Method for preparing polymer polyol

A technology of polyether polyols and polyols, applied in the field of preparing polymer polyols, which can solve problems affecting product quality, affecting normal production, and clogging pipes with products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

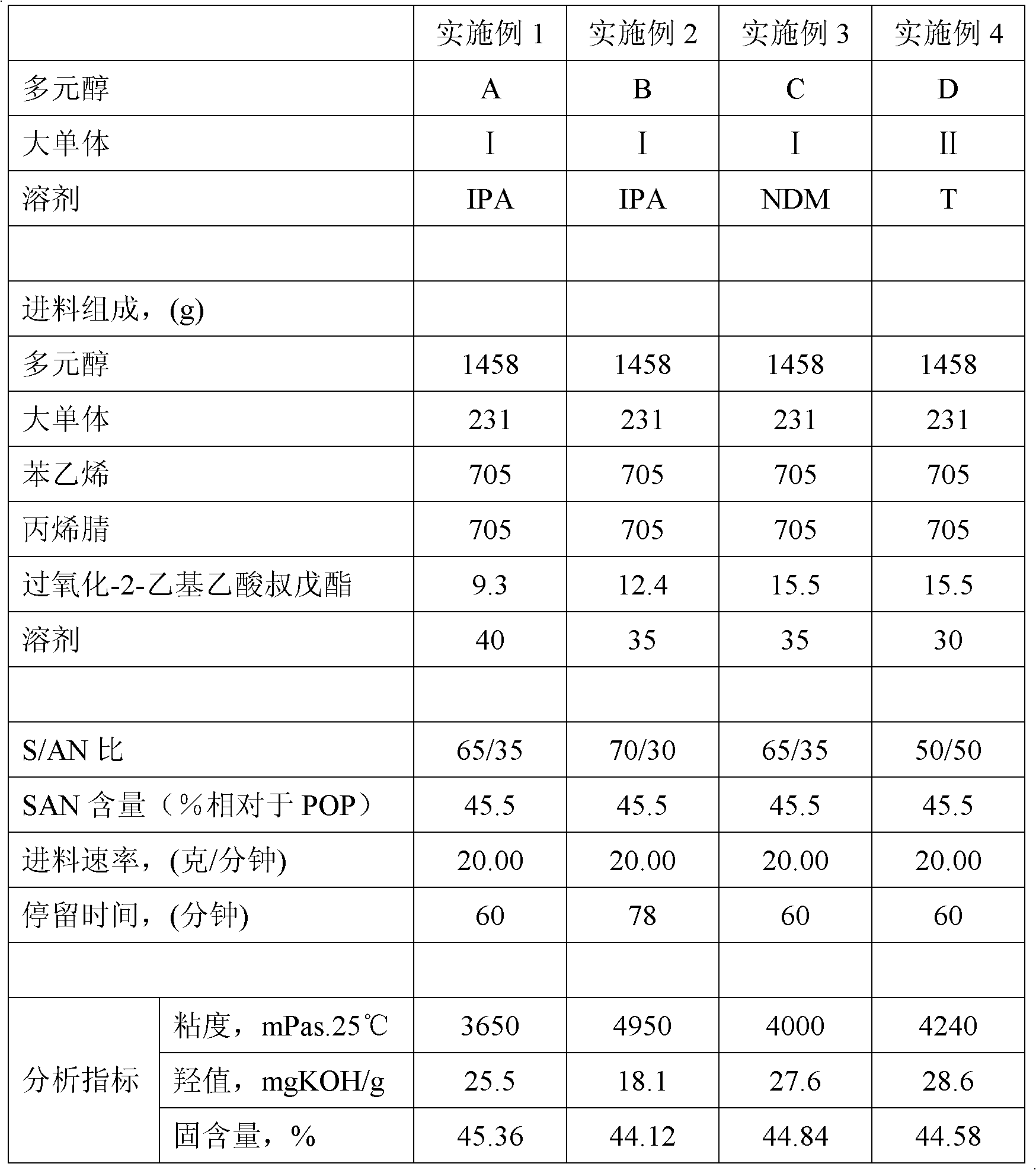

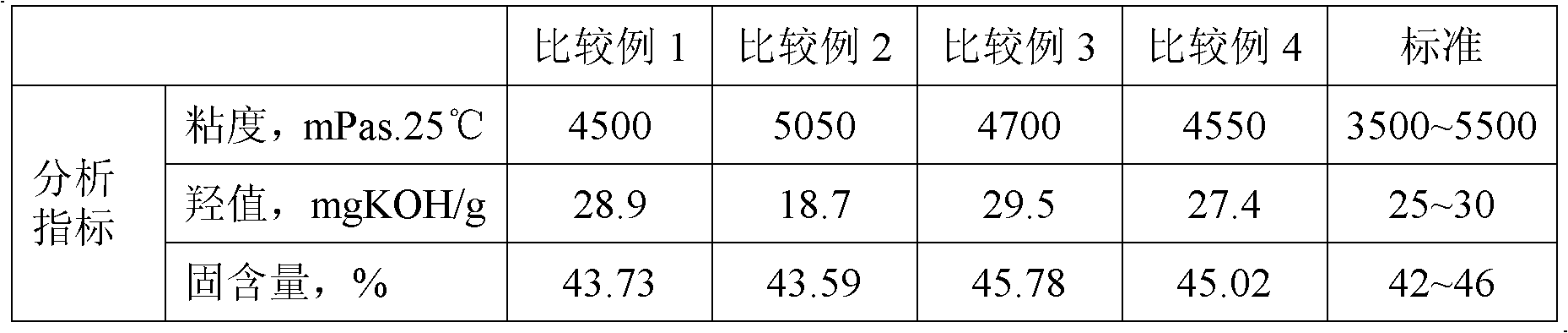

Examples

Embodiment 1~4

[0019] definition

[0020] Polyol A: Polyether prepared by reacting a mixture of glycerol and propylene glycol having a hydroxyl functionality of 3 with propylene oxide and ethylene oxide. The polyether had an ethylene oxide content of 8.1% by weight, contained mainly secondary hydroxyl groups and had a hydroxyl number of 56.

[0021] Polyol B: polyether prepared by reacting trimethylolpropane with propylene oxide and ethylene oxide. The content of ethylene oxide is 8.5% by weight, and the hydroxyl value of the polyether is 35.

[0022] Polyol C: polyether prepared by reacting trimethylolpropane with propylene oxide and ethylene oxide. The content of ethylene oxide is 5.0% by weight, and the hydroxyl value of the polyether is 58.

[0023] Polyol D: polyether prepared by reacting glycerol with propylene oxide and ethylene oxide. The polyether had an ethylene oxide content of 9.6% by weight and a hydroxyl number of 56.

[0024] Macromonomer I: Polyether containing induced u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degree of unsaturation | aaaaa | aaaaa |

| Degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com