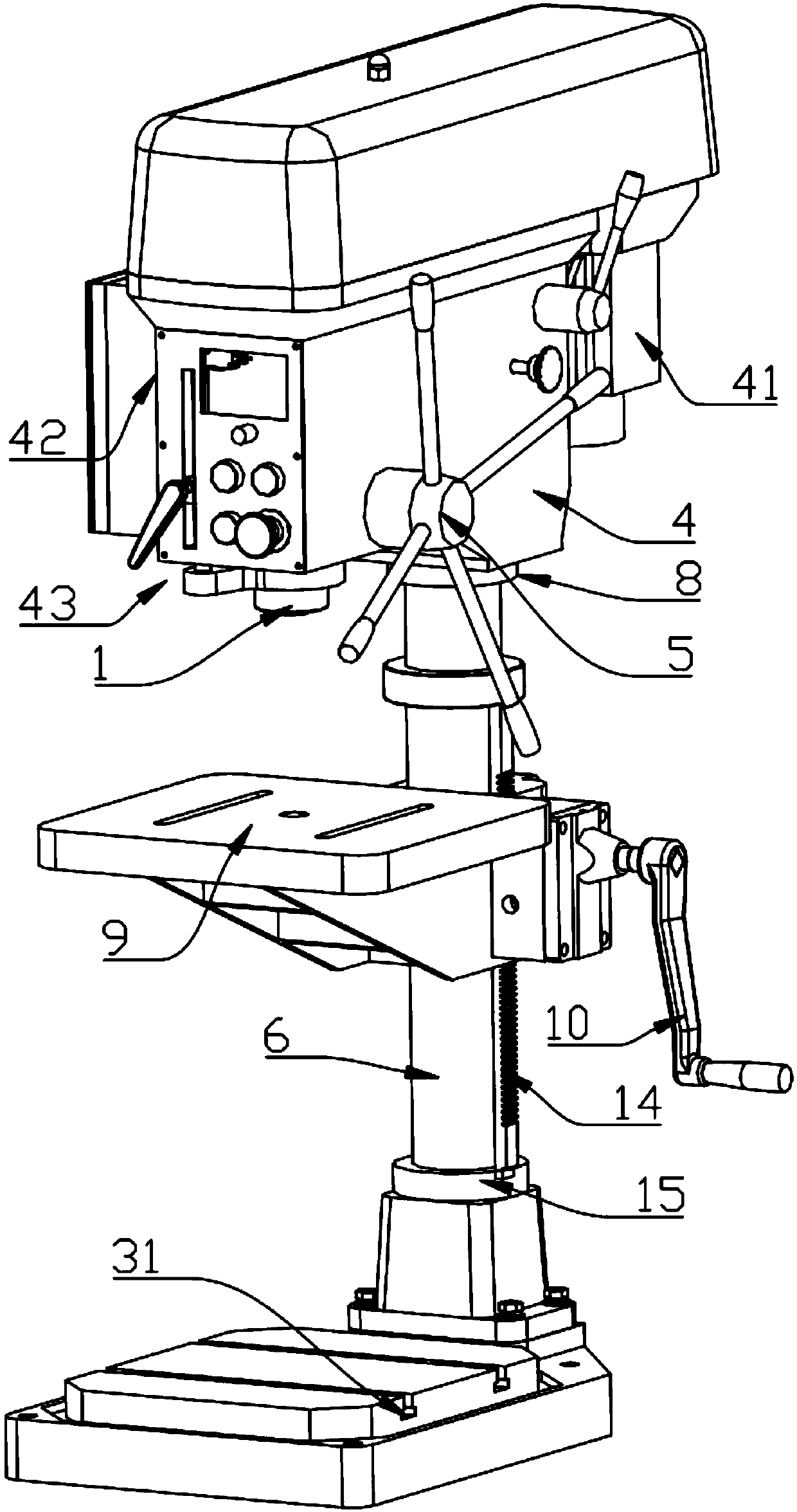

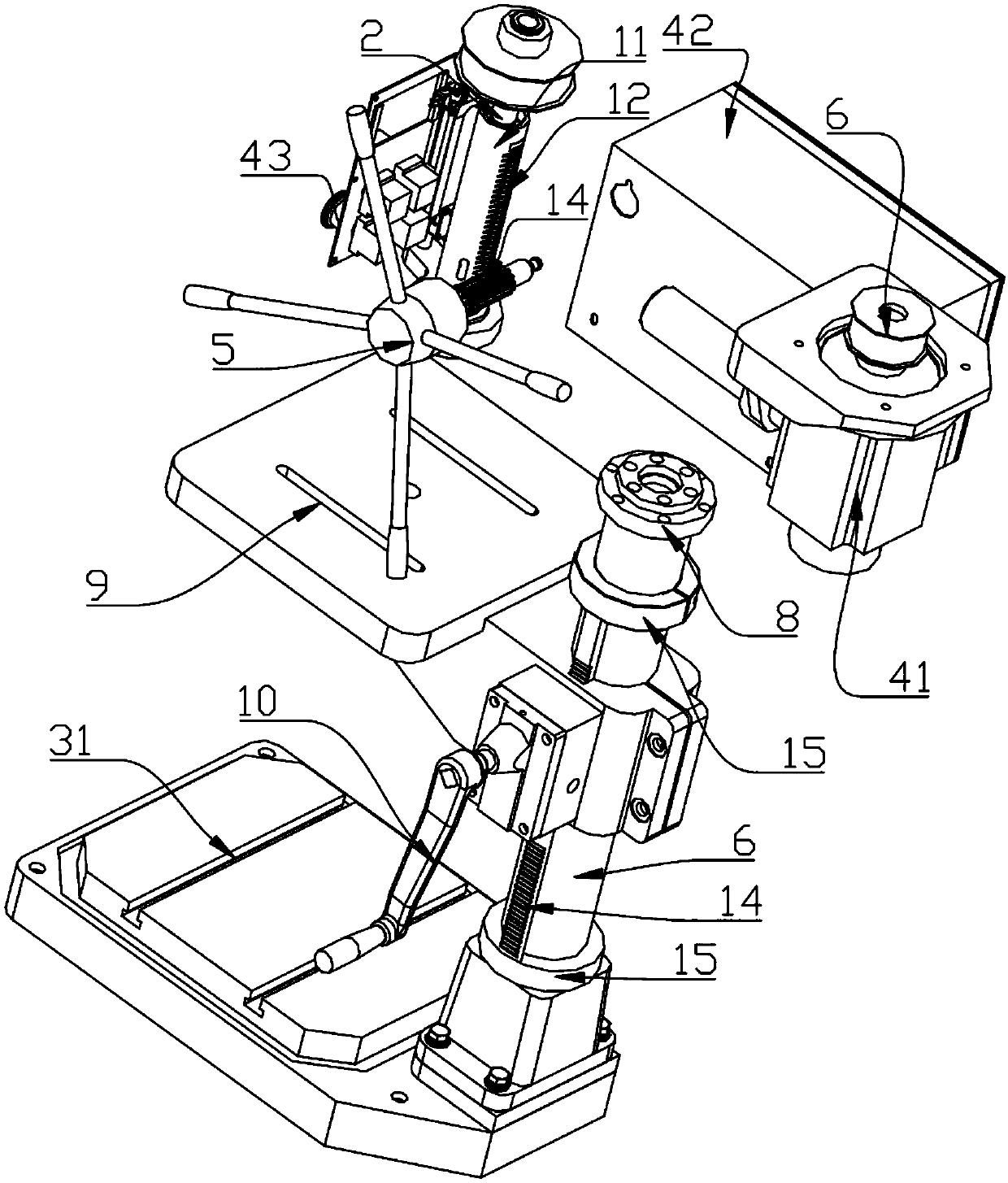

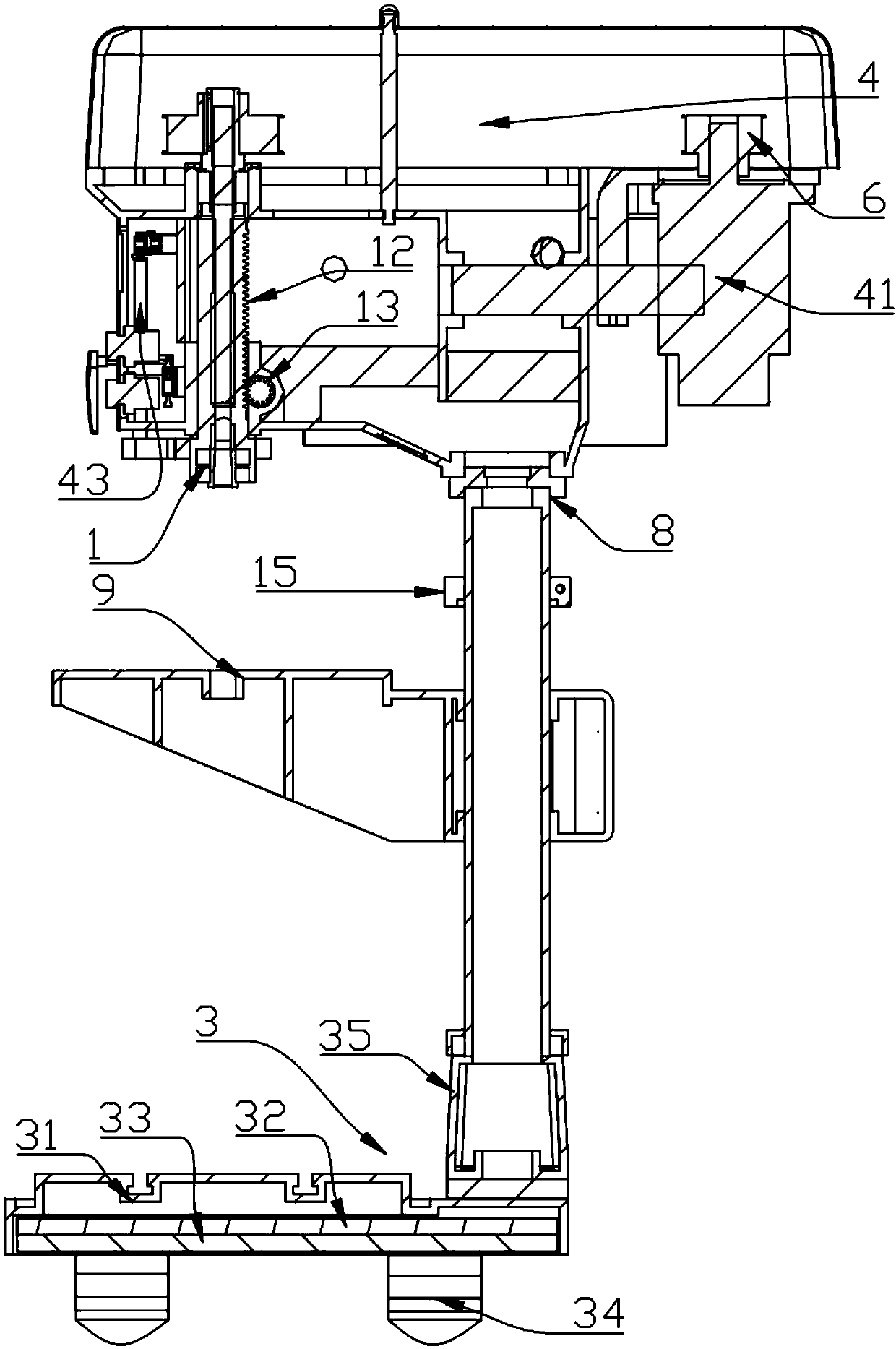

[0033] Embodiment one: if Figure 1-3 As shown, a drilling machine includes a base 31, a support rod 7, a workbench 9 and a machine head. The base 31 is provided with a support rod 7, and the support rod 7 is covered with a workbench 9. The workbench One side of the 9 is provided with a rotary rocker 10 capable of controlling the slide of the workbench 9 on the support column 7, and the upper end of the support column 7 is equipped with a machine head through a connecting flange 8, and the machine head includes a head frame 4, is arranged on One side of the head frame 4 and the rotating disk 5 that drives the main shaft 2 to move up and down, the gear box 67 and the permanent magnet motor 41 that drives the main shaft 2 to rotate, the output shaft of the permanent magnet motor 41 is connected with the pulley 6, and the permanent magnet motor 41 is connected to the pulley 6. One side of the magneto 41 is provided with a frequency converter 42, which is connected to each other t...

Embodiment 2

[0041] Embodiment two: if Figure 4-7 As shown: this embodiment is basically the same as Embodiment 1, the difference is that the side of the workbench 9 is provided with side baffles 22, the number of the side baffles 22 is three, and the three are vertically arranged The side baffles 22 are respectively positioned at both sides and the rear portion of the workbench 9, the front portion of the workbench 9 is provided with a front baffle 23, and the height of the front baffle 23 is lower than the side baffles 22; There is at least one group of fan units, and the side baffle 22 has a first air outlet 221 and a second air outlet 222, and the first air outlet 221 and the second air outlet 222 are connected with the air outlet pipe of the fan unit; the other side baffle 22 The outer side is connected with the storage body 24 , the lower part of the storage body 24 is a storage portion 240 , and a storage cavity 242 is formed in the storage portion 240 .

[0042] This technical so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com