Patents

Literature

144results about How to "Will not affect production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

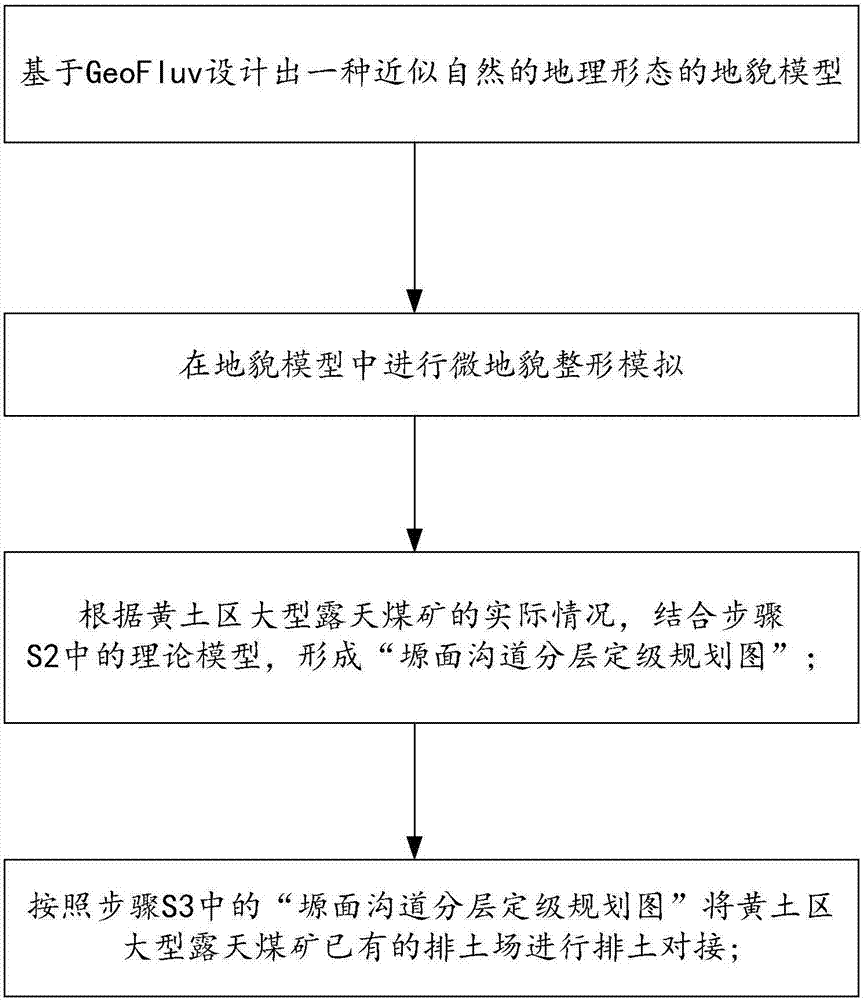

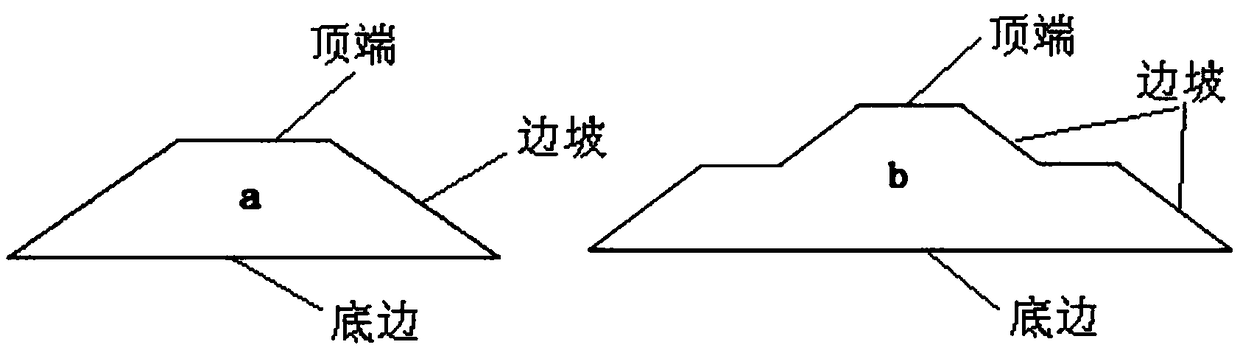

Method for optimizing topography and geomorphology of dump in large opencast coal mine in loess area

ActiveCN107194992AGuaranteed stabilityImprove securityData processing applicationsHydraulic engineering apparatusSurface runoffPlateau

The present invention relates to a method for optimizing the topography and the geomorphology of a dump in a large opencast coal mine in the loess area. The method comprises: "soft base removal", "base gully filling", "smooth base blasting treatment", "base piling for skid resistance", "fan-shaped disposal and layered compaction", and other steps. According to the method provided by the present invention, based on the simulation of the original "plateau" geomorphology millions years ago in the loess plateau, the artificial landmine terraces mode of the traditional sloping land in the water and soil erosion area in the Loess Plateau are changed; and relying on the convenient conditions of the mining and moving soil, the large-scale earthwork is used to deploy and form the basin geomorphology to co-ordinate the hydrological topography, and micro-topography modification is used to reduce the generation of the surface runoff, so that under the premise of ensuring the stability of the dump, the geomorphology of the dump in the large opencast coal mine in the loess area is restored to the "plateau" geomorphology, and the foundation is provided for the restoration of ecosystems and biological diversity.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

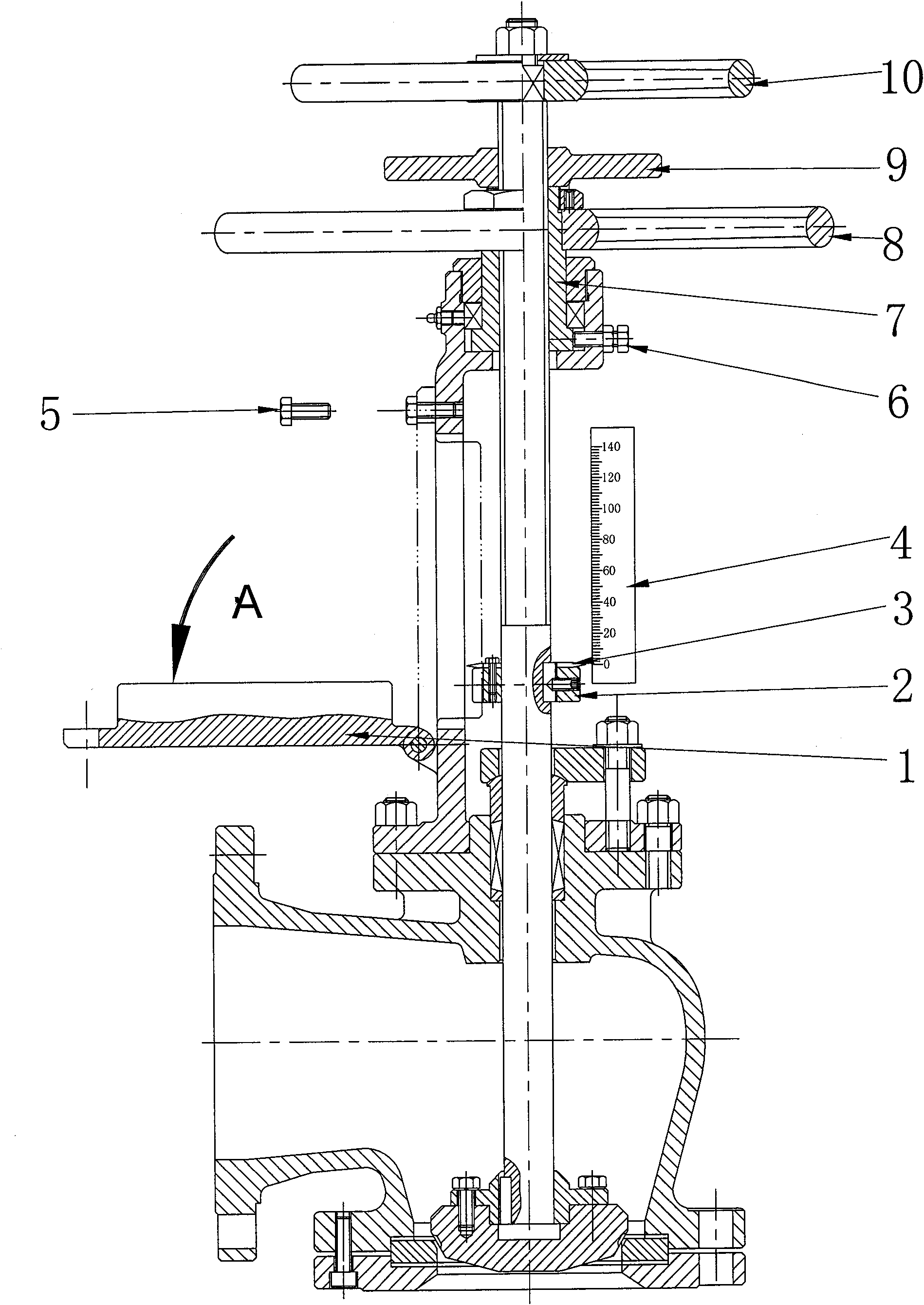

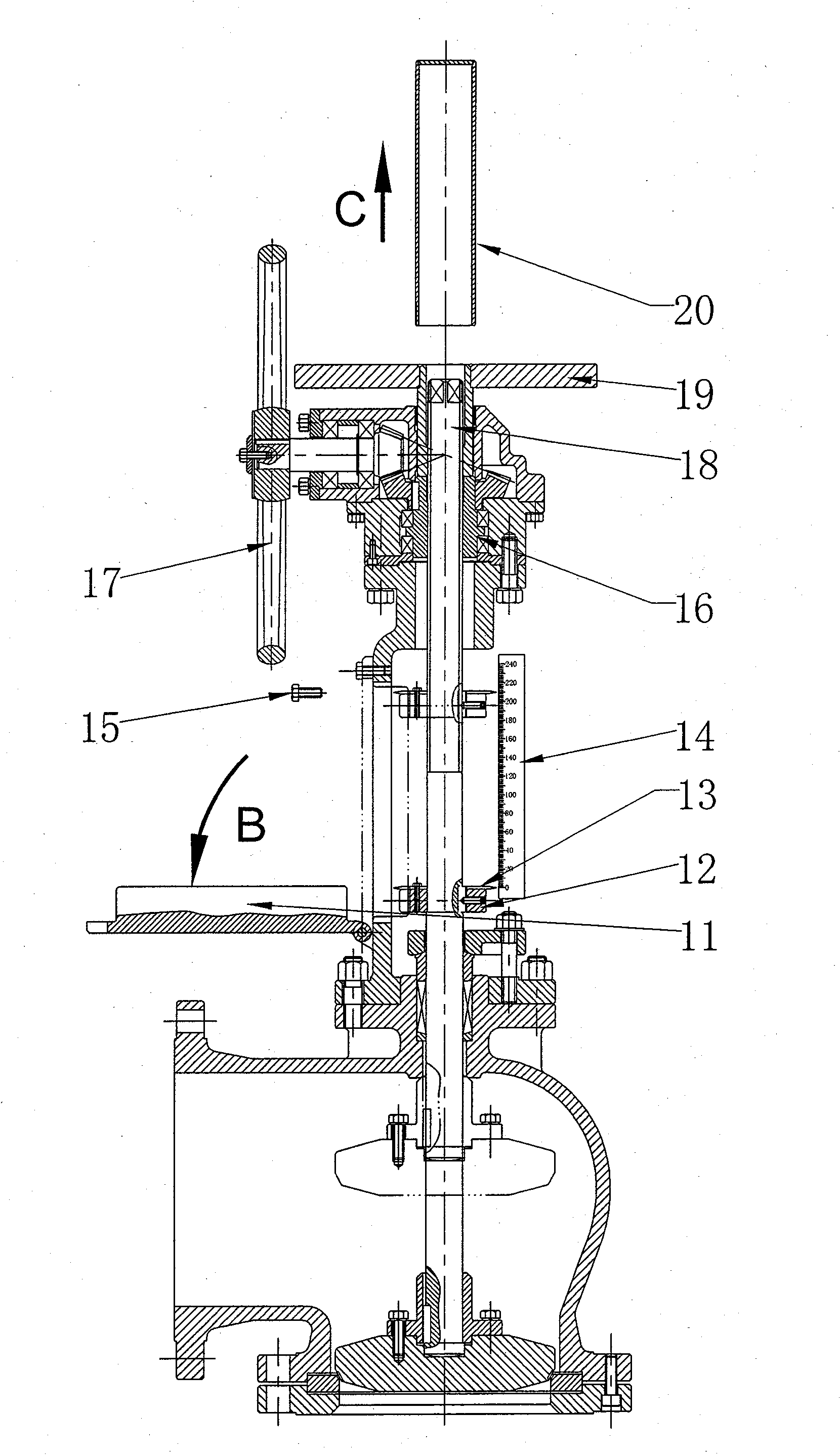

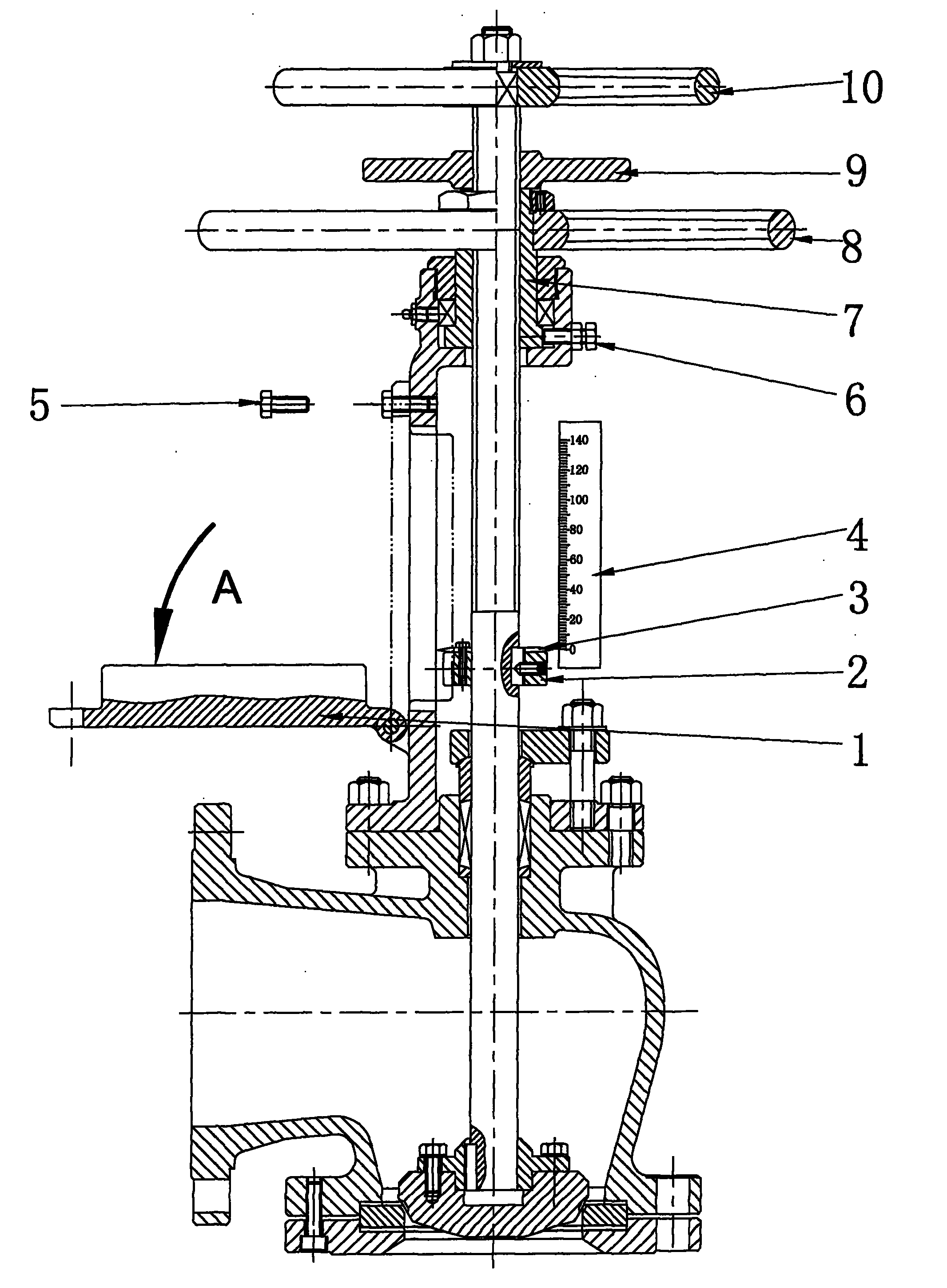

Sealing surface free-grinding repairing method of slurry valve

The invention relates to a repairing method of a valve, in particular to a sealing surface repairing method of a slurry valve. Aiming to provide the sealing surface repairing method of the valve, the valve on a process pipeline can be directly repaired without influencing production, and the repairing method has the characteristics of simplicity and low cost without dismantling the valve. The technical scheme comprises the following steps of: (1) cutting a transmission chain of an anti-rotating mechanism of a valve and a valve rod to ensure that the valve rod is provided with the freedom degree of rotating around an axis thereof and linearly moving along the axis thereof; and (2) pushing the valve rod to ensure that a valve flap at the front end of the valve rod is pressed on a valve seat, then rotating the valve rod to ensure that the valve flap rotates around the axis of the valve rod, and grinding between the sealing surface of the valve flap and the sealing surface of the valve seat until sediments and scarring objects on the sealing surface of the valve flap and the sealing surface of the valve seat are eliminated.

Owner:杭州耐特阀门股份有限公司

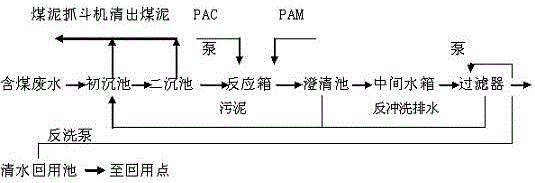

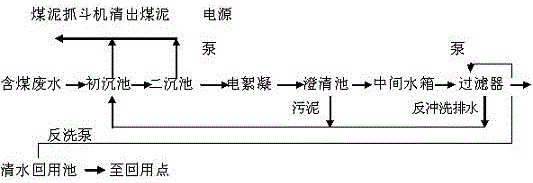

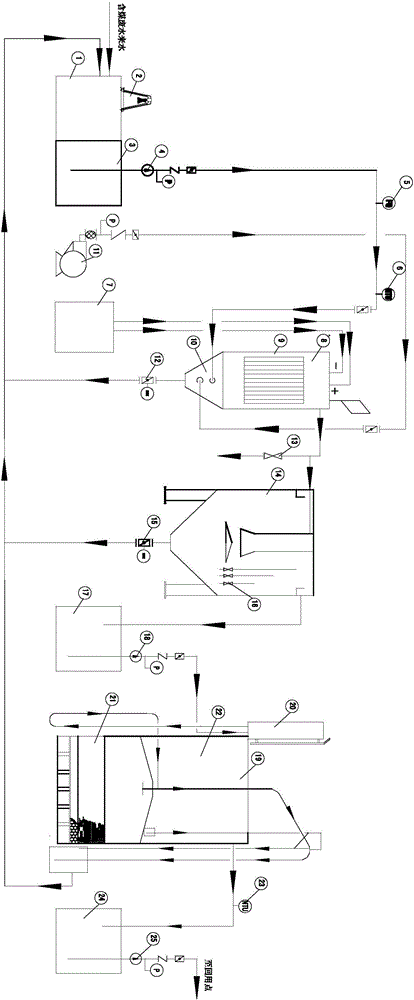

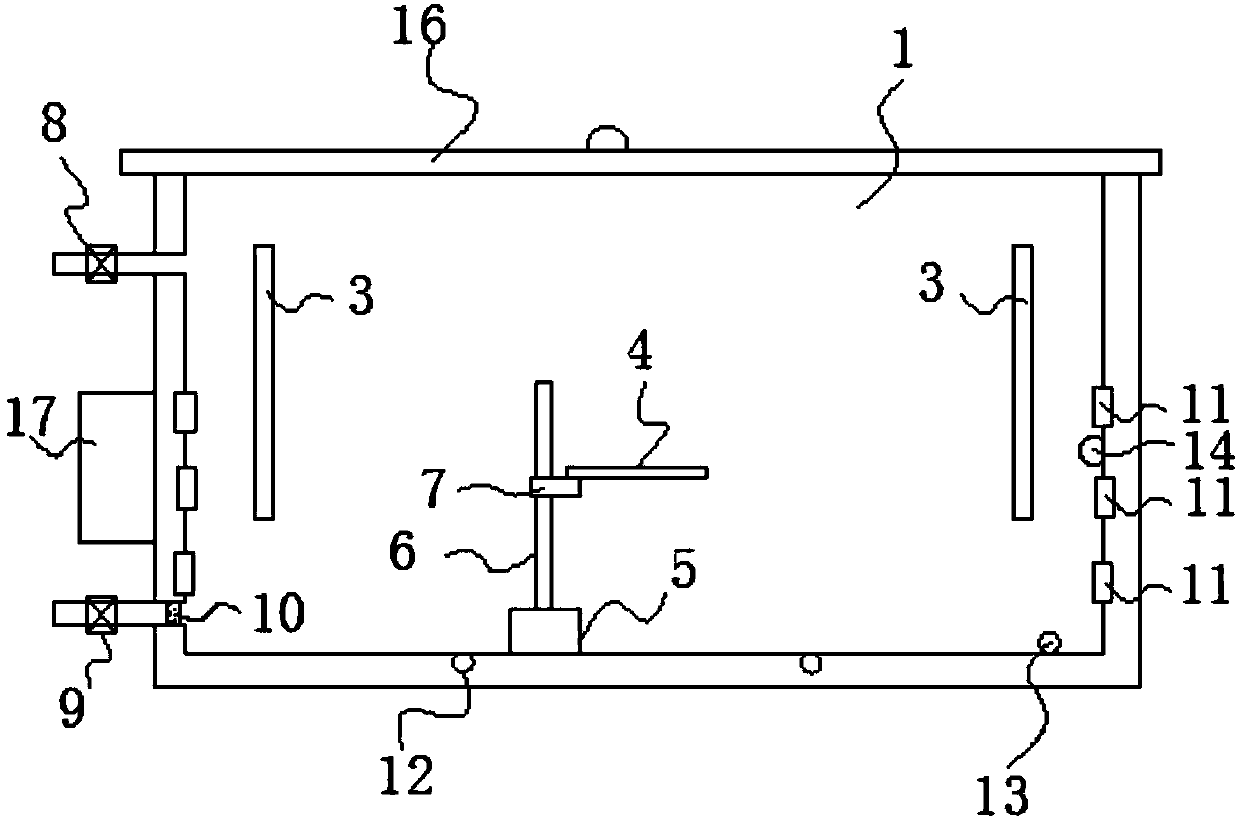

Novel intelligent electric flocculation treatment apparatus of power plant coal-containing wastewater

InactiveCN106045148AEfficient purificationAdaptableTreatment involving filtrationMultistage water/sewage treatmentAutomatic controlTurbidity

A novel intelligent electric flocculation treatment apparatus of power plant coal-containing wastewater is characterized in that the apparatus comprises a coal water primary precipitation tank (1), a secondary precipitation tank (3), a high frequency pulse power supply (7), a vertical electric flocculation box (8), a micro-aeration blower (11), a clarifier (14), a middle water tank (17) and a clear water tank (24), the middle-upper portion of the vertical electric flocculation box (8) is provided with a pole plate (9), the lower portion of the vertical electric flocculation box (8) is provided with a mud hopper (10), coal water goes through an elevator pump (18), enters the vertical electric flocculation box (8) and is electrically flocculated, the electrically flocculated coal water automatically flows into the clarifier (14) and is clarified, the clarified coal water flows into the middle water tank (17), the coal water is conveyed to a valveless filter (19) through a middle water tank elevator pump (18) and is filtered for reuse, an inlet water online turbidity meter (6) is in current connection with the high frequency pulse power supply (7), and the electric flocculation current is automatically adjusted according to the turbidity change of the inlet water. The running of the apparatus can be fully automatically controlled. The apparatus has the characteristics of novel technology, automatic control, stable running, energy consumption and investment cost saving, and substantial environmental and economic benefits.

Owner:国能朗新明环保科技有限公司 +2

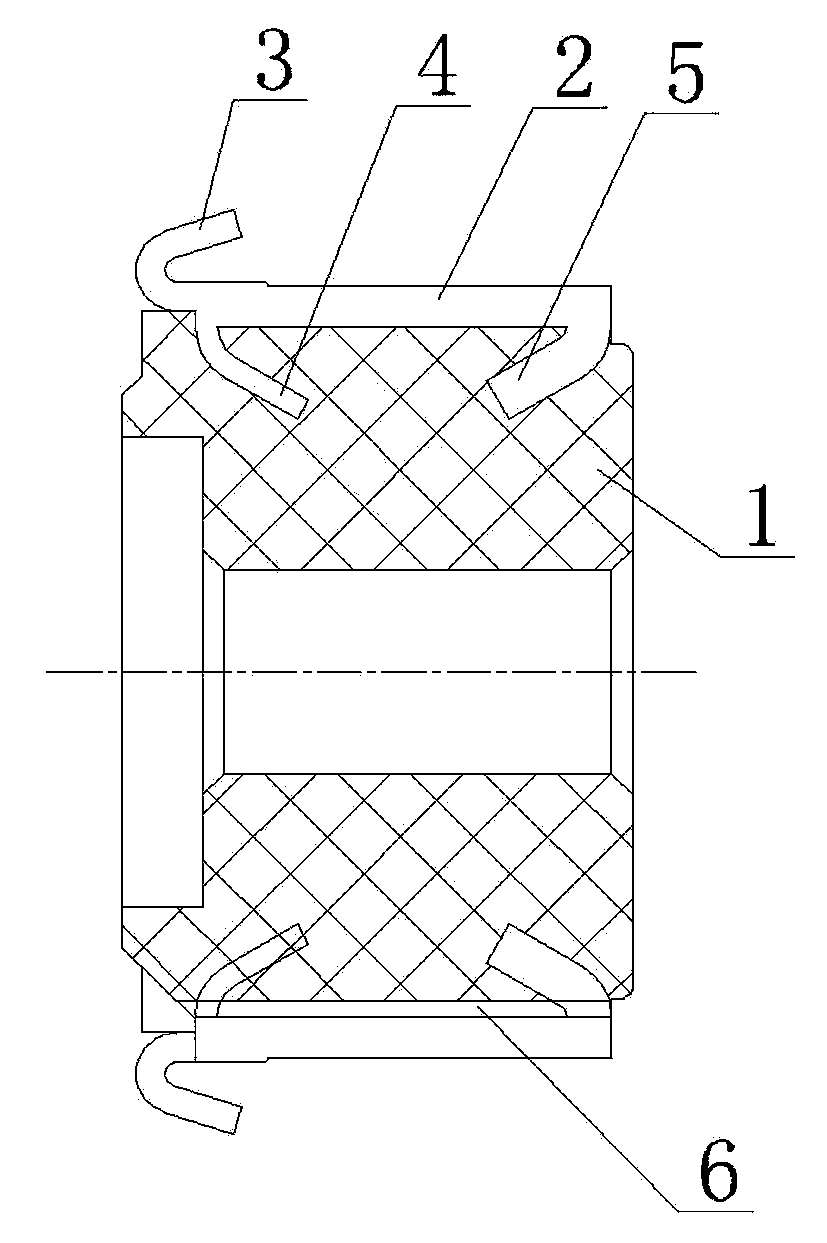

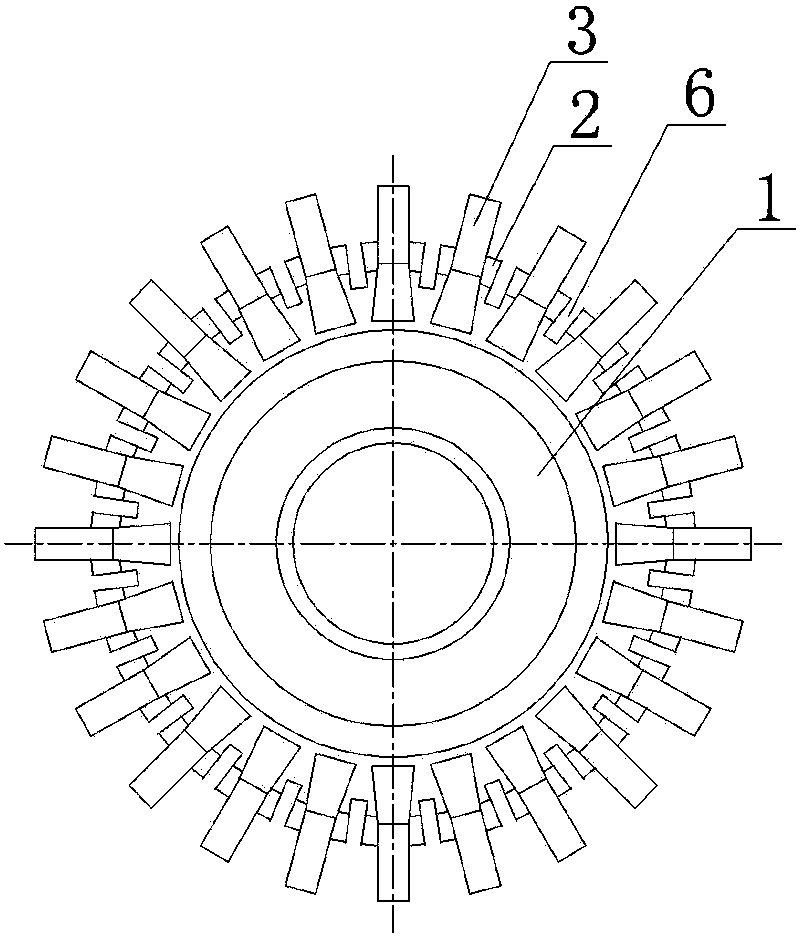

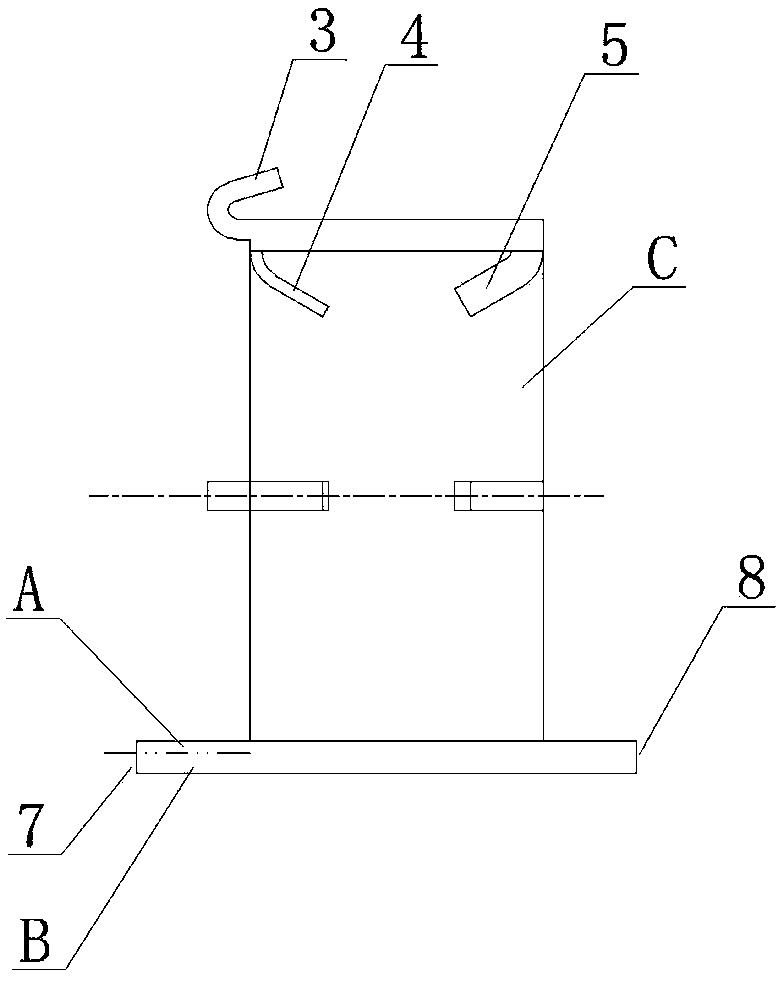

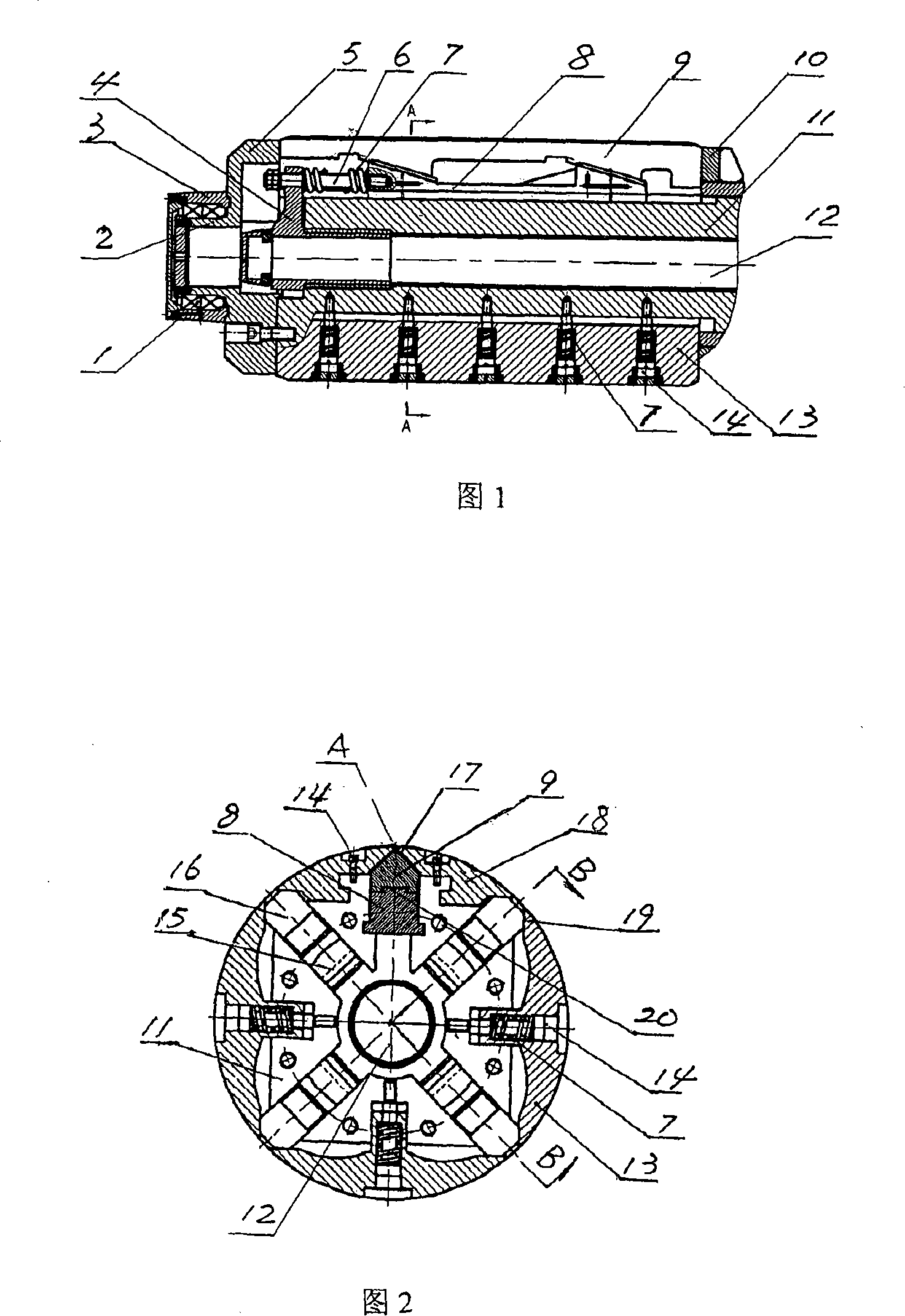

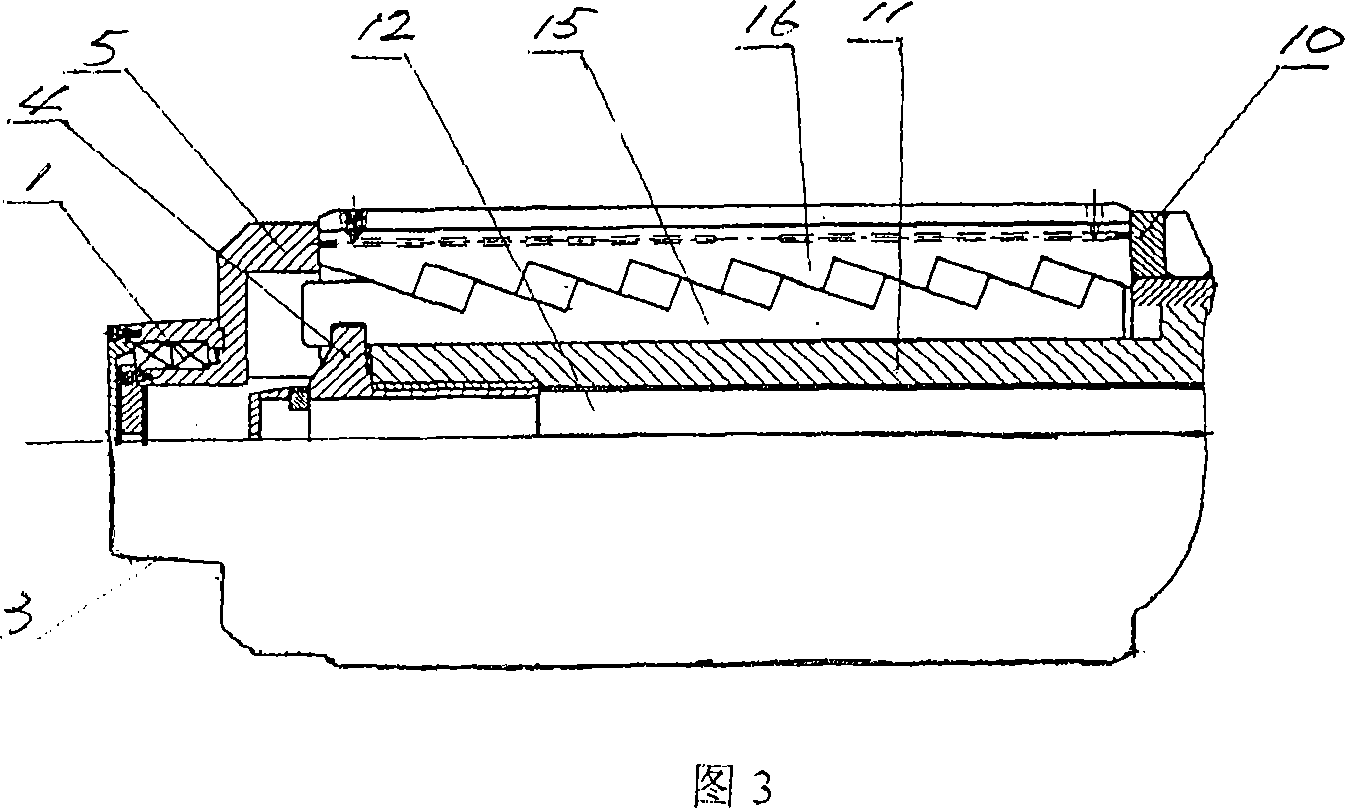

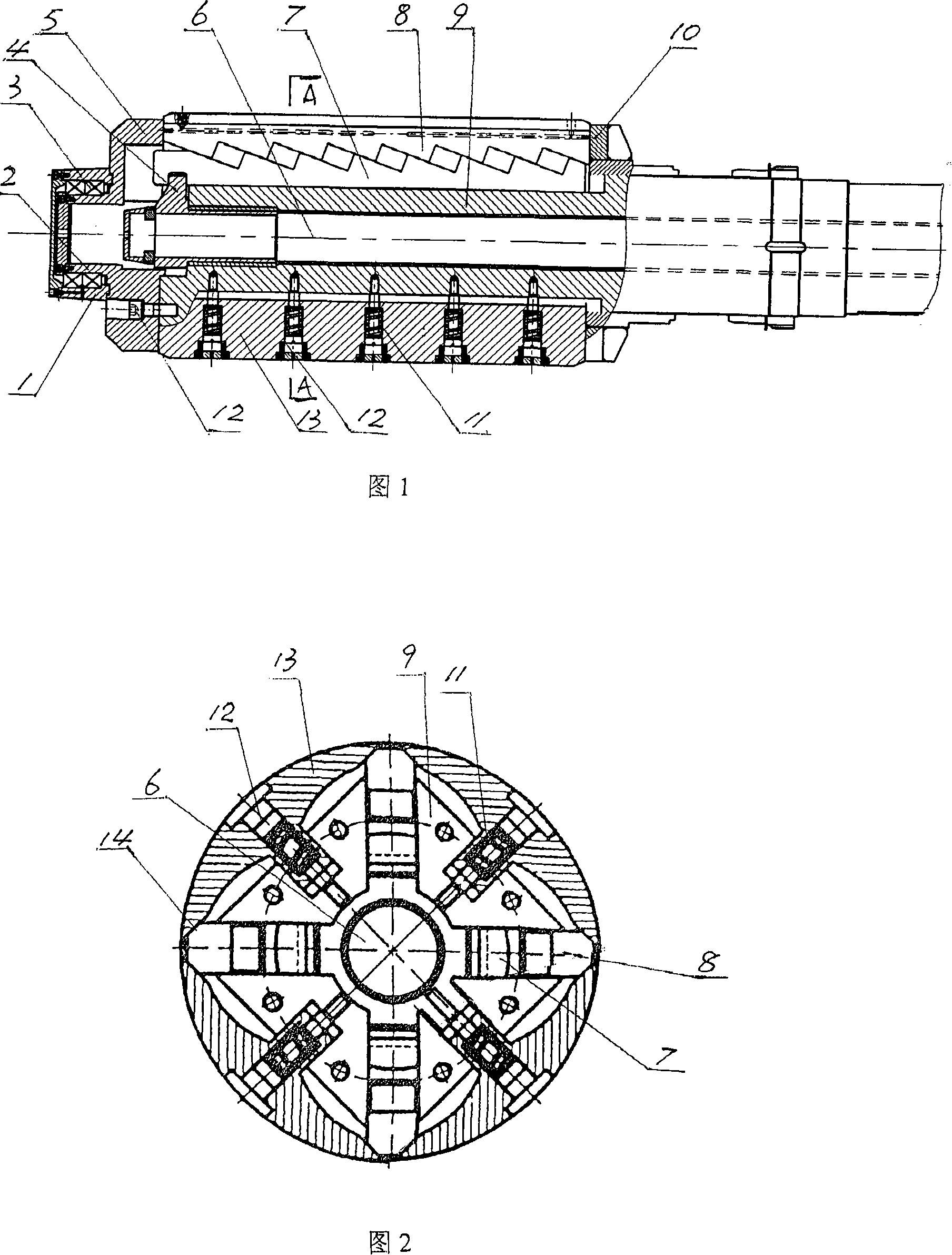

Hook-type commutator product, technology and mould

InactiveCN103904517AWill not affect productionImprove production efficiencyRotary current collectorCommutators manufactureEngineeringCopper

The invention discloses a hook-type commutator product which comprises an insulator and commutator bars distributed on the outer circle of the insulator. Hooks are arranged at the top ends of the commutator bars, and upper hook pins and lower hook pins are arranged on the inner sides of commutator bars to be combined with the insulator. The hook-type commutator product is characterized in that the commutator bar are cylindrical copper shells before bar insulation grooves are formed, upper bar-shaped bodies and lower bar-shaped bodies are arranged at the upper ends and the lower ends of the cylindrical copper shells at equal distances before the cylindrical copper shells are formed, the upper bar-shaped bodies are segmented into inner parts and outer parts in the wall thickness direction, the inner parts are bent inwards and then form the upper hook pins, the outer parts are bent outwards and then form the hooks, the lower bar-shaped bodies are integrally bent inwards and then form the lower hook pins, and the cylindrical copper shells are formed by stamping and coiling copper plates. Through the product structure, small bar distance hook-type commutators can be efficiently manufactured with low cost. Meanwhile, the invention further discloses a technology and a mould for manufacturing the hook-type commutator product.

Owner:ZHEJIANG SONGPU COMMUTATOR

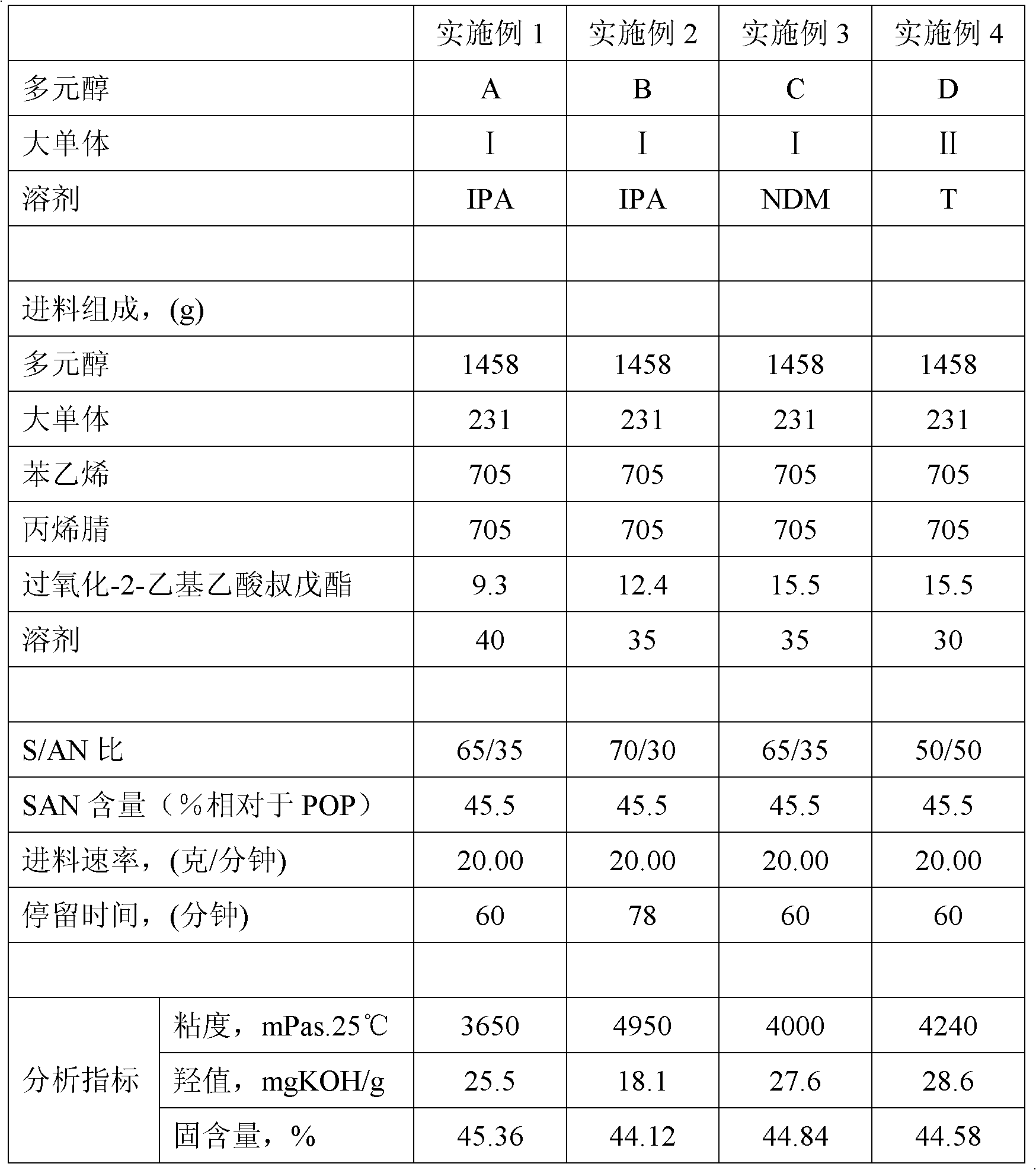

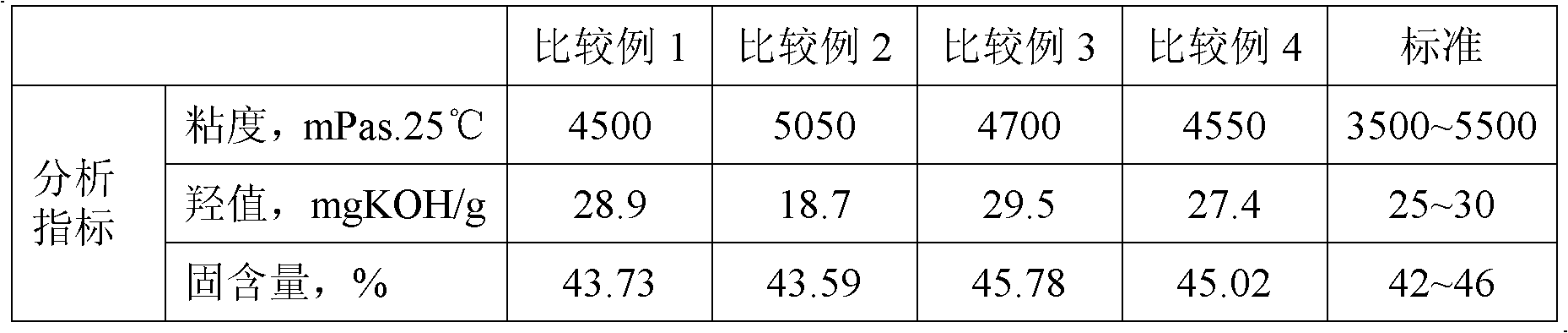

Method for preparing polymer polyol

The invention relates to a method for preparing polymer polyol, which is mainly used for solving the problems that 2, 2'-azobisisobutyronitrile is taken as an initiator in the prior art, decomposed products block pipelines, and normal production is influenced; and moreover, the decomposed products of the 2, 2'-azobisisobutyronitrile are mixed in the product, and the product quality is influenced. The method adopts the mixture of styrene, acrylonitrile, polyoxyalkylene polyether polyol and macromonomer to prepare the polymer polyol at the reaction temperature of at least 90 DEG C with the existence of a radical initiator and solvent with medium chain transfer activity, wherein the radical initiator is selected from peroxide-2-n-butyric acid-tert amyl, and the usage of the radical initiator accounts for 0.1-0.8% of the total weight of monomer. The technical scheme better solves the problems, and the method can be used for the industrial production of the polymer polyol.

Owner:CHINA PETROCHEMICAL CORP

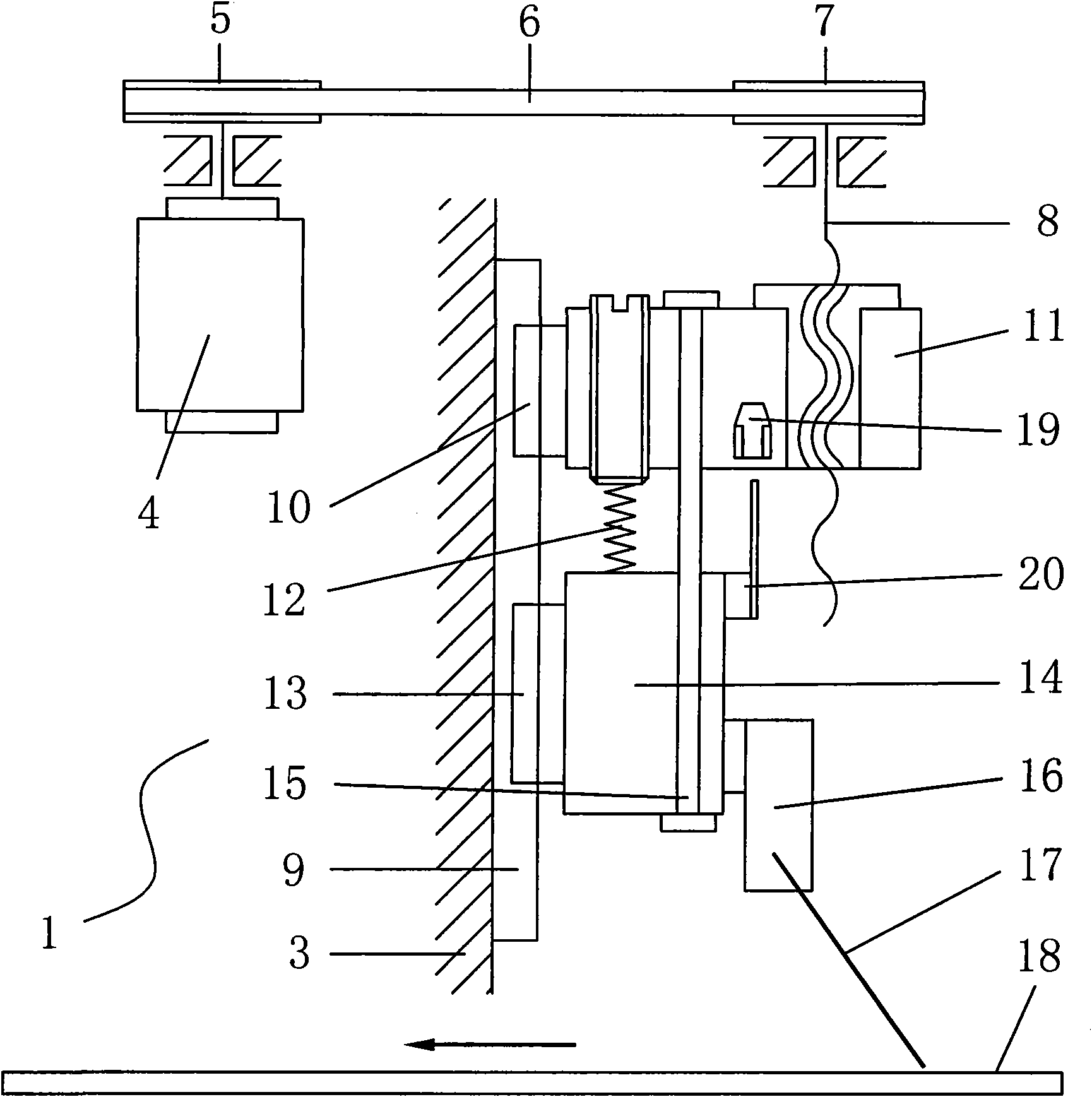

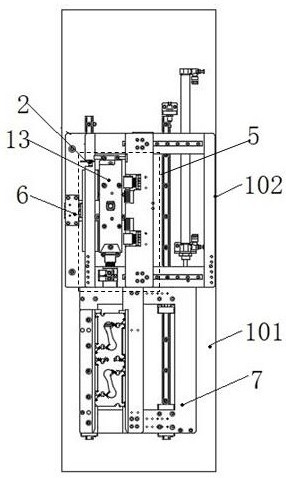

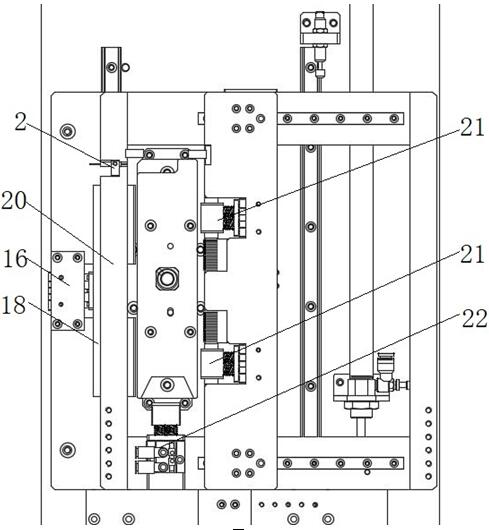

Contact sensing scarper mechanism and full automatic vision printer

ActiveCN101979249AAccurate pressure valueIntelligent controlScreen printersEngineeringPrinted circuit board

The invention discloses a contact sensing scarper mechanism and a full automatic vision printer and belongs to the field of printed circuit board (PCB) printers. A scraper lifting module of the mechanism is assembled with a scraper beam; a stepping motor, a screw rod and a slide rail are respectively assembled with a module seat; the screw rod is connected with the stepping motor through a synchronous belt wheel B, a synchronous belt and a synchronous belt wheel A and is connected with an upper sliding block seat; an upper sliding block is assembled with the upper sliding block seat; a lower sliding block seat is connected with the upper sliding block seat through an adjusting bolt; a lower sliding block is assembled with the lower sliding block seat; the upper sliding block and the lower sliding block are respectively matched with the slide rail; the upper end of a spring is connected with the upper sliding block seat; the lower end of the spring is connected with the lower sliding block seat; a photoelectric sensor is assembled with the upper sliding block seat; a sensing sheet which has sensing relation with the photoelectric sensor is arranged on the lower sliding block seat; a scraper seat is assembled with the lower sliding block seat; and a scraper is assembled with the scraper seat. The mechanism is movably assembled with a frame of the full automatic vision printer, so that the control of the mechanism is more intelligent, and the accuracy is higher.

Owner:GKG PRECISION MACHINE

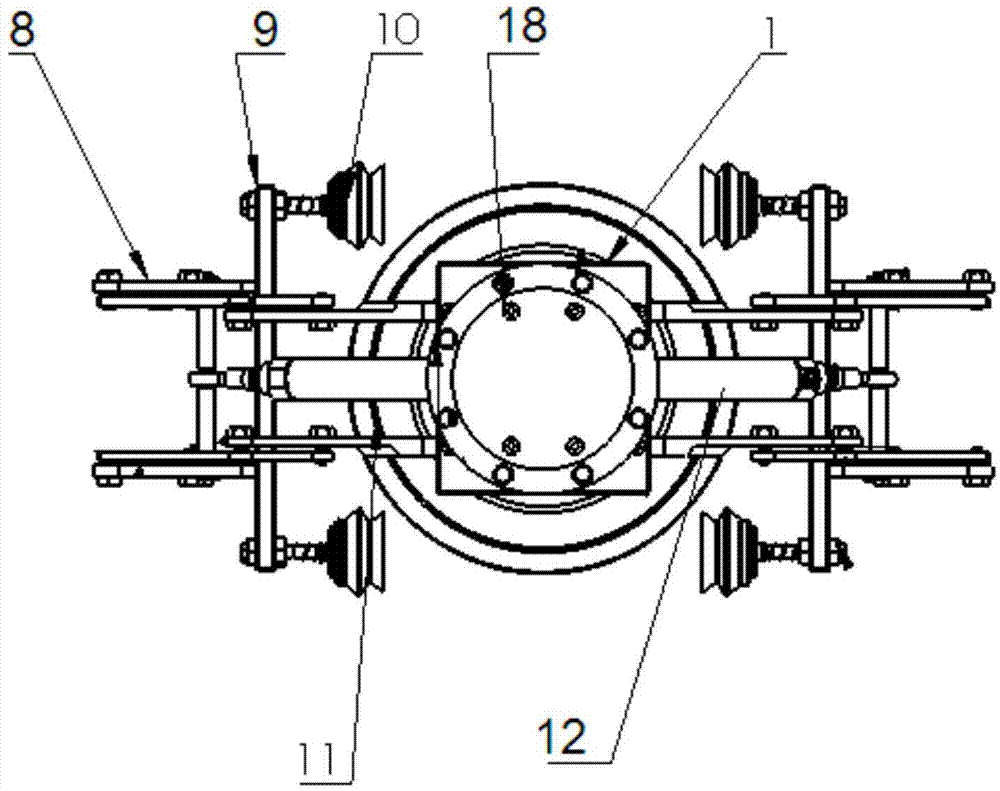

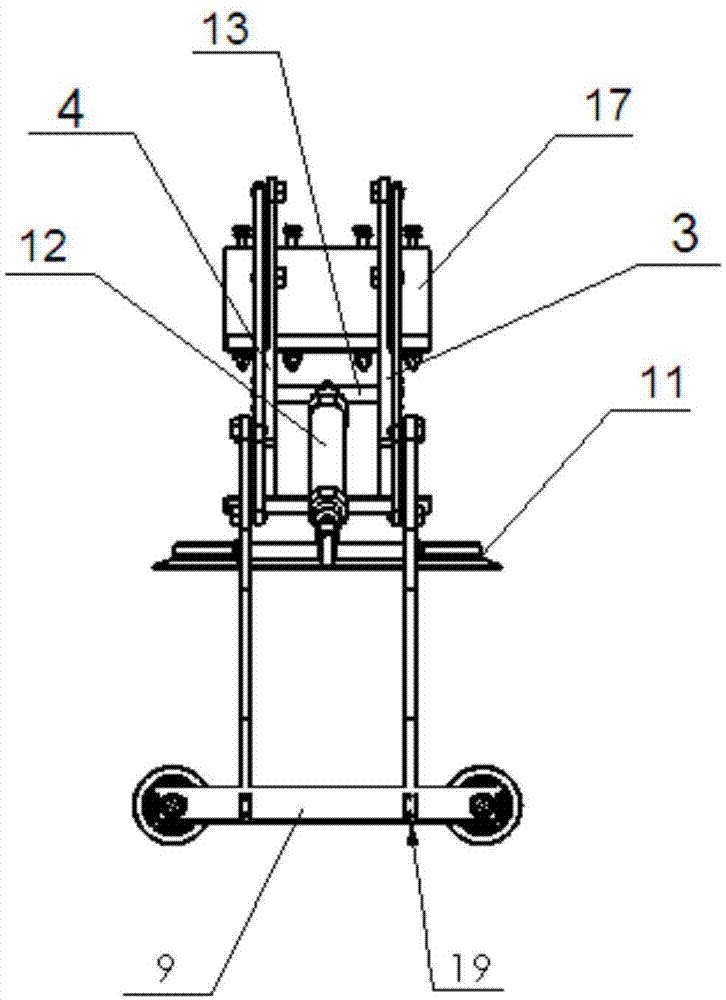

Gapless expansion and retraction reel with automatic clamping function

InactiveCN101147932AWith automatic clamping functionAvoid lock situationEngineeringMechanical engineering

The present invention discloses a seamless collapsible drum with automatic clamping function. It includes a mina shaft, a moving shaft, three curved plates and a retainer cover. On four corners of front part of said main shaft are respectively set axial recessed groove and axial toothed bar. The front end of said moving shaft is fit with seaming by means of cross shifting jaw. The curved plate is connected with said main shaft by means of spring and screw. The axial toothed bar and axial recessed groove are formed into slide fit between them. The outer side of said axial toothed bar is equipped with a radial toothed bar, they are slide-meshed together. On another face of said main shaft two narrow curved plates are set, said two narrow curved plates are connected with correspondent face of said main shaft by means of spring and screw. In the main shaft plane middle of inner side of two narrow curved plates a longitudinal slideway is set, in the longitudinal slideway interior an oblique wedge is set, the external surface of said oblique wedge is equipped with a caulking strip, and between them a slide fit is formed. The front end of said oblique wedge is connected with the front end of its moving bar by means of cross shifting jaw, guide bar and spring. The application of said collapsible drum can save labour and is safe for winding strip material, and between the main shaft and axial toothed bar they can not be locked.

Owner:朱惠兴

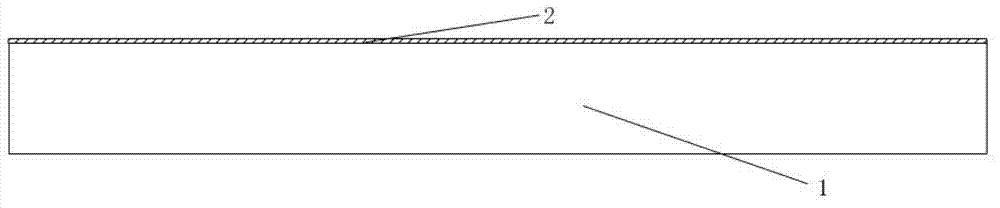

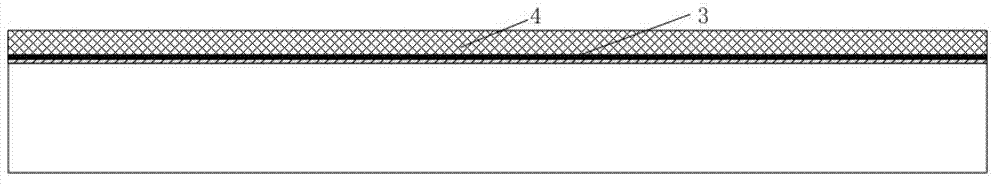

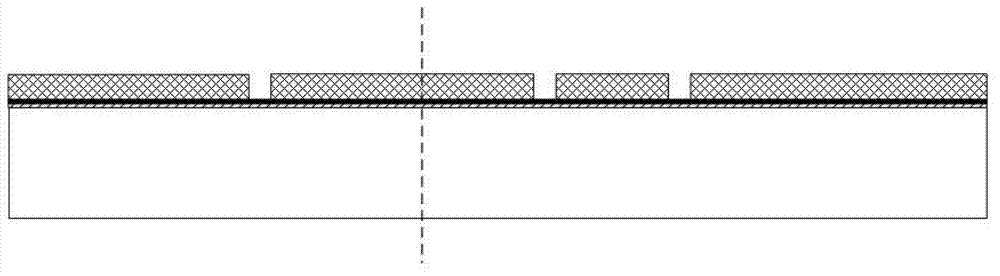

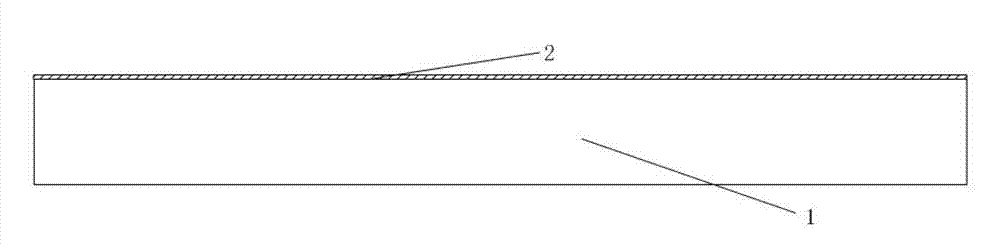

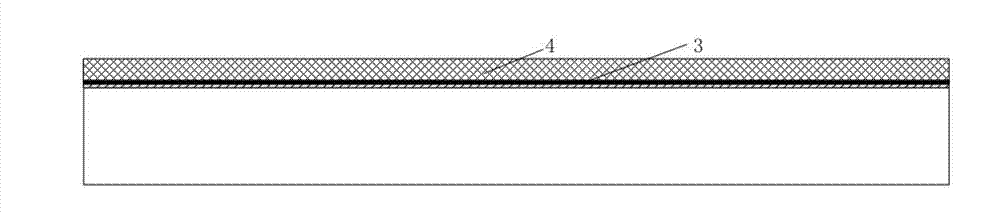

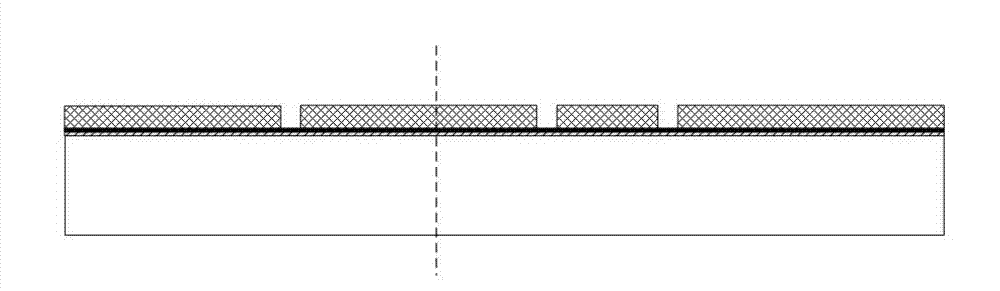

Method for determining etching time of sacrificial layer in real time

InactiveCN102963861ARealize online testNo impact on process reliabilityDecorative surface effectsChemical vapor deposition coatingNon destructiveEtching

The invention relates to a method for determining etching time of a sacrificial layer in real time. The method comprises the following steps of: manufacturing the sacrificial layer and a structural layer of an MEMS (Micro Electro Mechanical System) device on a substrate by virtue of a surface sacrificial layer process; depositing a metal layer on the structural layer; and carrying out wet etching on the sacrificial layer, and determining finish time of etching by observing the dropping condition of metal in the metal layer. By virtue of the method, the etching time of the sacrificial layer can be determined in non-contact and non-destructive manners through naked-eye observation, and the process quality and the rate of finished products of the MEMS can be improved.

Owner:PEKING UNIV

Method for planting two crops of red Bharati grapes a year in intelligent greenhouse

InactiveCN107278792AGuaranteed qualityGuaranteed outputSeed and root treatmentClimate change adaptationViticultureVitis vinifera

The invention belongs to the technical field of agricultural planting, relating to a method for planting two crops of red Bharati grapes a year in an intelligent greenhouse. By means of advantages of the intelligent greenhouse, temperature and illumination in all growth periods of grapes are effectively regulated. By management measures such as reasonable watering and fertilizing, shoot keeping and pinching, leaf picking and pruning, dormancy breaking and pre-germination, winter buds can germinate in the current year so that the second growth period within the year is started. Therefore, the targets of obtaining economic yield by planting grapes in the same year and achieving one-year-two-harvest cultivation starting from the following year are fulfilled. The fruits in the first season come into the market in the late June and fruits in the second season appear on the market before Spring Festival after New Year Day, which means avoiding the marketing period for open cultivation of grapes in the North. The unit selling price of products is increased by 3-5 times and the twice total yield of fruits goes up by 50%. The time gap for ripening between fruits in the first season and fruits in the second season is over six months. Sufficient time is provided for grapevines to accumulate nutrients. Therefore, quality and yield of grapes in the first season are ensured while production of grapes in the following year is not affected.

Owner:平度市职业中等专业学校

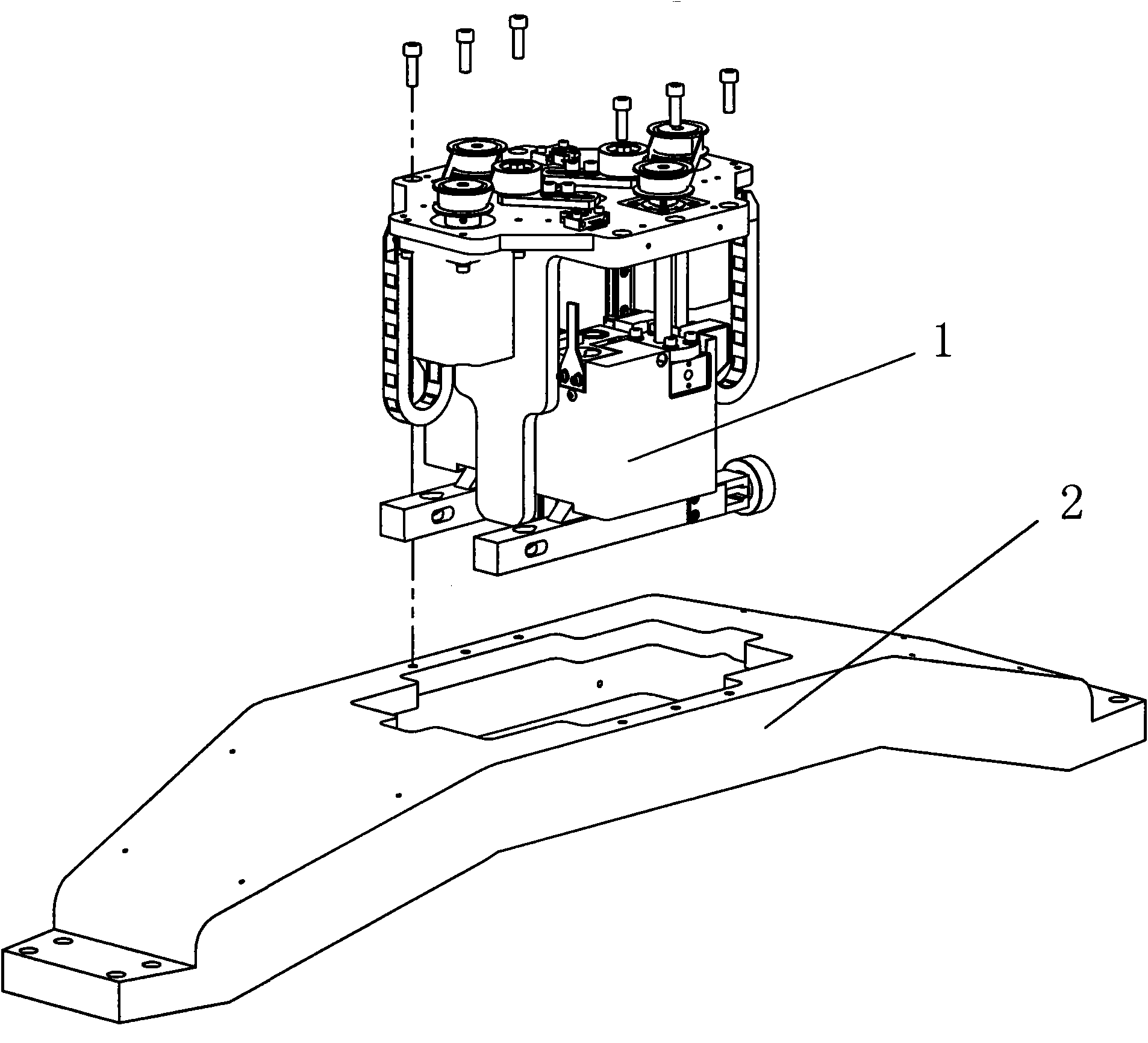

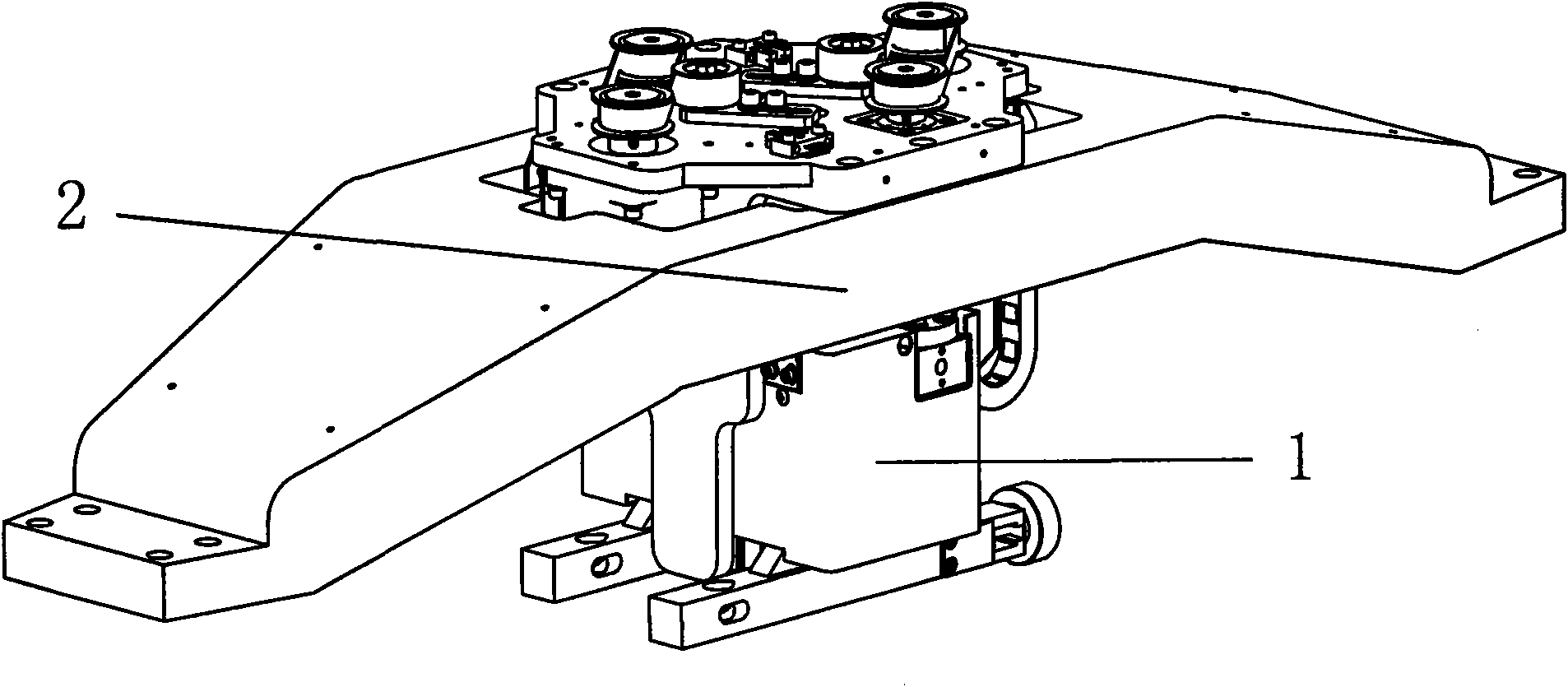

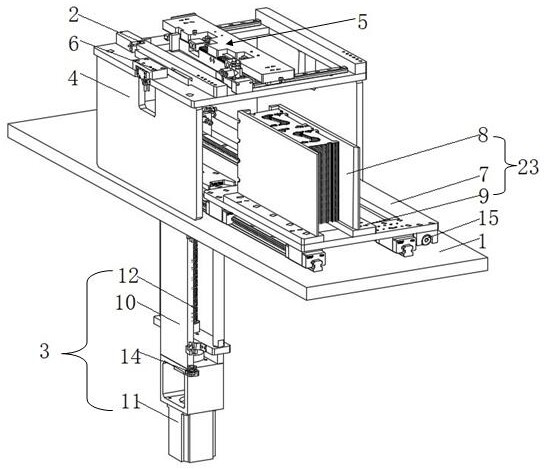

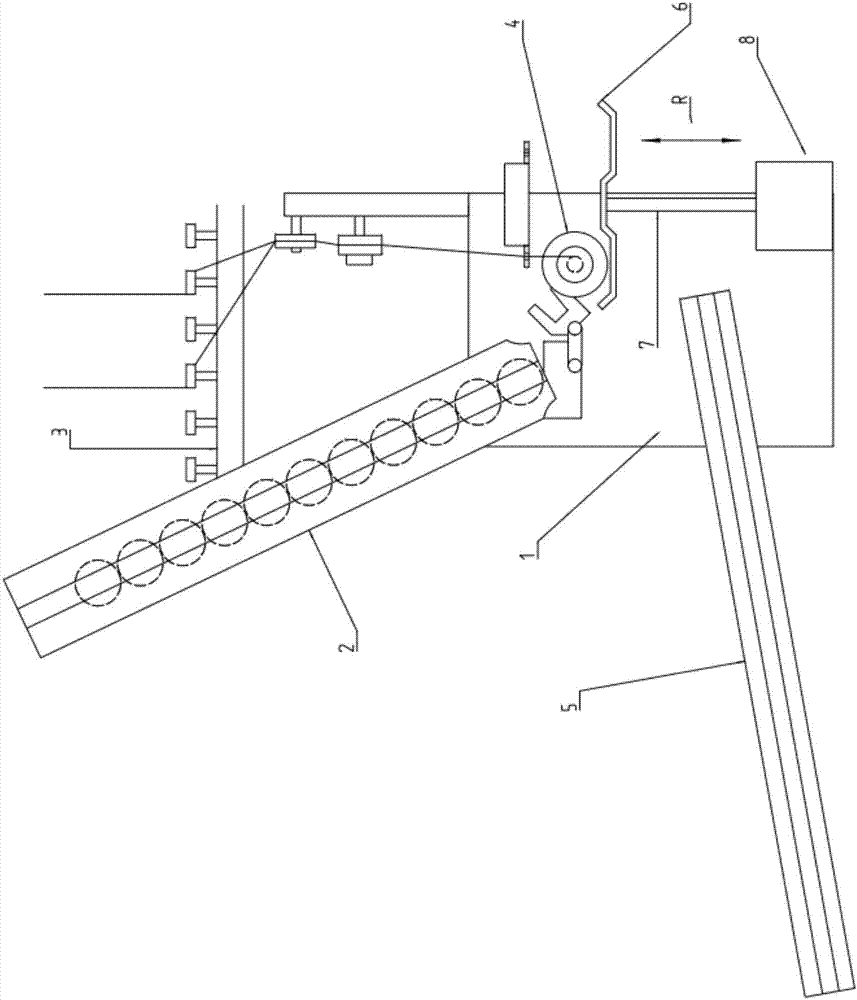

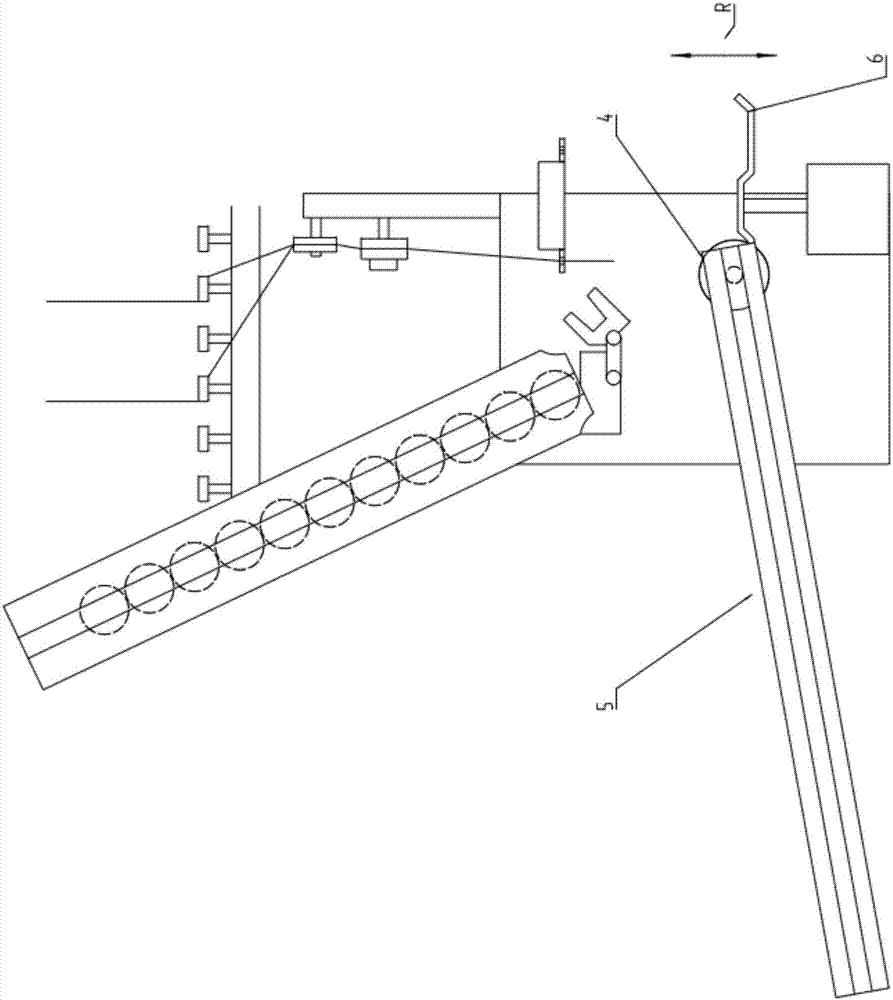

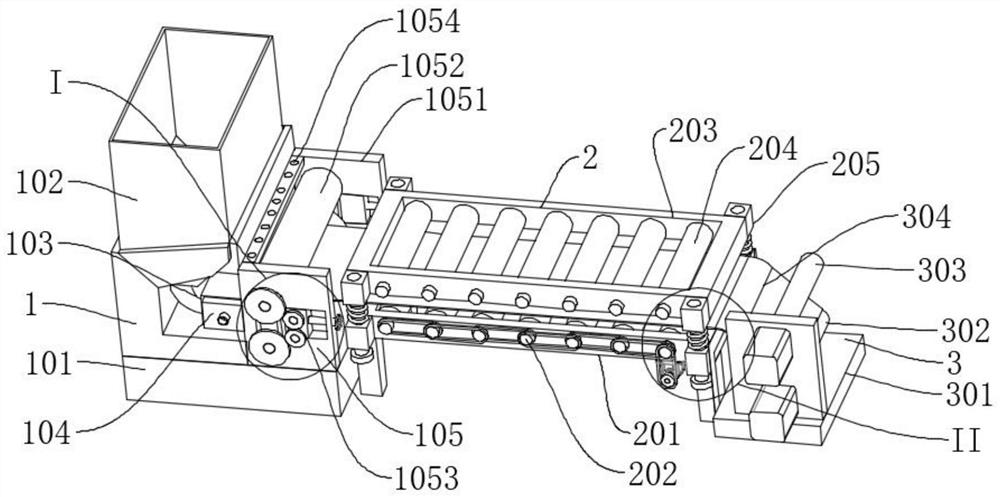

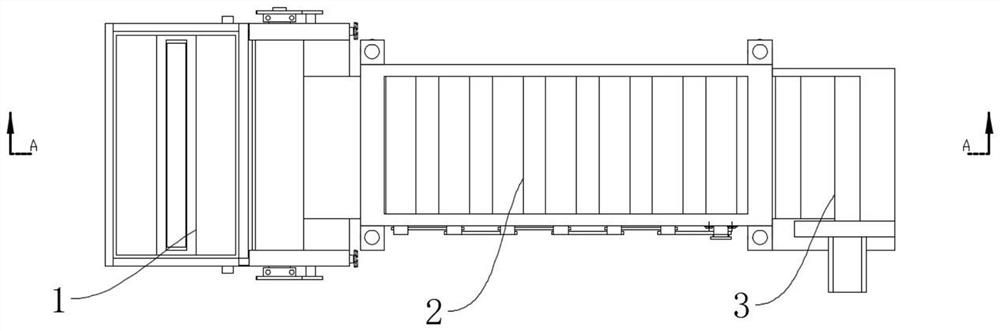

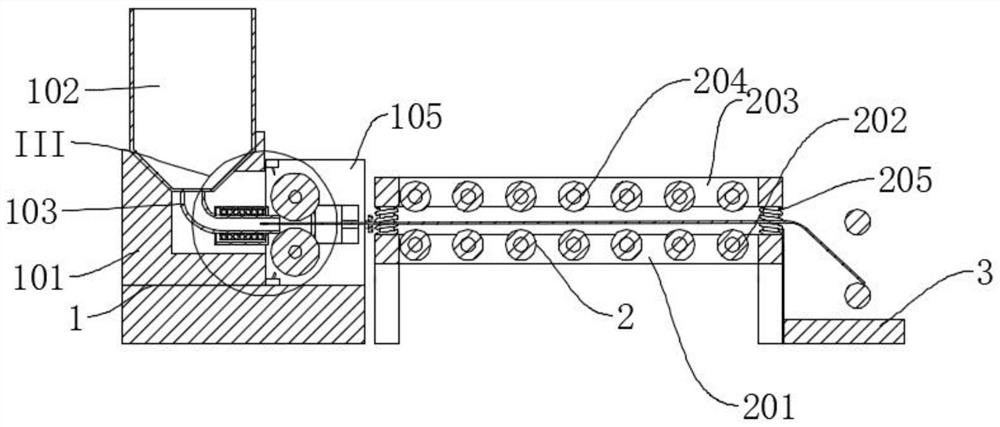

Cache type non-stop PCB feeding device

InactiveCN113353605AWill not affect productionIncrease productivityConveyor partsProcess engineeringMechanical engineering

The invention discloses a cache type non-stop PCB feeding device. The cache type non-stop PCB feeding device comprises a workbench and a PCB stock bin used for placing PCBs, wherein the PCB stock bin is located on the workbench, the bottom of the PCB stock bin is slidably connected with the workbench in the length direction, and the workbench is divided into a feeding station and a supplementing station; a jacking mechanism used for jacking the PCBs in the PCB stock bin upwards to a feeding position is arranged below the feeding station; and a locating frame is arranged on the feeding station, and a locating assembly used for locating the PCBs in the circumferential direction and a separating mechanism used for temporarily supporting the remaining PCBs in the stock bin when the jacking mechanism descends and the PCB stock bin retreats for supplementing are arranged on the locating frame. The cache type non-stop PCB feeding device is compatible with the PCBs of various sizes and specifications, the mechanism can realize feeding one by one after the stock bin is filled with the PCBs, after a certain number of materials is left, the separating mechanism is started, meanwhile, the jacking mechanism descends, the PCB stock bin retreats to a supplementing position and sends out a prompt signal to prompt adding, after the adding is completed, the materials are automatically connected with the separating mechanism, and non-stop feeding is realized.

Owner:中电鹏程智能装备有限公司

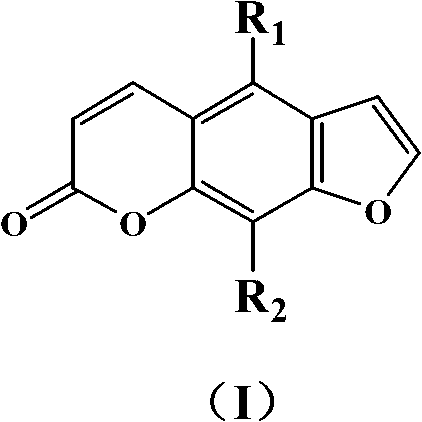

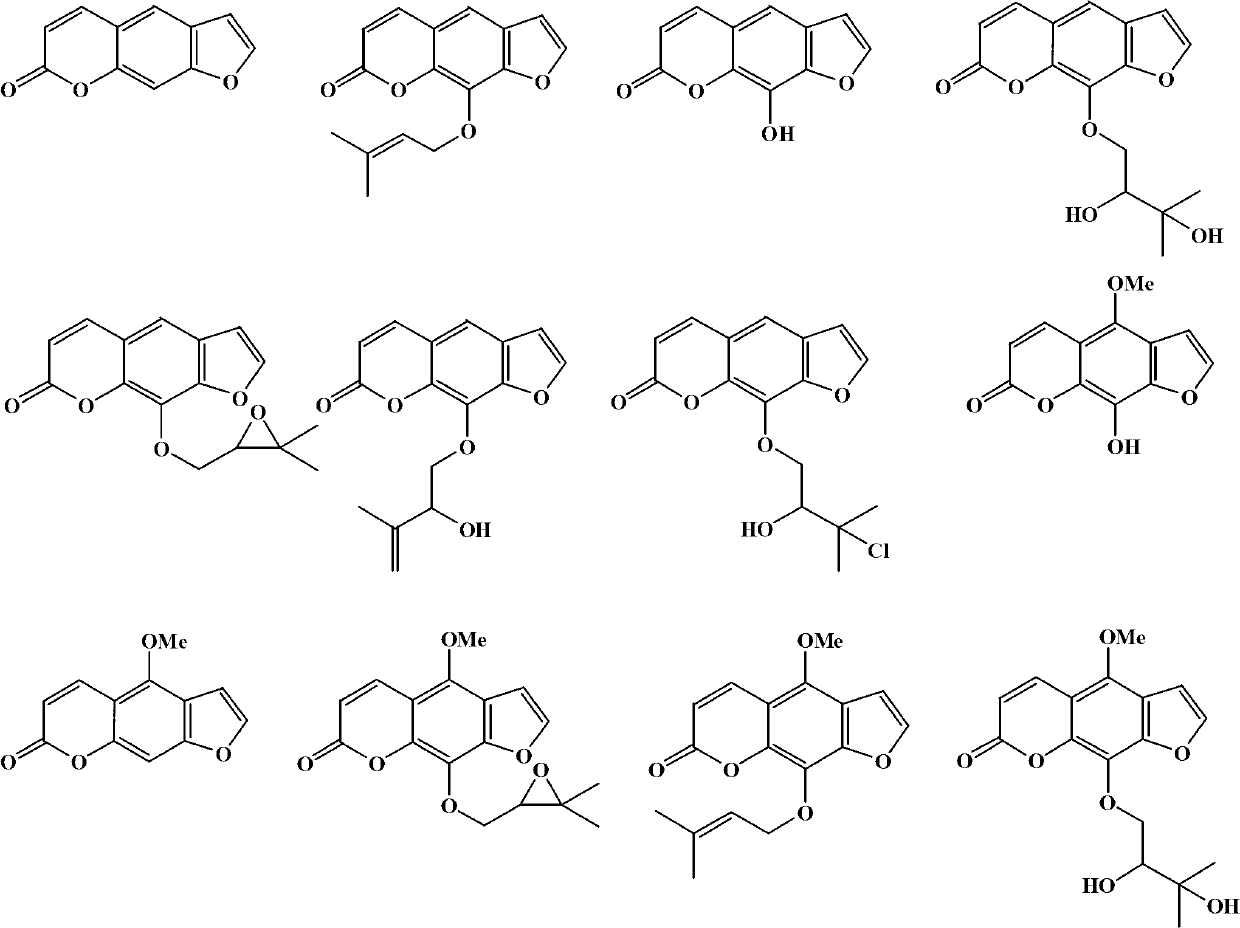

Application of furan coumarin compound in reducing toxic effect of amide herbicide on crops

ActiveCN102823588AReduce or eliminate harmWill not affect productionBiocideAnimal repellantsFuranHerbicide safener

The invention relates to an application of a furan coumarin compound, in particular to an application of a furan coumarin compound expressed in the general formula (I) and a composition thereof to protecting crops against the poison of an amide herbicide. The compound can be used for preparing a herbicide safener. The application of the furan coumarin compound has the beneficial effects that the harm of the herbicide to the crops can be reduced, the application scope of the herbicide is enlarged, the new application prospect is provided for the herbicide, the service life is prolonged, the development of new varieties is facilitated, and meanwhile, as the harm to the crops is reduced or eliminated, the yield of the crops is not affected.

Owner:HUNAN AGRICULTURAL UNIV

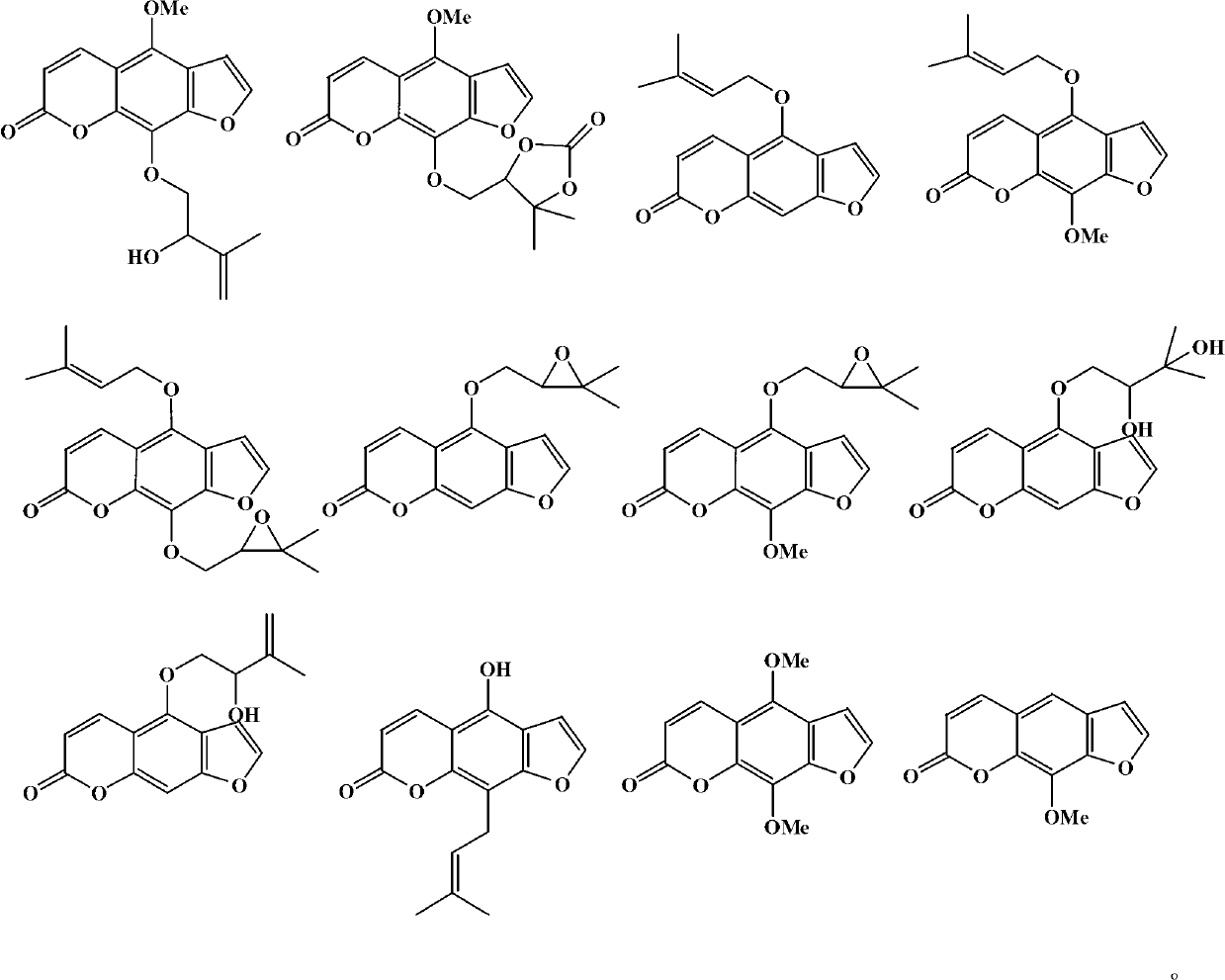

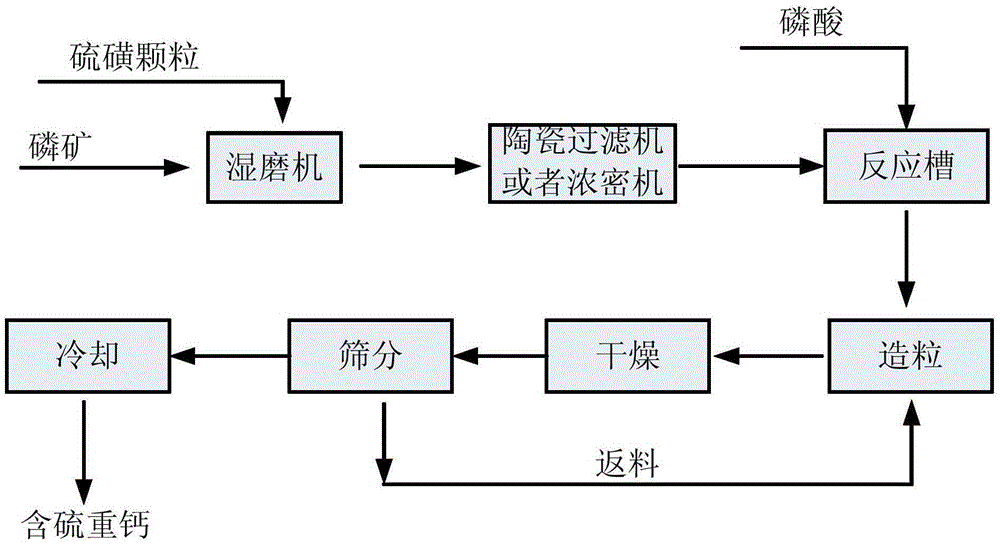

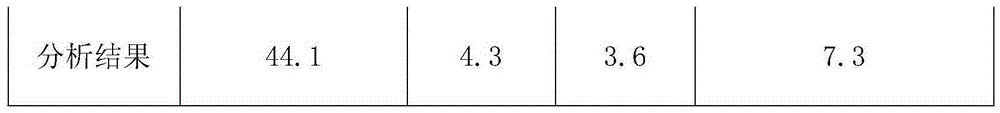

Preparation method of sulfur-containing heavy calcium

ActiveCN105254341AOvercome the disadvantage of uneven mixingImprove economySuperphosphatesPhosphatePhosphor

The invention discloses a preparation method of sulfur-containing heavy calcium. The preparation method comprises carrying out wet grinding on phosphate rock and elemental sulfur particles, conveying the ground product into a ceramic filter or a thickener, removing a part of water, conveying the materials into a slurry process-based heavy calcium production device, feeding phosphoric acid into the device, carrying out reaction preparation, carrying out granulation and carrying out drying to obtain a finished product. The preparation method utilizes the existing phosphate rock wet grinding device and the heavy calcium production device to produce fertilizer containing two or more nutrients such as phosphor and sulfur, does not change the original technology route and provides a low-cost product up-gradation method for the traditional device. The product contains uniform elemental sulfur, greatly reduces material returning frequency and reduces dust explosion possibility.

Owner:YUNNAN YUNTIANHUA

Local electroplating apparatus of mold

The invention discloses a local electroplating apparatus of a mold. The local electroplating apparatus comprises an electroplating bath, a heater, an anode conductive rod and a cathode conductive seat, wherein the bottom and the inner side of the electroplating bath are provided with a drive unit for driving the cathode conductive seat to lift up and down; the drive unit comprises a motor, a leadscrew and a slide block, the slide block sleeves the lead screw, the cathode conductive seat is installed on the slide block, the cathode conductive seat is provided with a clamp for storing the mold,the upper end of one side of the electroplating bath is provided with a liquid injection valve, the lower end of the electroplating bath is provided with a liquid discharging valve, and a filter netis disposed on the upstream of the liquid discharging valve in the electroplating bath; and the local electroplating apparatus also comprises a concentration sensor, a liquid level sensor and a PLC controller. By adopting the local electroplating apparatus, the automatic local electroplating of the mold can be realized, the concentration of an electroplating solution can be detected in real time,the electroplating solution can be automatically replaced, the thickness of a plating layer is uniform, the appearance and the mechanical performance of the local plating layer of the mold are ideal,and the strength and appearance of the mold can be improved.

Owner:苏州特精模具有限公司

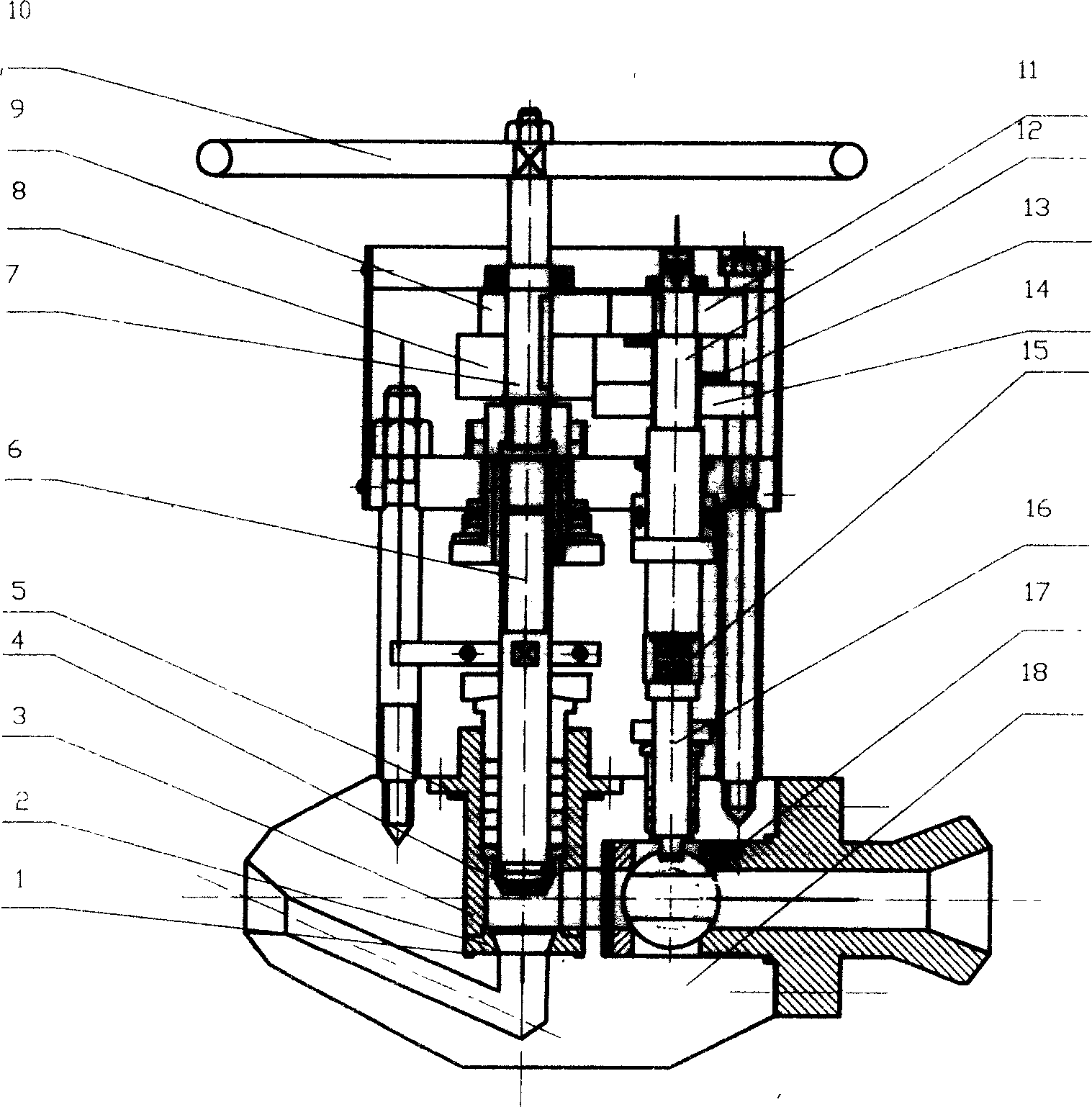

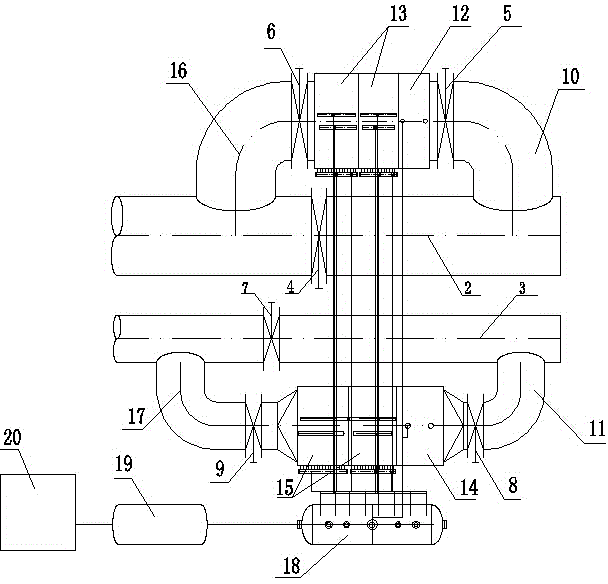

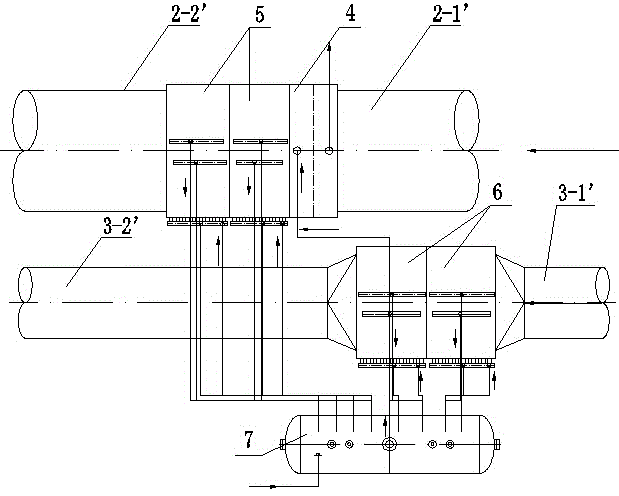

Movable combination valve

InactiveCN101012898AEasy to processWill not affect productionPlug valvesOperating means/releasing devices for valvesEngineeringControl quality

The invention relates to a movable composite valve formed by a stop valve and a ball valve, wherein, the cage sheath of stop valve is movably connected to the valve base; the valve base is movably connected with the valve body; the cage sheath has stuff holes; the valve element is movable; the valve rod is formed by lower stop valve rod and upper stop valve rod connected with spline; the upper stop valve rod is fixed with an active gear and an active cam while the active cam is above the active gear; the lower ball valve rod and upper ball valve rod of ball valve are connected via the connecting sheath; the upper valve rod is fixed with an inactive cam above the inactive gear; the inactive cam and the inactive gear are arranged with a clutch; the inactive gear is connected with the screw of upper ball valve rod; the active gear of stop valve is meshed with the inactive gear of ball valve; the active cam of stop valve is meshed with the inactive cam of ball valve. The cage sheath and the valve base are separated, with controlled quality and repaired property on site. And the invention uses cam device to improve the accuracy of seal position of ball.

Owner:ZHUZHOU HONGYUAN HIGH PRESSURE VALVE

Semi-finished product removing device of doubling machine

InactiveCN107973178AImprove removal efficiencyHigh degree of automationFilament handlingBobbinWork in process

The invention relates to a semi-finished product removing device of a doubling machine. The semi-finished product removing device of the doubling machine comprises a machine table, a bobbin supply rack, a doubling rack, a bobbin, a removing tank, a bracket, a sliding rod and an actuator, wherein the bobbin supply rack is arranged at the position, close to one end, of the front side of the machinetable, the bobbin to be wound with a wire is accommodated in the bobbin supply rack, a rotor is arranged in the middle of the front side of the machine table and used for removably installing the bobbin and driving the bobbin to rotate, the removing tank is arranged below the rotor, the bracket, the sliding rod and the actuator are arranged between the bobbin supply rack and the removing tank, theactuator is used for driving the sliding rod to move back and forth in the vertical movement direction, one end of the sliding rod is connected to the actuator in a sliding mode, and the other end ofthe sliding rod is fixedly connected to the bracket.

Owner:广东亿洋管业科技有限公司

On-line Repair Method of Corrugated Compensator in Gas Pipeline

InactiveCN102261538AEnsure safetyPlay the role of stretch compensationPipe elementsGas pipelineCoke oven gas

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Method for separating and purifying human antithrombin-III from human plasma

InactiveCN103613662AThe process steps are simple to operateImprove virus safetyPeptide preparation methodsProtease inhibitorsUltrafiltrationMolecular biology

The invention discloses a method for separating and purifying human antithrombin-III from human cryoprecipitate-reduced plasma. The method comprises the operating steps of performing chromatography on the human cryoprecipitate-reduced plasma, performing S / D (solvent / detergent) virus inactivation, and performing affinity chromatography for the second time; performing ultrafiltration; performing sterilizing filtration; filtering with a 20nm nano-filtration membrane to remove viruses; subpackaging; performing freeze-drying; performing dry heat virus inactivation; separating and purifying human antithrombin-III from the human cryoprecipitate-reduced plasma; performing pre-filtration treatment, and then directly separating and purifying antithrombin-III (AT-III) out of the plasma by adopting an affinity chromatography technology; adding an appropriate amount of a protective agent, replacing pasteurella virus inactivation process with an S / D virus inactivation process to reduce the loss and activity and shorten the preparation time; then performing affinity chromatography for the second time to further purify the AT-III, and finally performing the steps of ultrafiltration, virus removal through nano-filtration with a 20nm nano-membrane, freeze-drying and the like, wherein the purity of the final product is more than 95%, the specific activity is more than 6IU / mg, the virus safety is high, and blood plasma can not be influenced during preparation to produce a downstream product.

Owner:BLOOD TRASFUSION INST CHINESE ACAD OF MEDICAL SCI +1

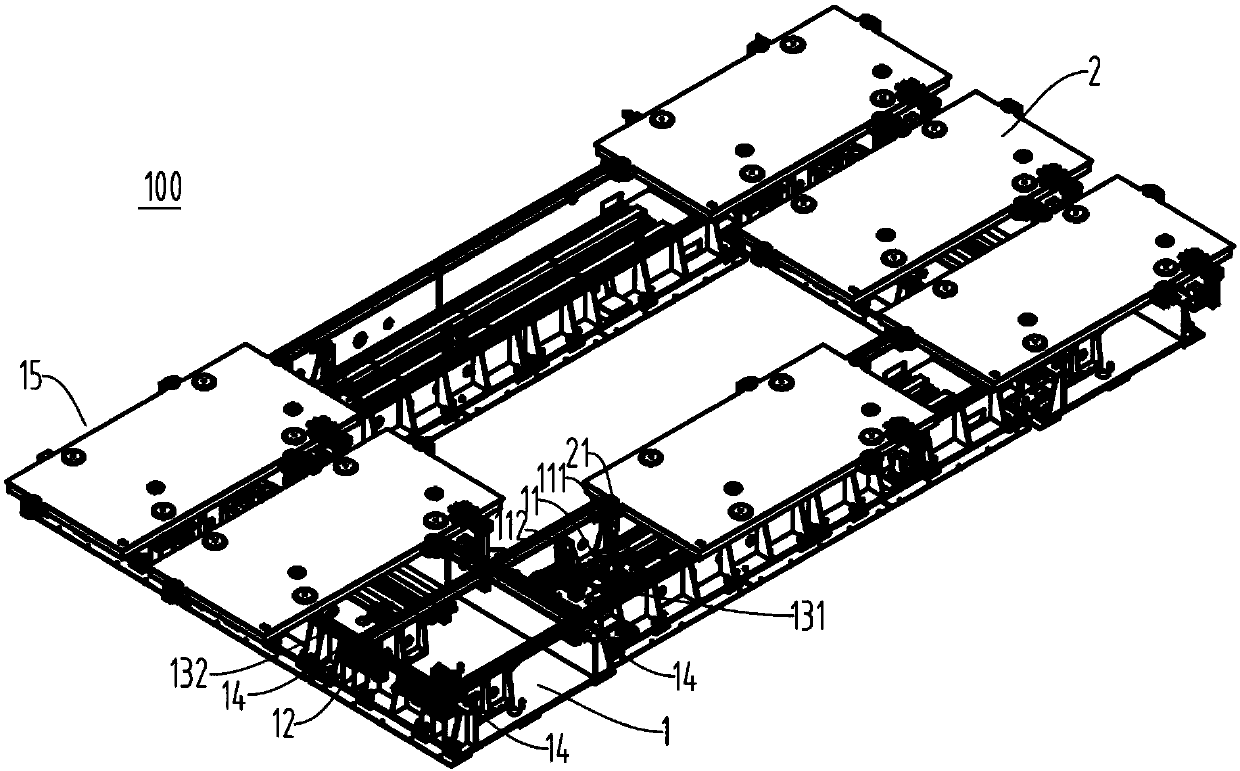

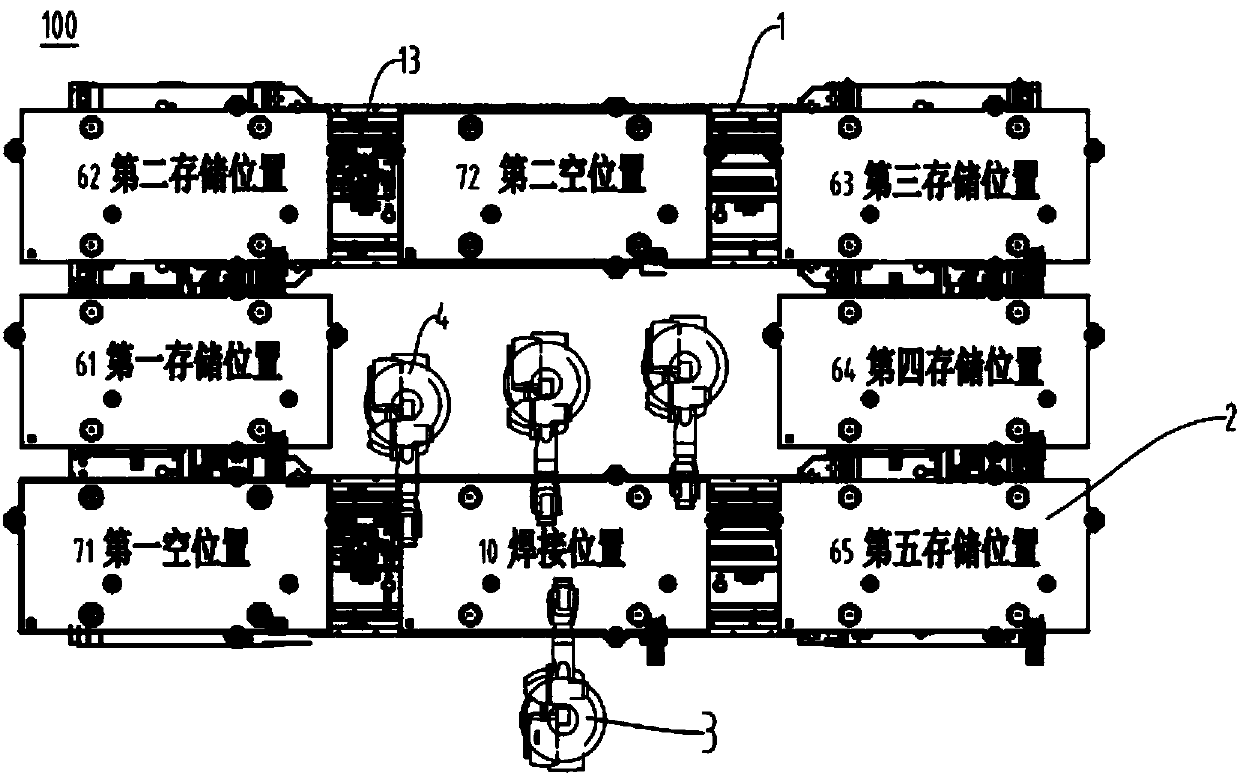

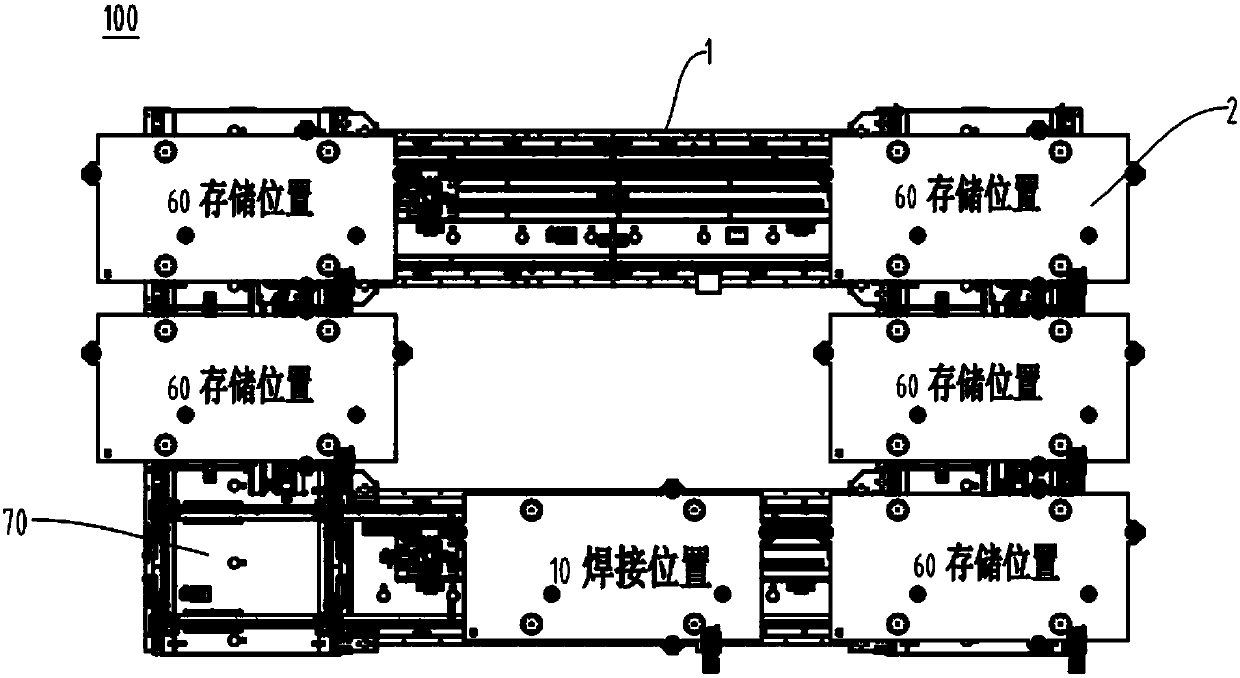

Welding tool, welding production line and welding method of vehicle

InactiveCN109894784ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention relates to a welding tool, a welding production line and a welding method of a vehicle. The welding tool comprises a base and multiple clamps used for fixing a vehicle to be welded. Thebase is provided with a welding machine position used for storing the clamps and a storing position. The clamps are arranged on the base in a sliding manner so as to slide from the welding position tothe storing position along the preset path, or slide from the storing position to the welding position. In this way, by means of the multiple clamps, the vehicle to be welded can be fixed, welding isconvenient, meanwhile, the multiple clamps are arranged on the base in a sliding manner, the vehicle located on the storing position can be switched to the welding position sequentially to be welded,production of the whole vehicle is not influenced, switching time is short, and the working efficiency is improved. In addition, the welding tool is wide in application range, applicable to the samevehicle model and different vehicle models, simple in structure, convenient to operate, flexible and efficient.

Owner:BORGWARD AUTOMOTIVE CHINA CO LTD

Method for wet drawing Al-enclosing steel wires for electrotechnics

InactiveCN1452185ANo stayWill not affect productionBridge structural detailsCable/conductor manufactureProduction lineWork in process

A wet drawing method for manufacturing the aluminium clad steel wire used for electric engineering is characterized by that the semi-finished aluminium clad steel wire is drawn through multi-pass drawing die by drawing machine while the lubricating oil is applied.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

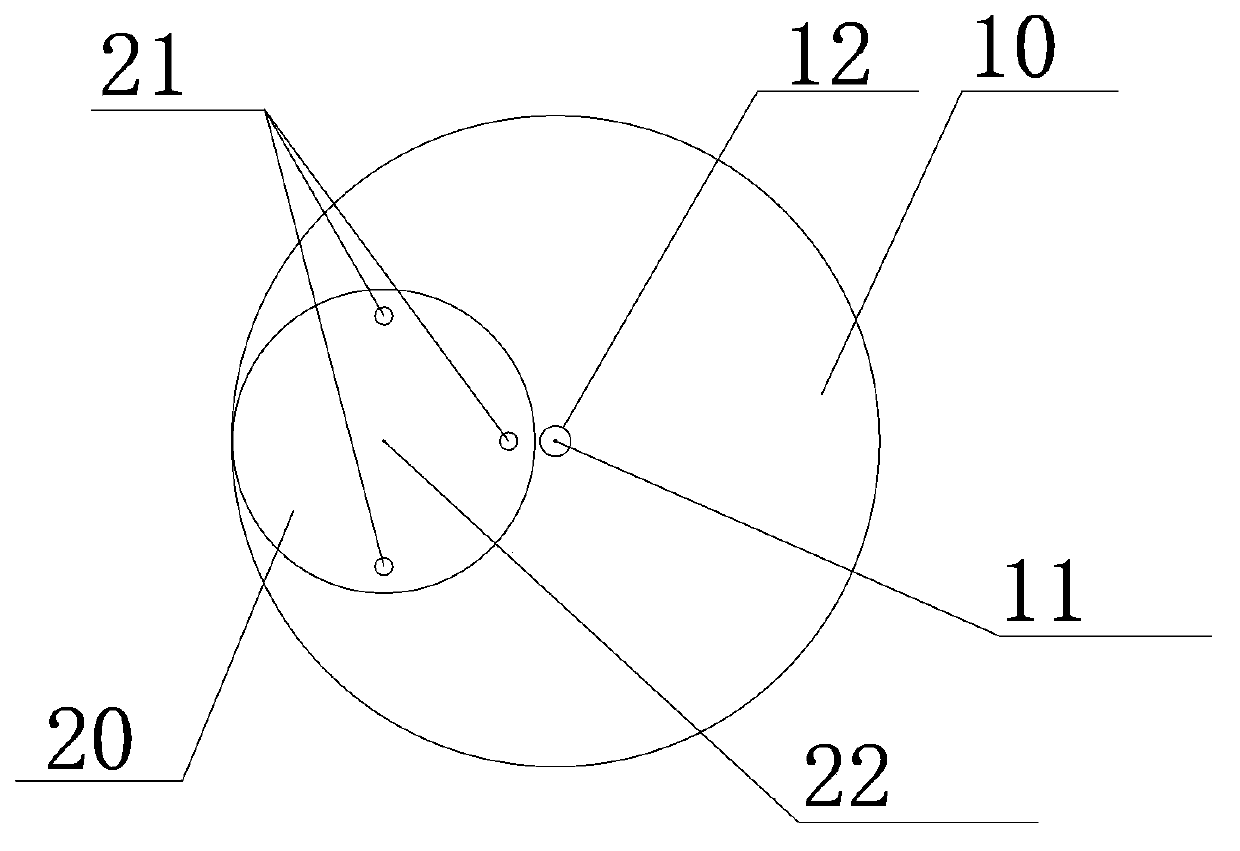

Twin-roll cast-rolling device for aluminum alloy clean production and deep processing

The invention discloses a twin-roll cast-rolling device for aluminum alloy clean production and deep processing. The twin-roll cast-rolling device comprises an oil absorption mechanism and a tractionwinding mechanism, and further comprises a cast-rolling mechanism, wherein the oil absorption mechanism is arranged on one side of the cast-rolling mechanism, and the traction winding mechanism is arranged on the side, far away from the cast-rolling mechanism, of the oil absorption mechanism; and the cast-rolling mechanism comprises a supporting table, a tundish, a discharging die, a cooling assembly and a forming assembly, and the tundish is connected to the top of the supporting table through bolts. According to the twin-roll cast-rolling device for aluminum alloy clean production and deep processing, the cooling assembly absorbs heat of liquid inside the discharging die, so that the liquid is solidified inside the discharging die, even a gap exists between the discharging die and a forming roller, normal production is not affected, and the function of adjusting the production thickness of aluminum alloy plates is also achieved; and through the arrangement of an oil spraying assembly, the situation that the production quality is affected due to the phenomenon of roll sticking on the surface of the forming roller is avoided, and the aluminum alloy plates can also be prevented frombeing corroded during later storage.

Owner:方新全

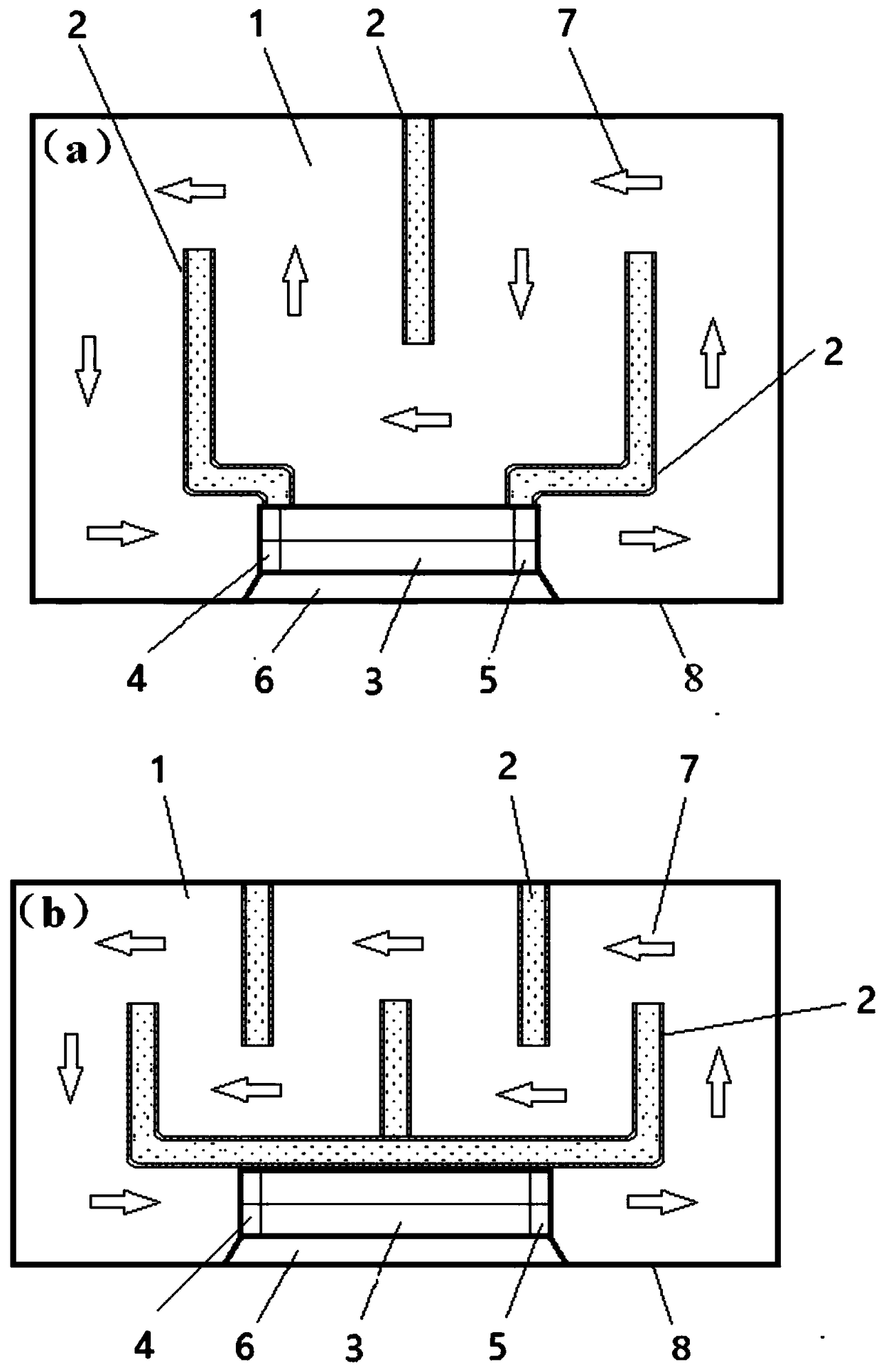

Water treatment system for internal-circulation running-water cultivation in pond

PendingCN109392823APrevent inflowReduce construction costsPisciculture and aquariaWater dischargeWater treatment system

The invention discloses a water treatment system for internal-circulation running-water cultivation in a pond. The water treatment system comprises a purification area (1), ecological islands (2), a breeding water tank (3), an aeration and water pushing area (4), a sewage collecting and drainage area (5), a working platform (6) and a pond (8). The long-strip-shaped ecological islands which are distributed in a staggered mode are arranged in the purification area, and aquatic plants are planted on the upper surfaces of the ecological islands and on the shallow water areas of side slopes of theecological islands, so that on one hand, water can be purified, on the other hand, water discharged from the breeding water tank can only flow along an "S-shaped" water path, a situation that the sewage is not fully purified and directly flows into the breeding water tank in a mode of "cutting a corner" is avoided, and meanwhile, a situation that dead water areas appear in a part of regions in thepond is avoided. The ecological islands are mainly prepared by piling the bottom mud of the pond, so that construction cost is low, the volume of the pond cannot be reduced, and shallow water areas and deep water areas can also be formed in the purification area, wherein the shallow water areas are beneficial to growth of aquatic plants, and the deep water areas can prevent water temperature frombeing too high in summer. Therefore, functions of purification areas of the pond can be enhanced, and the water purification effect can be improved.

Owner:SOUTHWEST UNIV

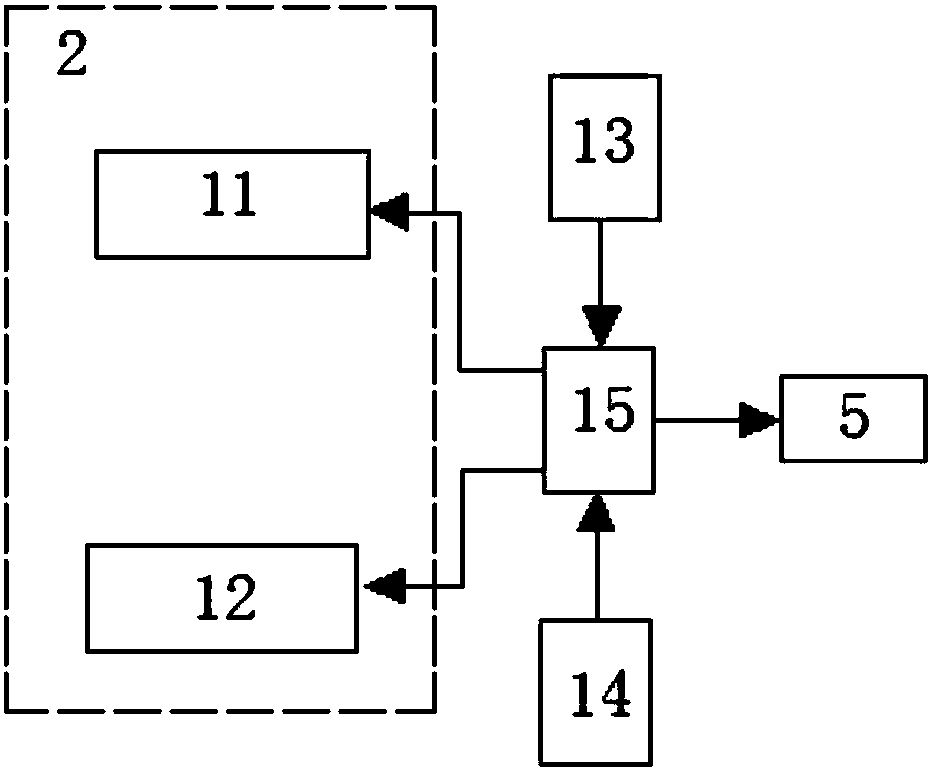

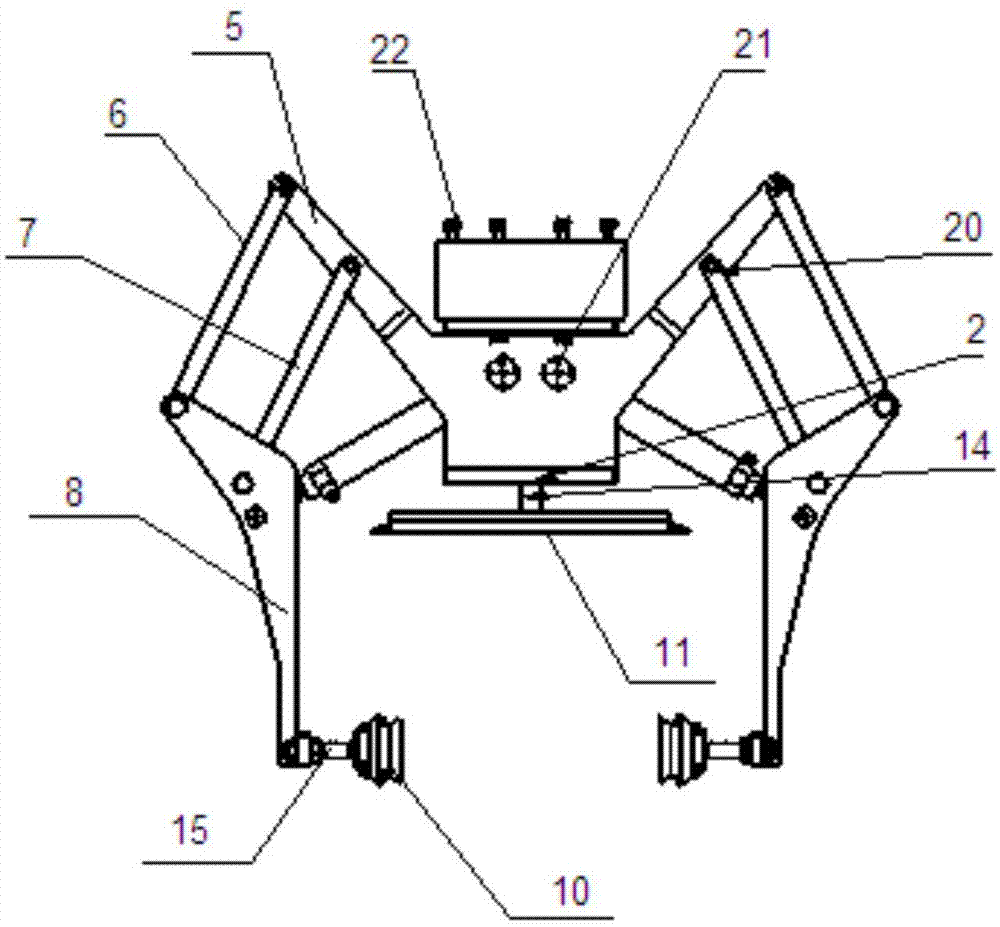

Self-adaptive carton gripper applicable to household appliances

The invention relates to a self-adaptive carton gripper applicable to household appliances. The self-adaptive carton gripper comprises a fixing support, a control unit, a rocker arm mechanism, corrugated suckers, flat suckers and horizontal fixing rods, the control unit is connected with the rocker arm mechanism, both the control unit and the rocker arm mechanism are connected on the fixing support, the horizontal fixing rods are connected with the rocker arm mechanism, the corrugated suckers are connected with the horizontal fixing rods, and the flat suckers are connected to the lower side of the fixing support; the control unit controls the rocker arm mechanism to move, the rocker arm mechanism drives the corrugated suckers to grip objects, and meanwhile, the control unit controls the corrugated suckers and the flat suckers to have the objected sucked. Compared with the prior art, the self-adaptive carton gripper has the advantages of safety and reliability, good part universality, lightweight and the like.

Owner:SHANGHAI TRIOWIN INTELLIGENT MACHINERY CO LTD

Water pipe heating pipe residual heat boiler system arranged in sintering machine flue

ActiveCN104832899AReasonable energyLess investment in equipmentIncreasing energy efficiencySteam generation using hot heat carriersFlueProcess engineering

The invention provides a water pipe heating pipe residual heat boiler system arranged in a sintering machine flue and relates to the technical field of steel smelting equipment. The water pipe heating pipe residual heat boiler system comprises a large flue and a small flue of a sintering machine, a large flue heat pipe type evaporator, a small flue heat pipe type evaporator, a large flue primary water pipe type evaporator, a large flue secondary water pipe type evaporator, a small large flue primary water pipe type evaporator, a small flue secondary water pipe type evaporator, a steam pocket and a water feeding system, wherein the large flue and the small flue are provided with a plurality of gas guide pipes respectively. According to the water pipe heating pipe residual heat boiler system, the water pipe type evaporators and the heat pipe type evaporators are divided into a plurality of heat exchange modules to be directly arranged on the large flue and the small flue of the sintering machine, so that the reasonable and effective gradient utilization of energy sources is realized; equipment investment is saved and an occupied area is small; respective advantages of the water pipe type evaporators and the heat pipe type evaporators are fully played in a use process; the flue gas residual heat is recycled to the greatest extent; meanwhile, the production of the sintering machine is not influenced and the water pipe heating pipe residual heat boiler system can be widely applied to the industry of a steel enterprise sintering machine.

Owner:江苏中天能源设备有限公司

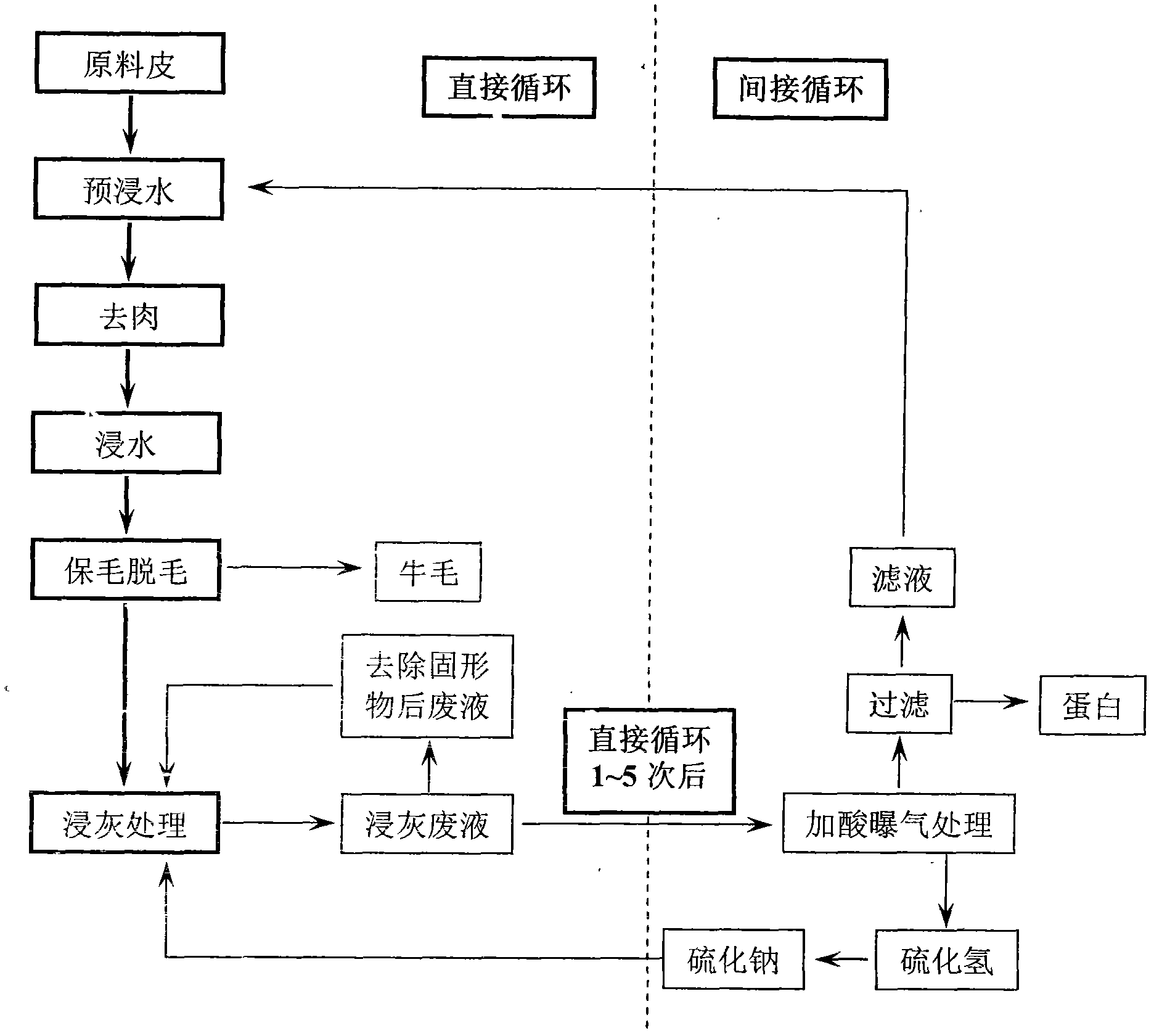

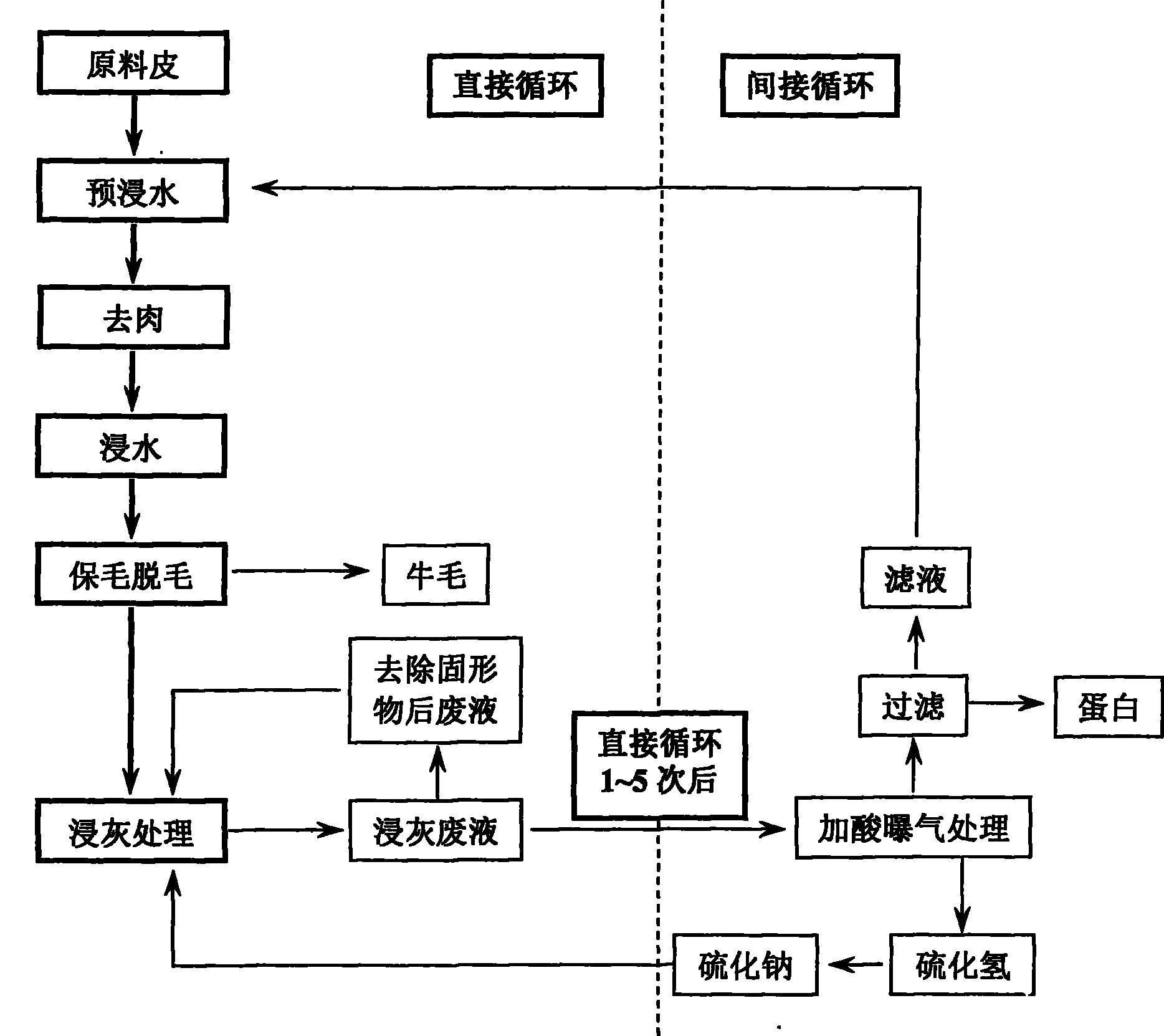

Hair-protection unhairing and liming waste liquor recycling method

InactiveCN102505056AReduce organic contentComplete hair shapePre-tanning chemical treatmentImpuritySodium sulphide

The invention provides a hair-protection unhairing and liming waste liquor recycling method in the tanning industry. In the method, an organic sulfur unhairing material is used to carry out hair-protection unhairing; sodium sulfide and lime are used to carry out liming processing; after solid impurities in liming waste liquor are removed, the liming waste liquor replaces water to be reused in theliming processing; after being circulated for 1 to 5 times, the liming waste liquor is processed by acid, so that sodium sulfide in the waste liquor is converted into hydrogen sulfide and proteins also generate precipitates; the generated sodium sulfide is adsorbed by using sodium hydroxide and is reused in the liming processing; after the proteins in the processed waste liquor are filtered, the processed waste liquor is reused for pre-soaking, so that the complete circulation of the liming waste liquor is realized.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Method for extracting and separating lupulone from lupulus

InactiveCN104447264ASolve the separation problemSolve the problem that it is not easy to crush too fine, otherwise the extraction liquid will be difficult to flow outCarbonyl compound separation/purificationFiltrationLiquid state

The invention relates to a method for extracting and separating lupulone from lupulus. The method comprises the following specific steps: filling the compressed lupulus into a subcritical ultrasonic extractor, introducing an R134a mixed solvent into the extractor, dissolving the active ingredients of the extracted material in the R134a mixed solvent in a liquid state or a subcritical state, and pumping the filtrate into a separator; regulating the temperature and pressure so that R134a in the R134a mixed solvent is converted from liquid state into gas state, separating the R134a from the extracting solution, concentrating the methanol-containing extracting solution by virtue of a concentration evaporator so as to obtain the lupulus extract, and entering a crystallization section; adding a certain amount of lupulus extract into a reaction kettle, adding water, stirring, standing at room temperature, performing suction filtration, and collecting the insoluble substance; adding water to the insoluble substance, stirring, standing at room temperature, and performing suction filtration; and stirring and performing suction filtration, collecting the insoluble substance, thereby obtaining the crude lupulone. According to the method disclosed by the invention, a subcritical ultrasonic extraction technology is utilized, the R134a mixed solvent is taken as an extraction solvent, and the solvent can return to a high-purity state without being subjected to special treatment in production.

Owner:SHANGLUO UNIV

Equipment and method for drawing instrument board

The invention provides equipment for drawing an instrument board. The equipment comprises a PC (personal computer), a compact disc face printer and an instrument board fixing base, the PC is connected with the compact disc face printer, the instrument board fixing base is fixedly mounted in a compact disc clamping groove of the compact disc face printer, thickness of the instrument board fixing base is smaller than or equal to depth of the compact disc clamping groove, and the instrument board fixing base is used for fixing the instrument board in the compact disc clamping groove. The equipment has the advantages that the equipment is low in cost, high in portability, high in maintainability and high in universality, so that production efficiency and applicability are improved.

Owner:SINOTO APP & INSTR SUZHOU

Testing structure for corrosion time of sacrificial layer and preparation method of MEMS (Micro-electromechanical System) device

InactiveCN102963859ANo impact on process reliabilityWill not affect productionMagnetic measurementsDecorative surface effectsProcess qualityDependability

The invention discloses a testing structure for determining the corrosion time of a sacrificial layer in real time. The testing structure comprises a sacrificial layer, an MEMS (Micro-electromechanical System) structural layer and a metal layer which are formed from bottom to top, wherein a metal in the metal layer falls off when the sacrificial layer is corroded. In the testing structure, a dual-material beam is taken as a sensitive element, and testing units are arranged preferably in an array way, so that the reliability of an entire online testing result is improved. A method for preparing an MEMS device by using the structure can be compatible with the conventional sacrificial layer process, the method and the conventional sacrificial layer process can be finished simultaneously, and online monitor of the process is realized. Due to the adoption of the testing structure, the corrosion time of the sacrificial layer can be determined in a non-contact and non-breaking way through a naked-eye observation way, the MEMS process quality and yield can be increased, and the process time is greatly shortened.

Owner:PEKING UNIV

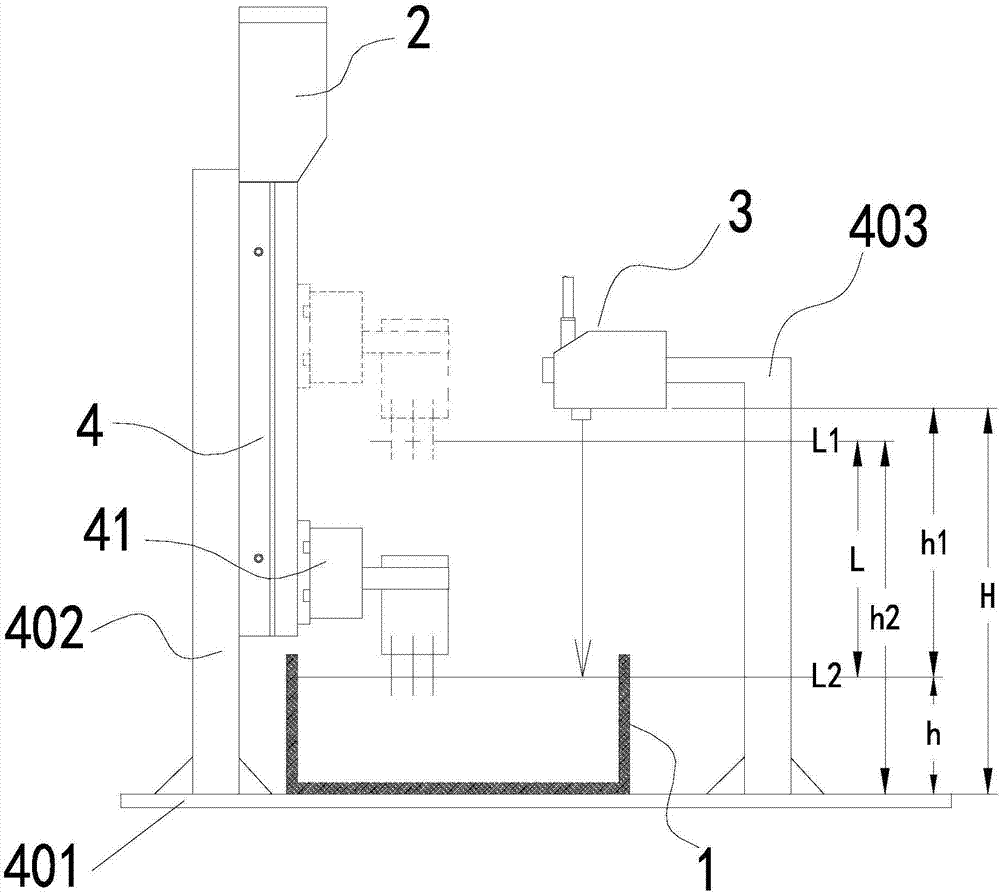

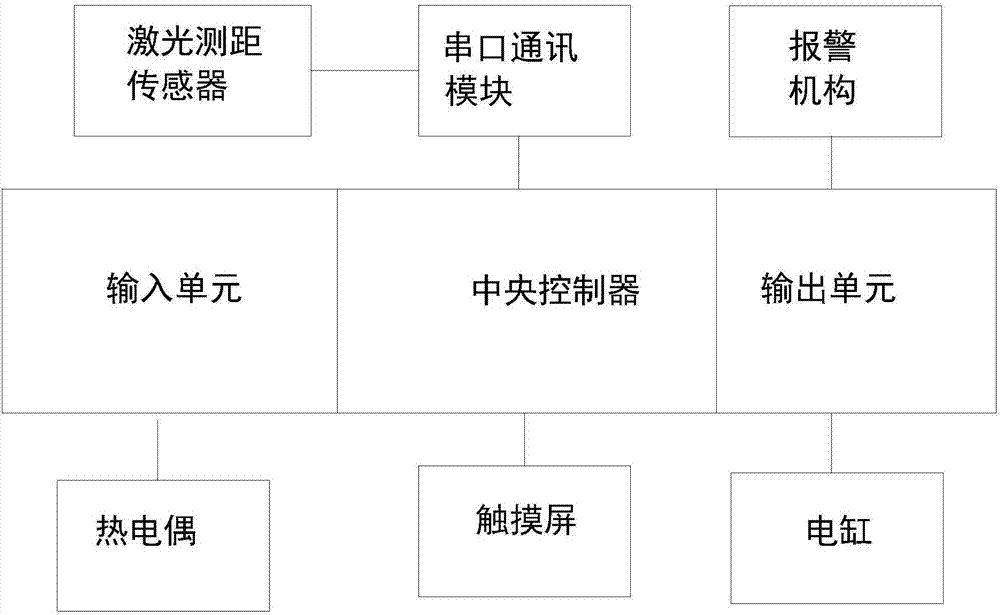

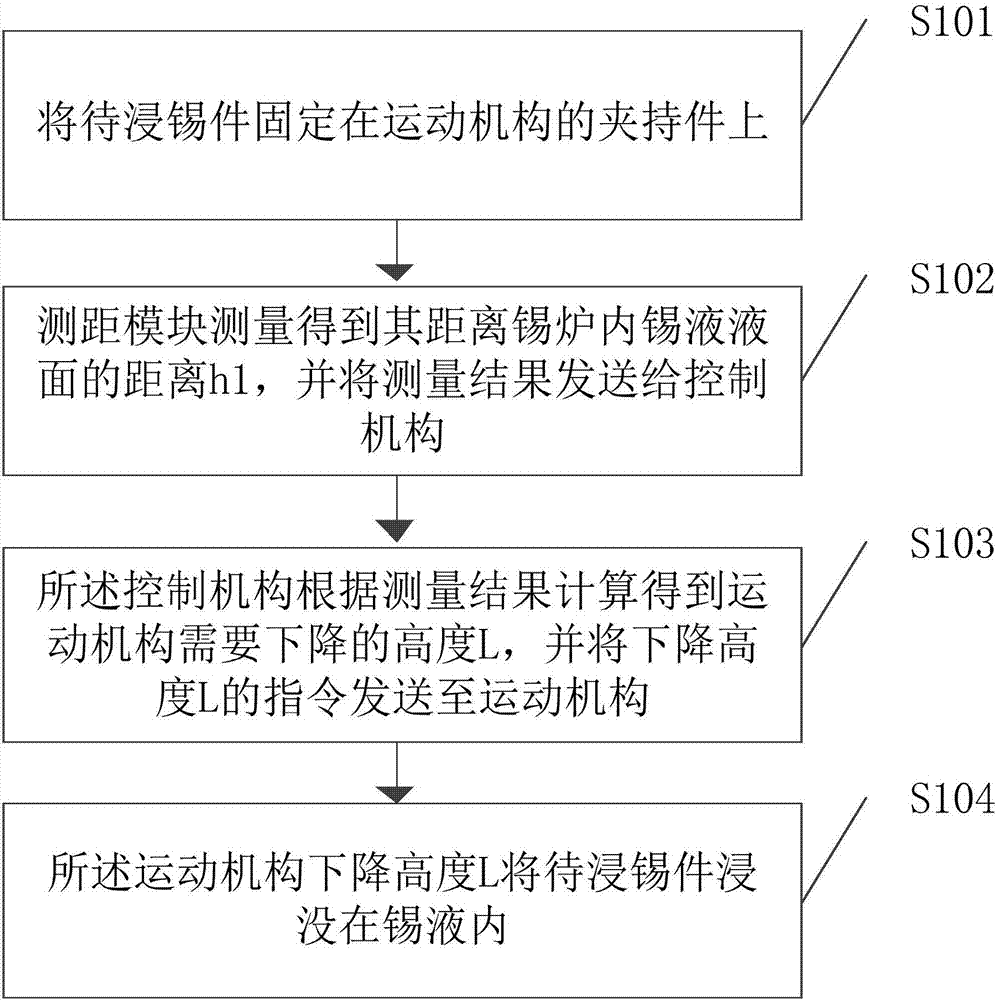

Tin immersion method and tin immersion device

InactiveCN107020430AThe detection process is fastHigh precisionSoldering auxillary devicesHeating furnaceTin

The invention discloses a tin immersion method and a tin immersion device. The tin immersion method comprises the following steps: a part to be subjected to tin immersion is fixed to a clamping element of a movement mechanism; a distance measurement module measures to obtain a distance h1 between the part to be subjected to tin immersion and the liquid level of molten tin in a tin furnace, and sends a measurement result to a control mechanism; the control mechanism calculates to obtain a height L needing to be descended, of the movement mechanism, according to the measurement result, and sends an instruction of descending the height L to the movement mechanism; and the movement mechanism descends the height L and immerses the part to be subjected to tin immersion in the molten tin. According to the tin immersion method and the tin immersion device, the liquid level of the molten tin is stable and free from fluctuation, and no temperature change and less liquid level oxidization are achieved; detection for the molten tin in the tin furnace can be realized before tin immersion every time, without the influence of the liquid level drop of the molten tin in the tin furnace; and the tin immersion method and the tin immersion device are high in detection speed and accuracy, free from influence on tin immersion rhythm, and capable of increasing the production efficiency.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com