Pressure sensor and manufacturing method thereof

A pressure sensor and manufacturing method technology, applied in the field of MEMS, can solve problems such as complex process steps and poor process manufacturability, and achieve the effect of improving manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation of the pressure sensor provided by the present invention and its manufacturing method will be described in detail below with reference to the accompanying drawings.

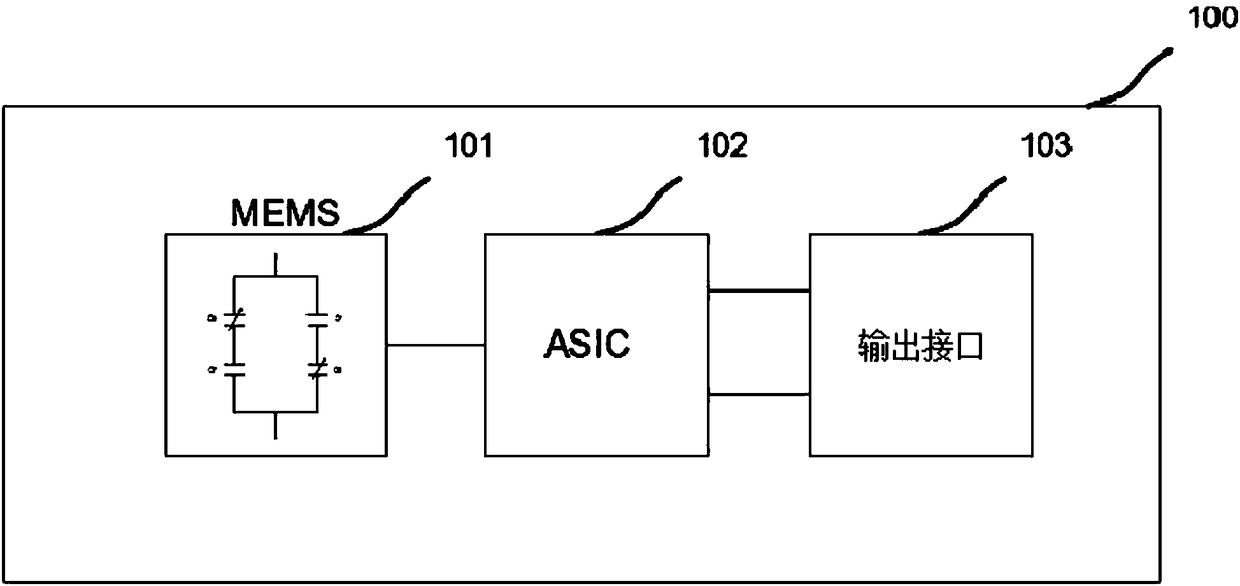

[0028] Please refer to figure 1 , is a schematic diagram of the module structure of the pressure sensor 100 according to a specific embodiment of the present invention.

[0029] The pressure sensor 100 includes a pressure sensing chip 101 , an application specific integrated circuit chip (ASIC) 102 and an output interface 103 . The pressure sensing chip 101 is a MEMS sensor. In this specific embodiment, the pressure sensing chip 101 is composed of four bridge arm capacitors, including a pair of sensing capacitors Cs and a pair of reference capacitors Cr. When the external air pressure changes, the sensing capacitance Cs of the pressure sensing chip 101 deforms, the sensing capacitance Cs changes, and the reference capacitance Cr does not change, and the output deltaC / C is pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com