Novel drilling machine

A drilling machine, a new type of technology, applied in the direction of boring machine/drilling machine parts, boring/drilling, drilling/drilling equipment, etc., can solve the problem that the bench drill has no low-speed and high-speed adjustment function, and it is difficult Precise control, improving production costs and other issues, to achieve the effect of rational use of electric energy, good processing performance, and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

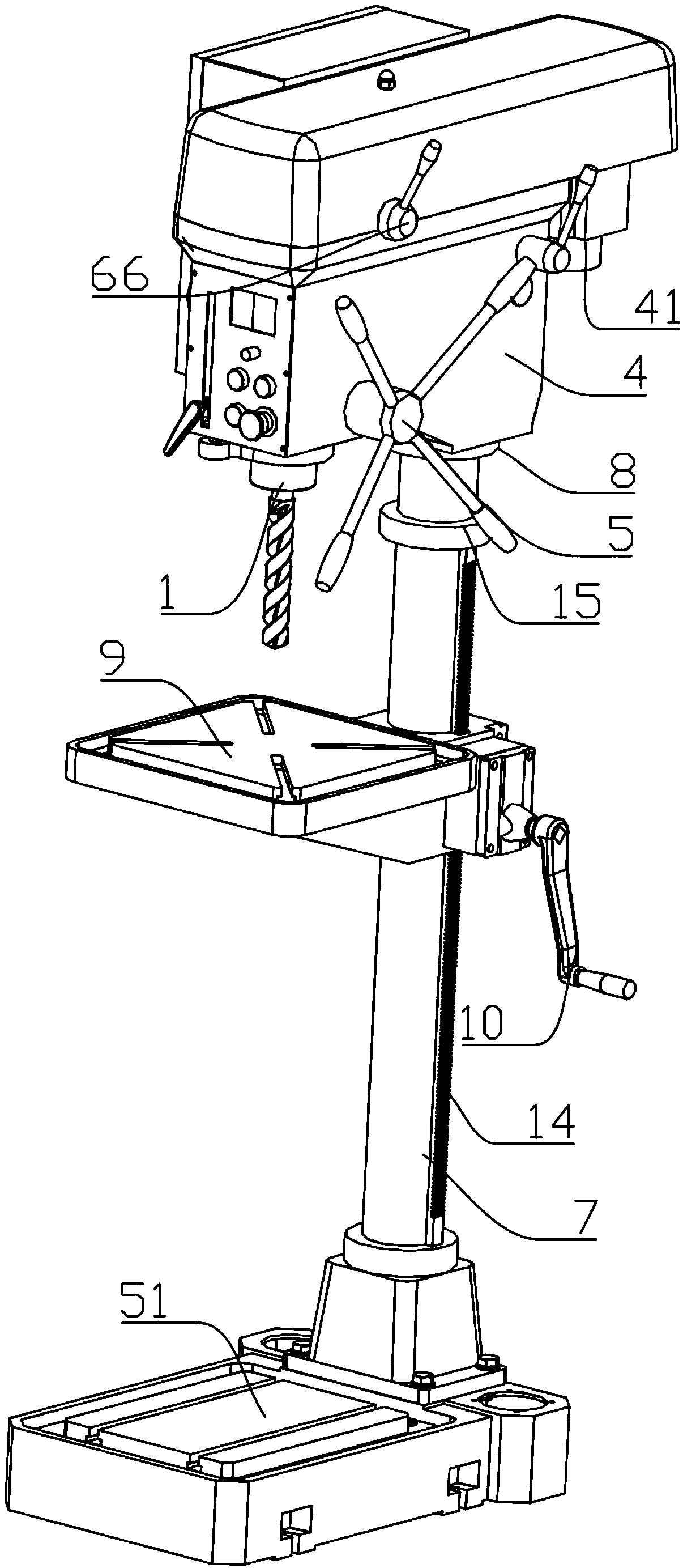

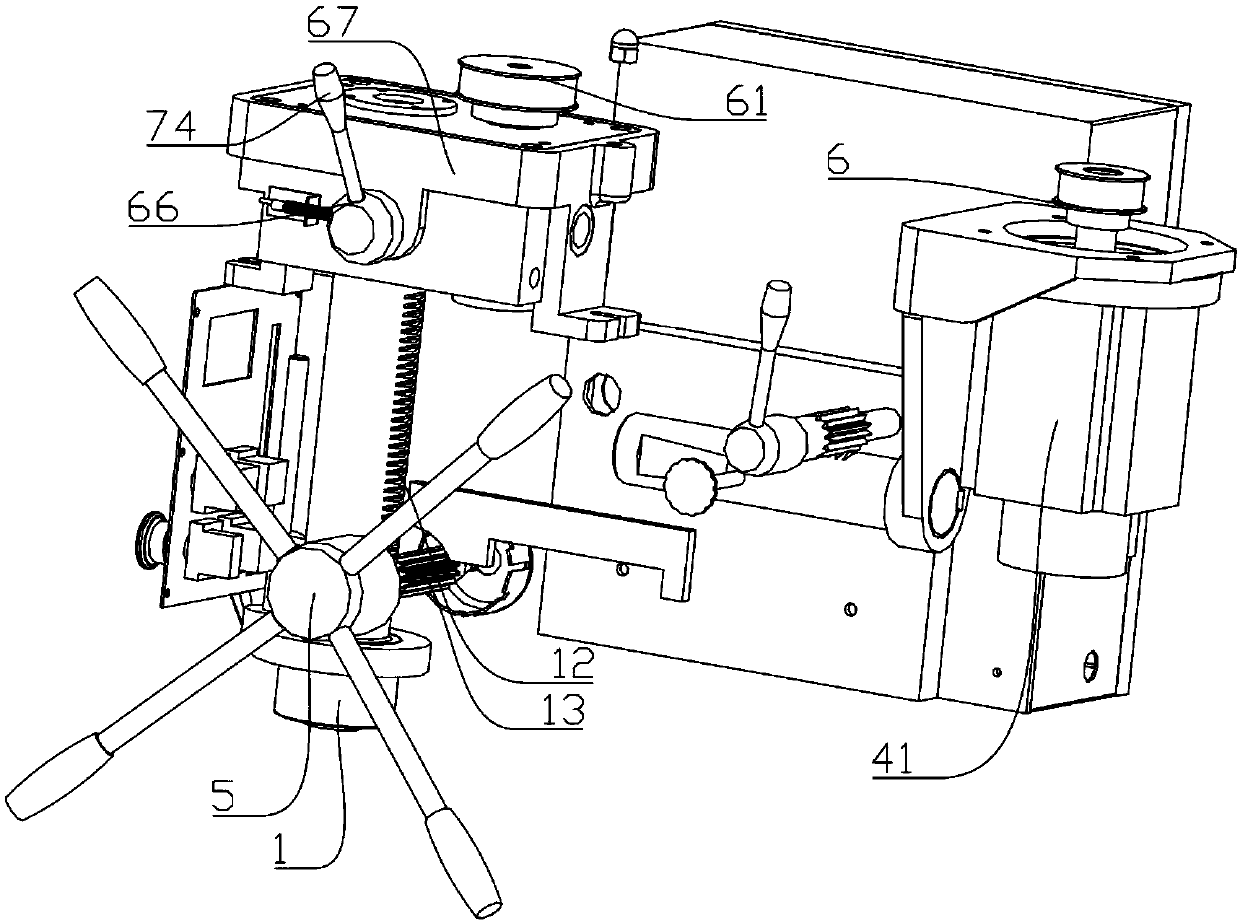

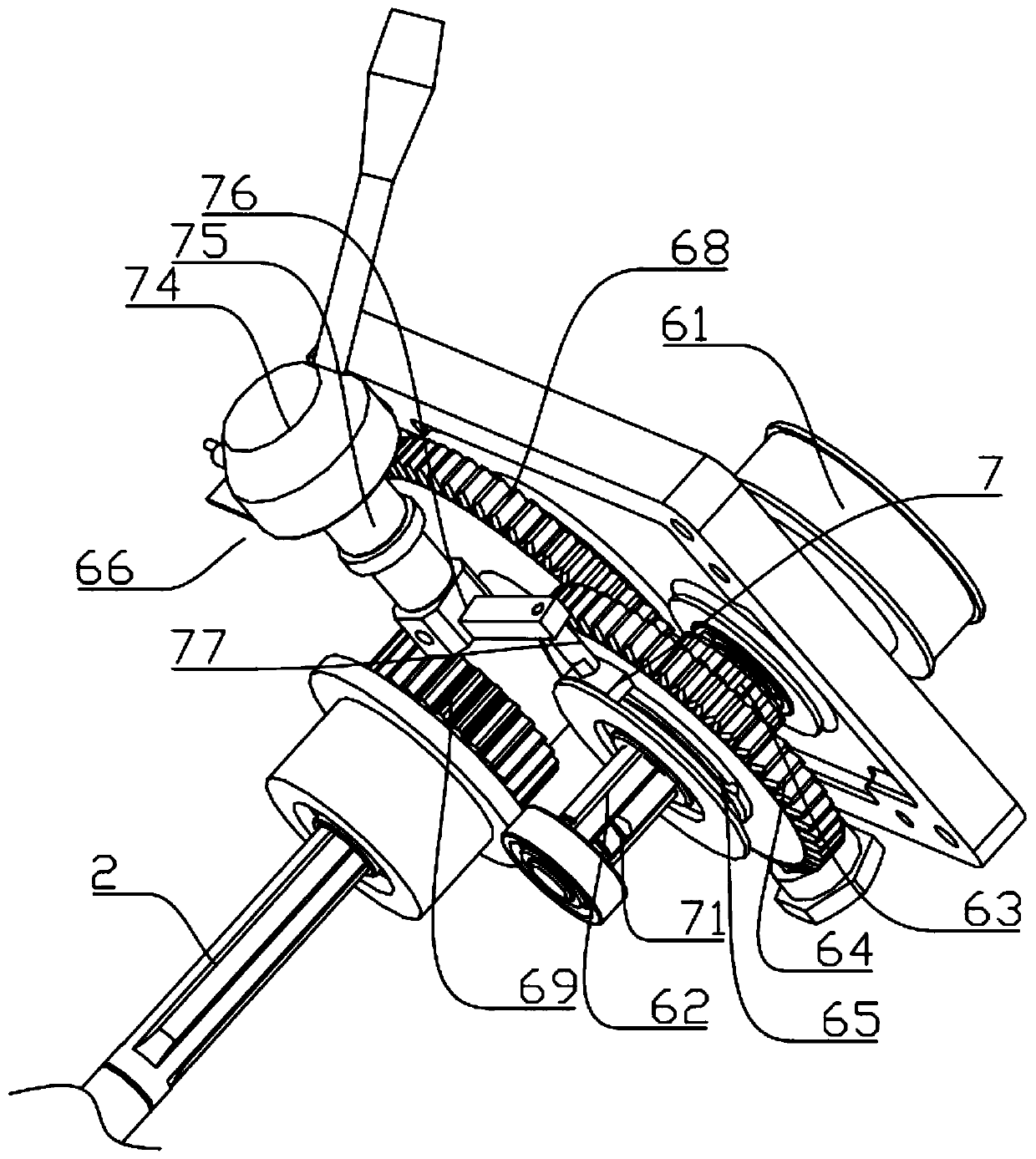

[0033] Embodiment one: if Figure 1-6 As shown, a novel drilling machine includes a base 51, a support rod 7, a workbench 9 and a machine head. The base 51 is provided with a support rod 7, and the support rod 7 is provided with a workbench 9. The work One side of the table 9 is provided with a rotary rocker 10 capable of controlling the sliding of the workbench 9 on the support column 7, and the upper end of the support column 7 is equipped with a machine head through a connecting flange 8, and the machine head includes a head frame 4, a set On one side of the head frame 4 and drive the rotating disk 5, the gear box 67 and the motor 41 that the main shaft 2 moves up and down, the output shaft of the motor 41 is provided with a first pulley 6, and one side of the first pulley 6 passes through The synchronous belt is provided with a second pulley 61, and a rotating shaft 62 is pierced in the second pulling wheel 61, and the rotating shaft 62 is provided with a first small gear ...

Embodiment 2

[0044] Embodiment two: if Figure 7-9 As shown, this embodiment is basically consistent with Embodiment 1, the difference is that a cooling device 79 is provided on one side of the head frame 4, and the cooling device 79 includes a box body 21, a liquid inlet 22, and a handle 23 , a fixed plate 24, a push rod 25, a liquid outlet pipe 26, a push plate 27, a first one-way valve 28, a dividing plate 29, a connecting pipe 210 and a second one-way valve 211, and the casing 21 is connected to the On one side of the head frame 4, a liquid inlet 22 is provided on the top of the box body 21, a partition 29 is arranged inside the box body 21, a communication pipe 210 is provided on the partition 29, and a second one-way valve 211 is arranged in the communication pipe 210. A push plate 27 is slidably provided between the bottom of the dividing plate 29 and the casing 21, and one end of the push plate 27 is provided with a push rod 25, and the push rod 25 passes through the casing 21, and...

Embodiment 3

[0048] Embodiment three: as Figure 10-11 As shown, this embodiment is basically the same as Embodiment 1, the difference is that a waste collection device 3 is provided on the base 51, and the waste collection device 3 includes a storage body 36, a stopper 37, a brush 38, The slag discharge port 39, the valve 310 and the first mesh plate 311, the base 51 is provided with a storage body 36 for collecting waste chips, the left and right sides of the storage body 36 are provided with limiters 37, the limiter 37 and the brush 38 are matched and connected, the lower part of the receiving body 36 is provided with a first mesh plate 311, the lower part of the right side of the receiving body 36 is provided with a slag discharge port 39, and a valve 310 is provided on the slag discharge port 39.

[0049] The waste chips and cutting fluid generated during the processing of the technical solution fall into the receiving body 36, which ensures the cleanliness of the workbench 9 and can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com