Contact sensing scarper mechanism and full automatic vision printer

A contact sensing and scraper technology, applied in the field of fully automatic visual printing machines, can solve the problems of inability to sense the initial position of contact between the scraper and the stencil, inconvenient maintenance of the scraper mechanism, and long maintenance time, so as to achieve quick installation and reduce maintenance time , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

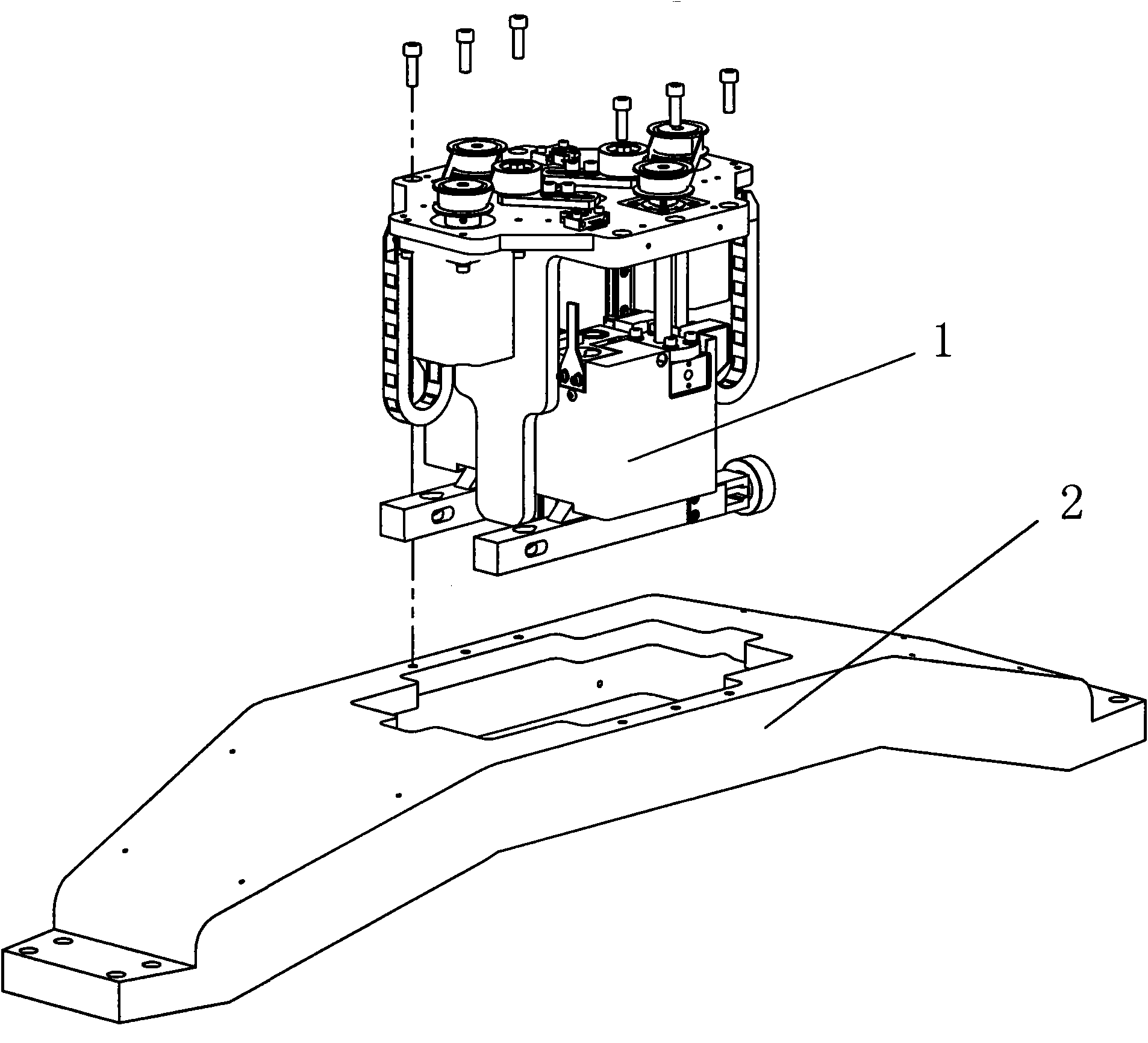

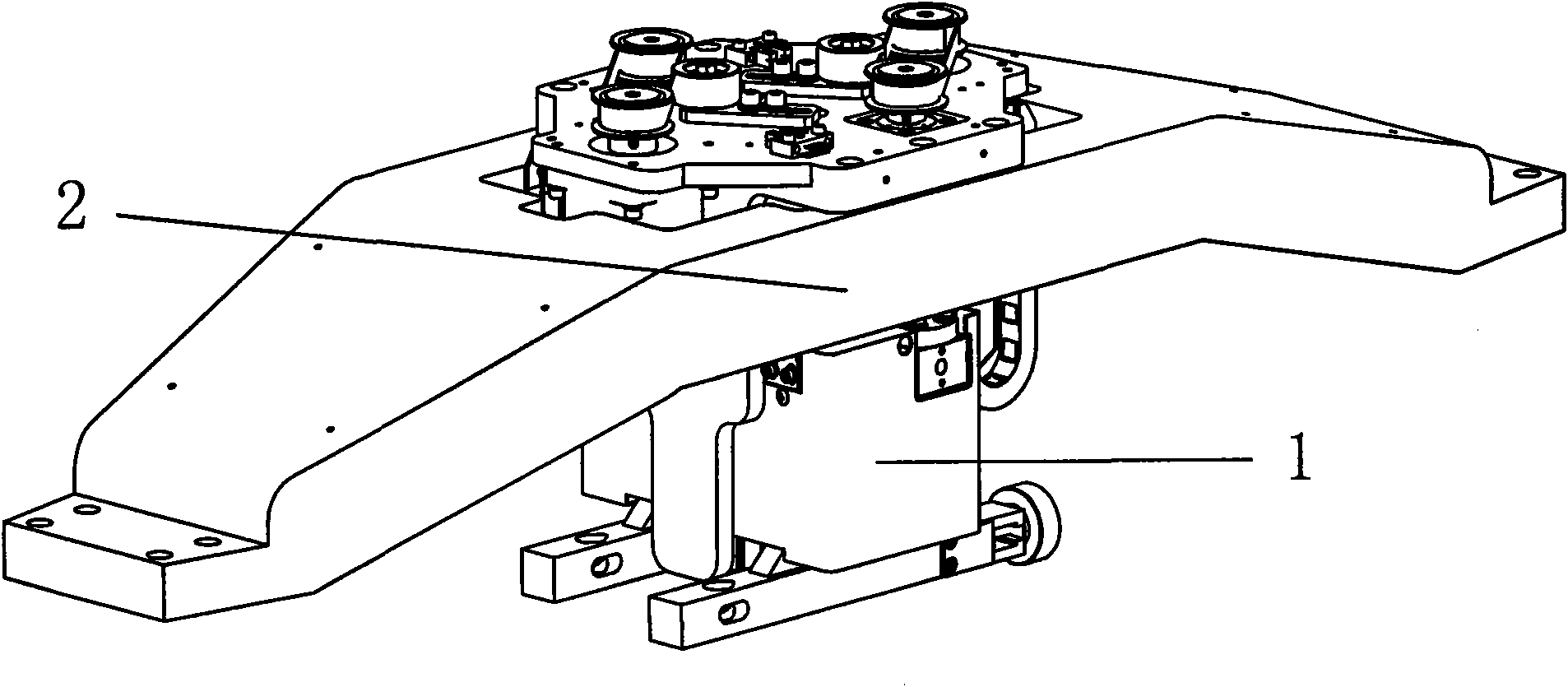

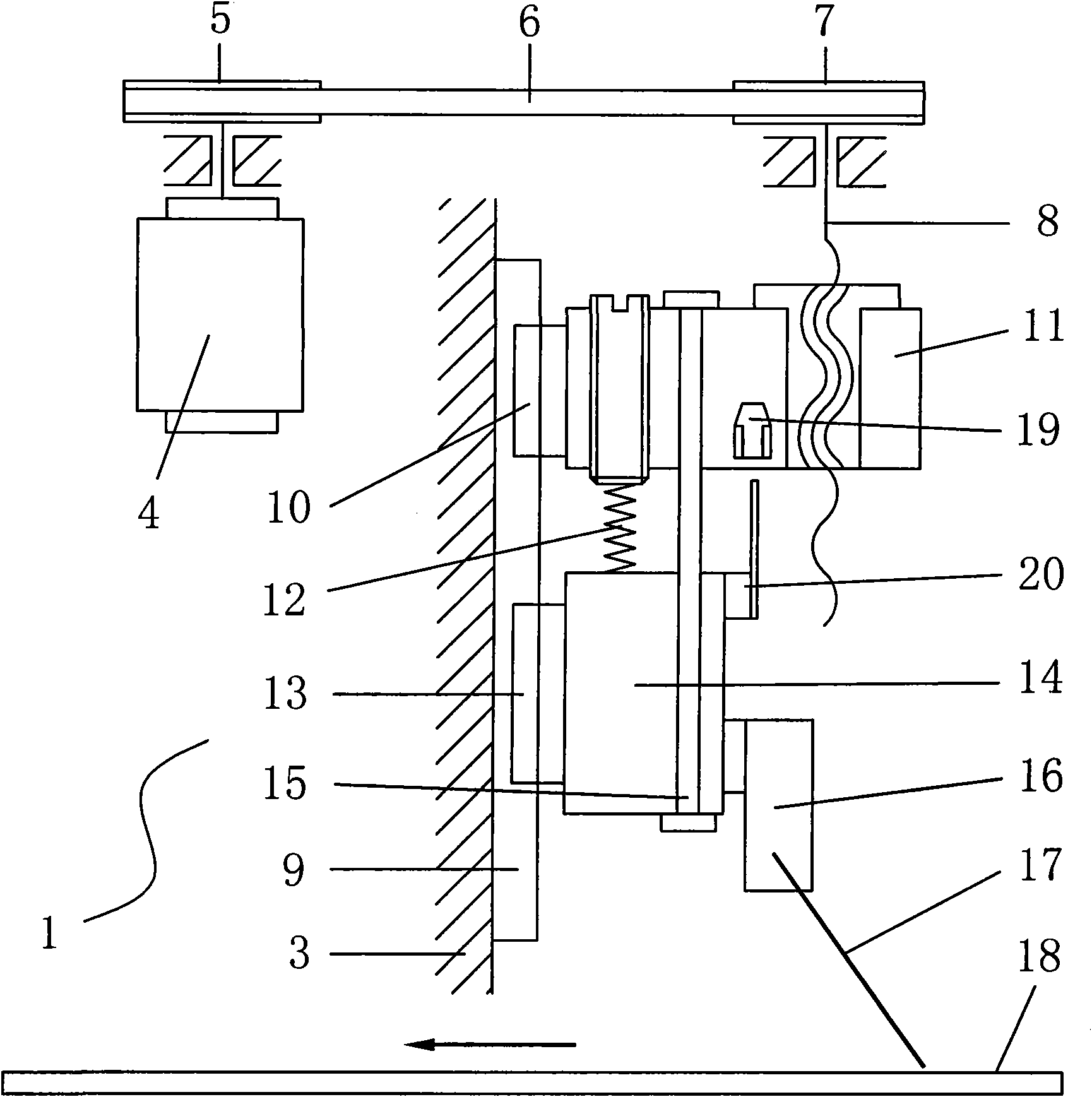

[0013] see figure 1 , figure 2 and image 3 , a contact-sensing scraper mechanism described in this embodiment includes a scraper beam 2 and a scraper lifting module 1, the scraper lifting module 1 is assembled with the scraper beam 2, and the scraper lifting module 1 includes a module seat 3, Stepper motor 4, screw mandrel 8, slide rail 9, upper slider 10, upper slider seat 11, spring 12, lower slider 13, lower slider seat 14, scraper seat 16, scraper 17, photoelectric sensor 19 and The induction plate 20, the stepping motor 4, the screw mandrel 8 and the slide rail 9 are respectively assembled with the module seat 3, and the screw mandrel 8 is connected to the stepping motor 4 through the B synchronous pulley 7, the synchronous belt 6 and the A synchronous pulley 5 , the screw rod 8 is connected to the upper slider seat 11, the upper slider 10 and the upper slider seat 11 are assembled together, the lower slider seat 14 is connected to the upper slider seat 11 through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com