Patents

Literature

67results about How to "Accurate pressure value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for simultaneously testing effective stress coefficient and porosity of porous rock under stress conditions

InactiveCN104133050AAccurate pressure valueEliminate errorsEarth material testingPorosityStress conditions

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

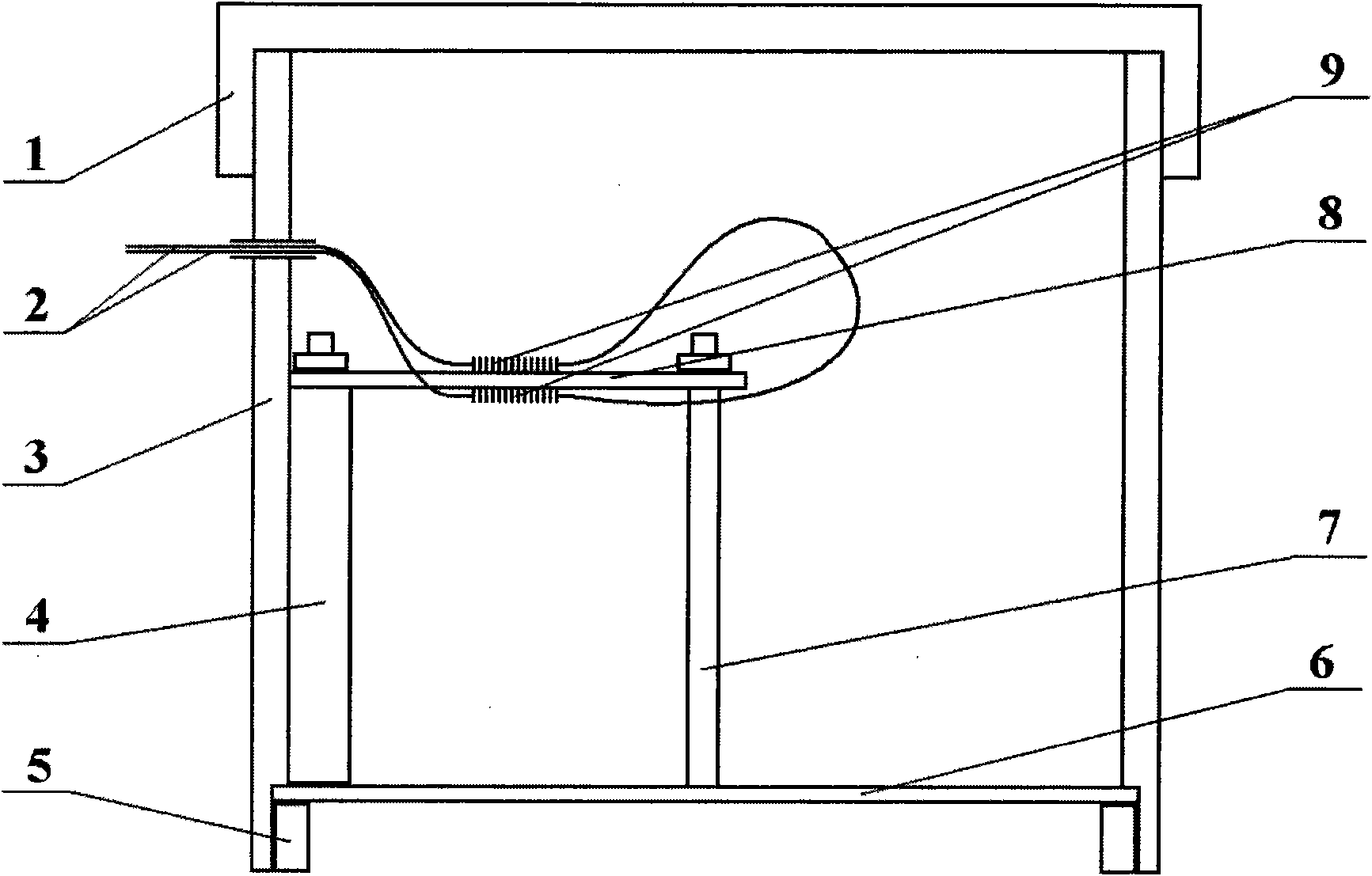

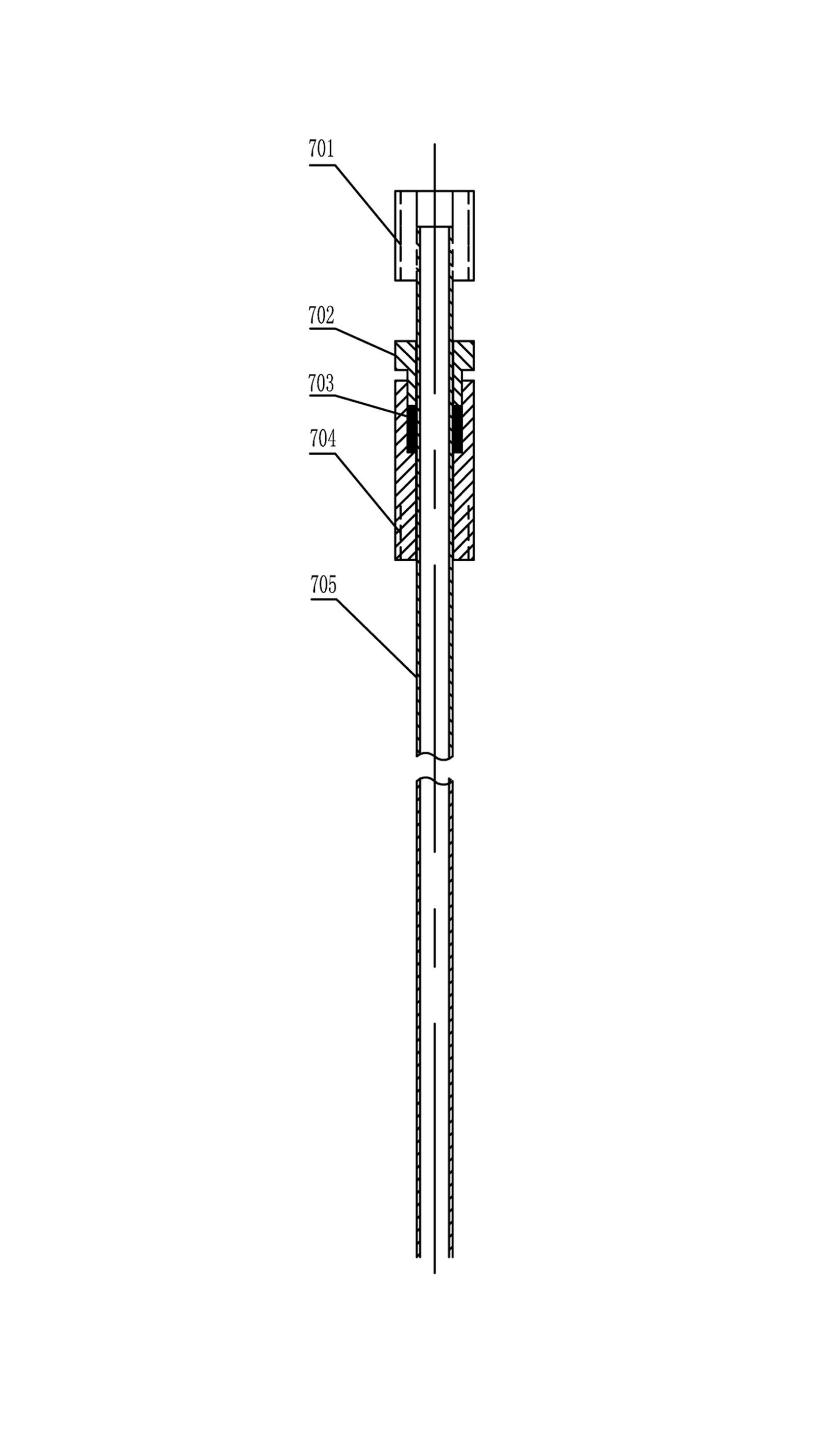

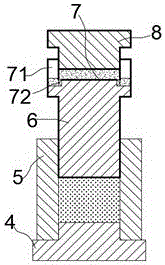

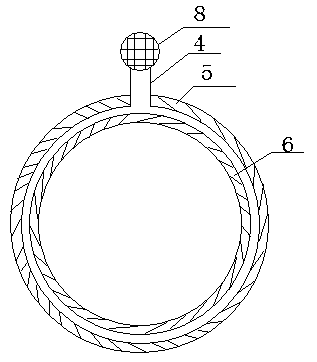

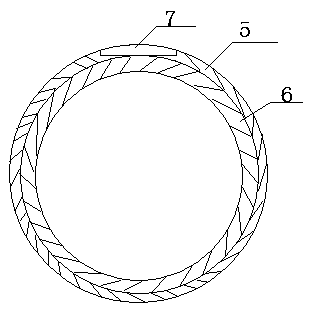

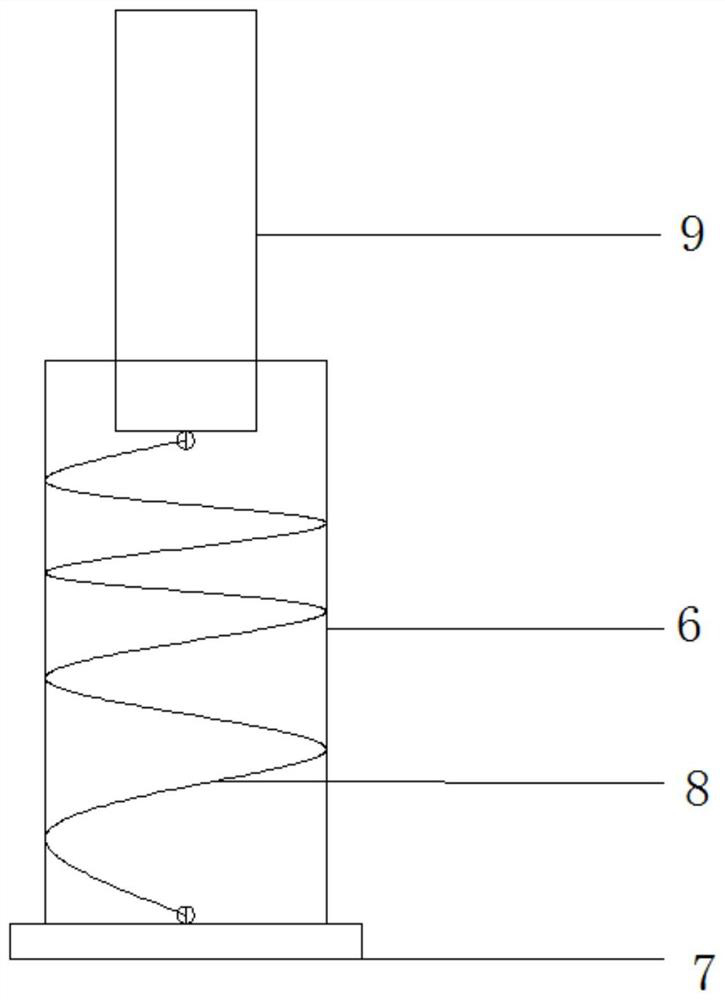

Convoluted diaphragm-type optical fiber Bragg raster liquid level sensor

InactiveCN101650209AAvoid chirpingAccurate pressure valueFluid pressure measurement by optical meansLevel indicators by pressure measurementGratingEngineering

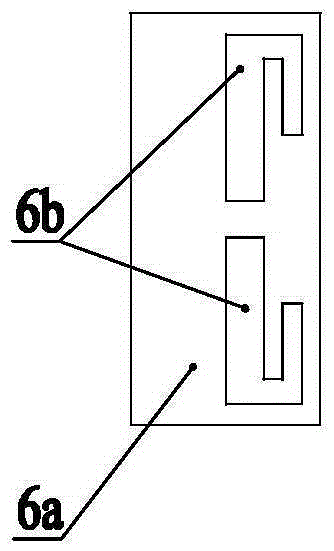

The invention relates to a convoluted diaphragm-type optical fiber Bragg raster liquid level sensor which consists of optical fiber Bragg rasters (9), a convoluted diaphragm (6), a transfer lever (7),a constant-strength cantilever girder (8), a leading-in and leading-out optical fiber (2), a fixed seat (4), a seal ring (5) and a protective barrel (8), wherein the convoluted diaphragm (6) is connected with the constant-strength cantilever girder (8) through the transfer lever (7), and the optical fiber Bragg rasters (9) are adhered on the constant-strength cantilever girder (8); in addition, the fixed seat (4) is used for fixing the constant-strength cantilever girder (8); the convoluted diaphragm (6) is fixed between the protective barrel (8) and the seal ring (5), and the leading-in andleading-out optical fiber (2) is respectively connected to both ends of two optical fiber Bragg rasters (9) connected in series. According to the sensitivity differences of the two sensing rasters topressure and temperature, well-known differential operation in the field is adopted to measure and compensate temperature fluctuation interference pressure, thereby realizing the accurate measurementon pressure generated by static liquid level.

Owner:KUNMING UNIV OF SCI & TECH

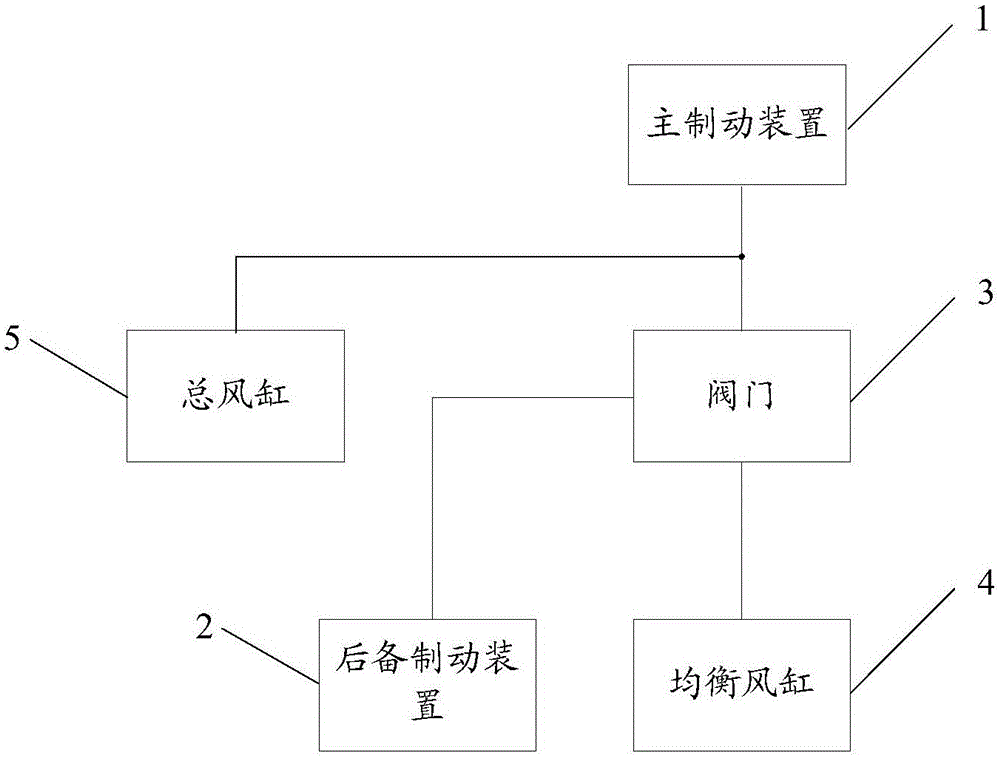

Braking system and locomotive

ActiveCN105035053AAccurate pressure valueAccurate detection of pressure valuesBraking action transmissionElectricityMechanical engineering

The invention provides a braking system and a locomotive including the same. The braking system comprises a main braking device, a back-up braking device, a valve, an equalizing reservoir, and a main air reservoir, a first valve port of the valve is connected with the main braking device and the main air reservoir, a second valve port of the valve is connected with the back-up braking device, and a third valve port of the valve is connected with the equalizing reservoir; when the braking system is in an electrically controlled braking working condition, the valve controls the first valve port and the third valve port to be in a breakover mode, and the second valve to be closed. Accordingly, when the braking system is in the electrically controlled braking working condition, electrically controlled braking work can be completed normally by the braking system through breakover of the first valve port and the third valve port of the valve; air circulation between the equalizing reservoir and the back-up braking device can not be conducted by closing the second valve port, therefore, the pressure value of the air in the equalizing reservoir can be detected accurately, and the pressure value of the air in the equalizing reservoir can be controlled accurately.

Owner:QINGDAO SRI TECH CO LTD

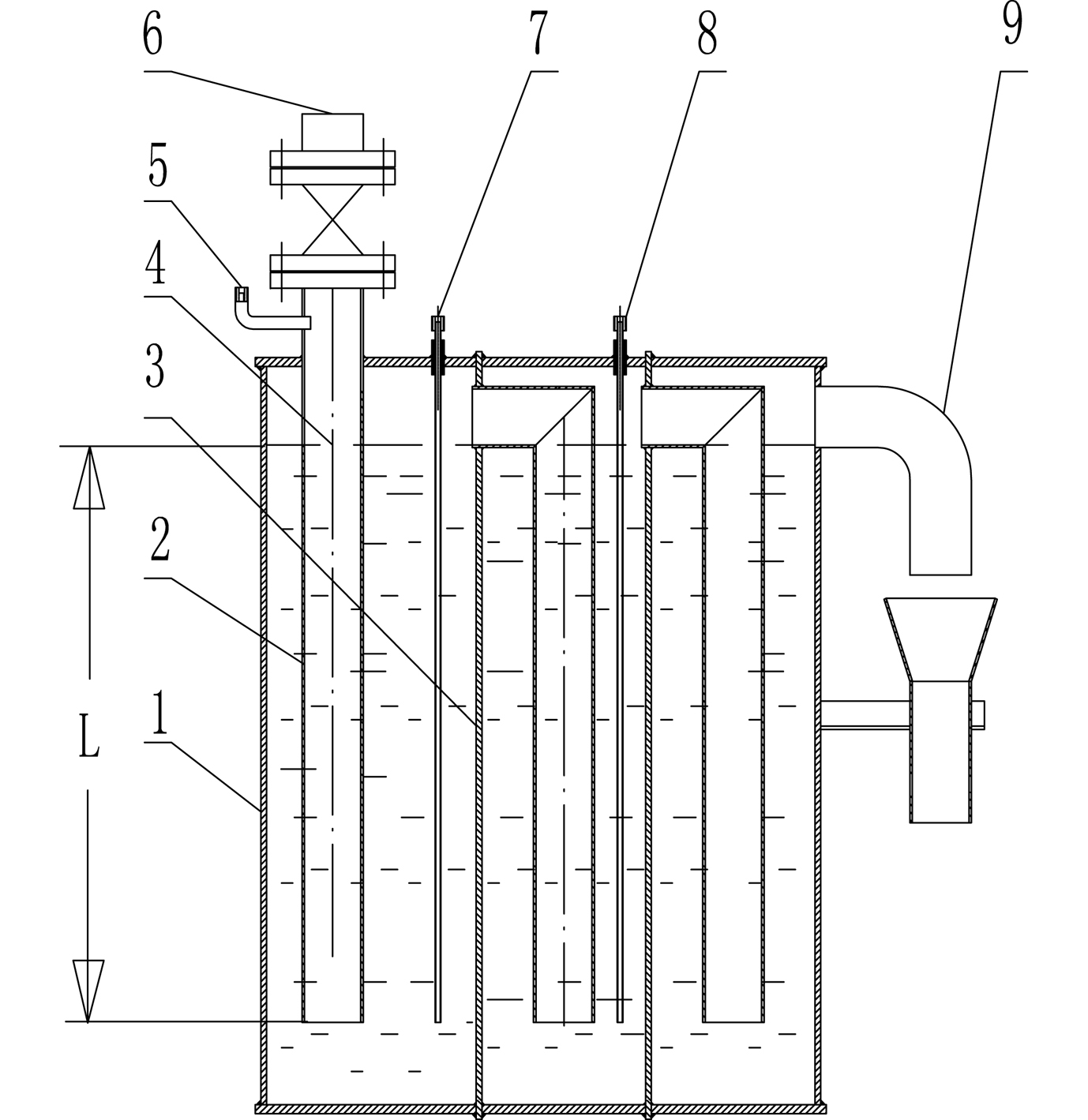

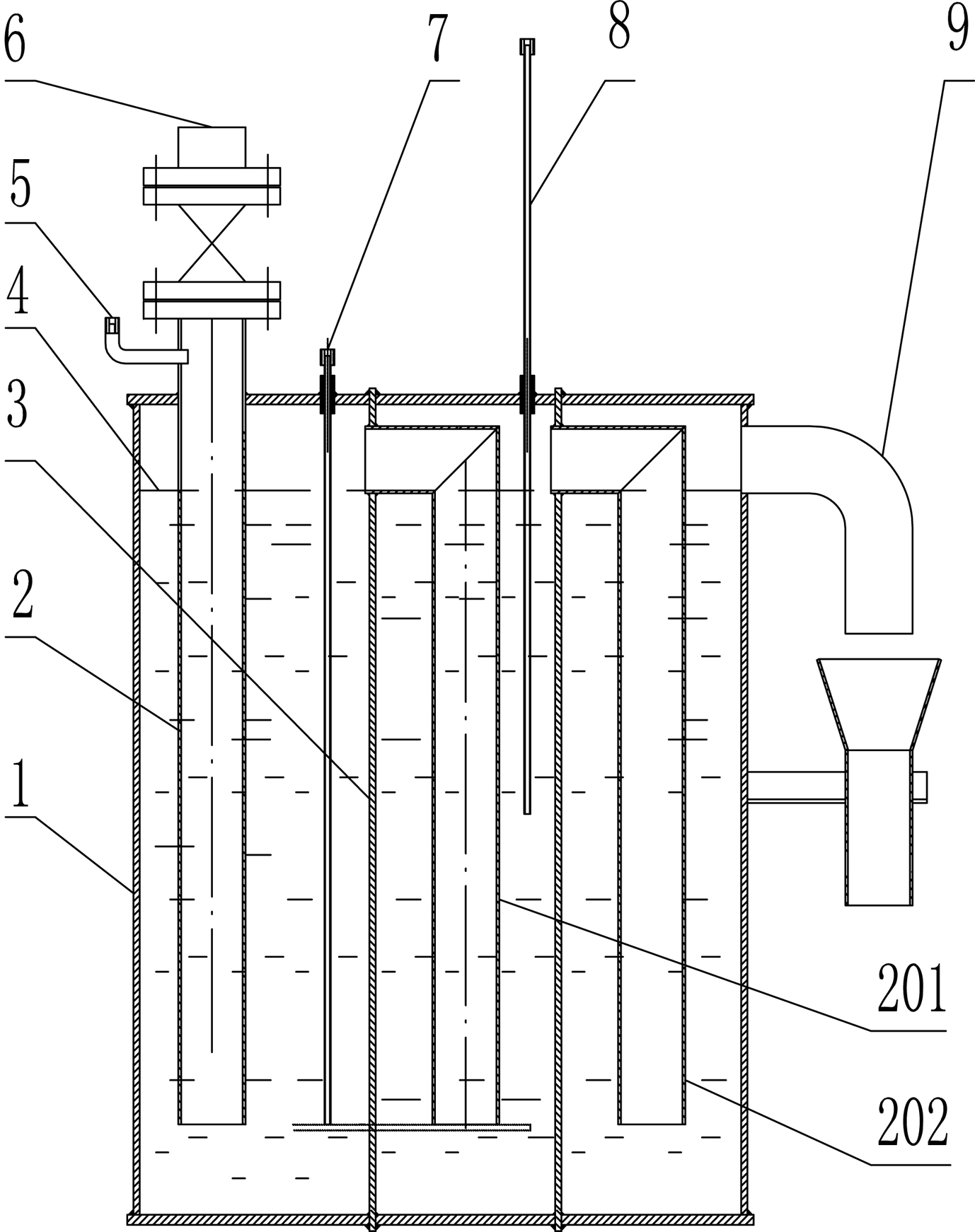

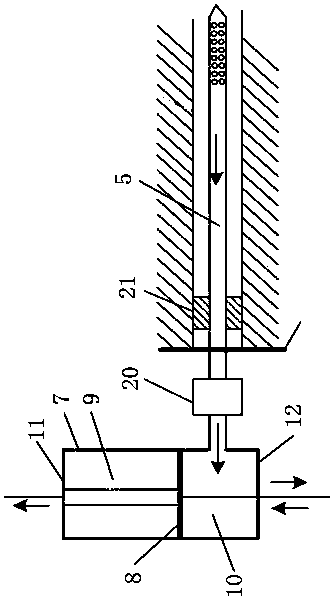

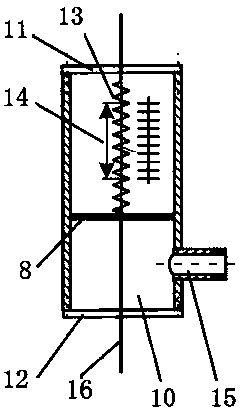

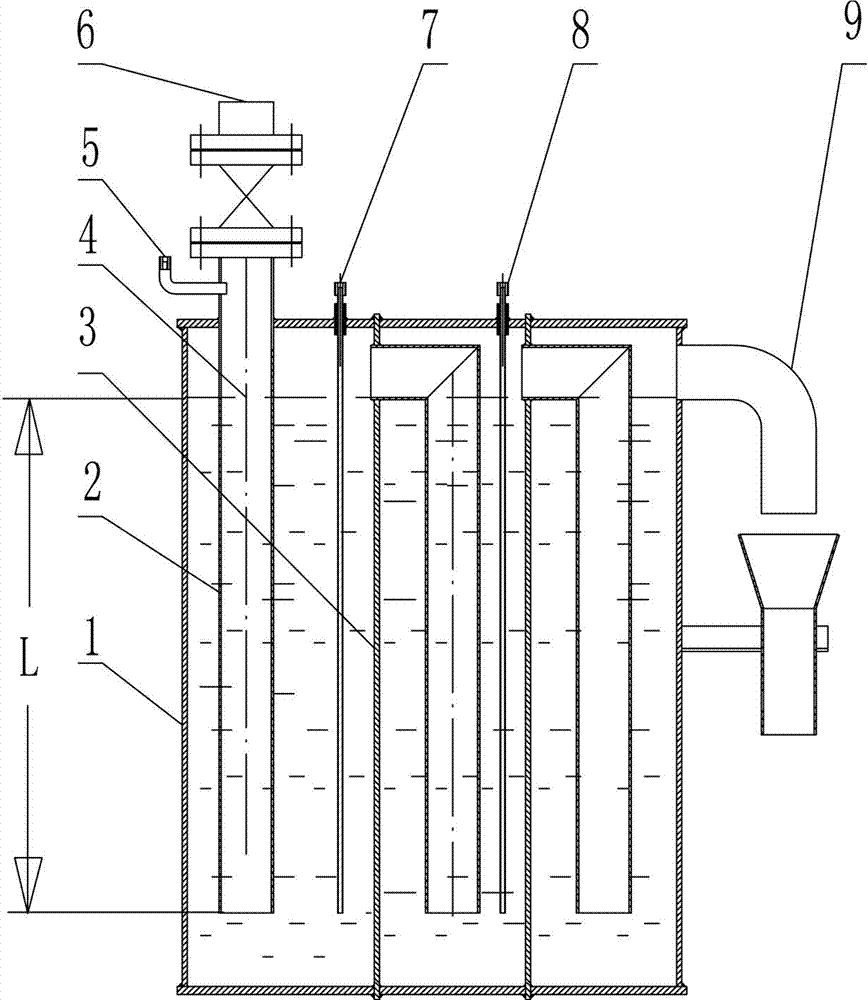

Method for realizing pressure tapping by using gas drainer and gas drainer for realizing pressure tapping

ActiveCN102032445ASimple methodAccurate pressure valuePipeline systemsCommunicating vesselsEngineering

The invention discloses a gas drainer and a method for realizing pressure tapping by using the gas drainer. The gas drainer is provided with N horizontal communicating vessels which are connected in series with one another, wherein water is filled in a water sealing chamber of each communicating vessel and a water sealing pipe is vertically arranged in the water sealing chamber; the lower end of each water sealing pipe is open; the upper ports of the second stage of water sealing pipe to the final stage of water sealing pipe are communicated with previous stages of water sealing chambers; theupper port of the first stage of communicating vessel is an inlet for receiving gas pressure; and the final stage of communicating vessel is provided with an outlet which is communicated with atmosphere. The method for realizing pressure tapping by using the gas drainer comprises the following steps that: the top of a water sealing chamber accommodating chamber between every two adjacent water sealing pipes is provided with a pressure tapping port; each port is provided with a sealed pressure tapping adjustment pipe which can adjust the length of the part inserted into plugging water within avertical length L range; the pressure tapping port is directly formed above the first stage of water sealing pipe; or as required, extension length of the pressure tapping adjustment pipe at a corresponding port is adjusted to realize pressure tapping at the pressure tapping port, or the pressure tapping port is directly formed above the water sealing pipe of the first stage of communicating vessel to tap pressure Vmax. The method can expand the application of the gas drainer and can be easily mastered by operation personnel.

Owner:秦皇岛莱特流体设备制造有限公司

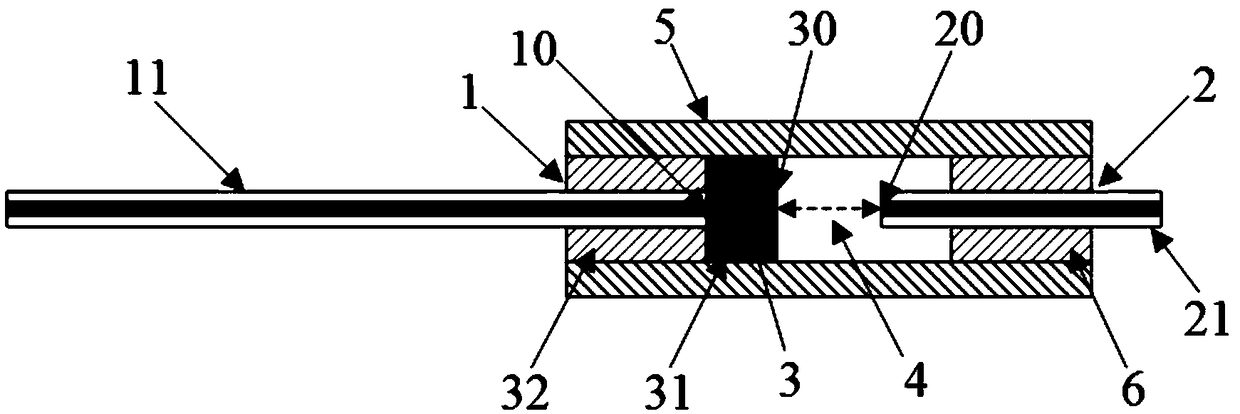

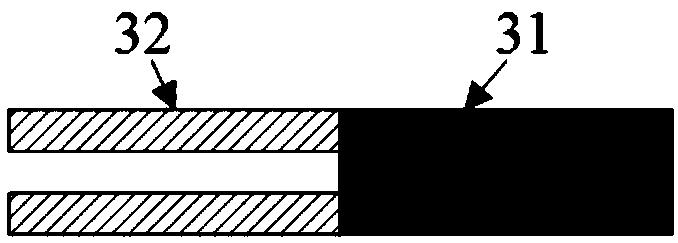

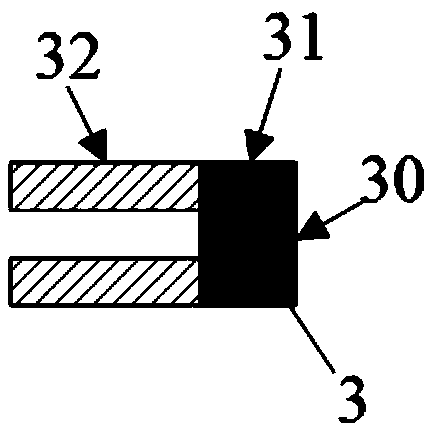

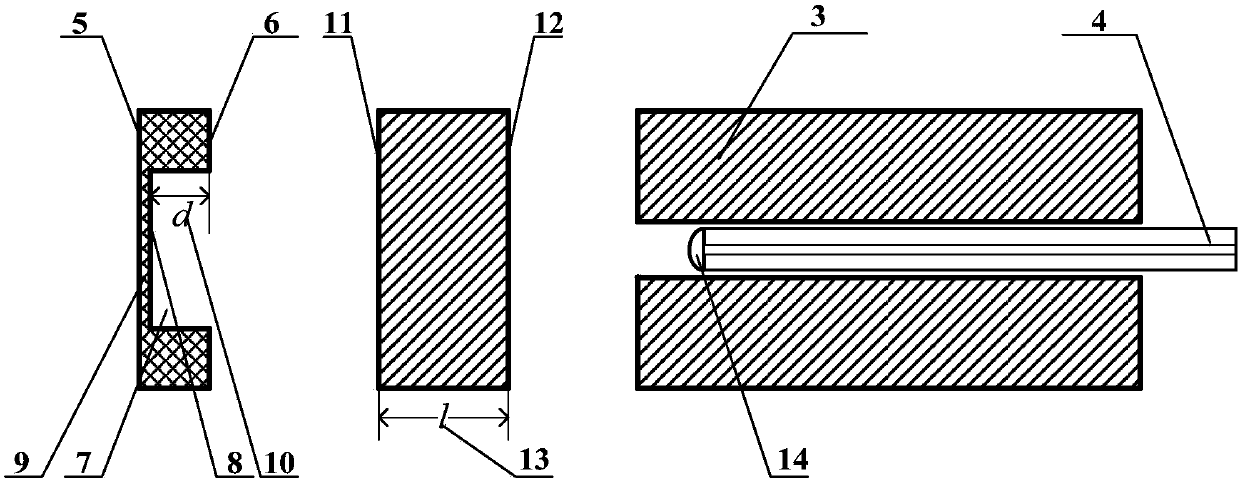

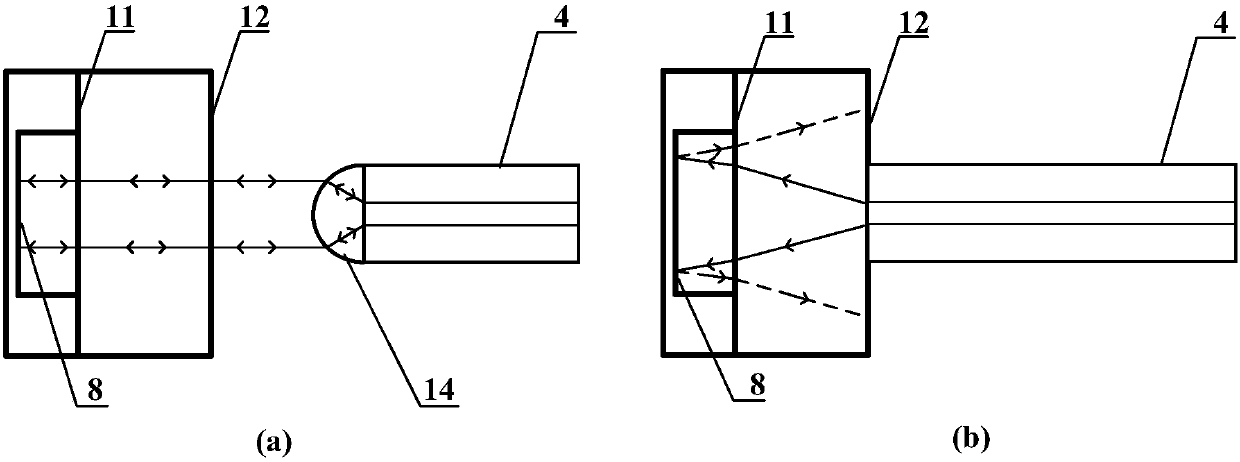

Optical fiber temperature and pressure sensor for double-cavity structure and a preparation method thereof

PendingCN108731840AAccurate pressure valueEasy to cut and grindForce measurement by measuring optical property variationThermometers using physical/chemical changesLight beamIntrinsics

The invention provides an optical fiber temperature and pressure sensor for a double-cavity structure and a preparation method thereof. The sensor comprises an incoming component, which is provided with an incoming optical fiber for guiding the incidence of related light beams; a reflecting component, which comprises a reflecting optical fiber used for keeping a reasonable distance with the incoming component so as to form an intrinsic type F-P cavity and a non-intrinsic type F-P cavity. The intrinsic type F-P cavity is formed by welding a second capillary tube and a section of optical fiber;the non-intrinsic type F-P cavity is formed by keeping reasonable distance with the end surface of the incoming component or the reflecting component; a first capillary tube is fixedly connected withthe components. According to reflection of the cavity length of the non-intrinsic type F-P cavity to the related light beams, the measuring temperature and pressure can be obtained; according to the reflection of the cavity length of the intrinsic type F-P cavity to the related light beams, the measuring temperature can be obtained; accurate measurement pressure is obtained after temperature compensation. The invention is advantageous in that the temperature compensation is carried out on the non-intrinsic cavity through the intrinsic cavity, obtaining accurate pressure value; the structure issimple and manufacturing is easy.

Owner:北京东方锐择科技有限公司

Optical fiber temperature and pressure composite sensor

InactiveCN107843291AAccurate pressure valueSimple structureSpecial purpose recording/indication apparatusSignal qualityPressure sense

The invention relates to an optical fiber temperature and pressure composite sensor, in particular to an optical fiber temperature and pressure composite sensor which can be used for simultaneous measurement of the temperature, absolute pressure or relative pressure of liquid and gas, and belongs to the field of optical fiber sensing technology. The sensor realizes simultaneous measurement of thetemperature and pressure through a simple two-layer structure, a transmission optical fiber with collimated microlenses on its end faces is used to enhance the signal quality of the sensor, two spectral analysis modules containing optical wedges with different thicknesses are used to demodulate a pressure sensing cavity length and a temperature sensing cavity length respectively, interference signals of the two cavities are separated through the one-to-one correspondence between the wedge thicknesses and the cavity lengths, in this way, the data processing steps are simplified, the demodulation speed is increased, and the measurement of dynamic pressure and temperature signals facilitated.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

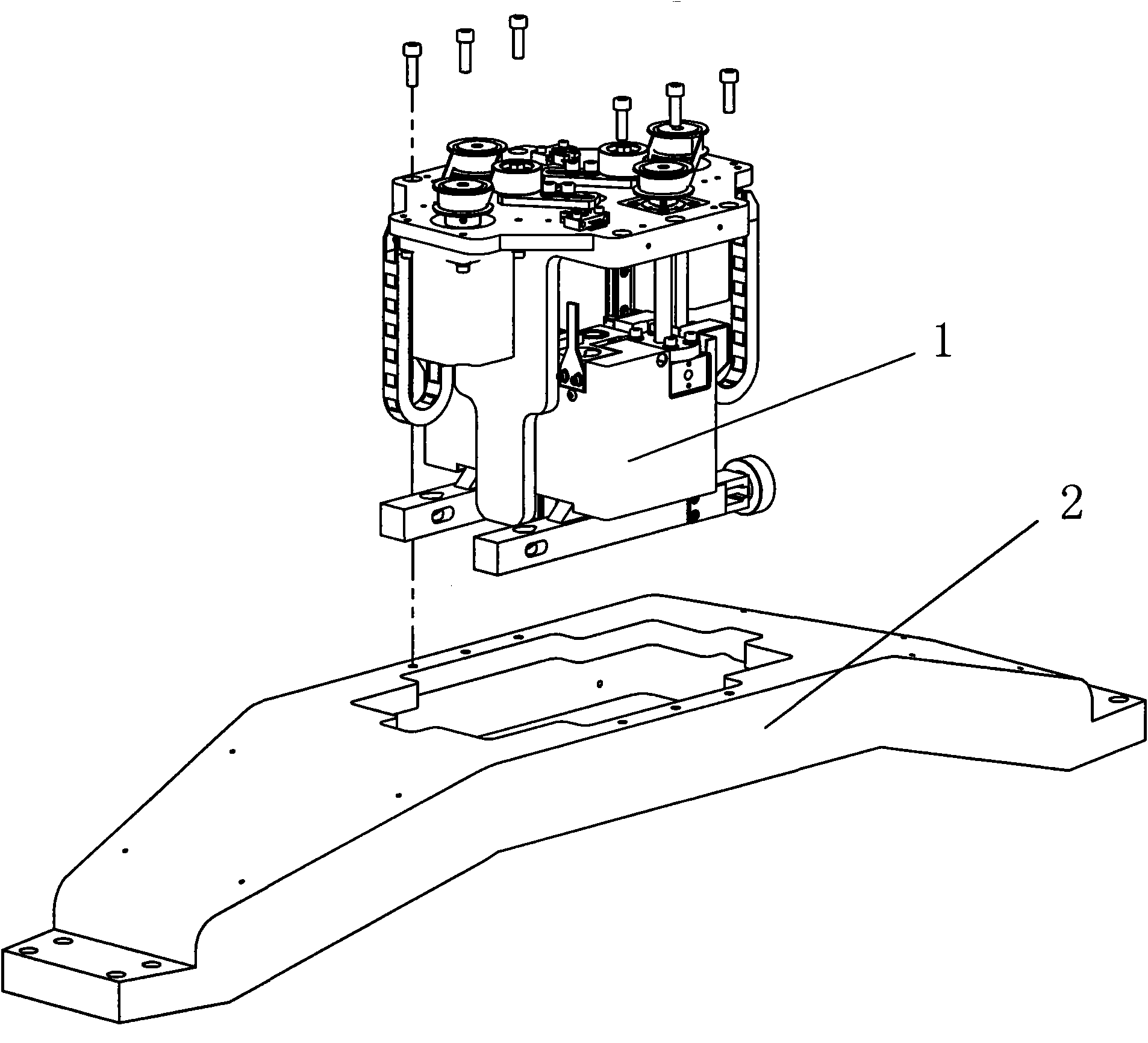

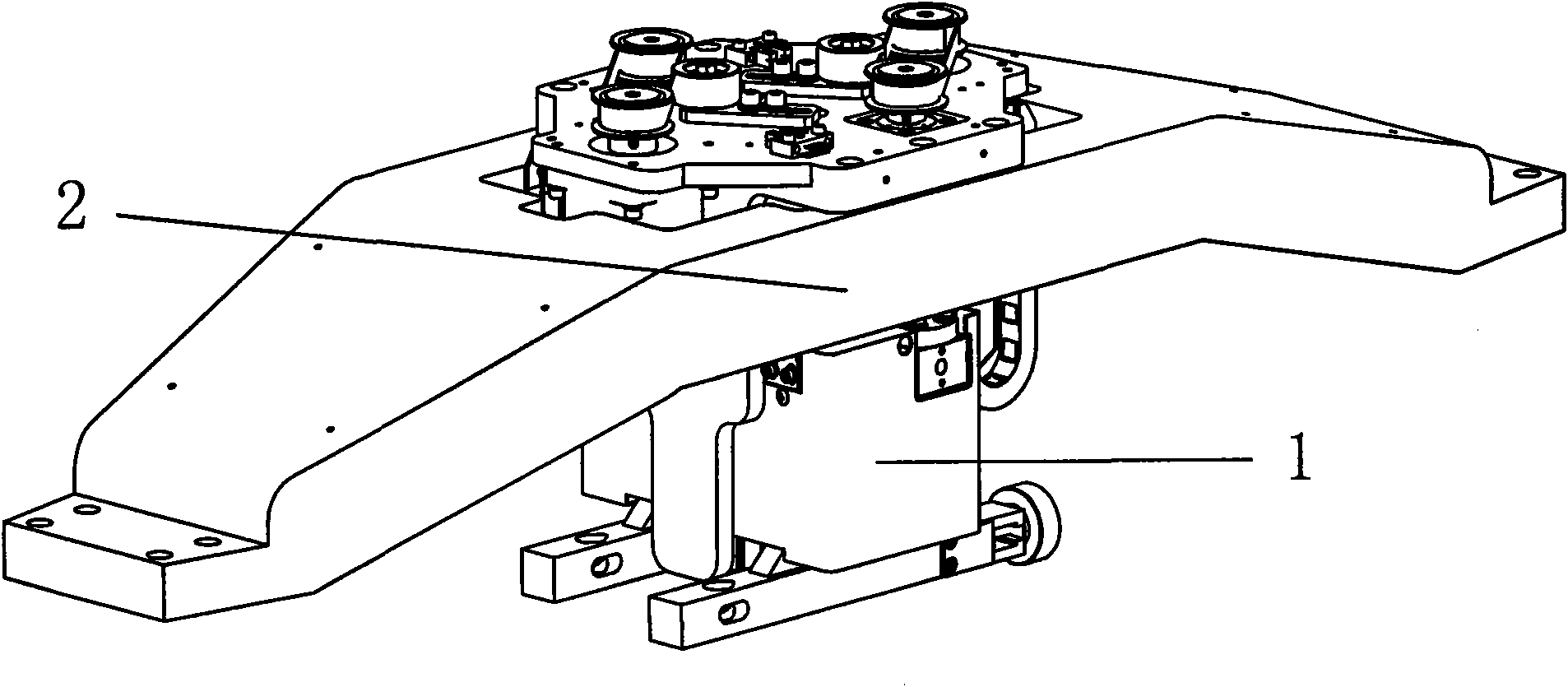

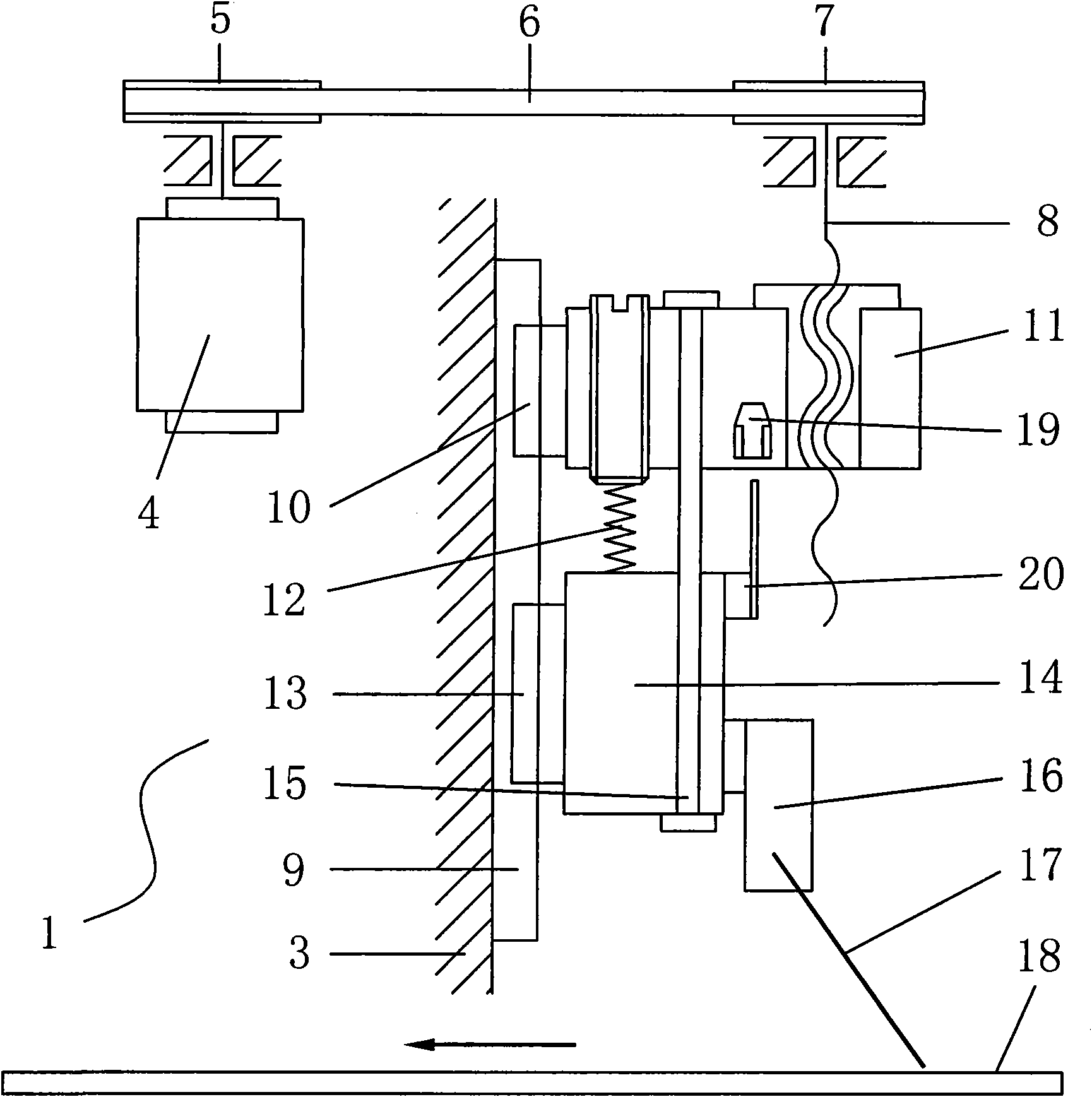

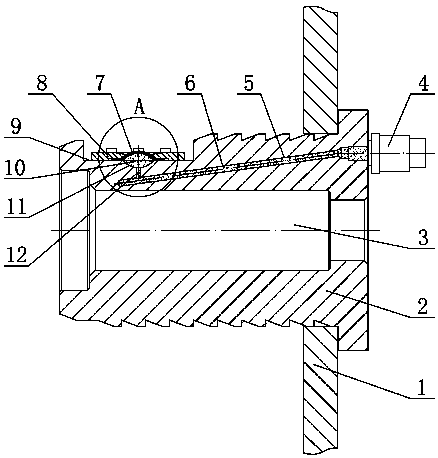

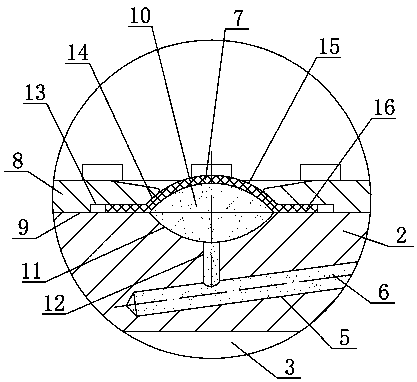

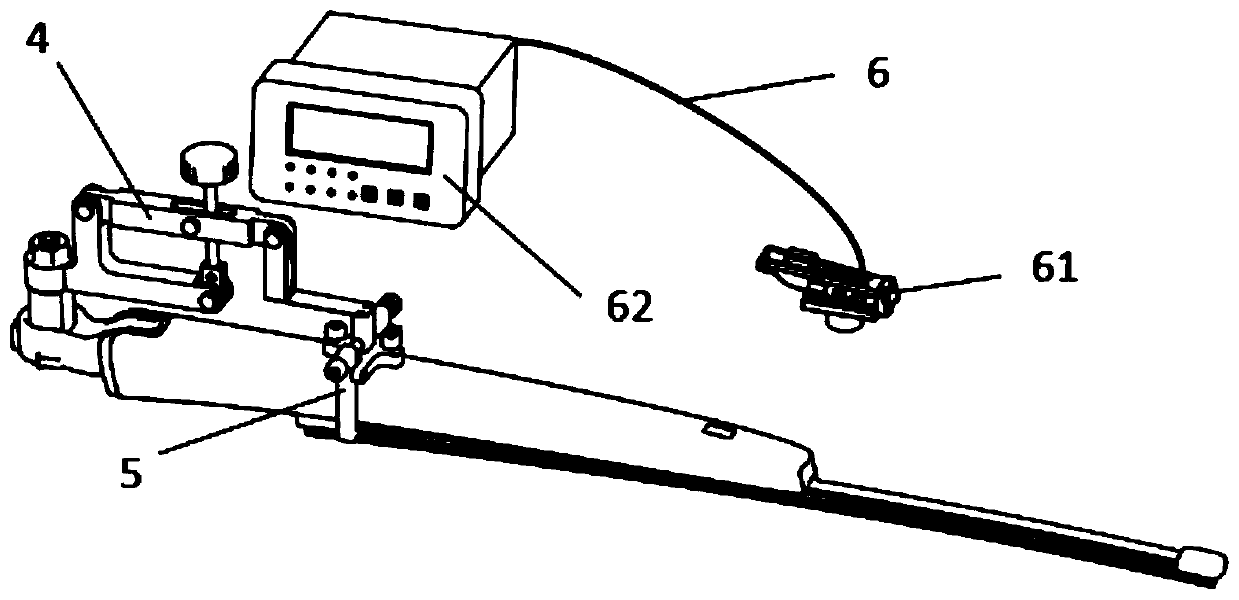

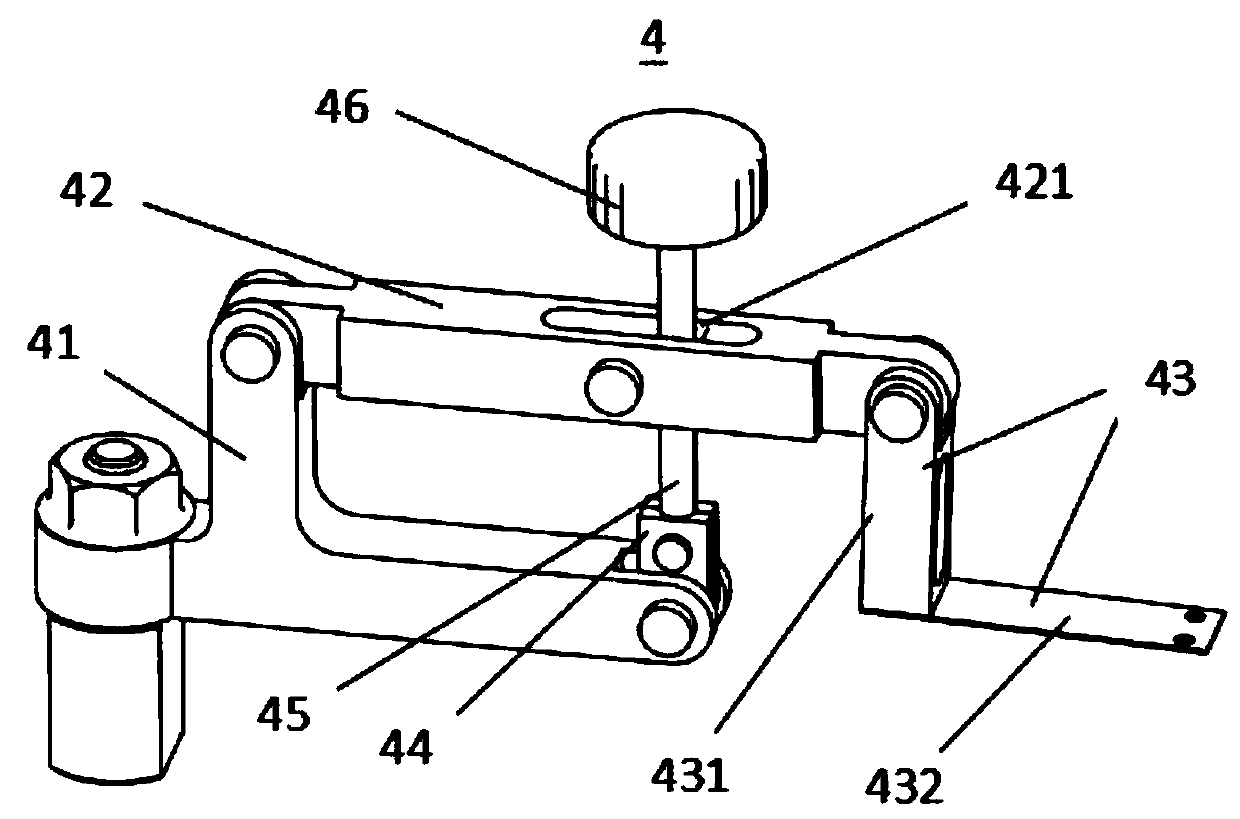

Contact sensing scarper mechanism and full automatic vision printer

ActiveCN101979249AAccurate pressure valueIntelligent controlScreen printersEngineeringPrinted circuit board

The invention discloses a contact sensing scarper mechanism and a full automatic vision printer and belongs to the field of printed circuit board (PCB) printers. A scraper lifting module of the mechanism is assembled with a scraper beam; a stepping motor, a screw rod and a slide rail are respectively assembled with a module seat; the screw rod is connected with the stepping motor through a synchronous belt wheel B, a synchronous belt and a synchronous belt wheel A and is connected with an upper sliding block seat; an upper sliding block is assembled with the upper sliding block seat; a lower sliding block seat is connected with the upper sliding block seat through an adjusting bolt; a lower sliding block is assembled with the lower sliding block seat; the upper sliding block and the lower sliding block are respectively matched with the slide rail; the upper end of a spring is connected with the upper sliding block seat; the lower end of the spring is connected with the lower sliding block seat; a photoelectric sensor is assembled with the upper sliding block seat; a sensing sheet which has sensing relation with the photoelectric sensor is arranged on the lower sliding block seat; a scraper seat is assembled with the lower sliding block seat; and a scraper is assembled with the scraper seat. The mechanism is movably assembled with a frame of the full automatic vision printer, so that the control of the mechanism is more intelligent, and the accuracy is higher.

Owner:GKG PRECISION MACHINE

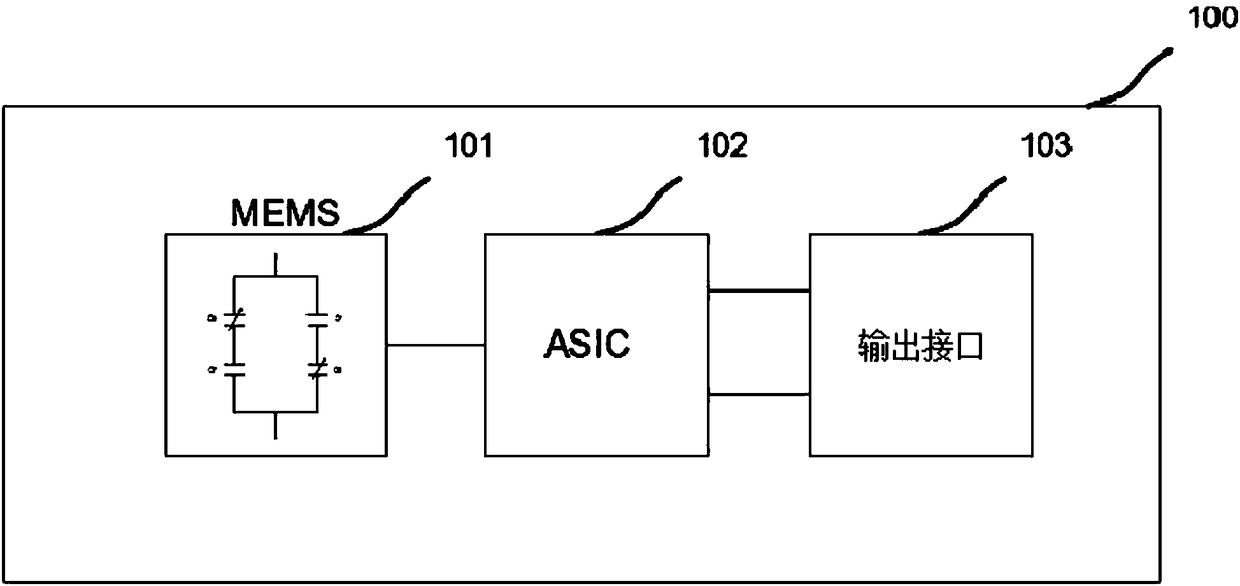

Pressure sensor and manufacturing method thereof

ActiveCN108362408AImprove manufacturabilityAccurate pressure valueForce measurementCapacitanceEngineering

The present invention relates to a pressure sensor and a manufacturing method thereof. The pressure sensor comprises: a substrate; a passivation layer located at the surface of the substrate; a firstlower electrode, a second lower electrode and a connection electrode which are located at the surface of the passivation layer, wherein the connection electrode is connected with the first lower electrode and the second lower electrode; a first upper electrode supported at the upper portion of the first lower electrode, wherein the first upper electrode and the first lower electrode form an inductive capacitor; a second upper electrode supported at the upper portion of the second lower electrode, wherein a support portion is arranged between the first upper electrode and the first lower electrode, and the second upper electrode and the second lower electrode form a reference capacitor; and an insulation layer covering the first upper electrode and the second upper electrode. The method provided by the invention is simple in step and can improve the process manufacturability.

Owner:MEMSENSING MICROSYST SUZHOU CHINA

Multigrid pressure solver for fluid simulation

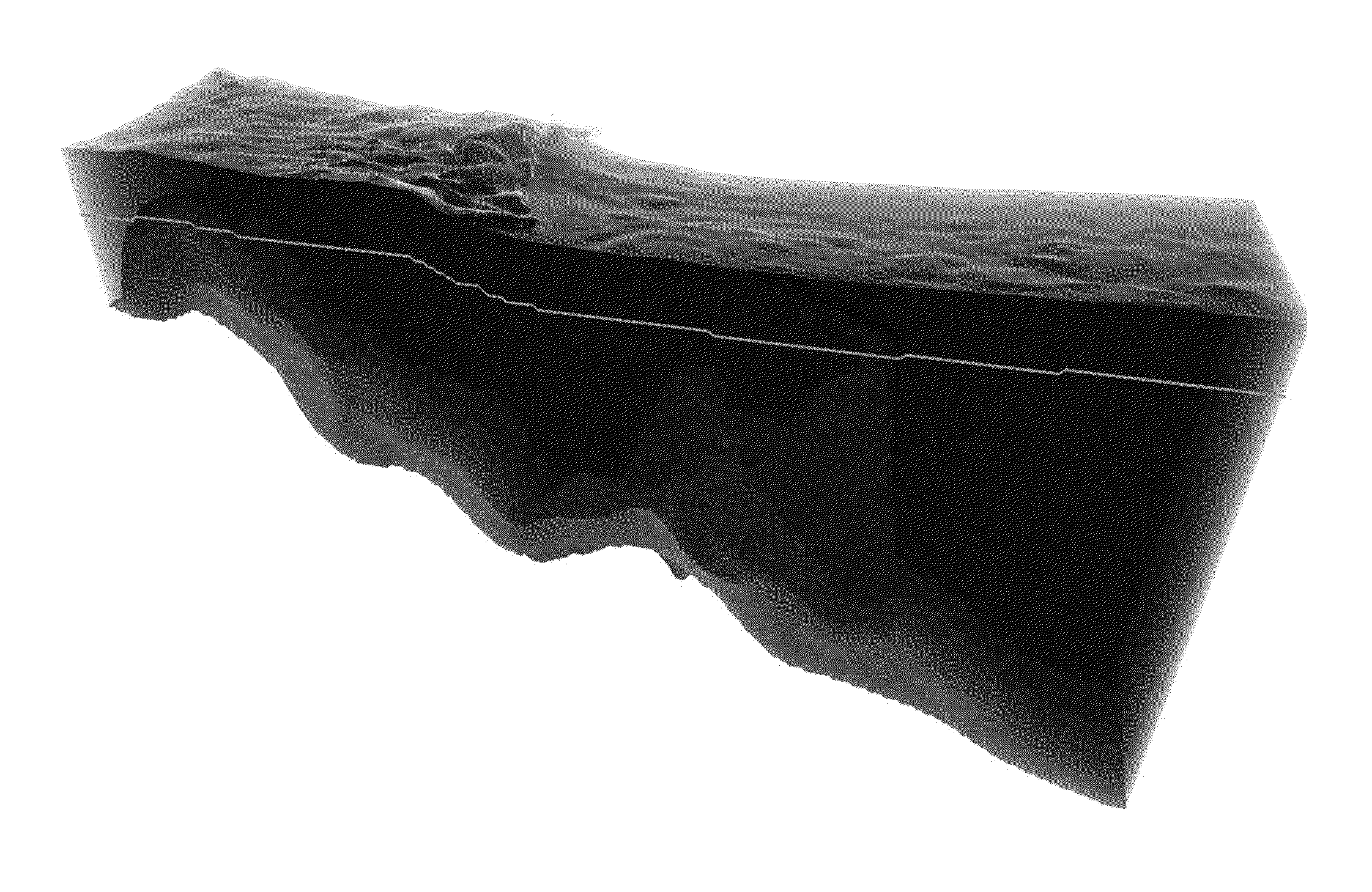

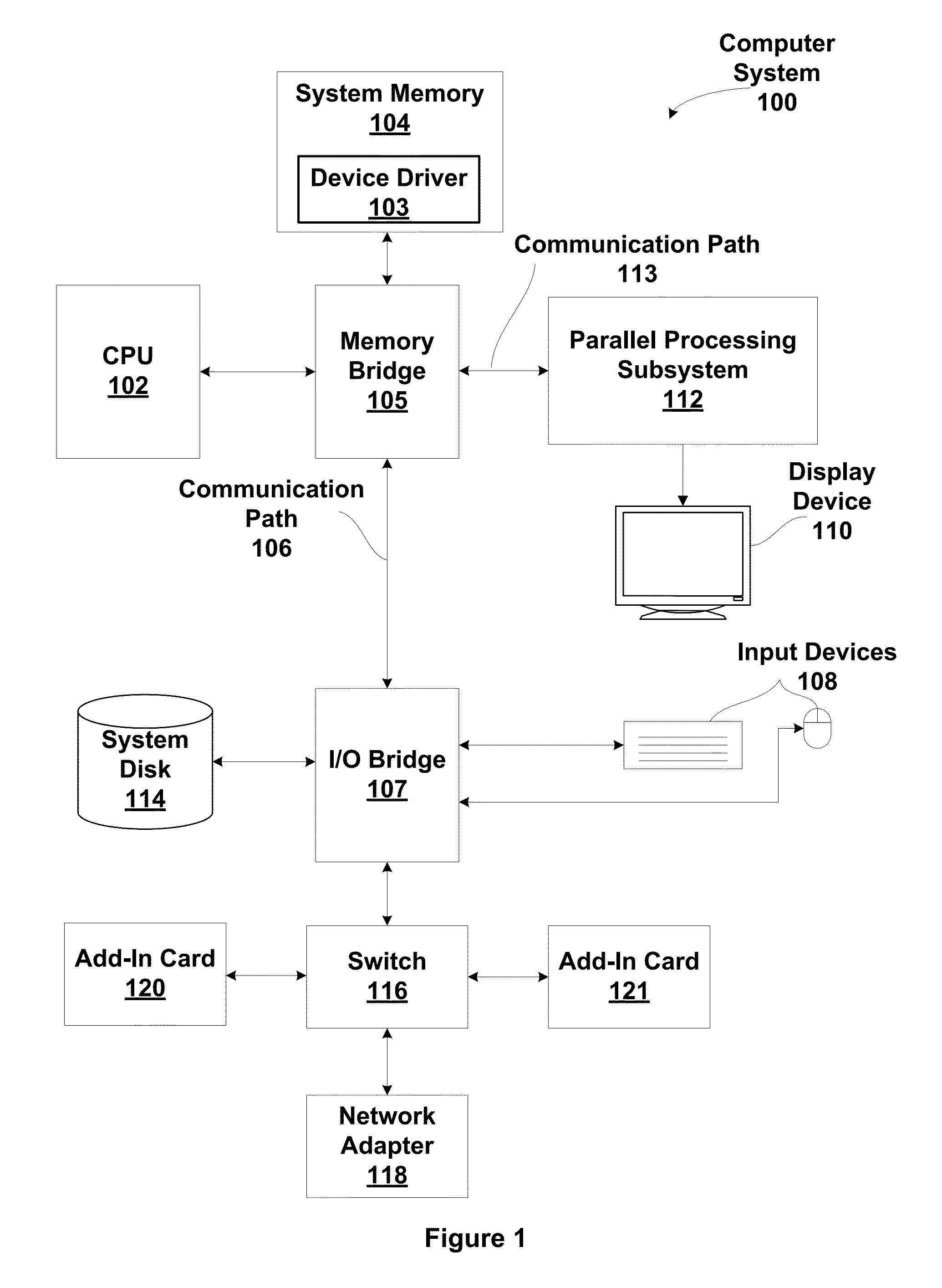

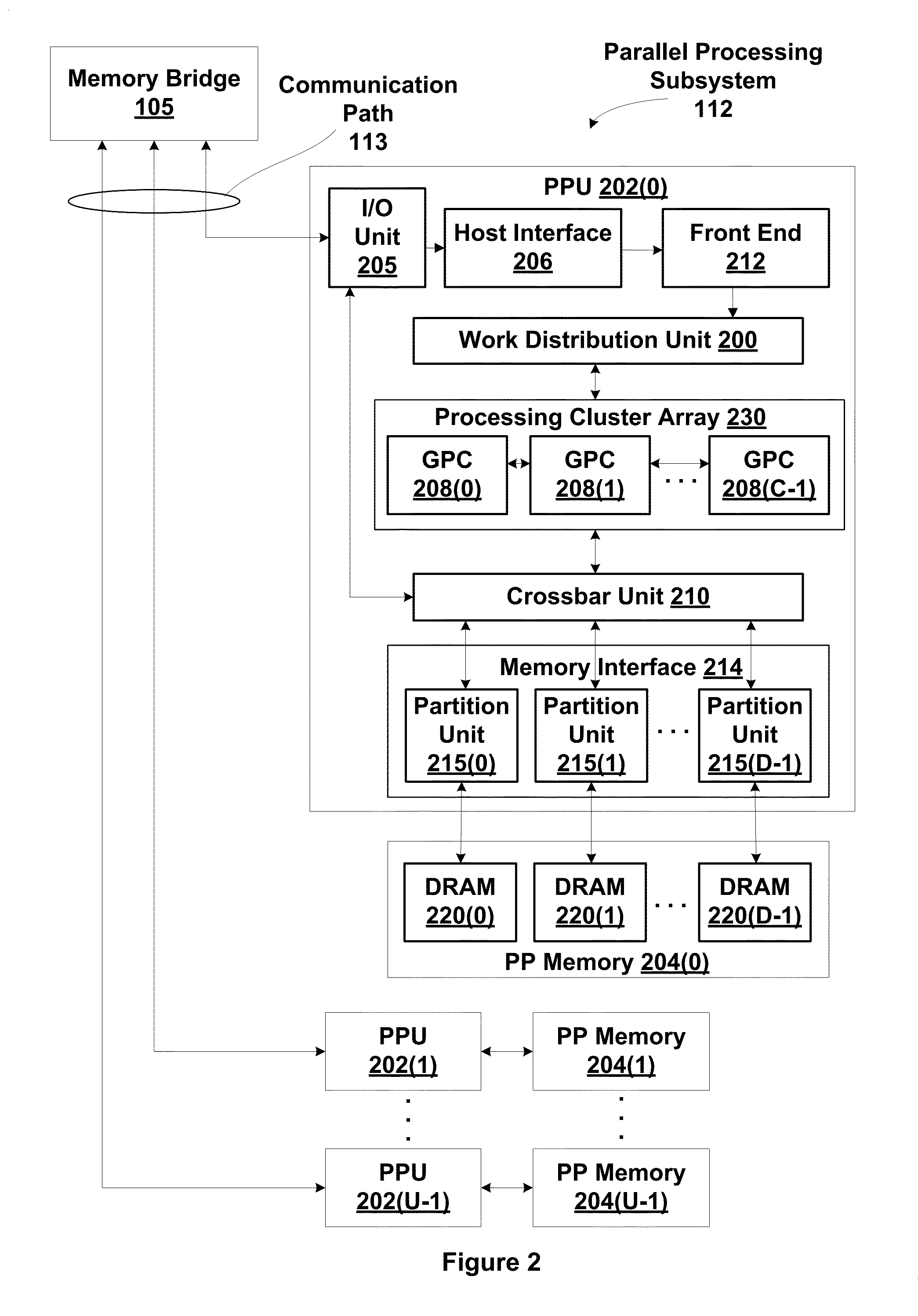

ActiveUS20130033489A1Raise the possibilityMaintain accuracyIndoor gamesImage memory managementGraphicsWater Movements

One embodiment of the present invention sets forth multigrid generation technique which enables accurate simulations of large scale three dimensional (3D) fluid volumes. A model of the fluid to be simulated is represented using a cell grid. The generated multigrid provides a hierarchy of increasingly coarser representations of the model that are used by a pressure solver. Eulerian simulation techniques require solving a linear system to determine pressure values for each cell within the cell grid. Different levels of the multigrid are then used to compute the pressure values for different regions of the model, maintaining accuracy near the surface of the fluid while simplifying the computations. The accurate pressure values ensure that the simulation produces detailed features of the water movement. Additionally, the multigrid pressure solver may be optimized for execution by a graphics processor.

Owner:NVIDIA CORP

Urodynamic monitoring system and drainage monitoring control unit thereof

PendingCN108771545AInnovative designReasonable structureMedical devicesCatheterInternal pressureAbdominal cavity

The invention relates to a urodynamic monitoring system and a drainage monitoring control unit thereof. The system comprises a mainboard, a control part, a monitoring main unit of a bearing part and the drainage monitoring control unit; the drainage monitoring control unit is formed by connecting a front drainage pipeline, a monitoring controller, a rear drainage pipeline and a urine storage bag in sequence, and the front drainage pipeline is provided with a first three-way valve capable of being communicated with the atmosphere. Accordingly, by arranging the first three-way valve capable of being communicated with the atmosphere on the front drainage pipeline, by switching the working conditions of the first three-way valve, atmospheric pressure of the position where a bladder is locatedis measured, and an accurate bladder internal pressure value is obtained by subtracting the atmospheric pressure of the position where the bladder is located from urine pressure in a monitoring control cavity; the technical problem that in the prior art, due to the fact that the internal pressure of the ladder cannot be accurately monitored so that bionic urinary continence cannot be achieved, andthe pressure in an abdominal cavity cannot be continuously and dynamically reflected are solved.

Owner:ZHEJIANG LEXIN MEDICAL TECH CO LTD

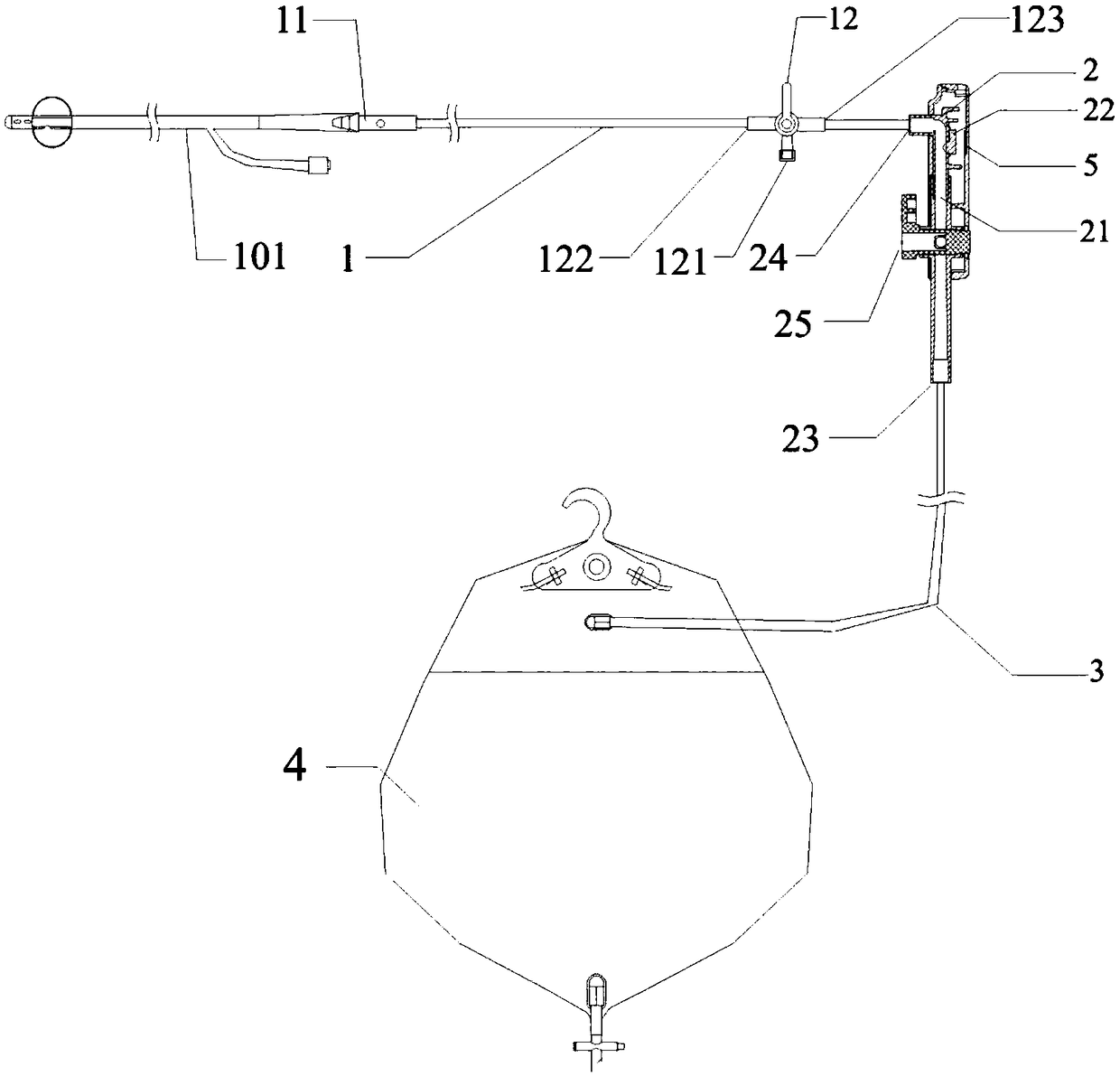

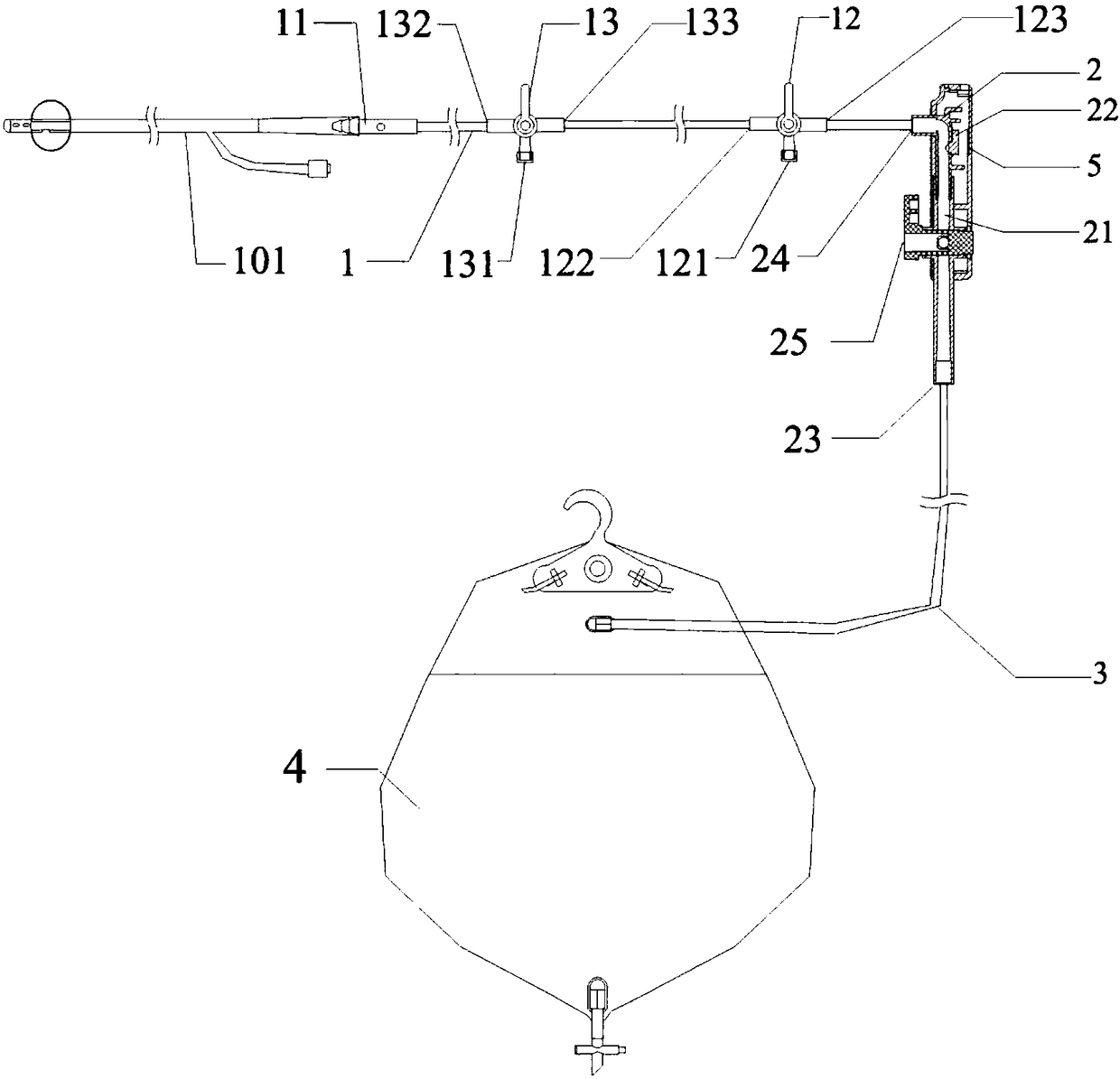

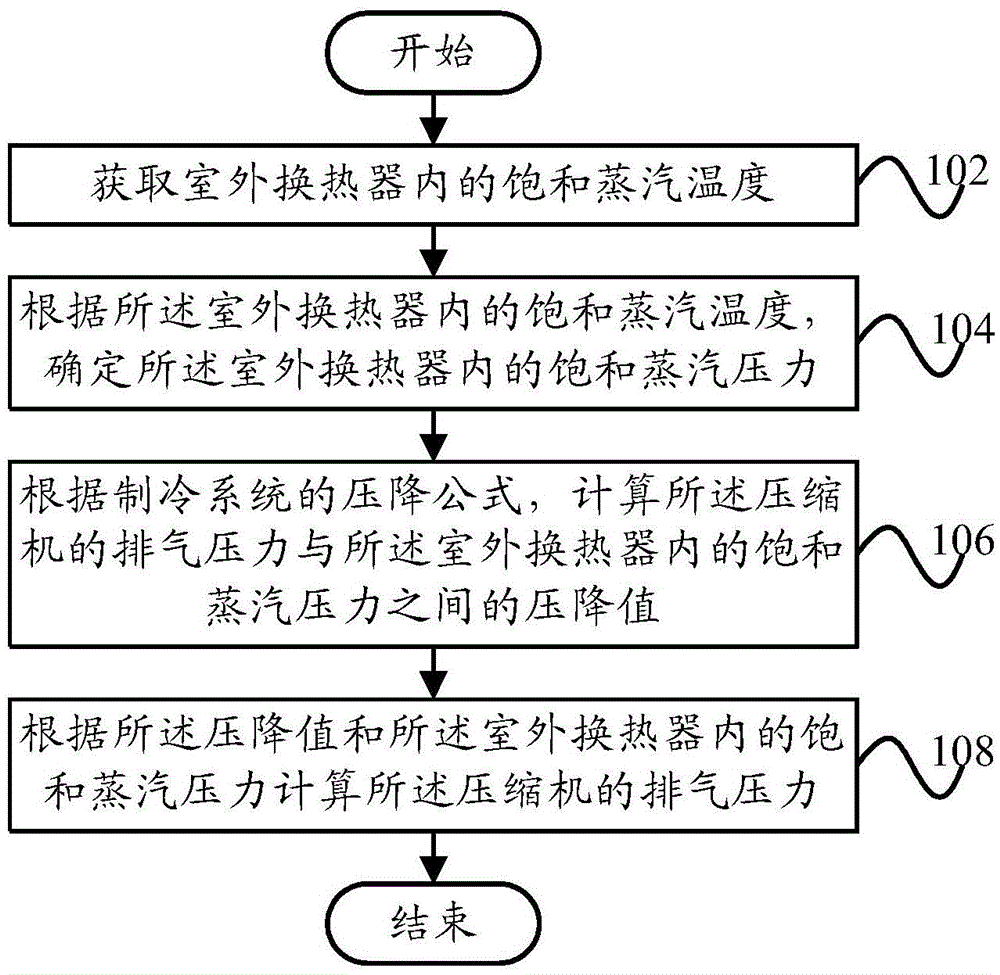

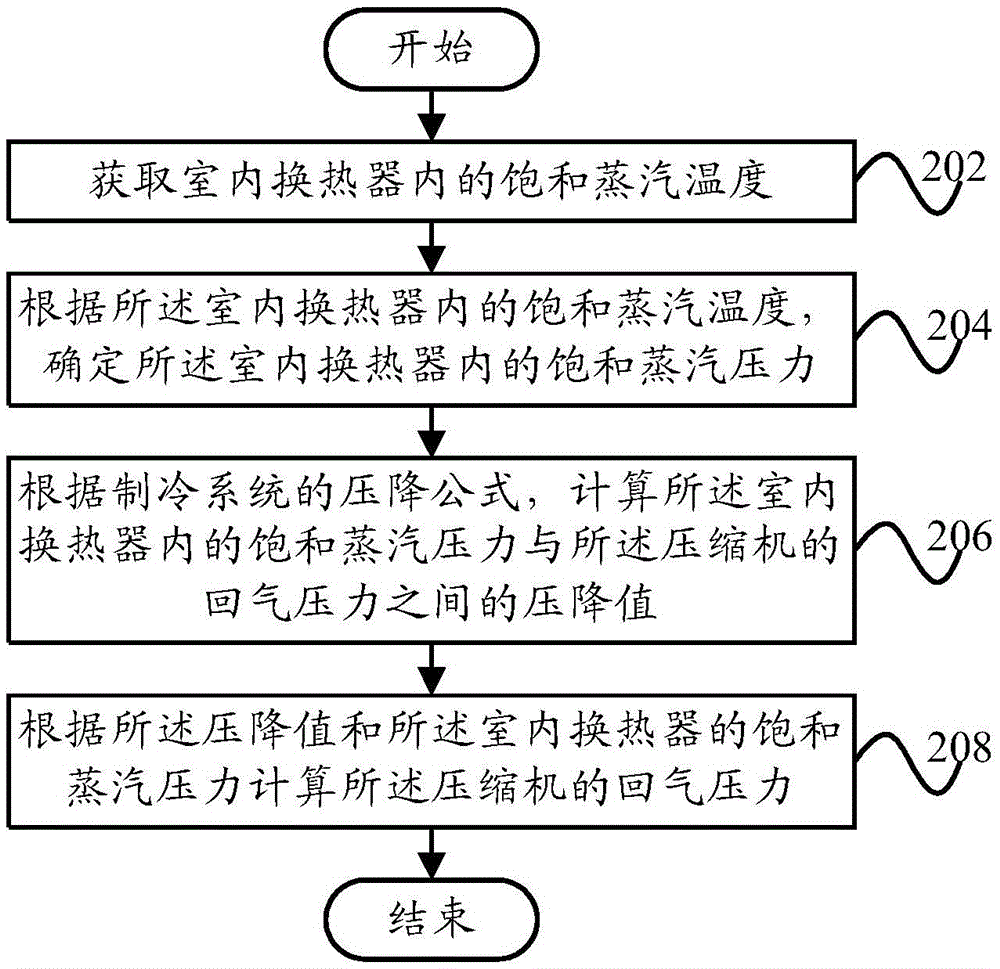

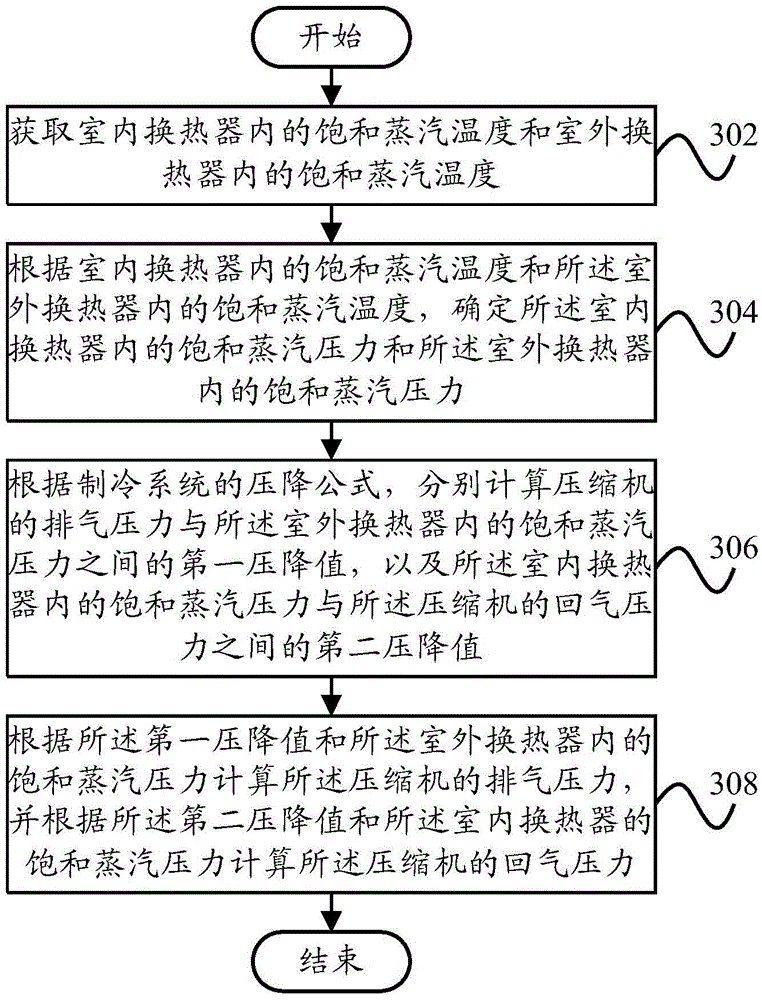

Virtual detection method and device for discharge pressure and back pressure of compressor

ActiveCN105466093ALow costEasy to detectRefrigeration safety arrangementSpecial data processing applicationsProcess engineeringEngineering

The invention provides a virtual detection method and device for discharge pressure and back pressure of a compressor in a refrigerating system. The refrigerating system at least comprises an indoor heat exchanger, an outdoor heat exchanger and the compressor; the virtual detection method for the discharge pressure of the compressor comprises the steps that the saturated steam temperature in the outdoor heat exchanger is obtained; according to the saturated steam temperature in the outdoor heat exchanger, the saturated vapor pressure in the outdoor heat exchanger is determined; according to the pressure drop formula of the refrigerating system, the pressure drop value between the discharge pressure of the compressor and the saturated vapor pressure in the outdoor heat exchanger is calculated; and according to the pressure drop value and the saturated vapor pressure in the outdoor heat exchanger, the discharge pressure of the compressor is calculated. According to the technical scheme, the cost is low, detection can be carried out without cutting a pipe of the refrigerating system open, and the detection process is convenient and simple.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

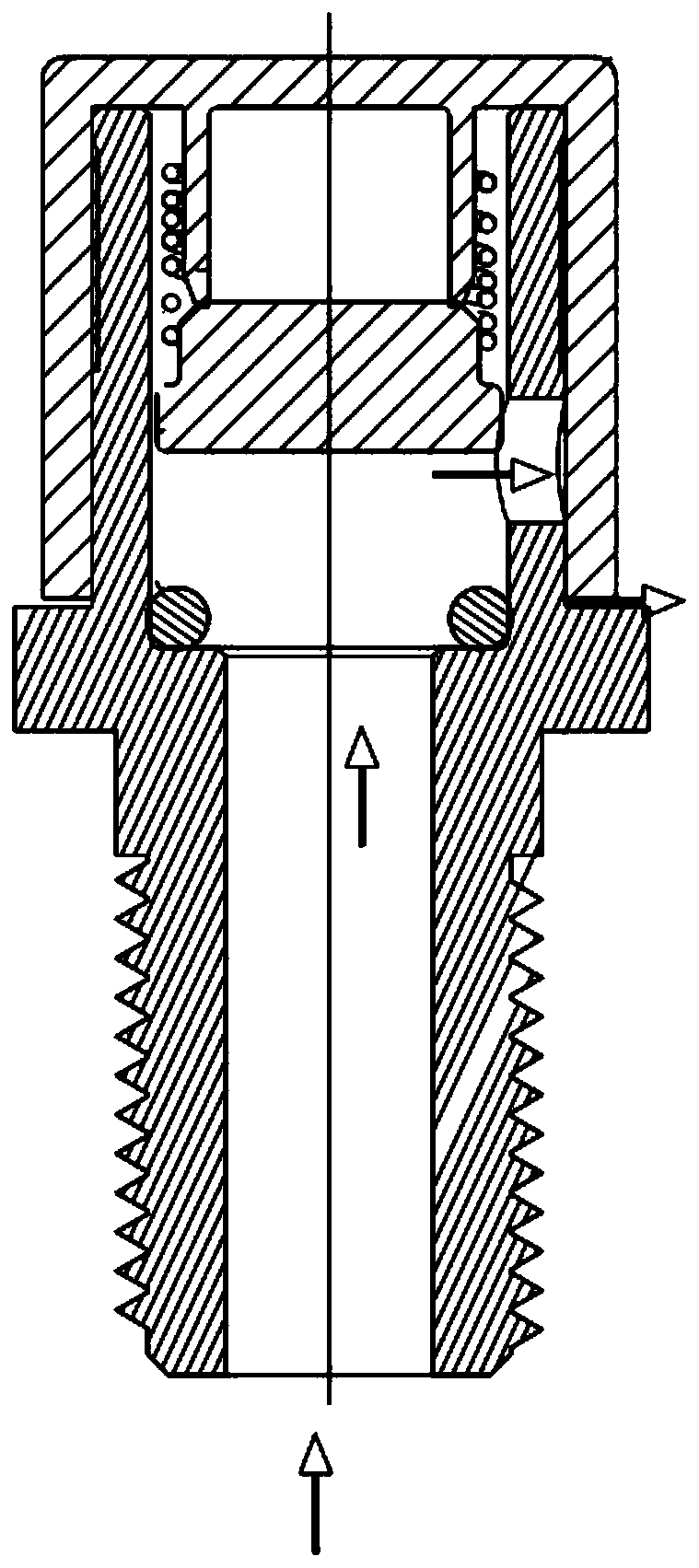

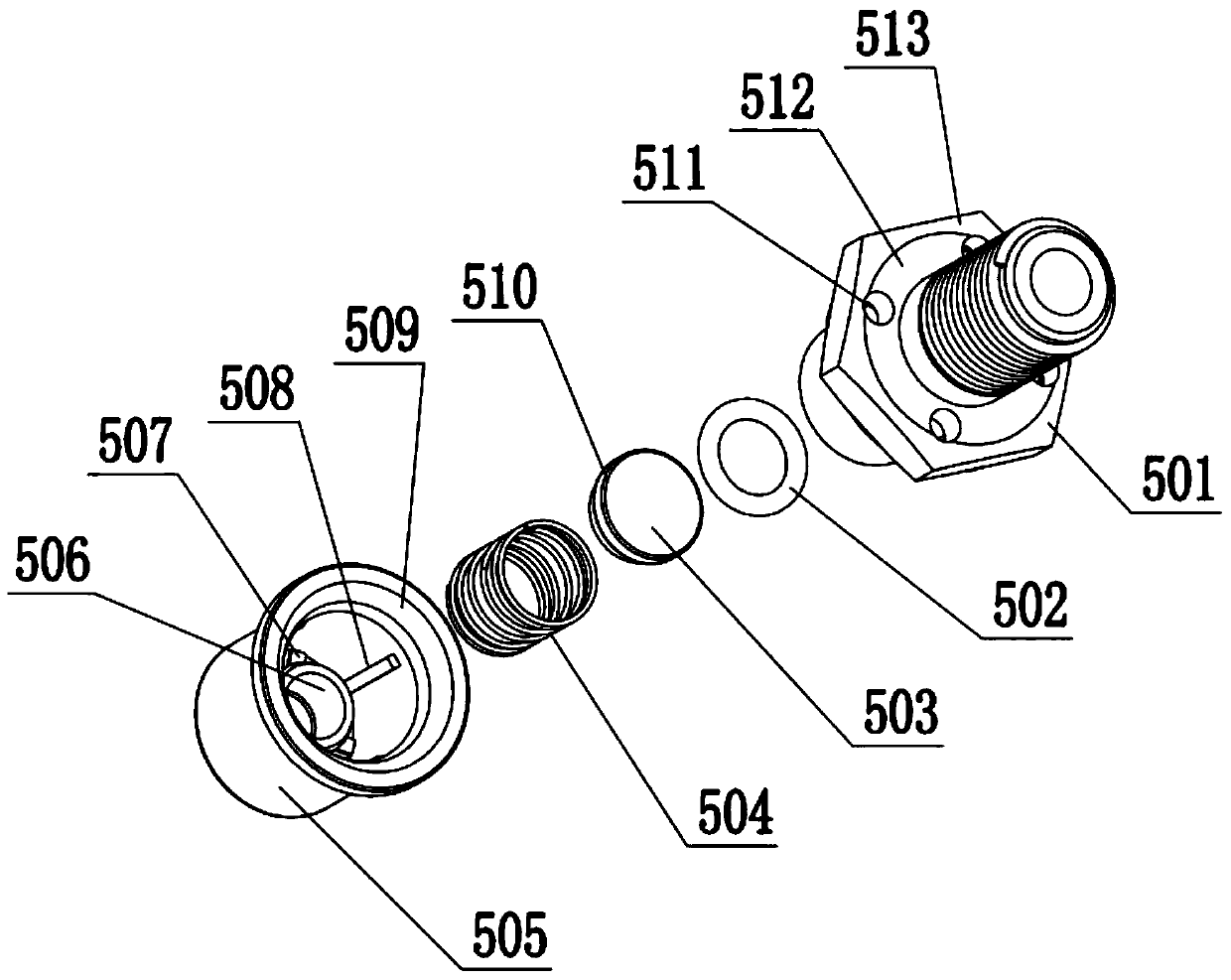

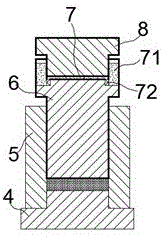

One-way exhaust valve

PendingCN110410538AIncrease the cross-sectional areaEasy dischargeCheck valvesValve housingsExhaust valveEngineering

The invention discloses a one-way exhaust valve, comprising a valve body, a sealing ring, a valve core, a spring and a valve cover, wherein an assembly lug boss is arranged on the outer wall of the valve body, vent holes are distributed in the assembly lug boss in the circumferential direction, and the valve cover covers the top of the valve body and is riveted and fixed to the assembly lug boss;an annular cavity is formed between a spring guide seat and the inner cavity wall in the valve cover, a plurality of first sub-cavity ribs which are arranged radially are distributed at the top of theannular cavity circumferentially, and a first exhaust passage is formed between the adjacent first sub-cavity ribs; a plurality of second sub-cavity ribs which are arranged axially are distributed onthe inner wall of the cavity body of the valve cover circumferentially, and a second exhaust passage is formed between the adjacent second sub-cavity ribs and communicates with the vent holes. According to the one-way exhaust valve, the exhaust passages have large cross-sectional area and can quickly discharge gas; connection between the valve body and the valve cover is stable and not easy to loosen, the spring can be stably contracted according to the specified pressure, and the exhaust valve can be accurately opened; and the operating stability of the exhaust valve can also be ensured.

Owner:北京平恩康汽车技术有限公司

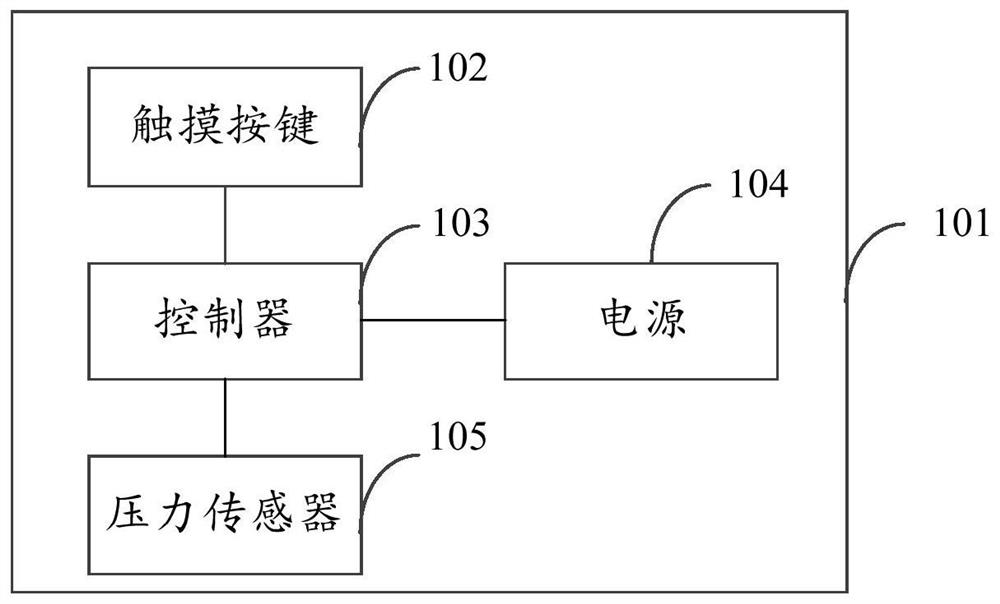

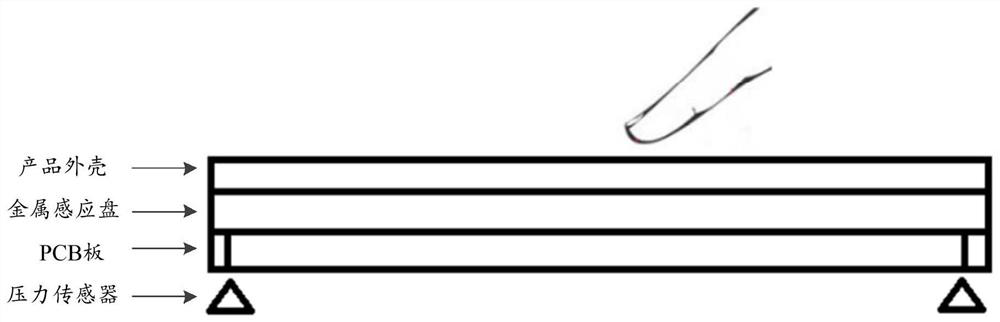

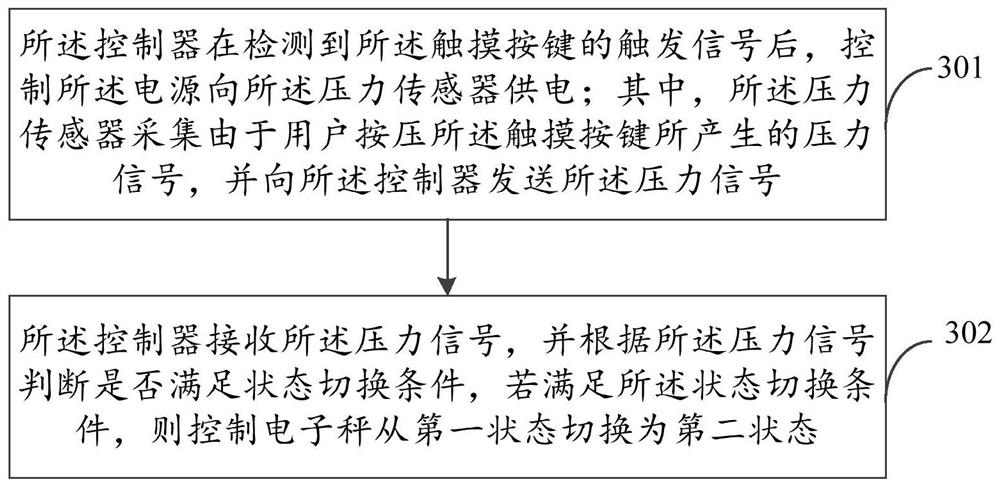

Electronic scale control method and electronic scale

InactiveCN111623863ASave electricityAvoid false triggering issuesApparatus for force/torque/work measurementWeighing auxillary devicesControl engineeringState switching

The invention provides an electronic scale control method and an electronic scale. The electronic scale comprises a touch key, a controller, a power supply and a pressure sensor. The method comprisesthe following steps: after detecting a trigger signal of the touch key, the controller controls the power supply to supply power to the pressure sensor; the pressure sensor collects a pressure signalgenerated by pressing the touch key by a user and sends the pressure signal to the controller; and the controller judges whether a state switching condition is met or not according to the pressure signal, and if the state switching condition is met, the electronic scale is controlled to be switched from the first state to the second state. According to the embodiment of the invention, the pressuresensor is controlled to start working after the touch key is detected to be triggered, and the electronic scale is controlled to perform state switching under the condition that the pressure signal is detected to meet the switching condition without periodic detection of the pressure sensor, so that the electric energy is saved; and whether the state of the electronic scale needs to be switched or not is determined by triggering the touch key and the pressure combination, and the problem of false triggering is avoided.

Owner:ZHONGSHAN TRANSTEK ELECTRONICS

Optical fiber sensing array-type collecting system for coal-bed gas dynamic pressure measuring

The invention discloses an optical fiber sensing array-type collecting system for coal-bed gas dynamic pressure measuring. The optical fiber sensing array-type collecting system comprises an optical fiber sensing array, a processing device and a compensation calibration device. The optical fiber sensing array is used for real-timely collecting gas pressure signals of all detecting points or designated detecting points in a measuring area and converting the gas pressure signals into optical measuring signals. The processing device is used for conducting spectrum parameter analysis through a sensor array spectrum processing unit and a measured information analyzing unit to obtain optical parameters to be subjected to data encapsulation. The compensation calibration device is used for analyzing the optical parameters transmitted by the processing device and subjected to data encapsulation and obtaining accurate gas pressure values after pressure calculating and compensation calibration according to the analyzed optical parameters. According to the optical fiber sensing array-type collecting system, the collected gas pressure information values can be subjected to compensation calibration through a scientific method, and an accurate data foundation is provided for forecasting and early warning of the coal-mine gas pressure.

Owner:HENAN POLYTECHNIC UNIV

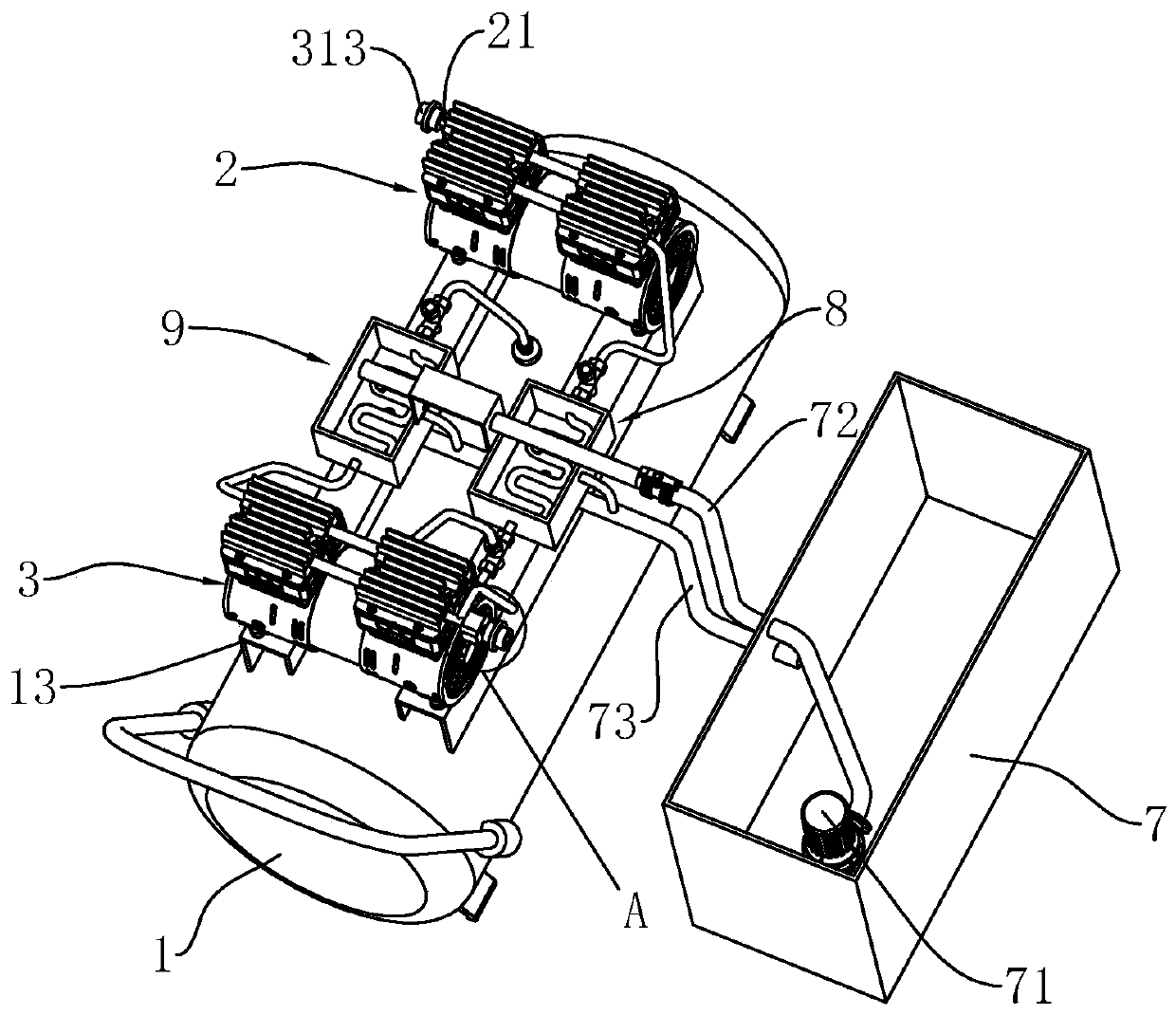

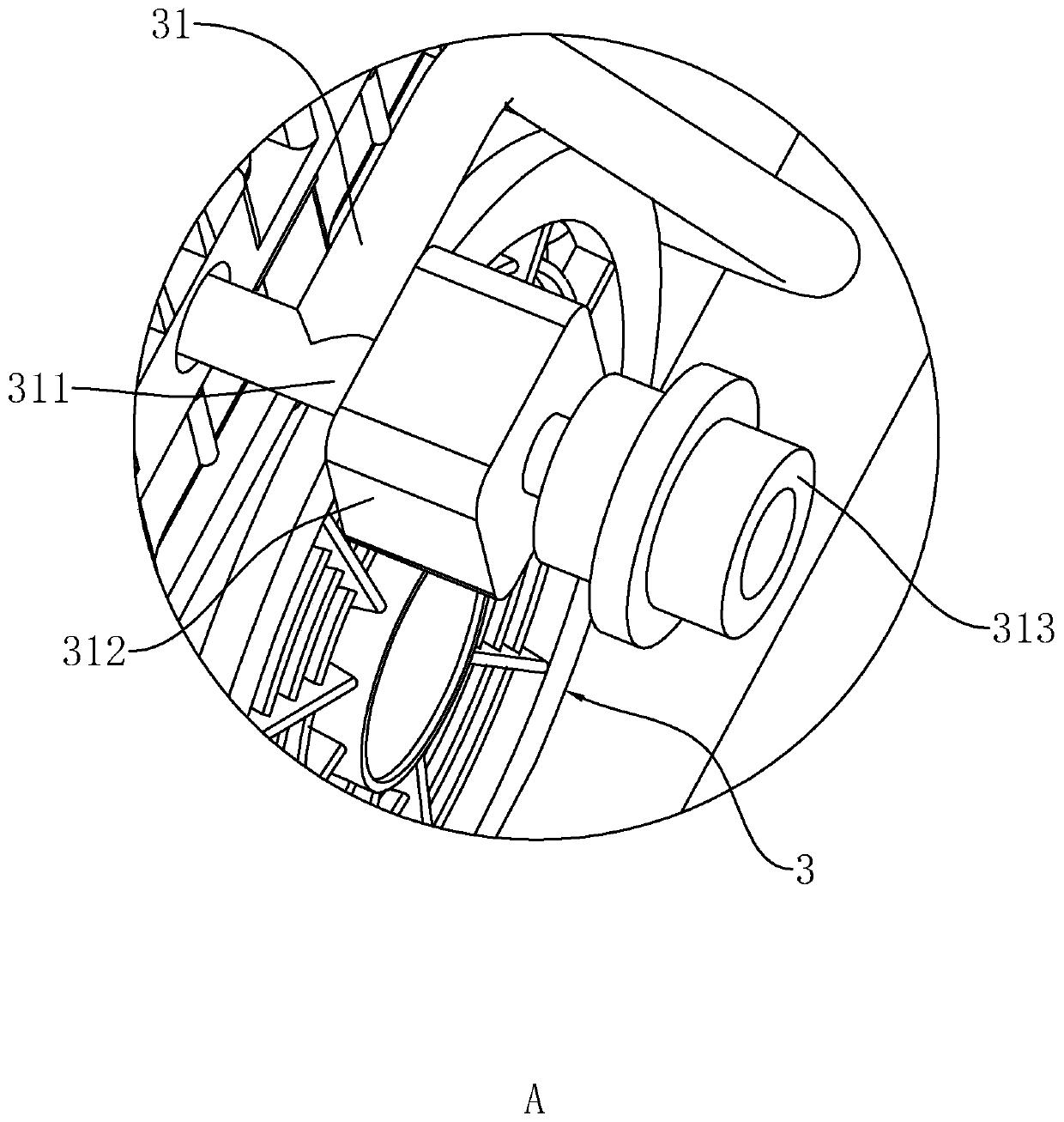

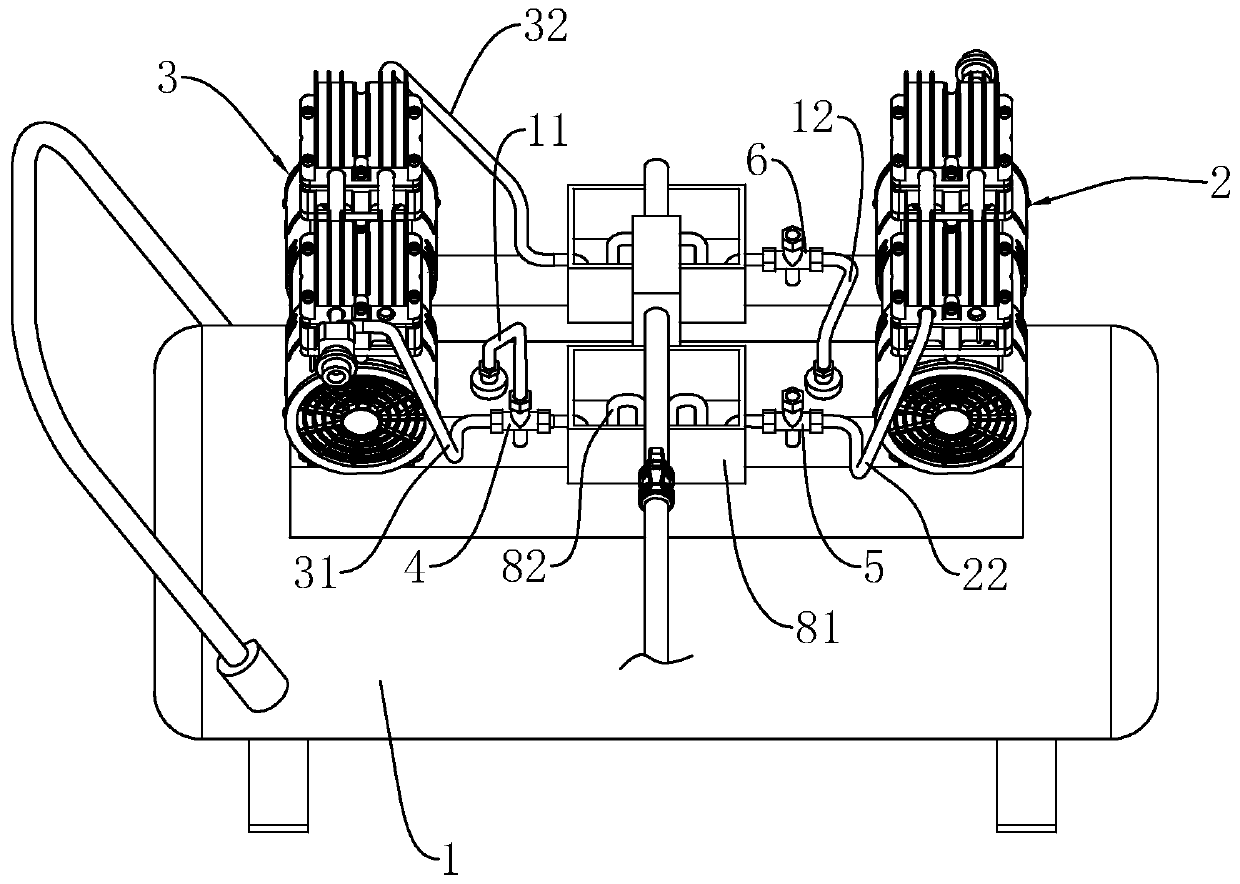

Air compressor

ActiveCN110552866AExtended service lifeReduce the impactPositive displacement pump componentsPump controlGas compressorEngineering

The invention discloses an air compressor. According to the technical scheme, the air compressor is characterized by comprising an air storage tank, wherein a low-pressure compressor, a high-pressurecompressor and a first three-way valve are arranged on the air storage tank; the low-pressure compressor is provided with a first air inlet pipe and a first air outlet pipe; the high-pressure compressor is provided with a second air inlet pipe and a second air outlet pipe; the first air outlet pipe is connected to the inlet end of the first three-way valve; one outlet end of the first three-way valve communicates with the air storage tank; the second air inlet pipe is connected to the other outlet end of the first three-way valve; the second air inlet pipe is connected with an air inlet branchpipe which is provided with an electromagnetic valve; and the second air outlet pipe is connected with the air storage tank. When the first air outlet pipe communicates with the air storage tank through the first three-way valve, the low-pressure compressor and the high-pressure compressor both carry out primary compression and supply air into the air storage tank, so that the displacement of thecompressed air is large; and when the first three-way valve communicates the first air outlet pipe and the second air inlet pipe, the high-pressure compressor carries out secondary compression, and the pressure of the compressed air discharged into the air storage tank is high.

Owner:浙江凯途科技有限公司

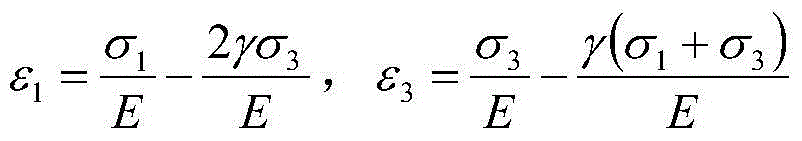

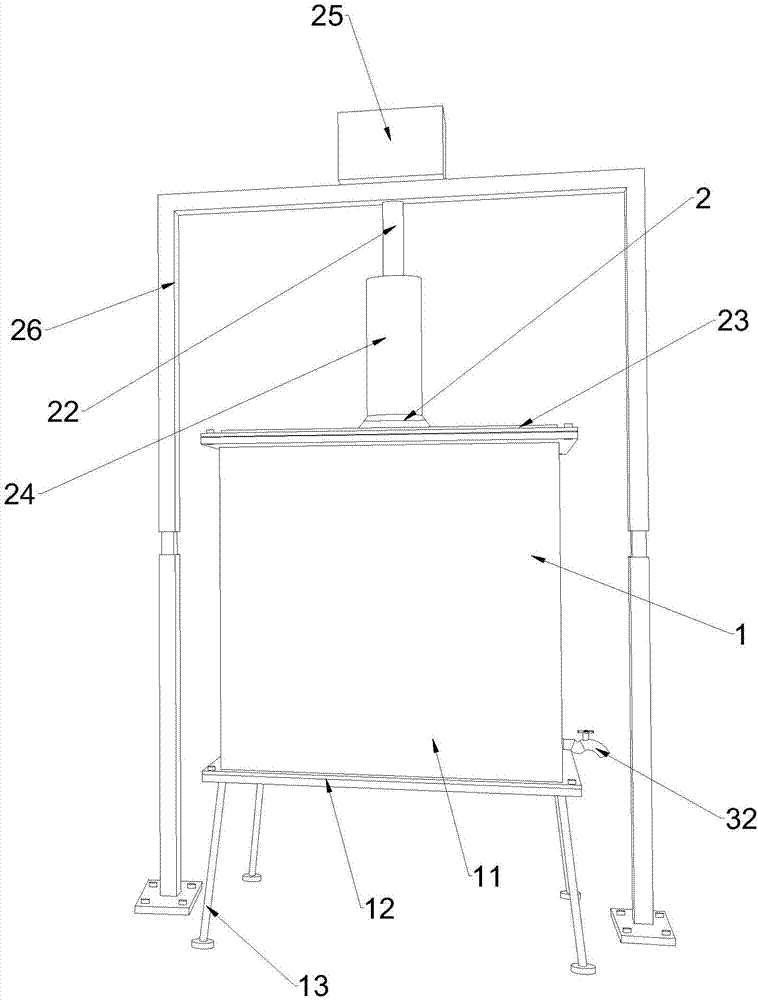

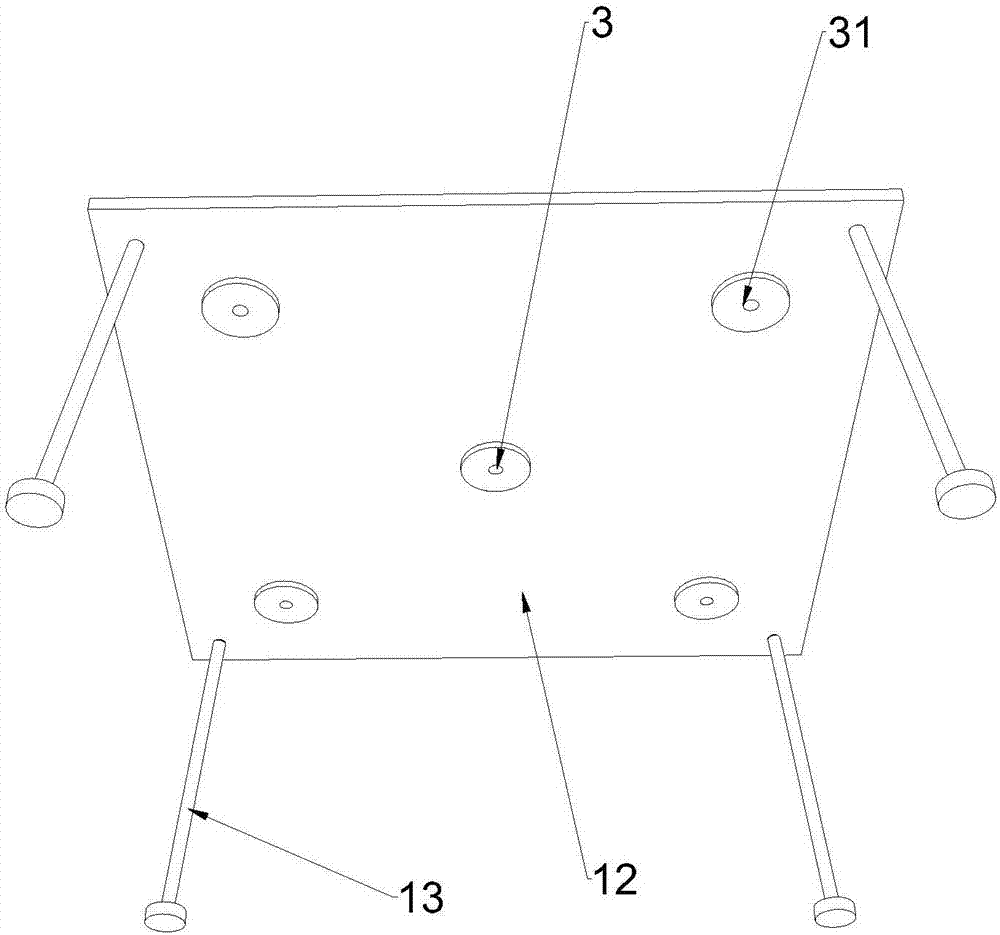

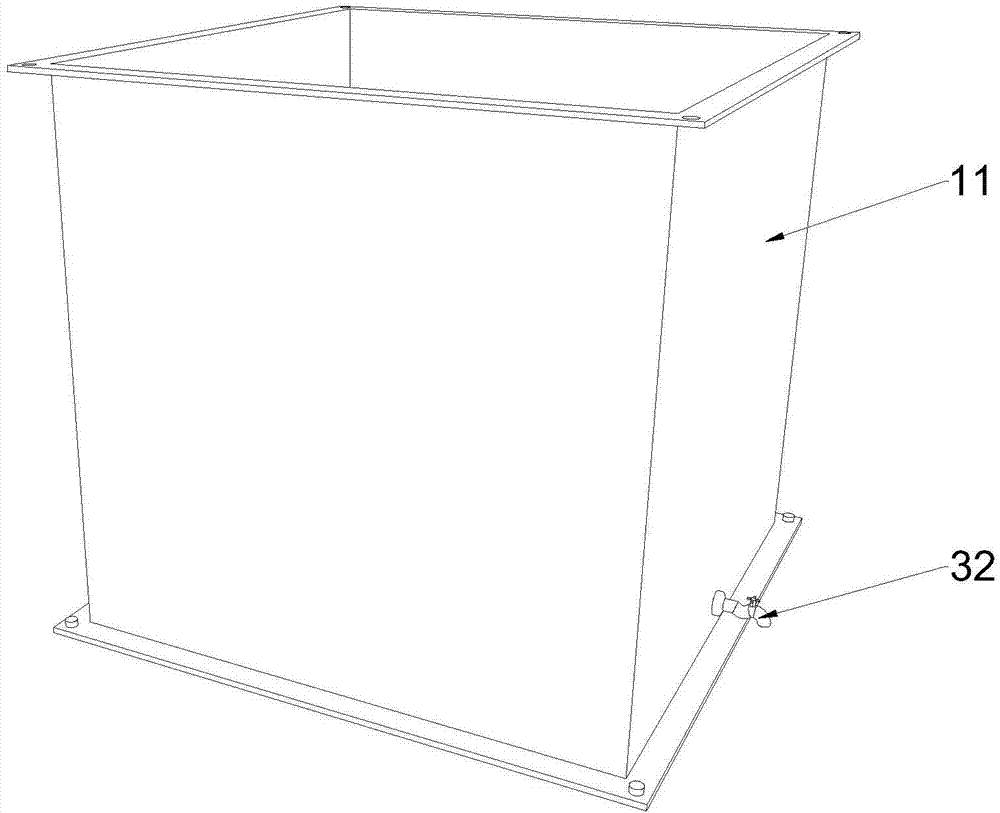

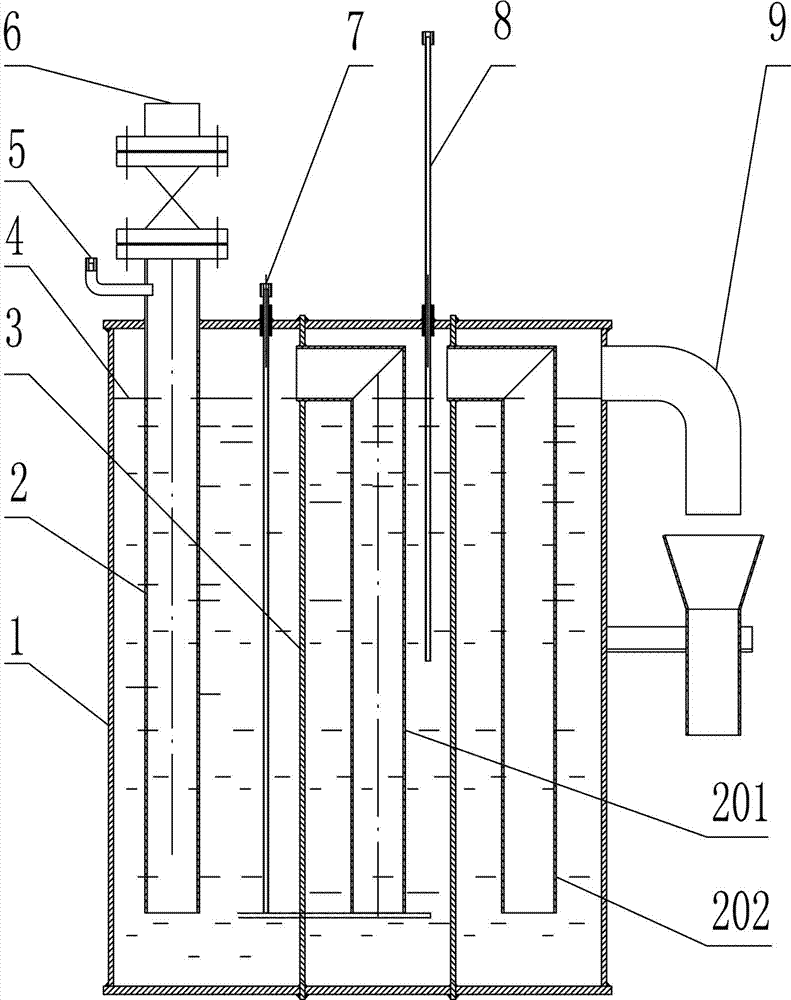

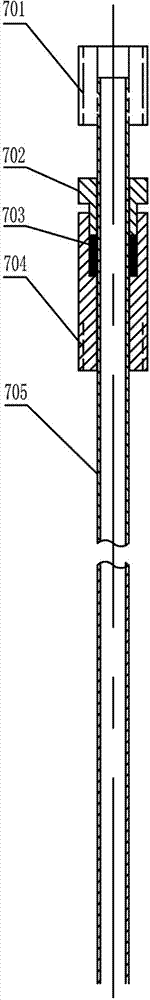

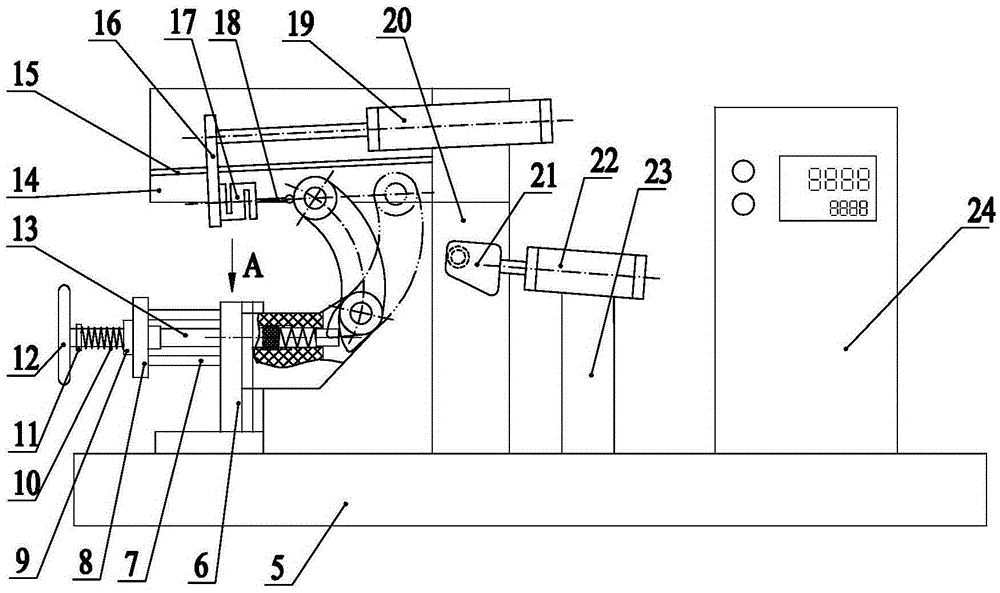

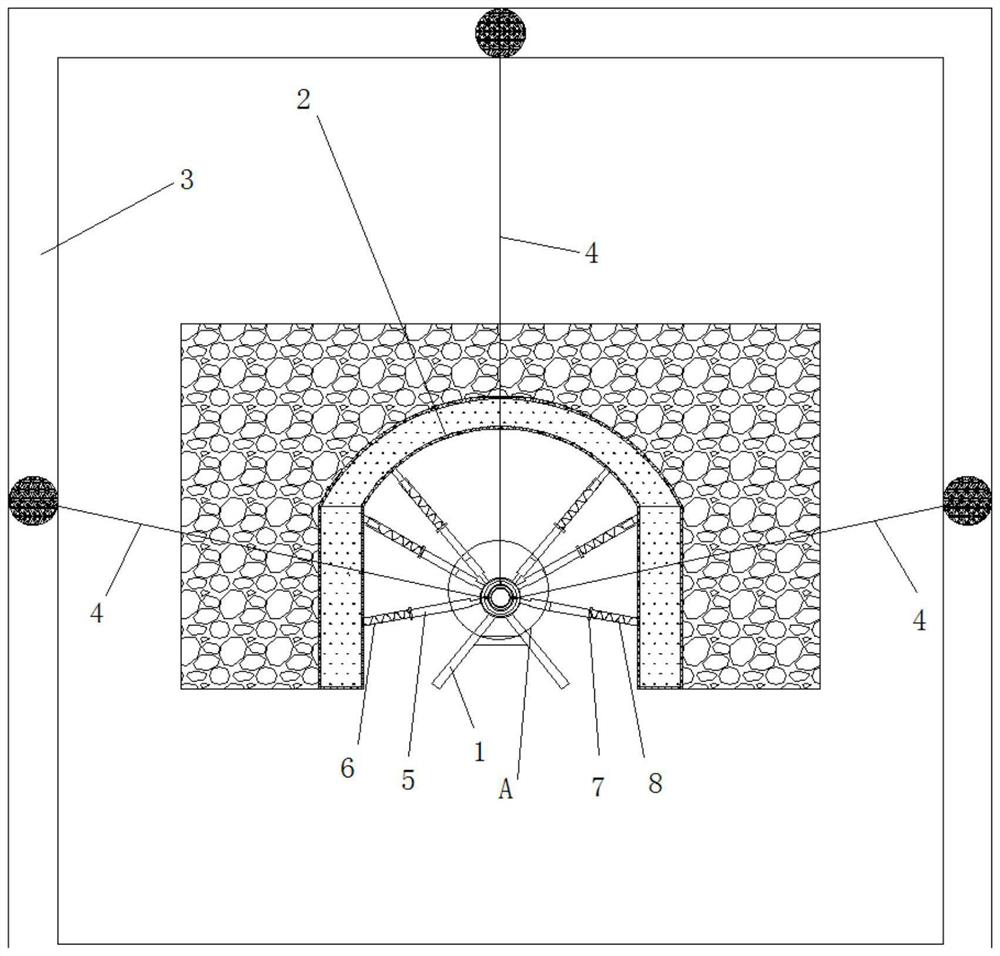

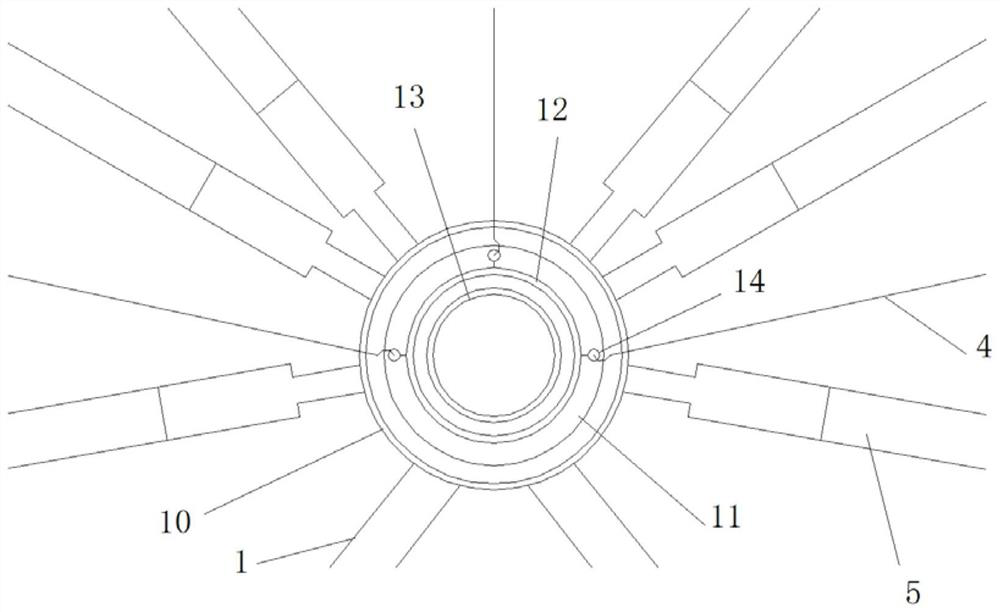

Simulation system and experimental method for shield-method synchronous grouting

InactiveCN107976369AAccurate pressure valueMonitor interaction forcesMaterial strength using tensile/compressive forcesExperimental methodsSlurry

The invention belongs to the technical field of shield tunnel engineering simulation experiments, and concretely relates to a simulation system for shield-method synchronous grouting. The simulation system comprises a model device, a propulsion device, a monitoring device and a processing device. The invention also relates to an experimental method for shield-method synchronous grouting. The method comprises the following steps of (1) mixing an experiment soil body and a synchronous slurry to form a mixed slurry; (2) applying pressure on the mixed slurry until the mixed slurry is coagulated toform a test block; (3) acquiring experiment data of surface pressure and coagulation time of the mixed slurry; (4) analyzing the experiment data, and determining parameters of the test block. The invention aims to provide the simulation system and the experimental method for shield-method synchronous grouting aiming at the problem that an existing simulation shield method synchronous grouting experiment is limited in site instruction function. Through a simulated result obtained through the simulation system and the experimental method, a site instruction function is remarkably improved.

Owner:SOUTHWEST PETROLEUM UNIV

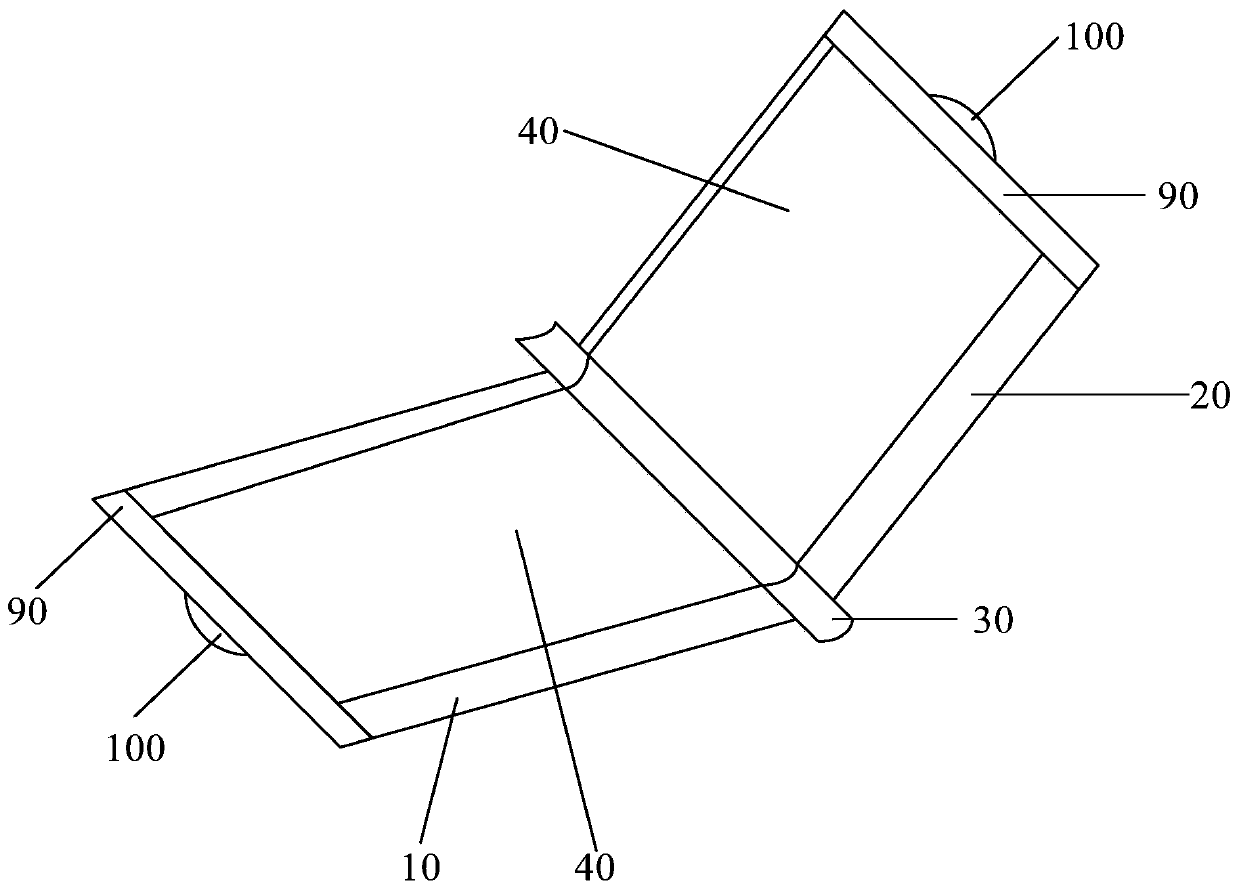

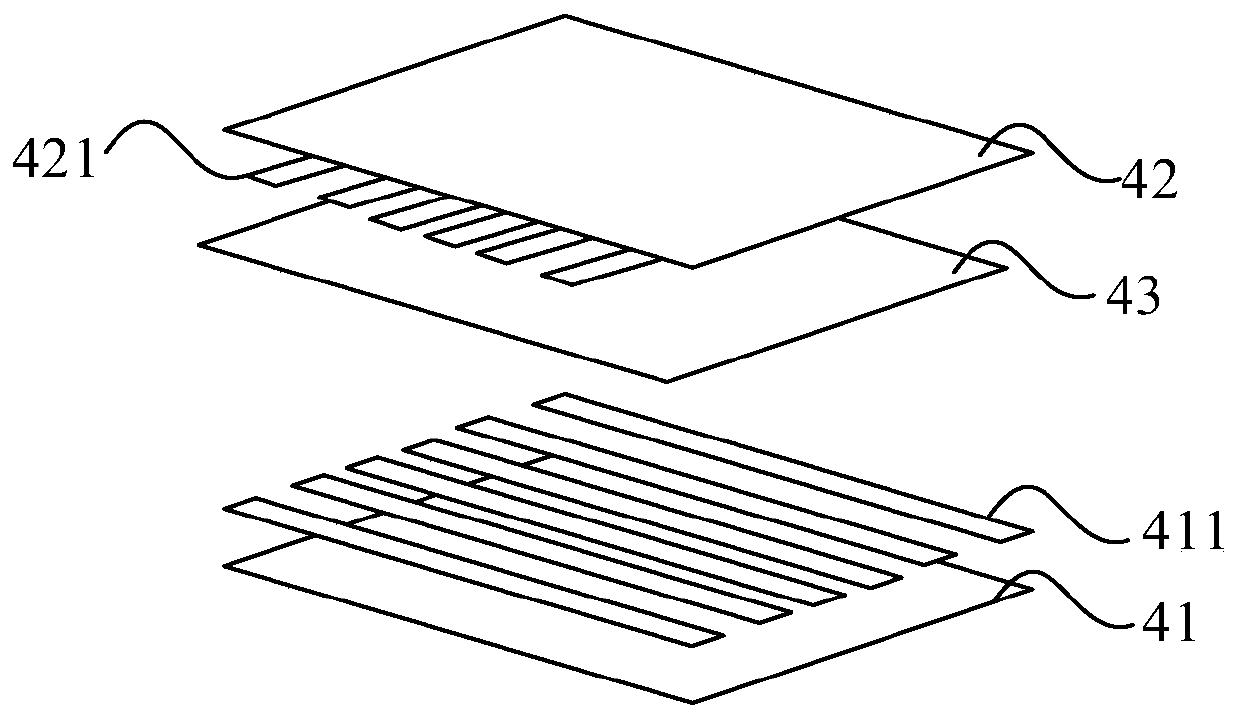

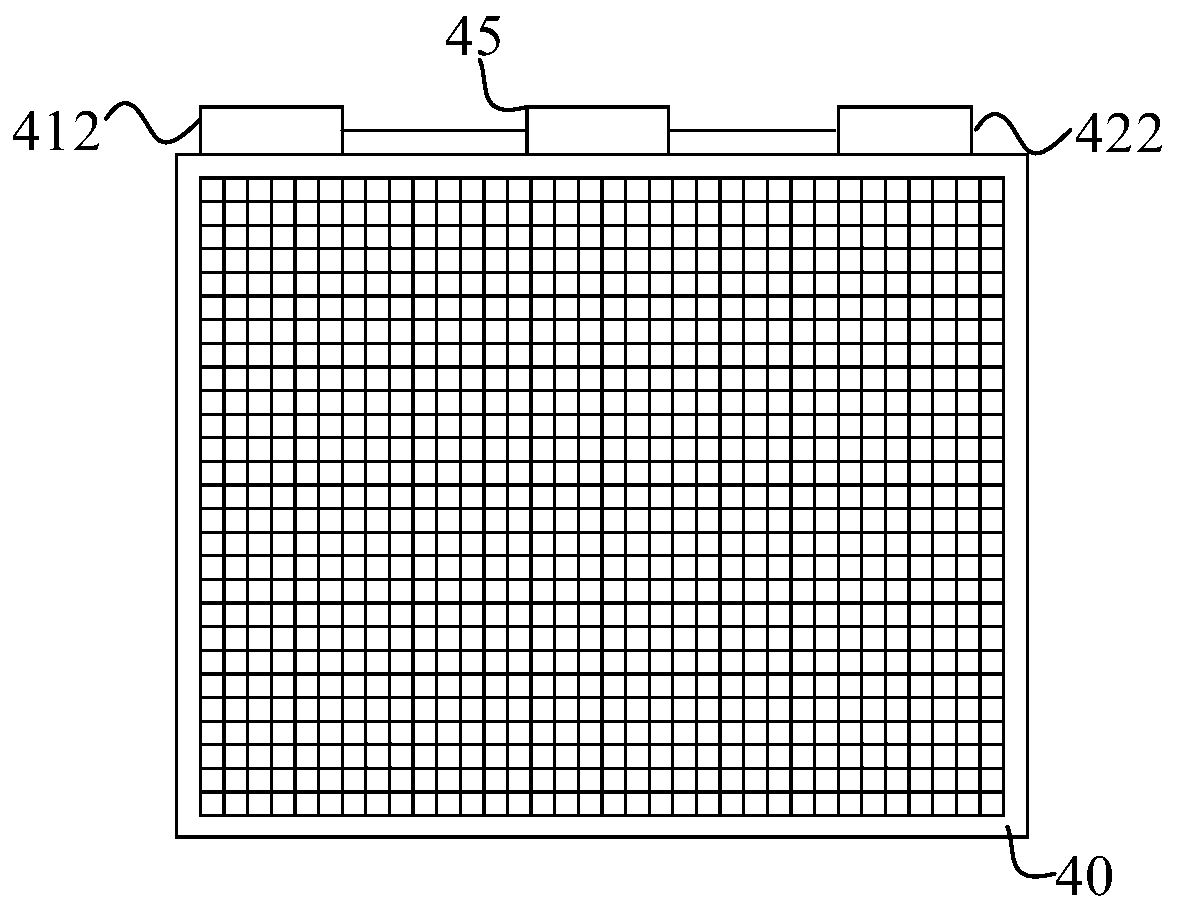

Planar pressure detecting device

PendingCN109738096AReduce space consumptionSimple processForce measurement using piezo-resistive materialsConductive materialsPressure sensor

Owner:BEIJING NOITOM TECH

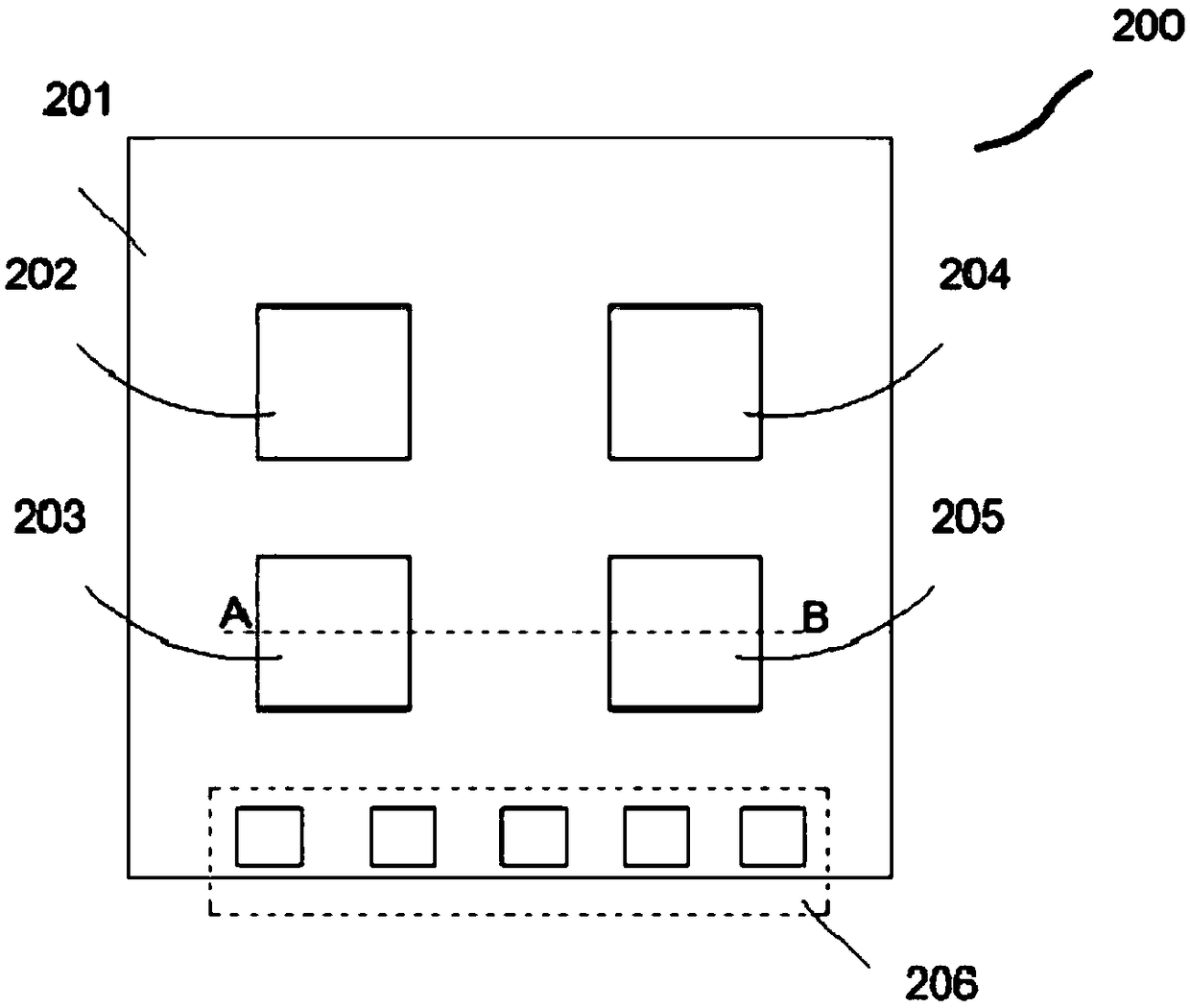

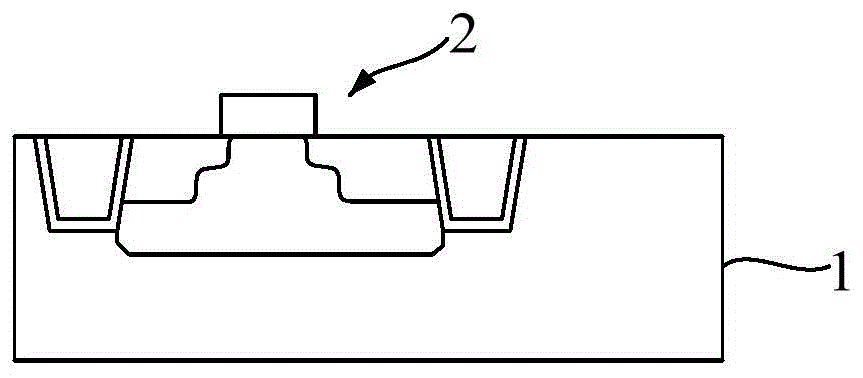

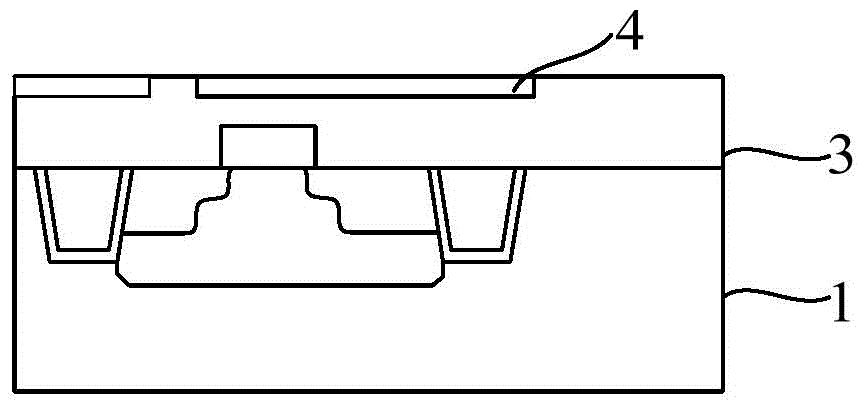

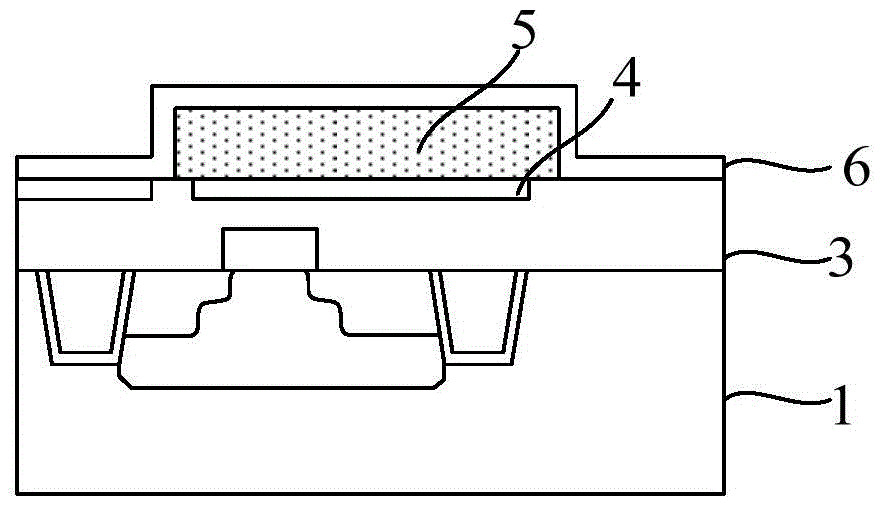

Pressure sensor and forming method thereof

ActiveCN104614119AAvoid warpingWill not deformDecorative surface effectsChemical vapor deposition coatingLower poleEngineering

The invention discloses a pressure sensor and a forming method thereof. The pressure sensor comprises a substrate, an interlayer dielectric layer, a pressure induction film and a plurality of mutually isolated blocky members, wherein a transistor is formed in the substrate; the interlayer dielectric layer is positioned on the substrate and covers the substrate and the transistor; a lower pole plate is formed in the interlayer dielectric layer; the upper surface of the lower pole plate is exposed; the lower pole plate is electrically connected with the transistor; the pressure induction film is positioned on the interlayer dielectric layer, covers the interlayer dielectric layer and is electrically connected with the transistor; a cavity is formed between the lower pole plate and the pressure induction film; the block members are positioned on the pressure induction film and are positioned on the upper side of the cavity, the upper surface of the pressure induction film is exposed. In the technical scheme, stress of the pressure induction film is released by the gravity of the multiple blocky members; the sensitivity of the pressure sensor is enhanced, and the performance is better.

Owner:SEMICON MFG INT (SHANGHAI) CORP

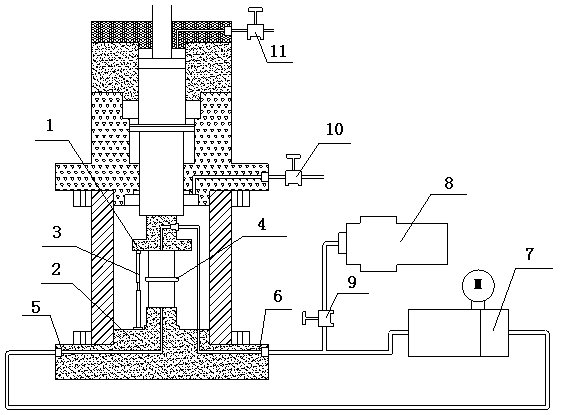

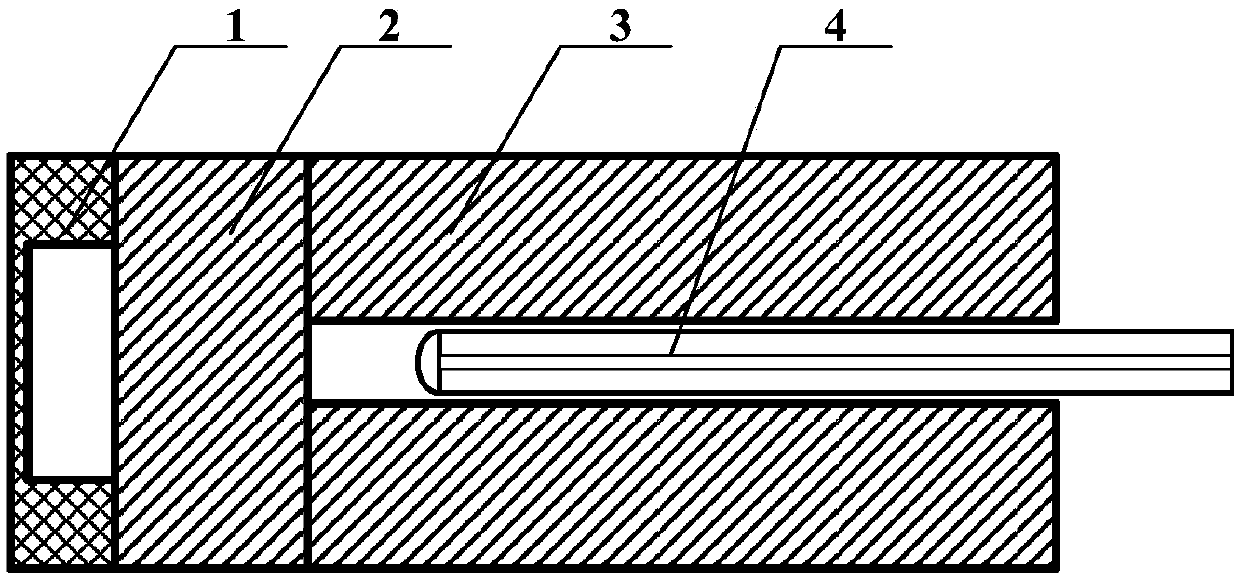

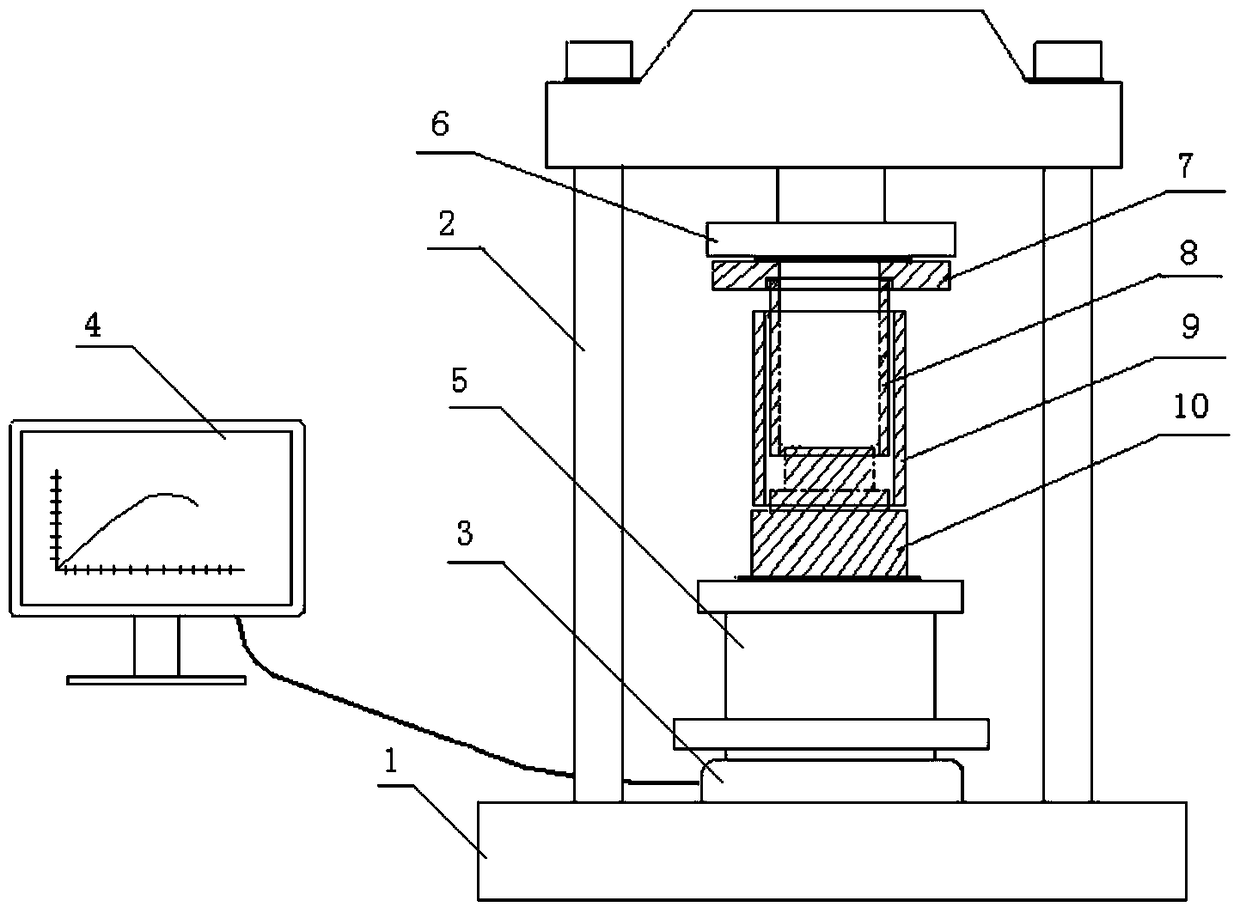

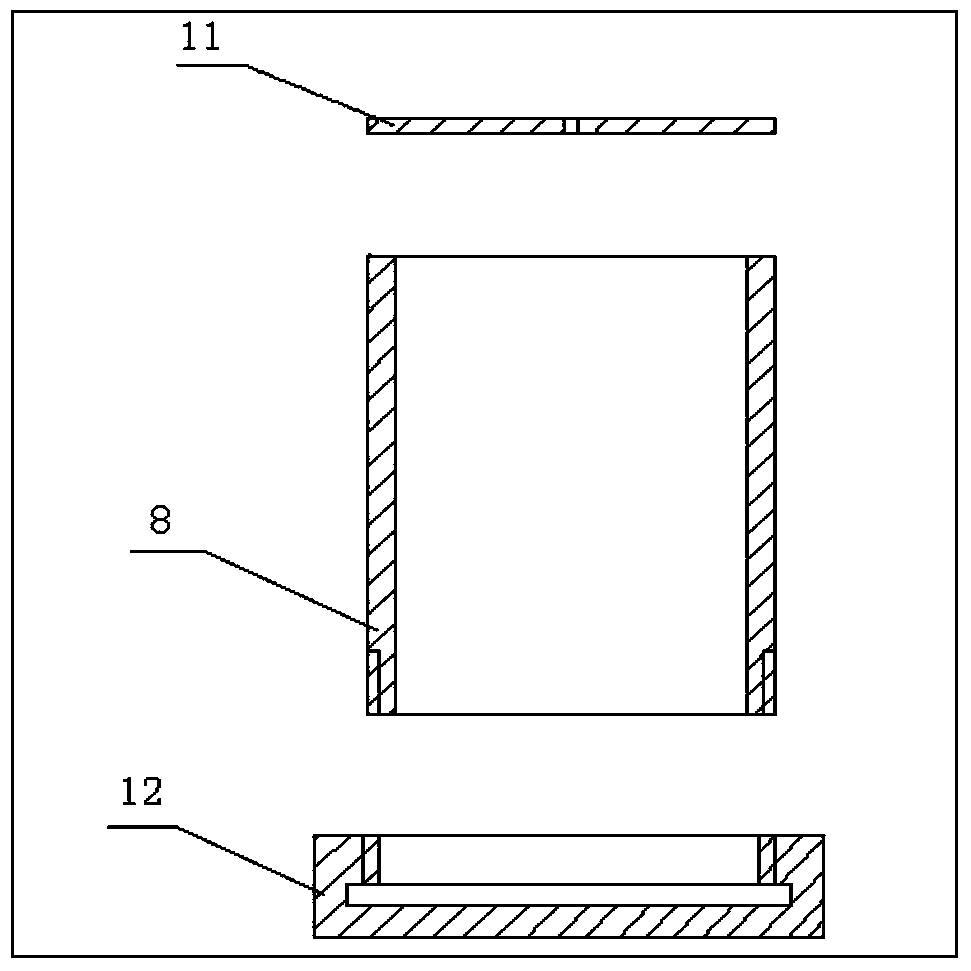

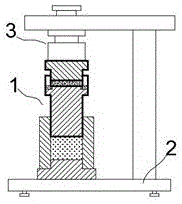

A cementing cement bonding strength testing device and method

ActiveCN105092465BAvoid interactionAccurate pressure valueUsing mechanical meansMaterial analysisEngineeringUltimate tensile strength

The invention discloses a device and a method for testing cementing strength of cementing cement. The device comprises a base, supports, a hydraulic power system, a pressure sensor, a support pillar, a retainer sleeve, a cementing barrel, a fixed baffle and a movable baffle, wherein the hydraulic power system is fixedly arranged at the middle part of the base; the pressure sensor is arranged at the bottom part of the hydraulic power system; the support pillar is arranged at the middle part of the upper plane of the hydraulic power system; the support pillar comprises a support pillar lower step and a support pillar bulge; the retainer sleeve is arranged on the support pillar lower step; the cementing barrel is arranged in the retainer sleeve; the support pillar bulge is arranged in the cementing barrel; the fixed baffle is fixedly arranged at the upper parts of the supports; the movable baffle is located below the fixed baffle and sheathes the cementing barrel; when the support pillar is pushed by the hydraulic power system to move upwards to push out set cement in the cementing barrel, a pressure acquisition system is used for acquiring a pressure value detected by the pressure sensor. Through the technical scheme, the technical problem that the testing accuracy of the cementing strength in the prior art is lower is solved, and the accuracy during cementing strength testing is improved.

Owner:PETROCHINA CO LTD

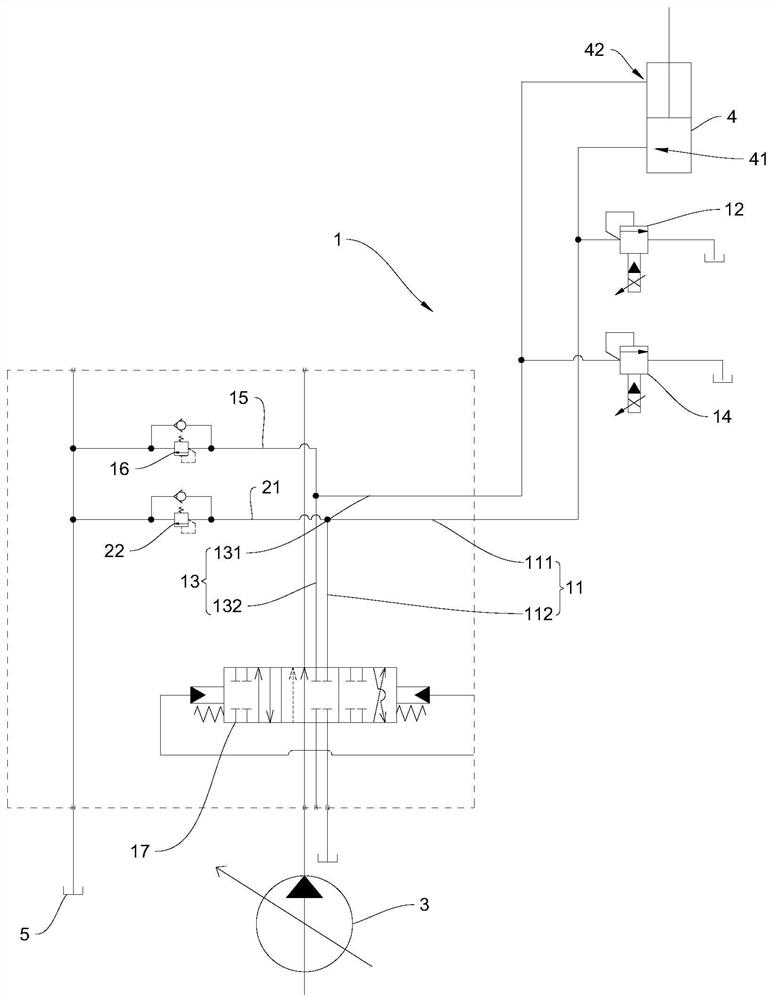

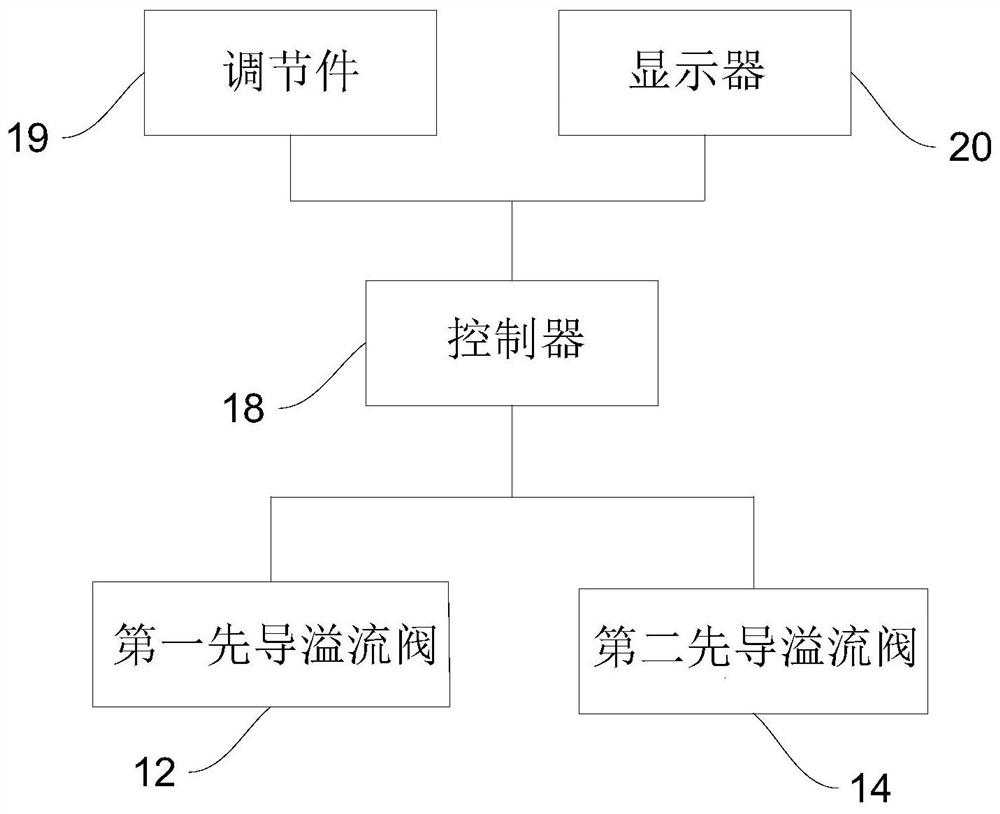

Auxiliary adjusting system, excavator and excavating equipment

PendingCN111733916AAccurate pressure valueAchieve homeworkMechanical machines/dredgersControl engineeringHydraulic pump

The embodiment of the invention provides an auxiliary adjusting system, an excavator and excavating equipment, and relates to the field of engineering machinery. The auxiliary adjusting system comprises a first connecting pipe and a first pilot overflow valve arranged on the first connecting pipe. One end of the first connecting pipe is used for communicating with a hydraulic pump, the other end of the first connecting pipe is used for communicating with a preset accessory, and the first pilot overflow valve is used for limiting the pressure value of hydraulic oil flowing from the hydraulic pump to the preset accessory. By means of the auxiliary adjusting system, the pressure value of the hydraulic oil flowing to the preset accessory can be more accurate, and therefore normal operation ofthe preset accessory is achieved.

Owner:SANY HEAVY MACHINERY

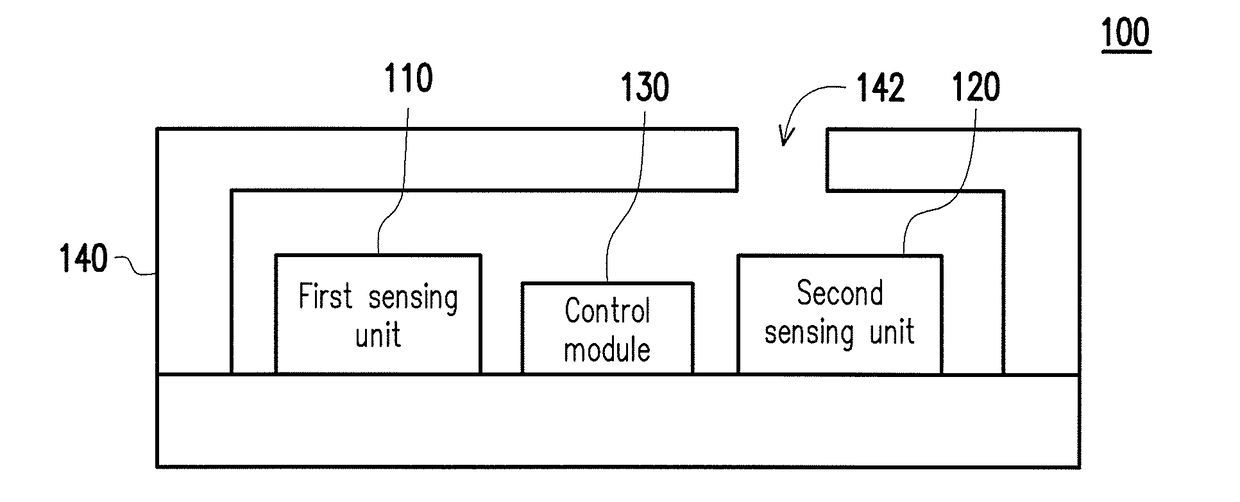

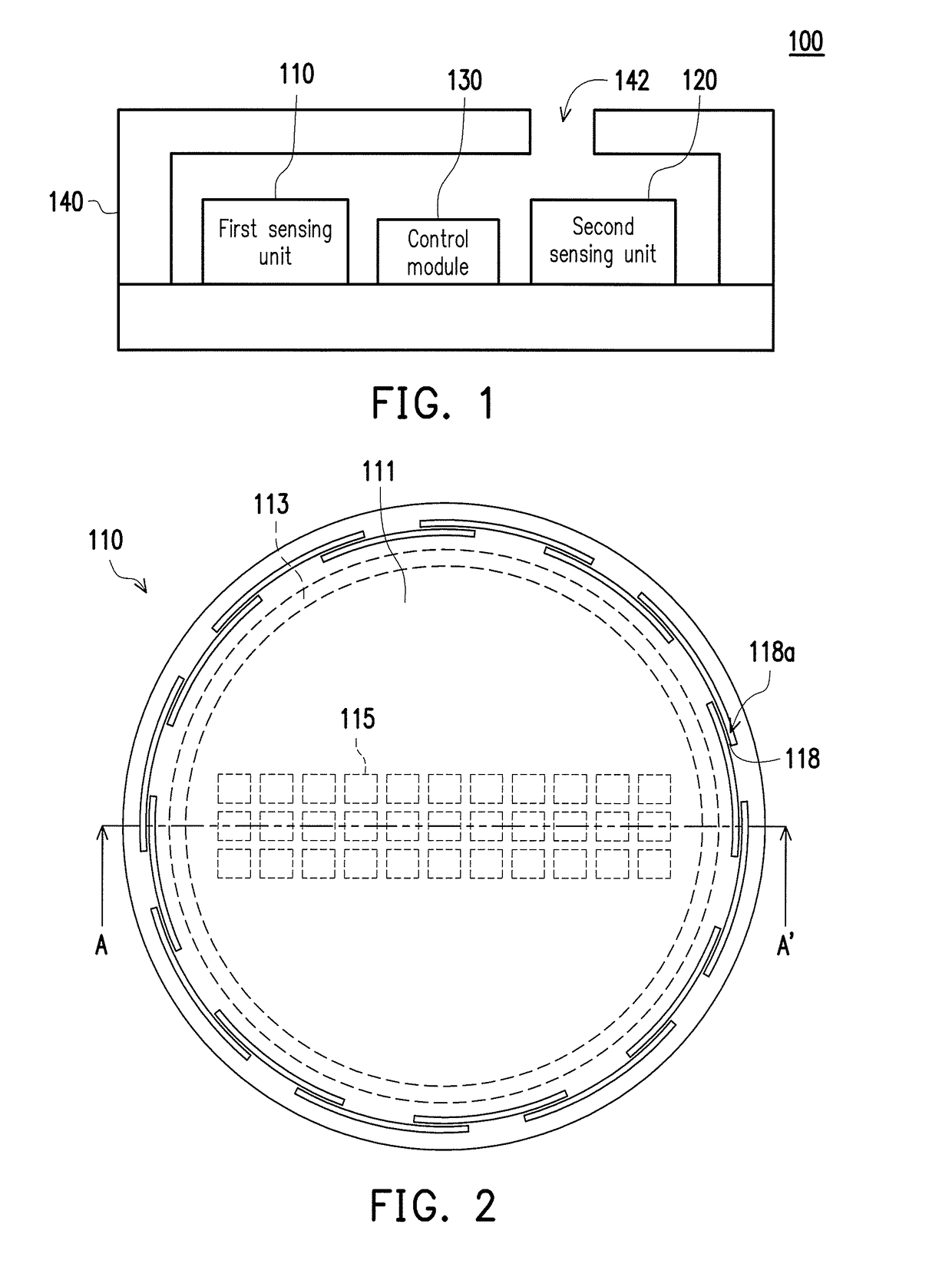

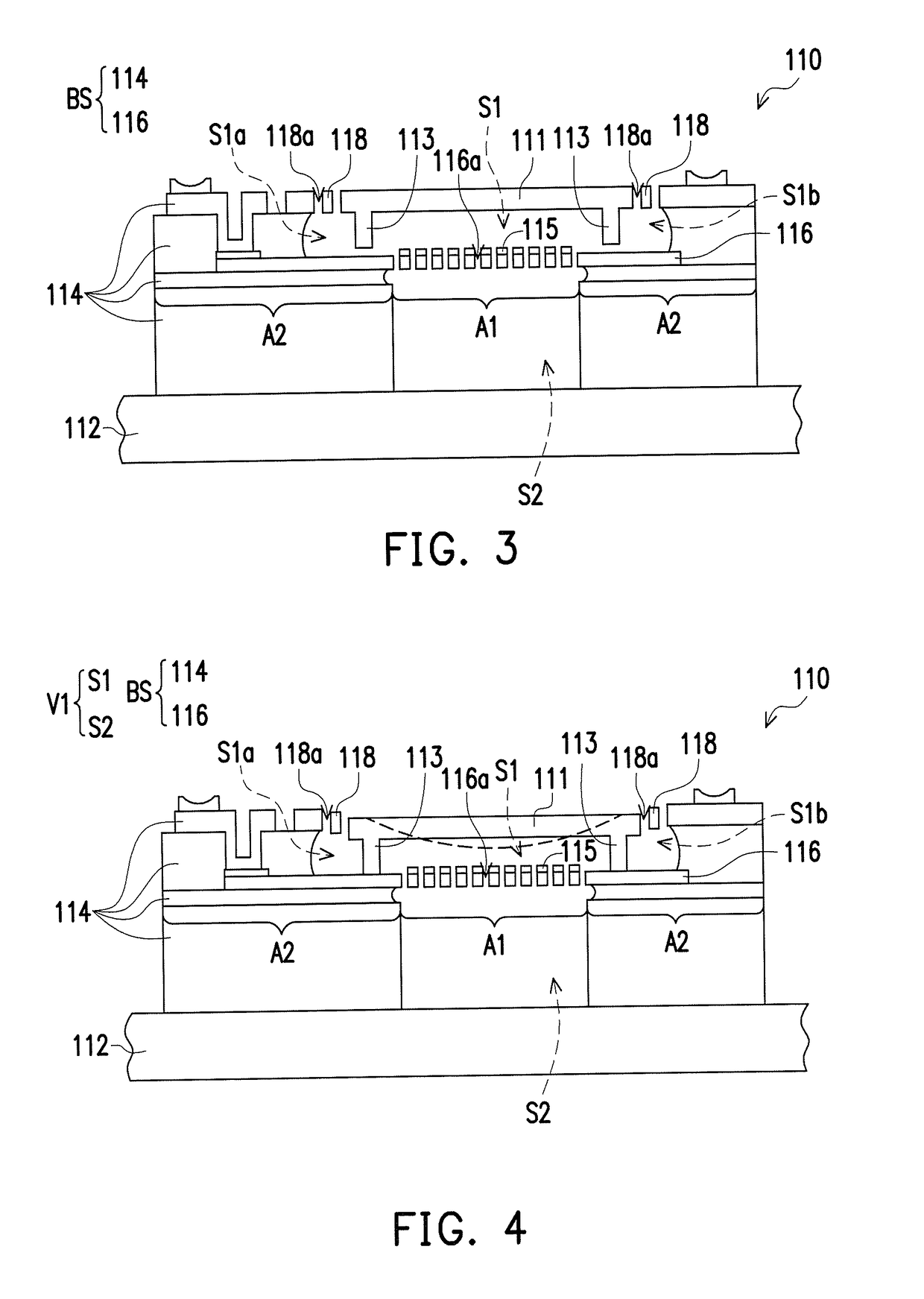

Air pressure sensing system and air pressure sensing method

ActiveUS20170343441A1Improve accuracyIncrease the scope of applicationFluid pressure measurement by electric/magnetic elementsPressure difference measurement between multiple valvesEngineeringAtmospheric pressure

An air pressure sensing system including a first sensing unit and a second sensing unit is provided. The first sensing unit includes a substrate, a diaphragm, and a supporting member. The substrate has a cavity connected with an exterior environment. The diaphragm is movably and deformably disposed at the substrate and suspended in the cavity. An electrostatic force is provided to the substrate and the diaphragm to move the diaphragm, such that a portion of the base, the supporting member and the diaphragm are contacted with each other and a closed space is formed therebetween in the cavity. The closed space and the exterior environment are divided by the diaphragm, and the diaphragm is deformed due to an air pressure difference between the closed space and the exterior environment. An air pressure sensing method is also provided.

Owner:MERRY ELECTRONICS SUZHOU

Medicine single-stamping tablet press

ActiveCN107433729AKeep the pressure steadyStable under pressureShaping pressTABLET CUTTEREngineering

The invention relates to a medicine single-stamping tablet press. The medicine single-stamping tablet press comprises a die, a press body, a bearing plate and a pressed column. The die is detachably placed between the bearing plate and the pressed column and comprises a bottom plate, a sleeve and a pressed rod; a buffer groove is formed in the top end of the pressed rod, and the groove wall of the buffer groove is hollow; a control valve communicating with the groove wall is arranged at the bottom of the buffer groove, and the buffer groove is filled with a buffer solution; when the pressure exceeds a threshold value, the control valve is opened; a pressure stabilizing rod is slidably arranged in the buffer groove and can keep on sliding back and forth in the buffer groove in a solution-sealed mode; the pressure stabilizing rod and the buffer groove are made of permanent magnet materials which are repellent and have the same pole; and the medicine single-stamping tablet press can buffer pressure changing, so that pressure transmitting is more stable, and cracking pieces are effectively prevented.

Owner:江苏绿途环保科技有限公司

Method for realizing pressure tapping by using gas drainer and gas drainer for realizing pressure tapping

ActiveCN102032445BSimple methodAccurate pressure valuePipeline systemsCommunicating vesselsMechanical engineering

Owner:秦皇岛莱特流体设备制造有限公司

Pressure sensing device

The invention discloses a pressure sensing device. A base is fixed in a wall body, wherein an axial through hole is formed in the center of the base; a membrane is fixedly arranged on the periphery ofthe base; a flow guide hole and a channel which are communicated are formed in the base corresponding to the membrane; a sensing cavity is formed between the membrane and the flow guide hole; the sensing cavity, the flow guide hole and the channel are filled with media; a pressure transmission device is formed; a sensor is arranged on the outer side of the channel; and the sensor is fixed on thebase; the membrane transmits pressure information to the sensor through the pressure transmission device. According to the pressure sensing device, the pressure information of the hole bottom is collected and monitored through the sensor under the indirect action through the pressure transmission device, the implementation difficulty is small, the feasibility is high, the pressure of the hole bottom can be monitored in real time according to the information monitored by the sensor, and the stability of the hole forming quality is ensured; in addition, the membrane is arranged close to the bottom of a drill hole, the pressure condition of the bottom of the drill hole can be accurately reflected, and an accurate pressure value is provided for a drilling operator.

Owner:无锡市安曼工程机械有限公司

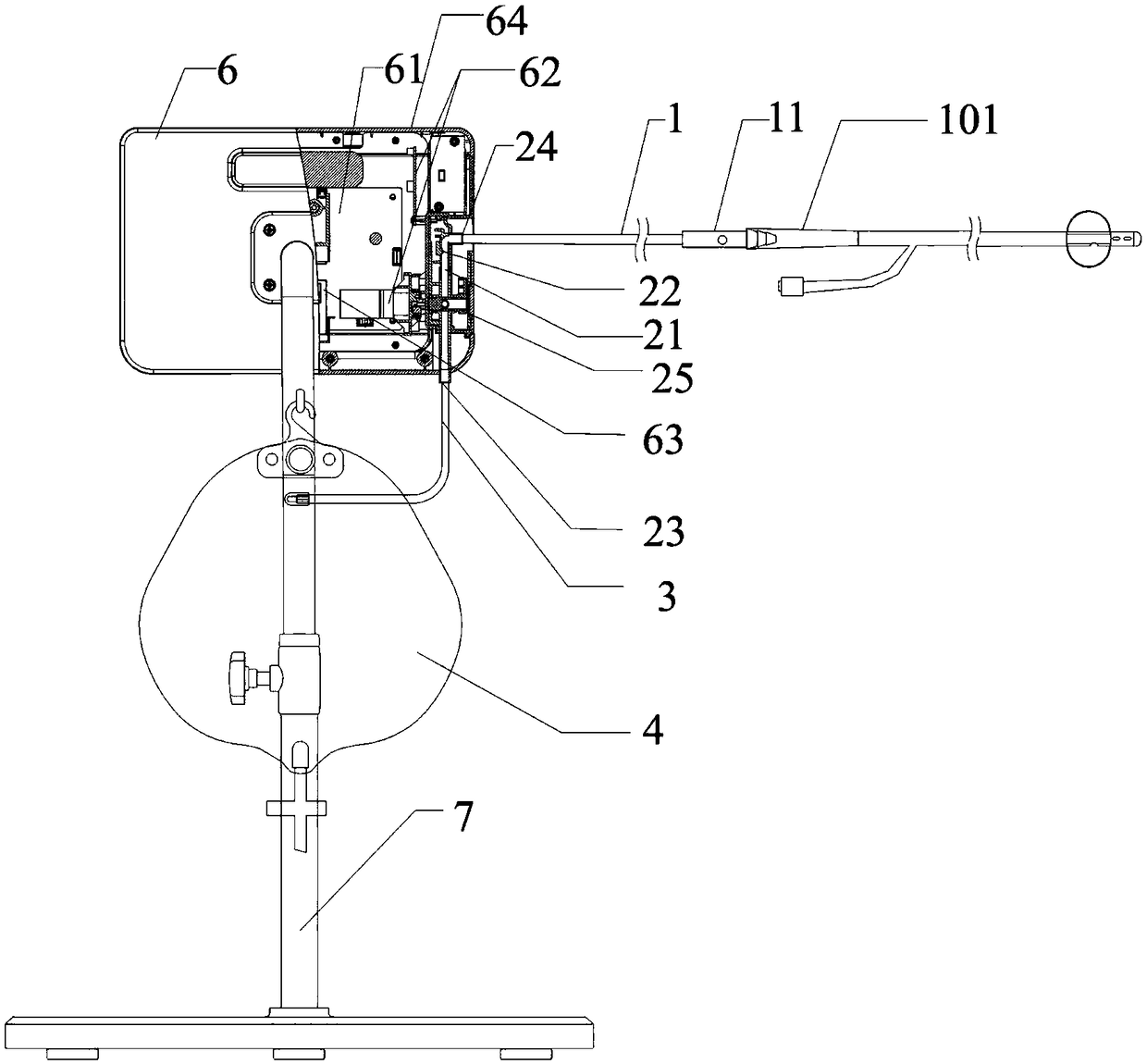

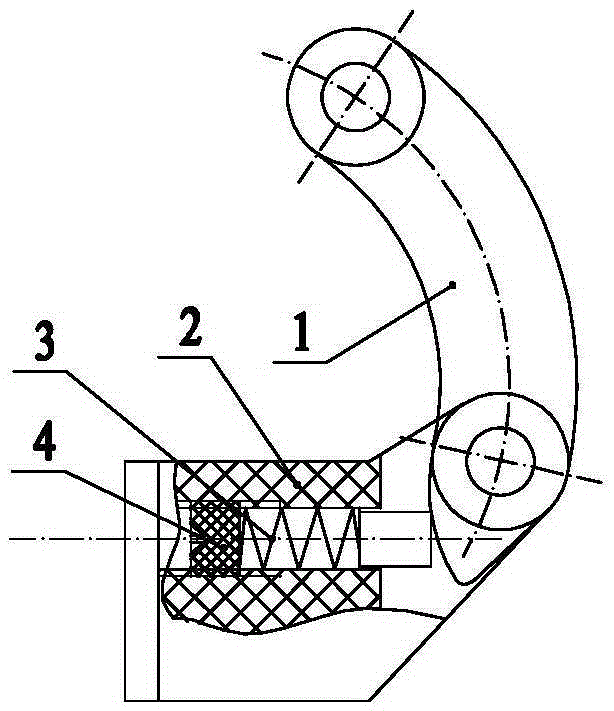

Force measuring adjustment device of pressing wheel arm assembly of textile machinery

ActiveCN105424253AFully automatedReduce labor intensityApparatus for force/torque/work measurementEngineeringMechanical engineering

The invention relates to a force measuring adjustment device of the pressing wheel arm assembly of textile machinery. The force measuring adjustment device is characterized in that the force testing adjustment device comprises a base, a fixing bracket, a feeding bracket, a force measuring sensor, a push rod and a control box; the fixing bracket is fixed on the base and is used for fixing the supporting arm of the pressing wheel arm assembly; the feeding bracket is fixed on the base; a constant-speed feeding mechanism is installed on the feeding bracket; the force measuring sensor is connected with the feeding mobile component of the constant-speed feeding mechanism; the force induction end of the force measuring sensor is connected with the push rod; the push rod is used for pushing a pressing wheel arm in the pressing wheel arm assembly, so as to make the pressing wheel arm unfolded; the signal output end of the force measuring sensor is connected with the control box; and the control box is provided with a display screen. The force measuring adjustment device of the invention is simple, compact and reasonable in structure. With the force measuring adjustment device adopted, the automation of the force measurement of the pressing wheel arm assembly can be realized, and product quality and production efficiency can be improved, and the labor intensity of workers can be greatly reduced.

Owner:WUXI YUANSHENG TECH & SCI DEV CO LTD

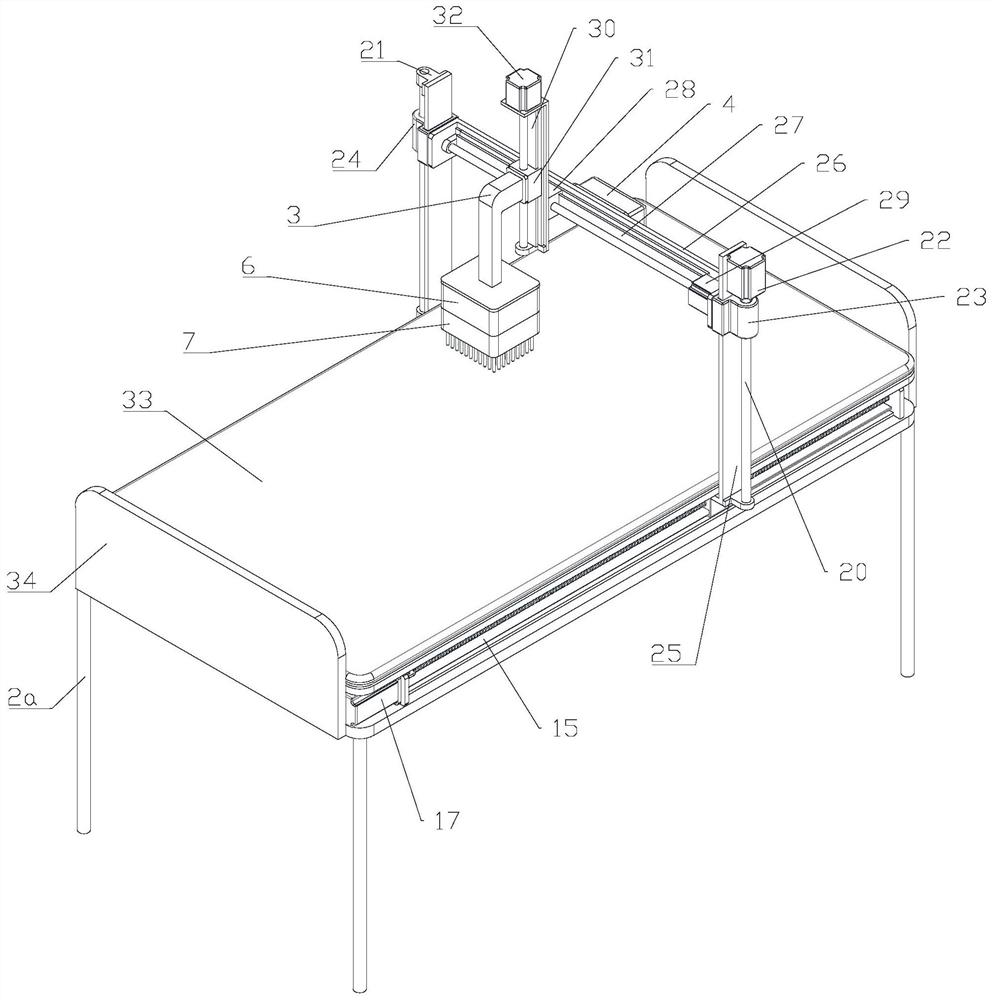

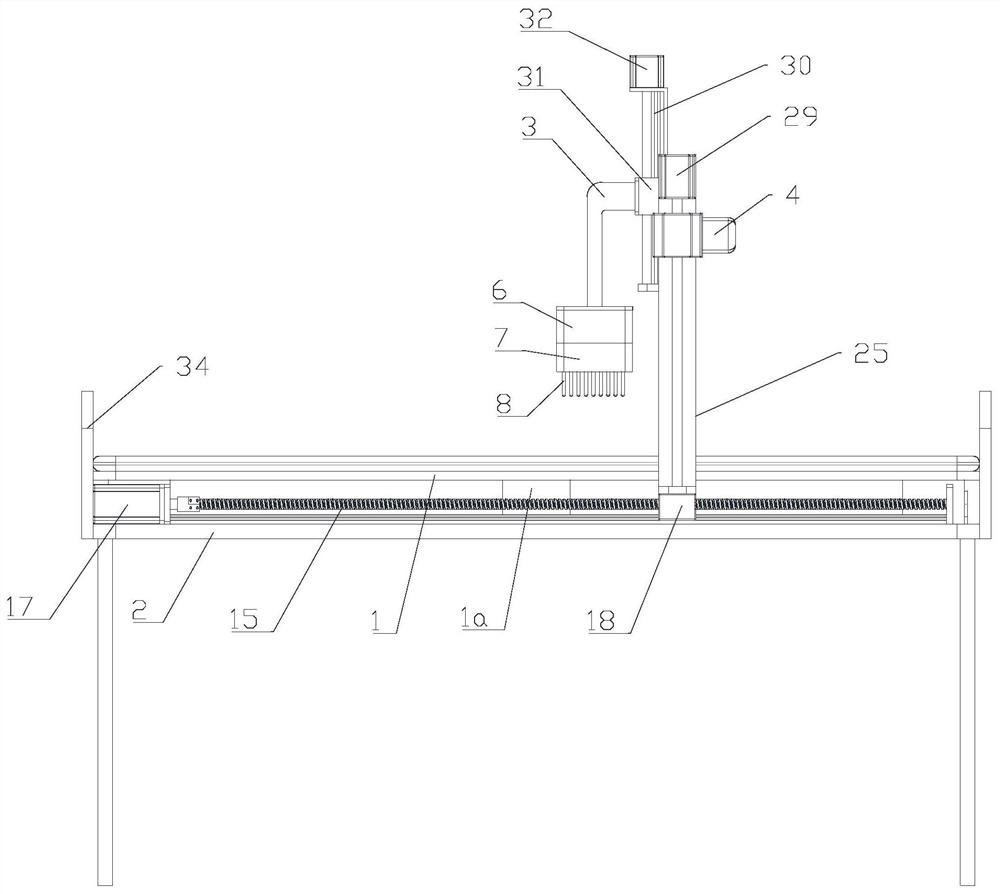

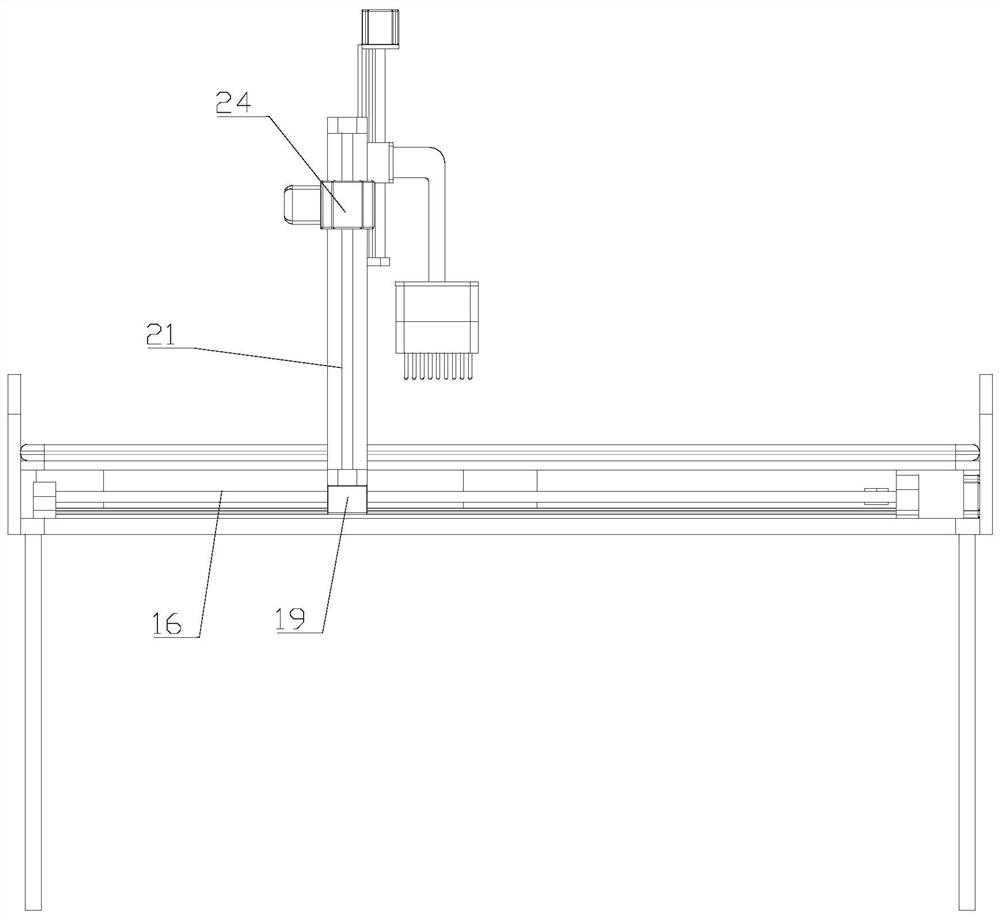

Medical multifunctional insulin injection subcutaneous fat hyperplasia detection device and detection method thereof

ActiveCN112587090AAccurate pressure valueDiagnostic recording/measuringSensorsUrologyInsulin injection

The invention discloses a medical multifunctional insulin injection subcutaneous fat hyperplasia detection device and a detection method thereof. The medical multifunctional insulin injection subcutaneous fat hyperplasia detection device comprises a bed body, a horizontal moving device, a vertical moving device, a detection head moving device and a detection head, wherein the detection head is provided with a plurality of detection pipes, the detection pipes are sleeved with positioning rings, and a pressure sensor is arranged at one end of each detection pipe. The position and height of the detection head can be adjusted according to the body type of a patient, pressure detection is conducted on the skin hyperplasia position of the patient through the detection head, the position of the hyperplasia area is judged according to the measured pressure value, and the position of the hyperplasia area is marked through the positioning rings.

Owner:JIANGSU PROVINCE HOSPITAL THE FIRST AFFILIATED HOSPITAL WITH NANJING MEDICAL UNIV

Expansion type cardiovascular piezometry catheter

InactiveCN103284711AAvoid blockingNo pollution in the processCatheterAngiographyAcid corrosionCatheter

An expansion type cardiovascular piezometry catheter comprises a catheter body and an expansion sac, one end of the catheter body is provided with a conical port, and the other end of catheter body is provided with an inflating connector, the expansion sac is arranged on the body of one end of the catheter body close to the conical port, and the inflating connector is communicated with the expansion sac. No bubbles are generated in the catheter, resonance and attenuation are not caused during monitoring, and occlusion caused by blood clotting during monitoring can be well avoided. Monitoring results are accurate, and accurate pressure values can be obtained without time delay and extra steps. Besides, the expansion type cardiovascular piezometry catheter is resistant to alkali and acid corrosion, has the advantages of excellent organic solvent resistance, is non-toxic and pollution-free and can be widely used to substitute for existing materials on and on.

Owner:陈绍良

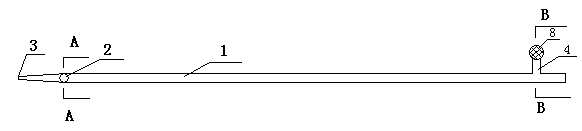

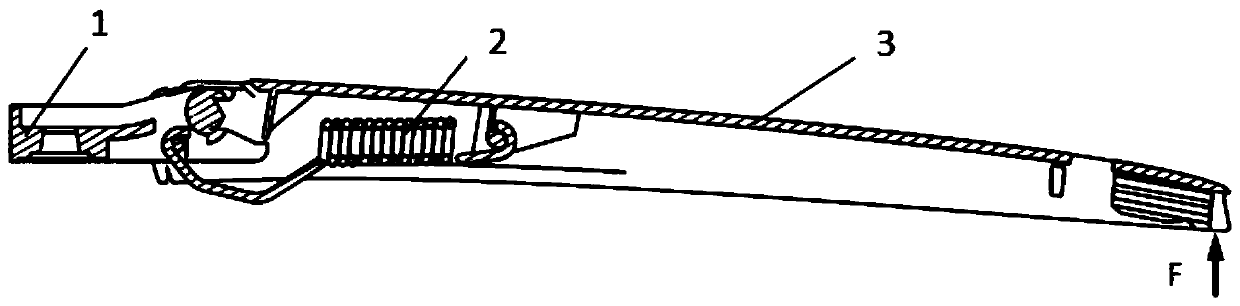

Wiper rod pressure adjusting device, wiper rod and vehicle

ActiveCN111252036AStable forceAccurate pressure valueVehicle cleaningStructural engineeringMechanical engineering

The invention discloses a wiper rod pressure adjusting device, which comprises an adjusting mechanism and a pressure detection device. The adjusting mechanism comprises an adjusting support, a swing cross beam, a reed assembly, a sliding connecting block and an adjusting bolt. A swing nut with internal threads is arranged in the swing cross beam, a head end of the swing cross beam is hinged to theadjusting support, and a tail end is connected to the reed assembly; the sliding connecting block is hinged to the adjusting support; the adjusting bolt is in threaded connection with the swing nut,and the lower end of the adjusting bolt is connected to the sliding connecting block, so that the adjusting bolt can rotate around the axis of the adjusting bolt relative to the sliding connecting block and cannot axially move relative to the sliding connecting block; the pressure detection device is used for detecting the pressure of a wiper rod. When the adjusting bolt rotates around the axis ofitself, the swing nut drives the swing cross beam to swing, therefore the elastic force exerted on the wiper rod by the reed assembly is adjusted. The invention further discloses a wiper rod and a vehicle using the wiper rod pressure adjusting device, and the wiper rod pressure adjusting device is adjustable in pressure and convenient to use.

Owner:SAIC VOLKSWAGEN AUTOMOTIVE CO LTD

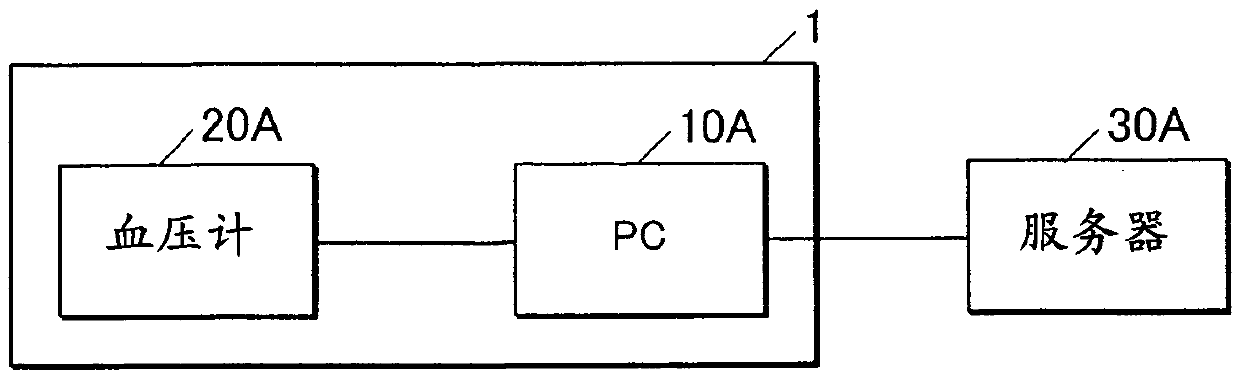

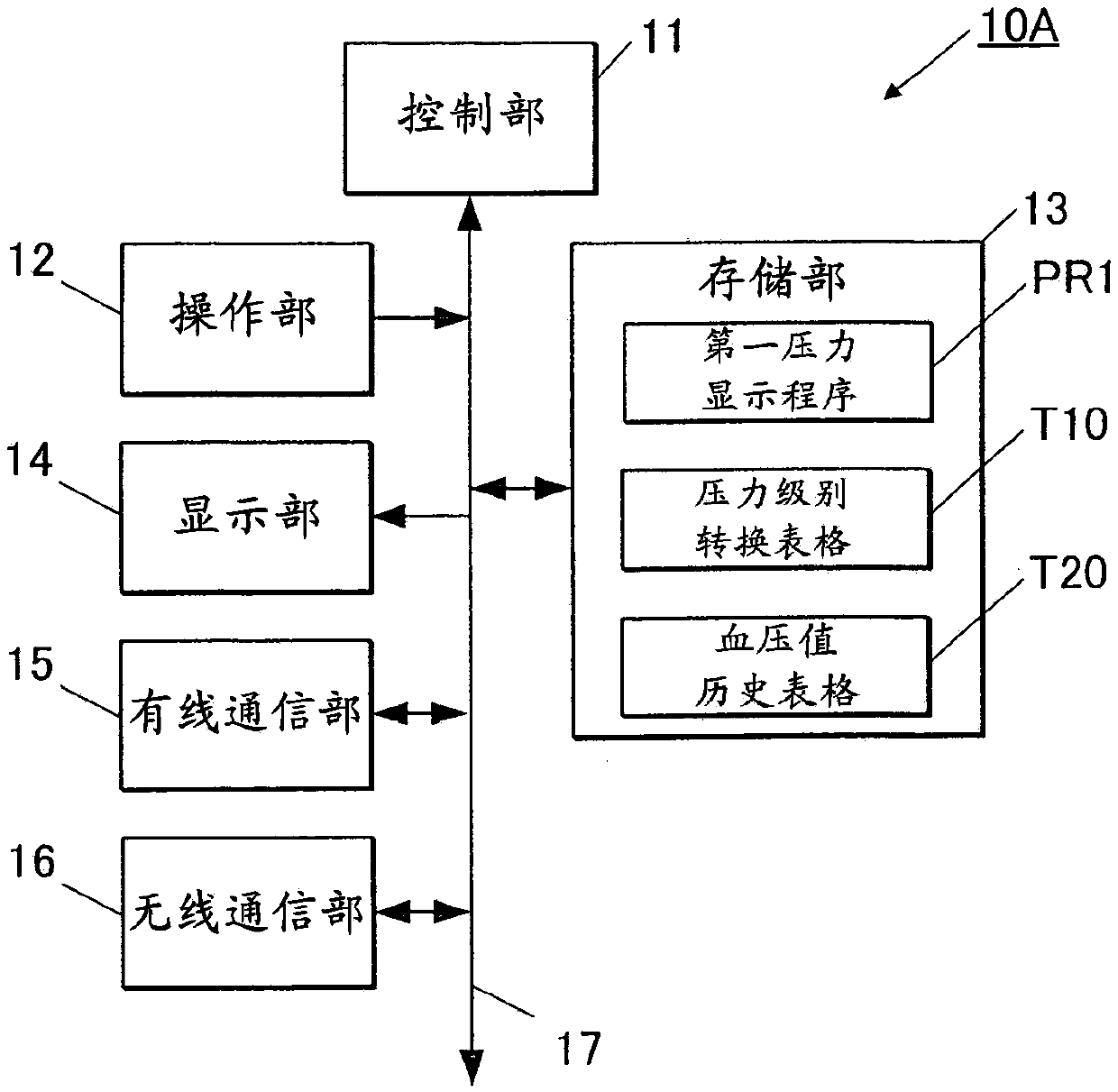

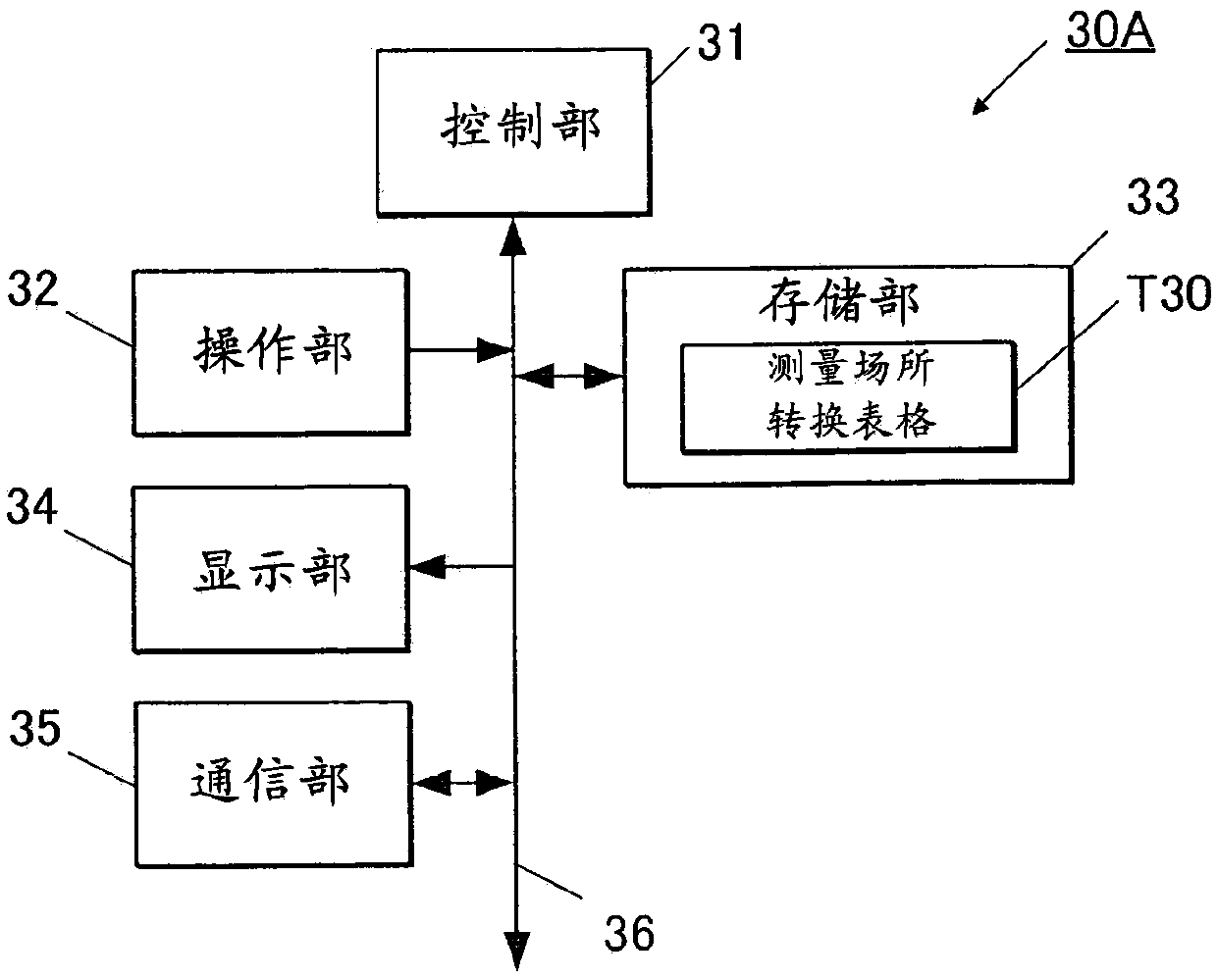

Pressure notification system and recording medium

InactiveCN110169778AAccurate pressure valueEvaluation of blood vesselsSensorsSphygmomanometerSide information

Provided are a pressure notification system and a recording medium. The object of the invention is to obtain an accurate pressure value. A pressure display system (1) of the pressure notification system that notifies the pressure value of a user includes: a sphygmomanometer (20A) that measures biometric information of the user; and a PC (10A) acquiring, from a server (30A) external to the pressuredisplay system (1), location information of a measurement location as auxiliary information for generating the pressure value, generating the pressure value based on the acquired biological information and the auxiliary information, and displaying the generated pressure value on a display unit.

Owner:KONICA MINOLTA INC

Tunnel deformation test device

ActiveCN113983916BEasy to assembleEasy to operateMechanical solid deformation measurementsMonitoring siteStructural engineering

The application provides a tunnel deformation testing device including a bracket, an outer pipe assembly, a support rod, a collar, and a test rod assembly. One end of the test rod assembly is fixed on the outer wall of the collar, and the other end is fixed or supported on the tunnel wall; The test rod assembly includes a telescopic ruler. The telescopic ruler includes a main pipe, an auxiliary pipe and a return spring. The auxiliary pipe is inserted into the main pipe through the plug-in end of the main pipe and can be retracted into the main pipe. It is used to drive the auxiliary pipe to reset, and the outer pipe assembly wall of the auxiliary pipe is provided with an axial length scale line, and the length scale line is used to indicate the real-time length of the telescopic ruler. The displacement test device of the present application is simple to assemble, easy to operate, easy to fix the reference point, light in weight and easy to move, unlimited in monitoring points, comprehensive in monitoring range, high in monitoring accuracy, low in cost and reusable, and can be applied to tunnels under different conditions. Research.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com