Aluminum substrate processing technology

A processing technology, aluminum substrate technology, applied in the direction of electrical components, printed circuit manufacturing, electrical components, etc., can solve problems such as waste, increased labor costs, material cost waste, etc., to reduce raw material costs, avoid redundant waste, double cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] A kind of aluminum substrate processing technology is characterized in that comprising the following steps:

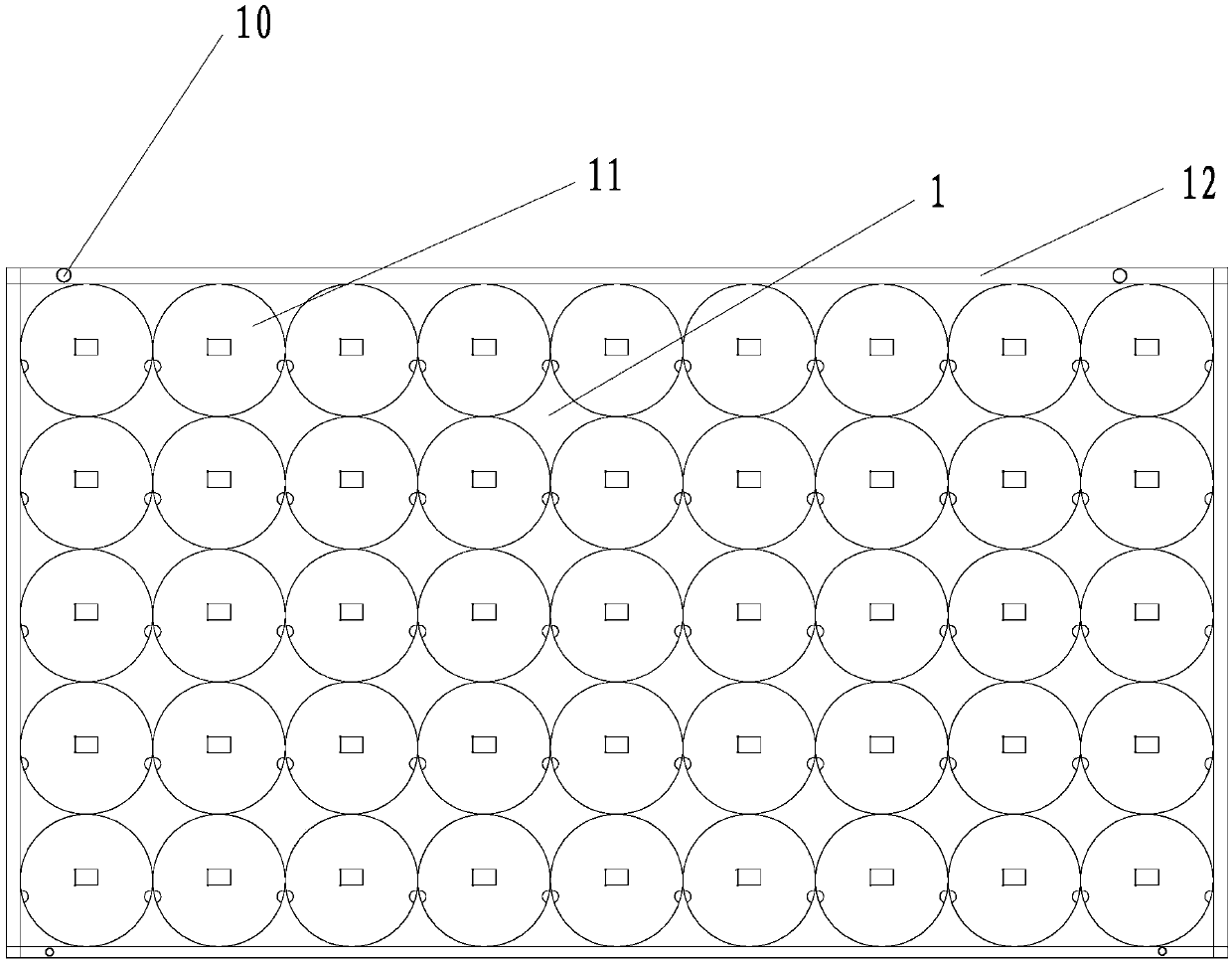

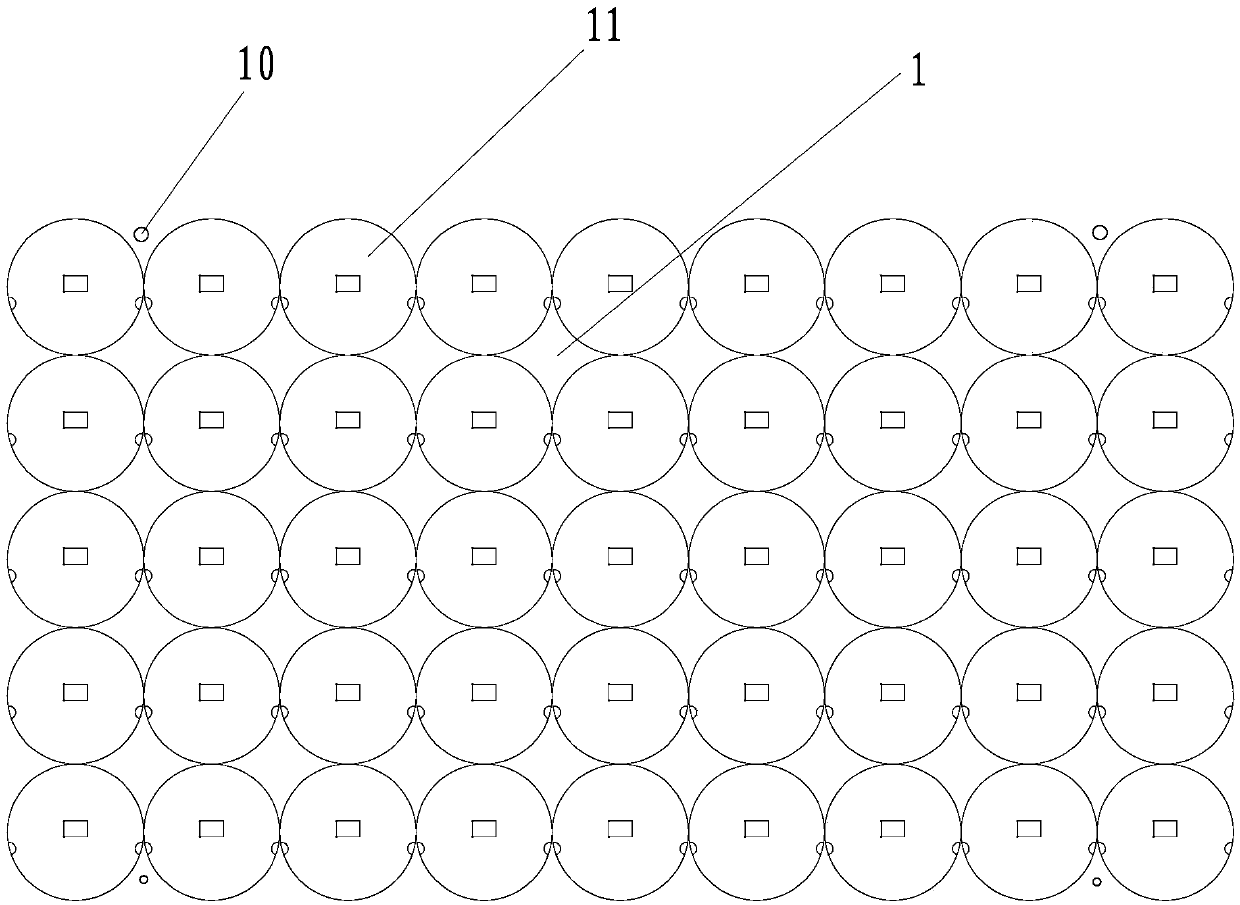

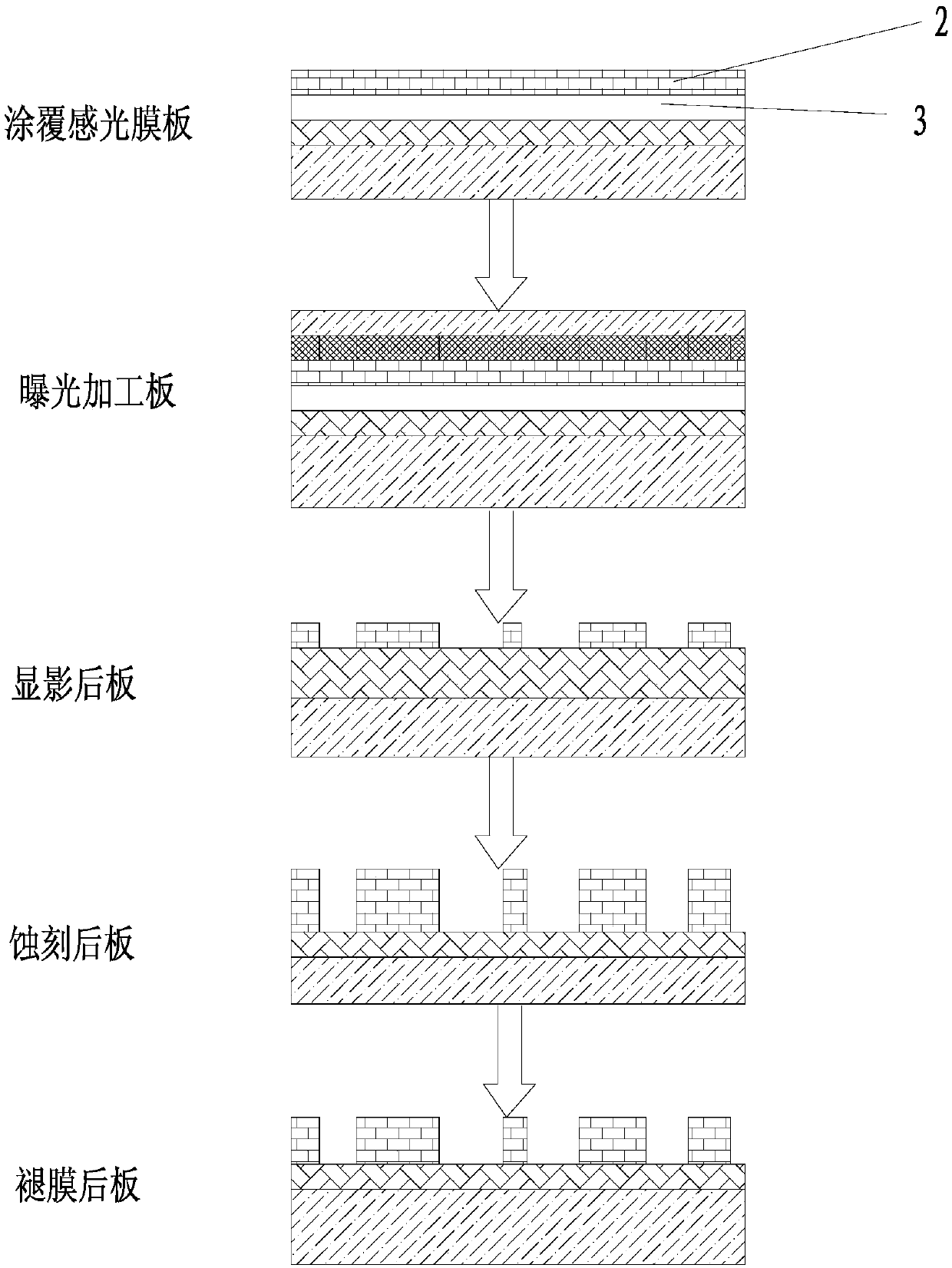

[0023] 1) Press the heat-conducting material and copper foil 3 onto the aluminum plate to form a first plate, and cut the first plate into plate units without process edges according to different imposition requirements. In this embodiment, the imposition requirements are not The sheet material unit is required to have a process edge, so the sheet material unit has no process edge setting; there are multiple single-piece aluminum substrates on the sheet material unit; the copper foil 3 is the circuit layer;

[0024] 2) Baking the above-mentioned sheet material unit at a certain temperature for a certain period of time to eliminate the internal stress of the sheet material unit during the production process and absorb the moisture...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com