Processing apparatus and method of instant dry noodles eaten after mixing with water

A technology for processing equipment and dry noodles, which is applied in the fields of food science, dough mixer, dough forming and cutting combination, etc. It can solve the problems of cumbersome delivery, loss of nutrients, and inability to fully guarantee the source of nutrients, and achieve high content and nutrients. The effect of less loss and high absorption and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

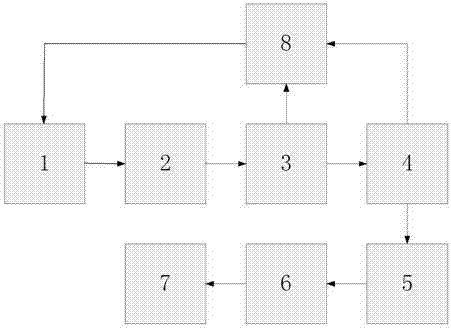

[0023] A brewing instant dry noodle processing equipment, comprising a vacuum noodle mixer 1, a pressure cutter 2, a boiling water tank 3, a spraying device 4, an acid leaching device 5, a dryer 6 and a sterilizing packaging device 7 connected in sequence. The discharge port of the boiling water tank 3 and the spraying device 4 is directly connected to the concentration tank 8, and the water outlet of the concentration tank is connected to the vacuum dough mixer 1; a removable stainless steel grid is placed in the boiling water tank 3, and the stainless steel The aperture of the mesh is 1-3mm.

Embodiment 2

[0025] Utilize the technique described in embodiment 1 to produce brew instant dry noodles, comprise the following steps:

[0026] (1) Take each component of the following parts by weight: 45 parts of flour, 45 parts of yam powder, 25 parts of potato starch, 1.5 parts of edible salt, 1.2 parts of edible alkali, 1.5 parts of gluten enhancer, 1 part of sorbitol, 40 parts sterile water;

[0027] (2) Take flour and edible alkali and put them in sterile water, stir and mix evenly, continue to stir at 70°C for 40 minutes, then cool to room temperature, add formula yam powder, potato starch, edible salt, gluten enhancer and sorbitol, Mix evenly, put it into a vacuum dough mixer, process for 25 minutes, then cover the dough with plastic wrap and place it at 33°C for 25 minutes;

[0028] (3) Press the dough with a pressing machine, cut it into strips with a width of 5 mm and a thickness of 2 mm, put it in a boiling water tank and cook for 20 minutes, then take out the cooked noodles b...

Embodiment 3

[0033] Utilize the technique described in embodiment 1 to produce brew instant dry noodles, comprise the following steps:

[0034] (1) Weigh each component of the following parts by weight: 30 parts of flour, 30 parts of yam powder, 20 parts of potato starch, 1 part of edible salt, 1 part of edible alkali, 1 part of gluten-enhancing agent, 2 parts of sorbitol, 30 parts sterile water;

[0035] (2) Take flour and edible alkali and put them in sterile water, stir and mix evenly, keep stirring at 60°C for 30 minutes, then cool to room temperature, add the formula yam powder, potato starch, edible salt, gluten enhancer and sorbitol, Mix evenly, put it into a vacuum dough mixer, process for 20 minutes, then cover the dough with plastic wrap and place it at 30°C for 20 minutes;

[0036] (3) Press the dough with a cutting machine, cut it into strips with a width of 2 mm and a thickness of 2 mm, put it in a boiling water tank and cook for 10 minutes, then take out the cooked noodles b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com