Testing structure for corrosion time of sacrificial layer and preparation method of MEMS (Micro-electromechanical System) device

A technology for testing structures and sacrificial layers, applied in microstructure technology, electric solid state devices, semiconductor devices, etc., can solve problems such as reducing yield, increasing tape-out time, destroying chips, etc., to improve reliability and reduce uncertainty , the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below through specific embodiments and accompanying drawings.

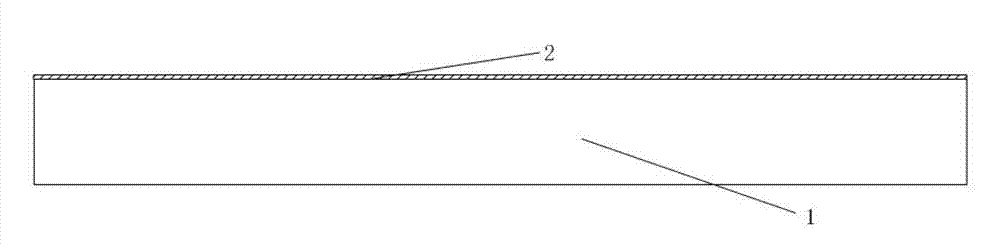

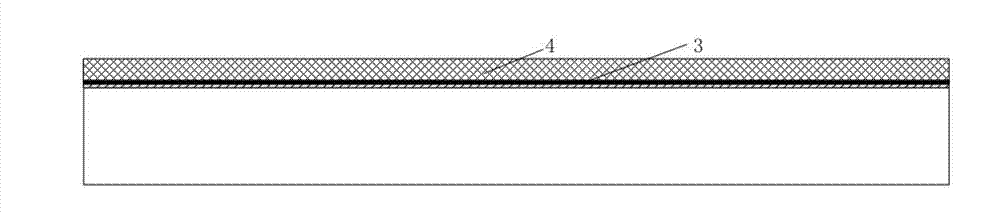

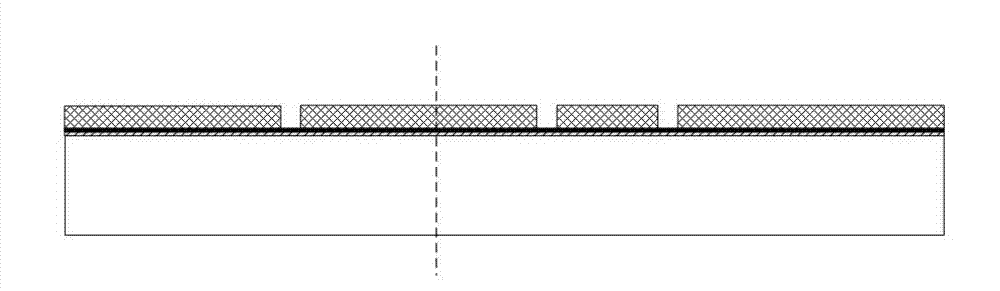

[0034] The corrosion time detection method of the present invention is mainly applicable to MEMS device chips with movable structures processed by surface sacrificial layer integration technology, such as sensors such as accelerometers and gyroscopes, and actuators such as adjustable capacitance structures. Taking the manufacture of a comb-shaped resonator as an example, the manufacture of the corrosion time detection structure and the manufacture of the resonator are combined. The specific process flow is shown in Figure 1, where the left side of the dotted line is the detection structure area, and the right side is the chip main structure area. , which is described as follows:

[0035] 1. Preparation: monocrystalline silicon substrate as the substrate of the chip;

[0036] 2. Deposit the substrate protective layer, including: LPCVD SiO2, with a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com