Patents

Literature

59 results about "TABLET CUTTER" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tablet cutter

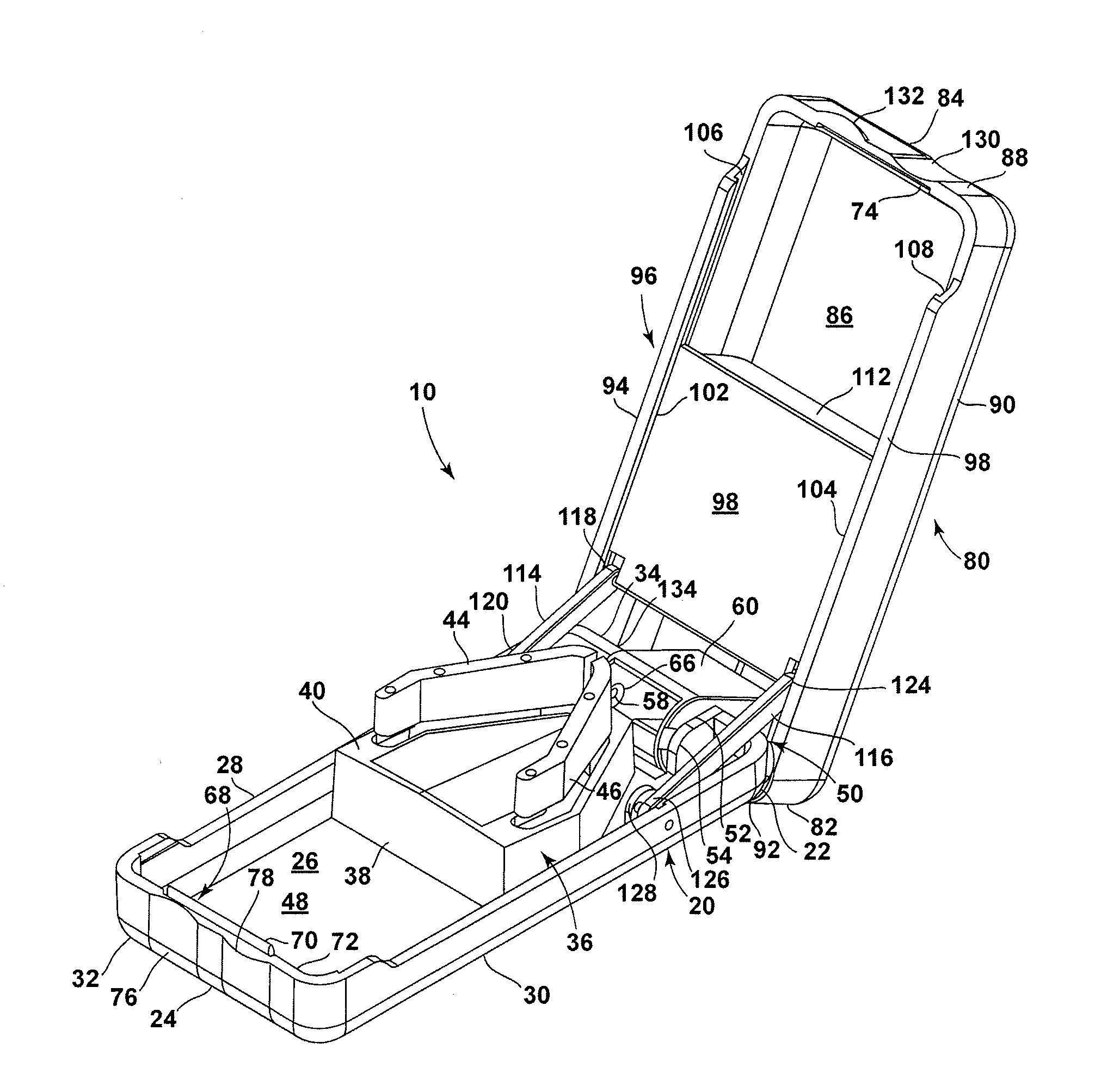

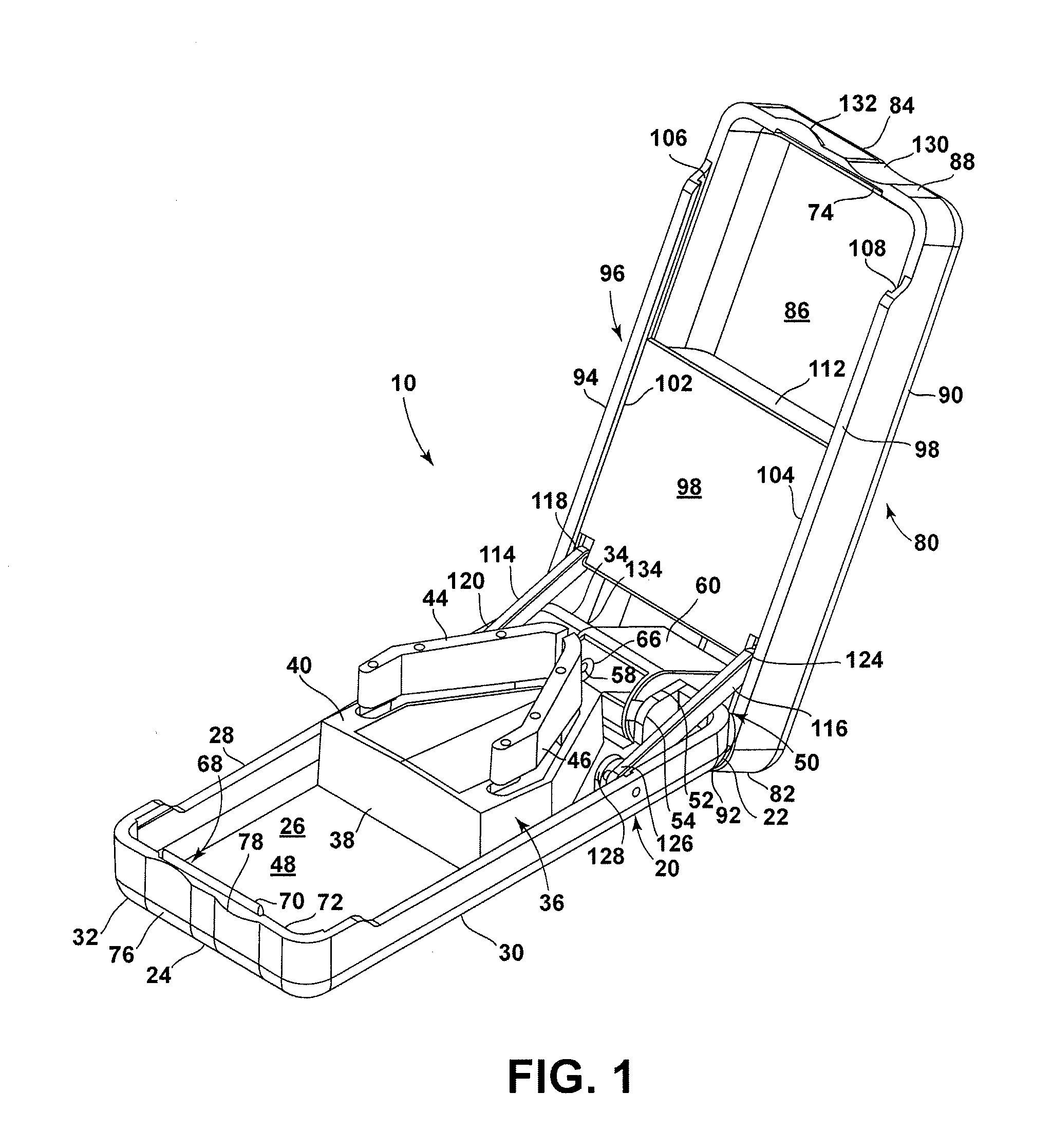

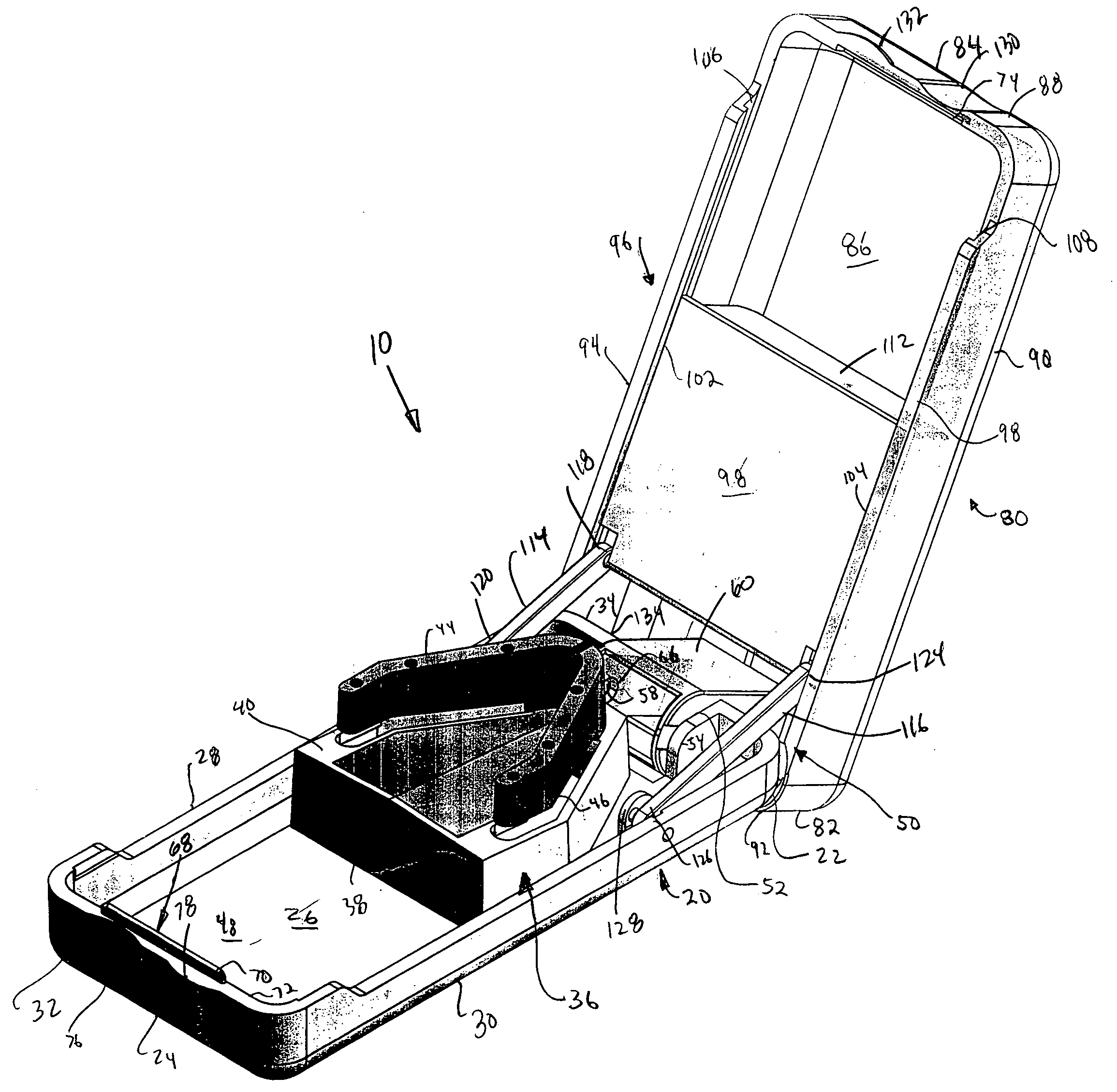

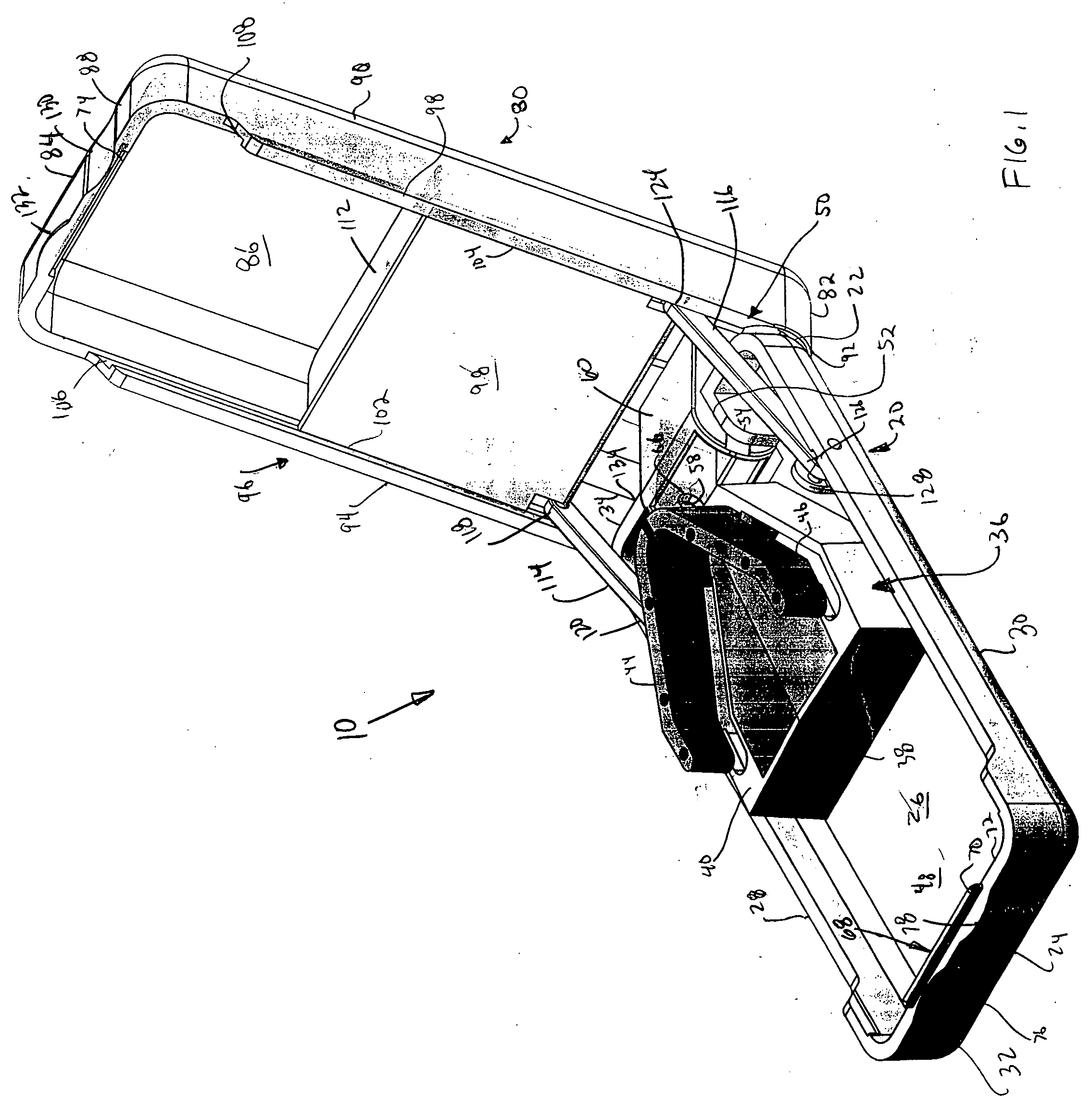

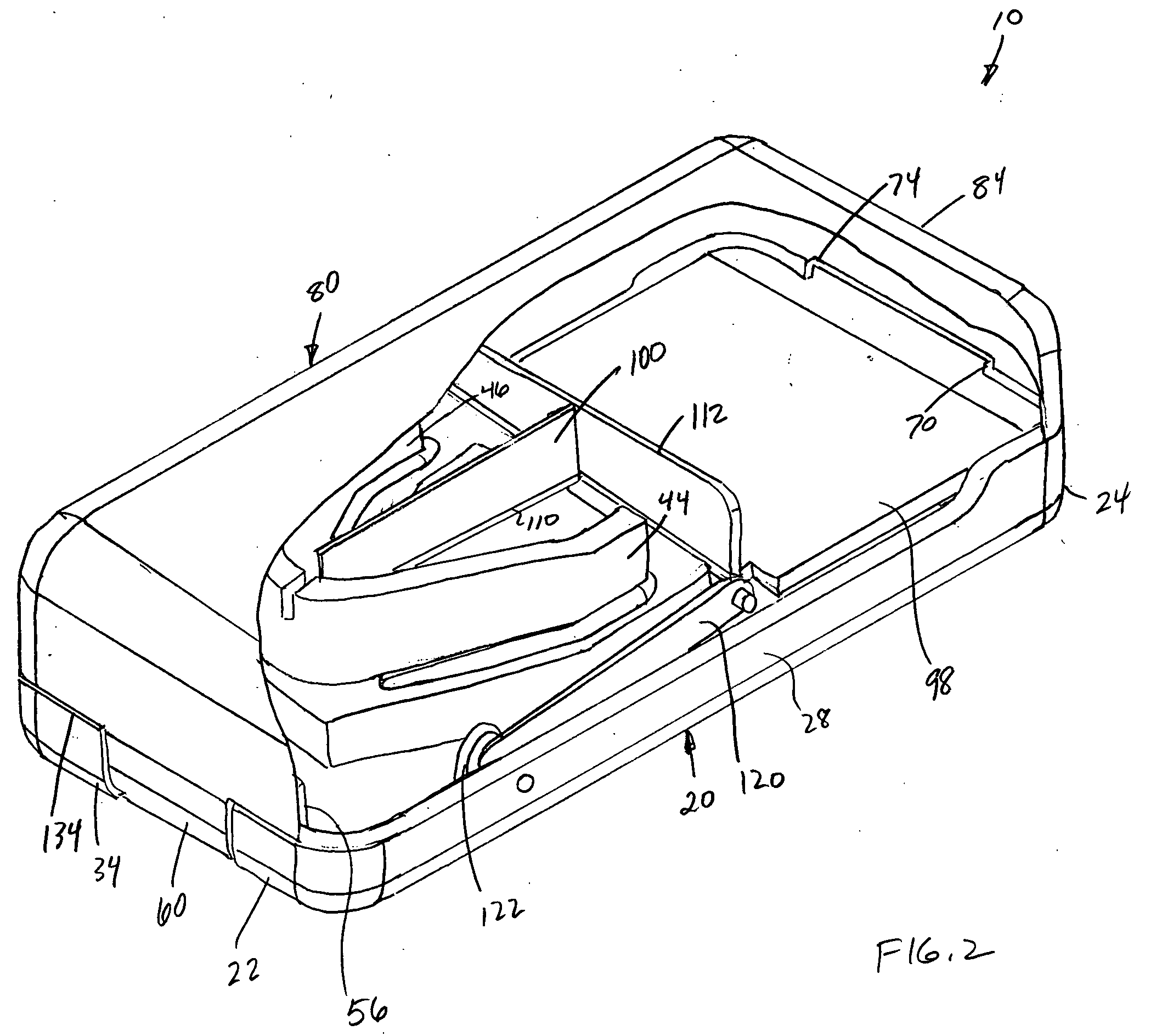

The invention is directed to a pill cutter that has a protected cutting edge. The pill cutter includes a guard, a base, and a cover. The components are arranged such that the guard slides over the cutting edge when the pill cutter is in an open position and the guard exposes the cutting edge when the pill cutter is in a closed position. The invention is also directed at a method for assembling the pill cutter and a method of using the pill cutter to cut a pill or tablet.

Owner:APOTHECARY PROD

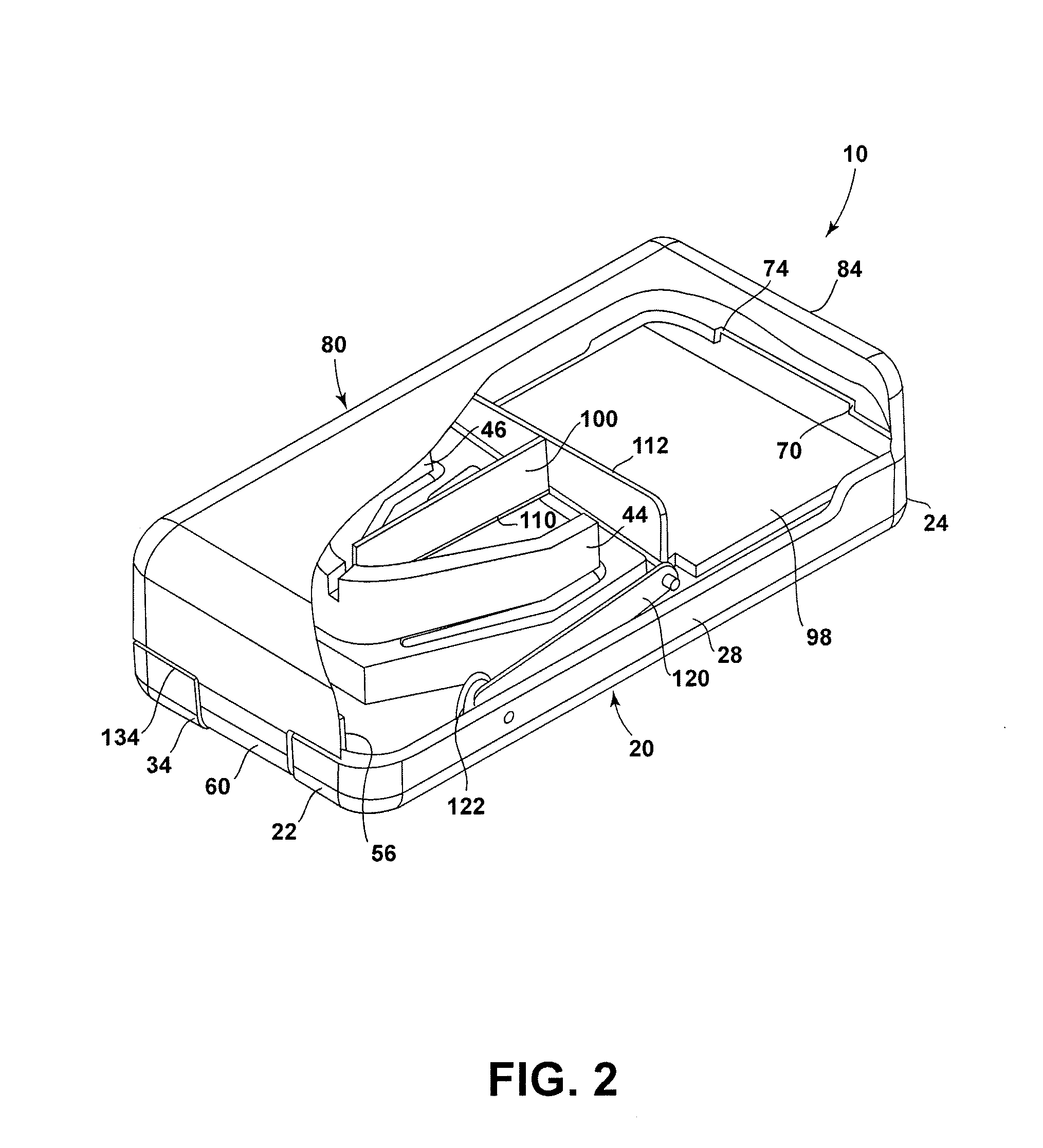

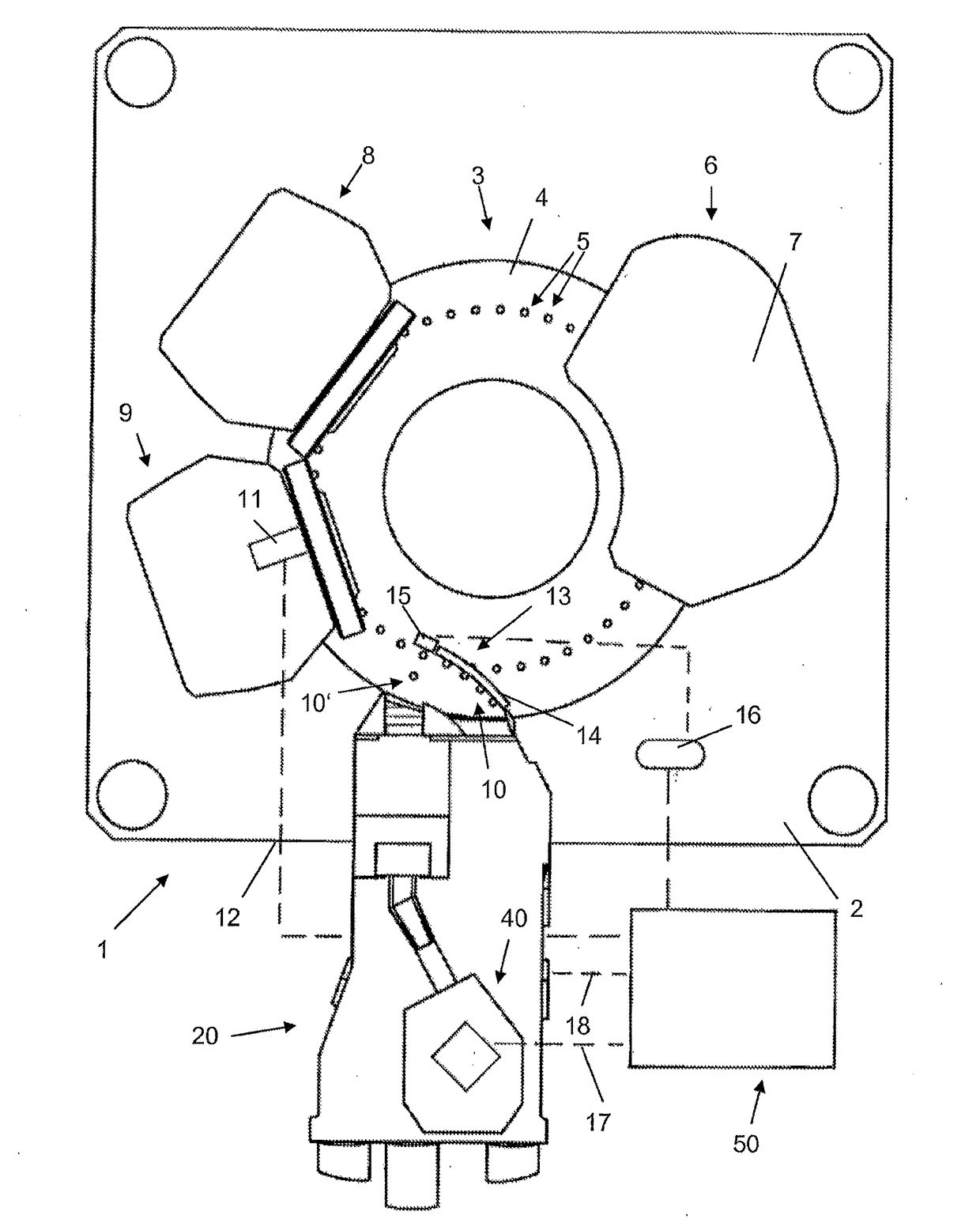

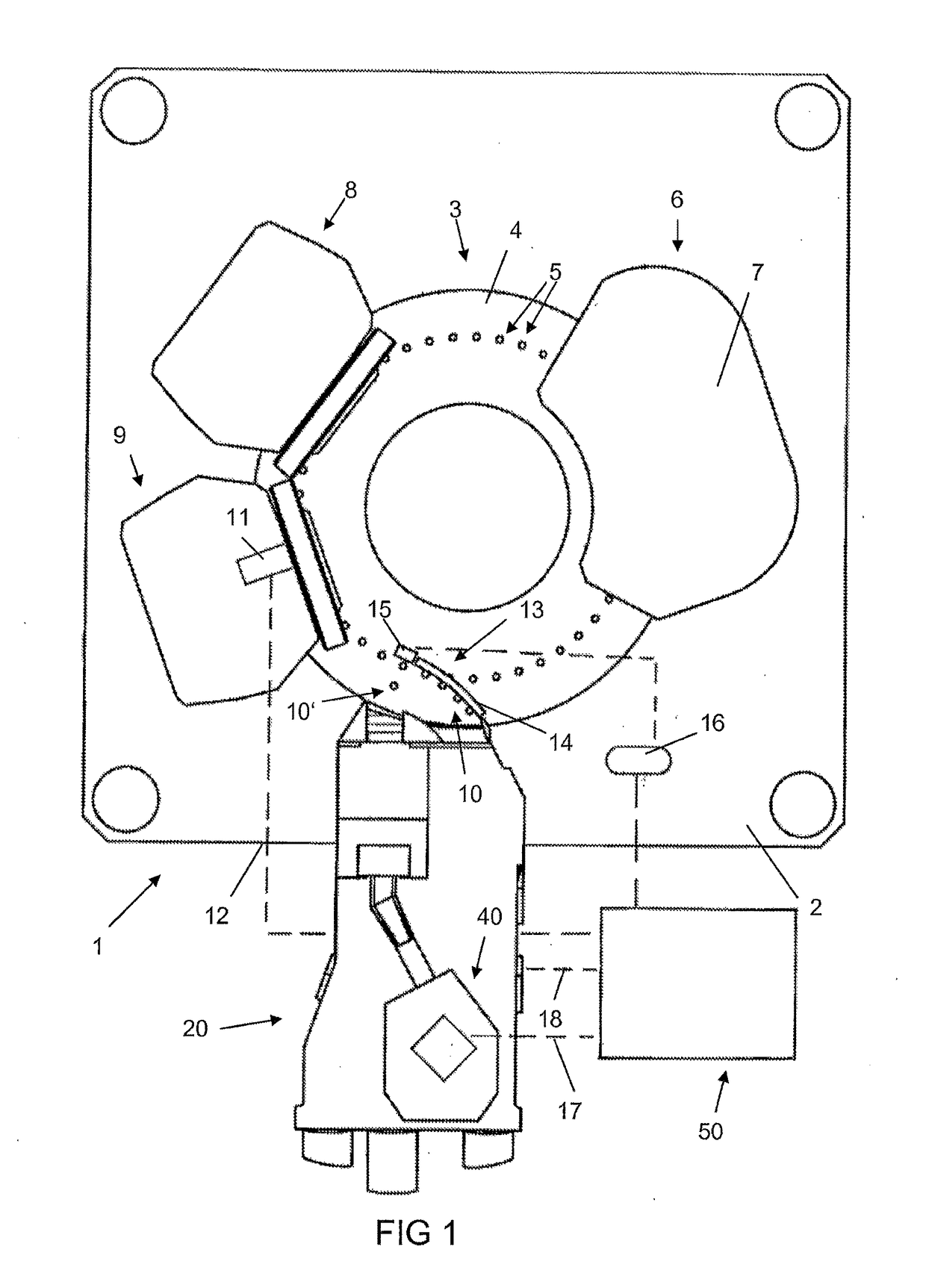

Method of operating a rotary tablet press and rotary tablet press

The invention relates to a method of operating a rotary tablet press. A rotary tablet press comprises a rotor that has a die plate and upper and lower punches. The rotary tablet press also includes a filling station with a filling apparatus and a pressing station downstream of the filling station in the rotational direction of the rotor with a pressing apparatus. An ejector station is positioned downstream of the pressing station in the rotational direction of the rotor with an ejector apparatus. The filling apparatus has a filling chamber. A filling wheel is arranged in the filling chamber and has a plurality of agitator blades arranged on the perimeter that pass over the filling opening during rotation of the filling wheel. During the operation of the rotary tablet press, a control apparatus automatically changes the filling wheel rotary speed according to prestored adaptation instructions when the rotor rotary speed changes, and / or changes the rotor rotary speed according to the prestored adaptation instructions when the filling wheel rotary speed changes. The invention also provides the corresponding rotary tablet press.

Owner:FETTE COMPACTING GMBH

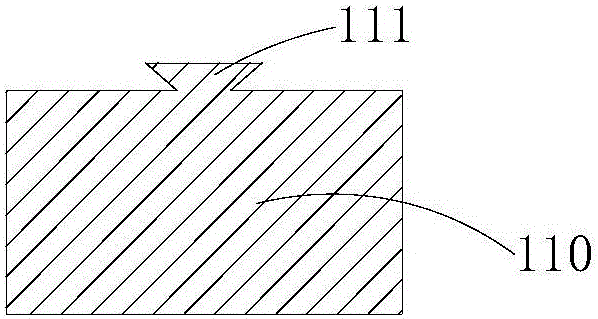

Tablet cutter

The invention is directed to a pill cutter that has a protected cutting edge. The pill cutter includes a guard, a base, and a cover. The components are arranged such that the guard slides over the cutting edge when the pill cutter is in an open position and the guard exposes the cutting edge when the pill cutter is in a closed position. The invention is also directed at a method for assembling the pill cutter and a method of using the pill cutter to cut a pill or tablet.

Owner:APOTHECARY PROD

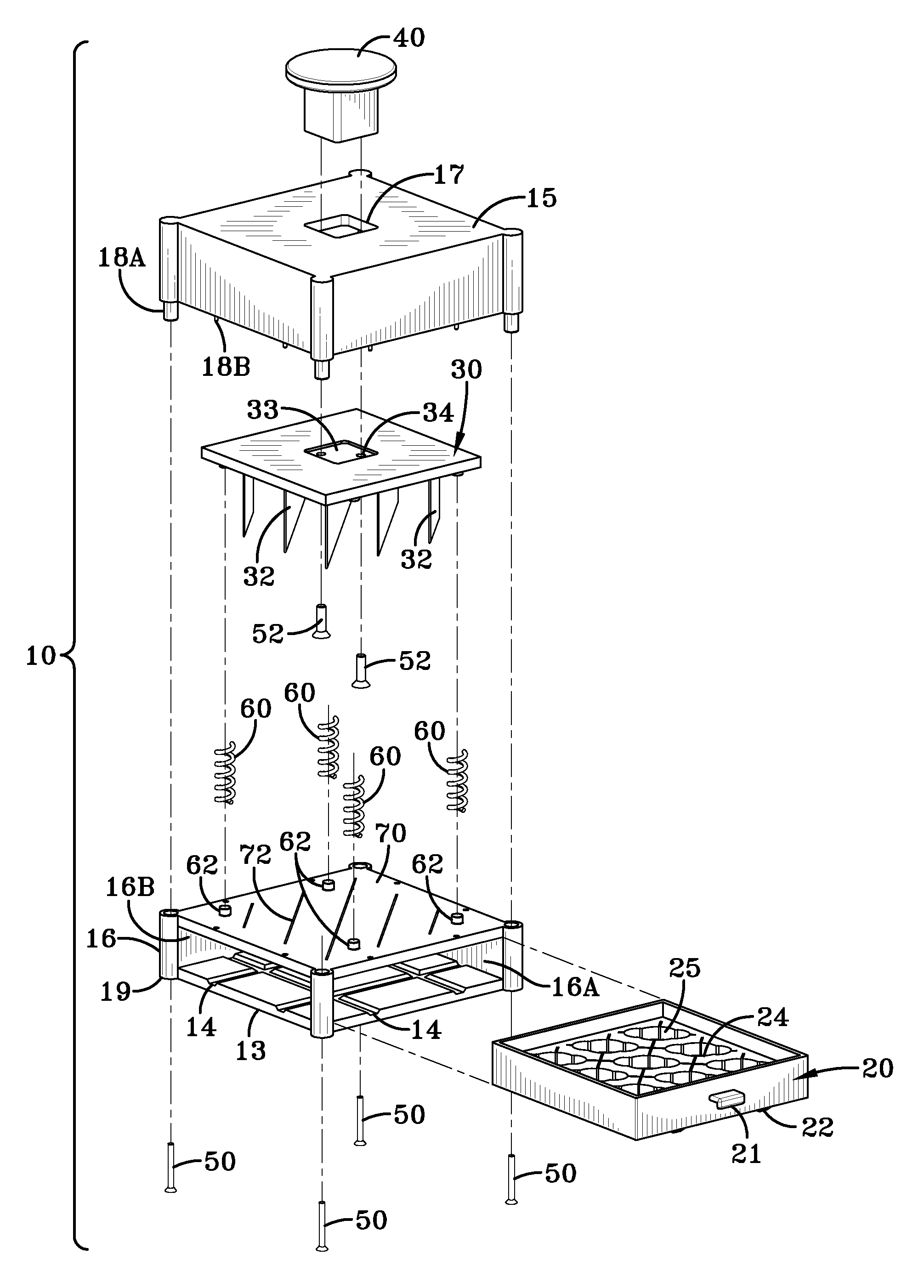

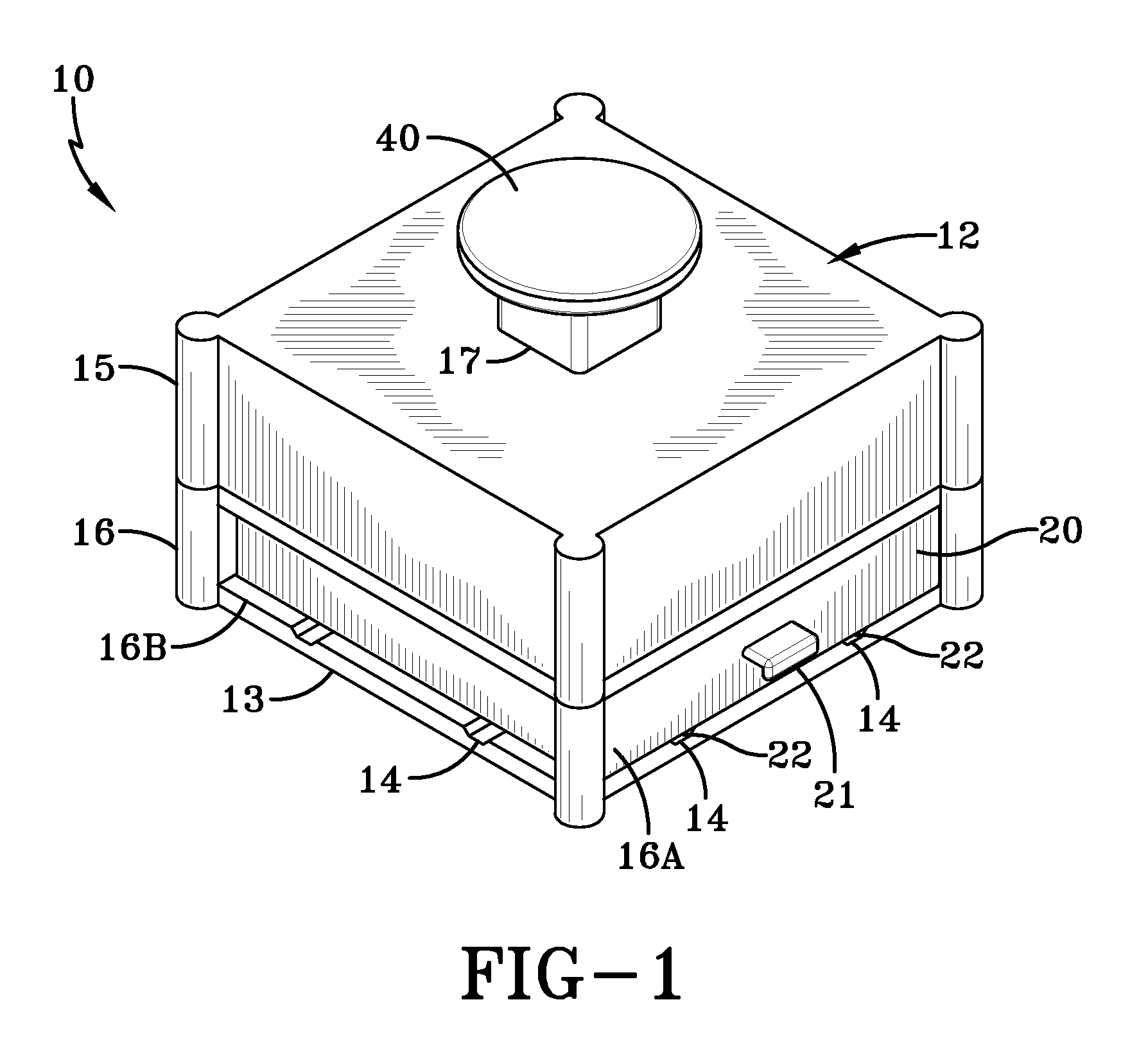

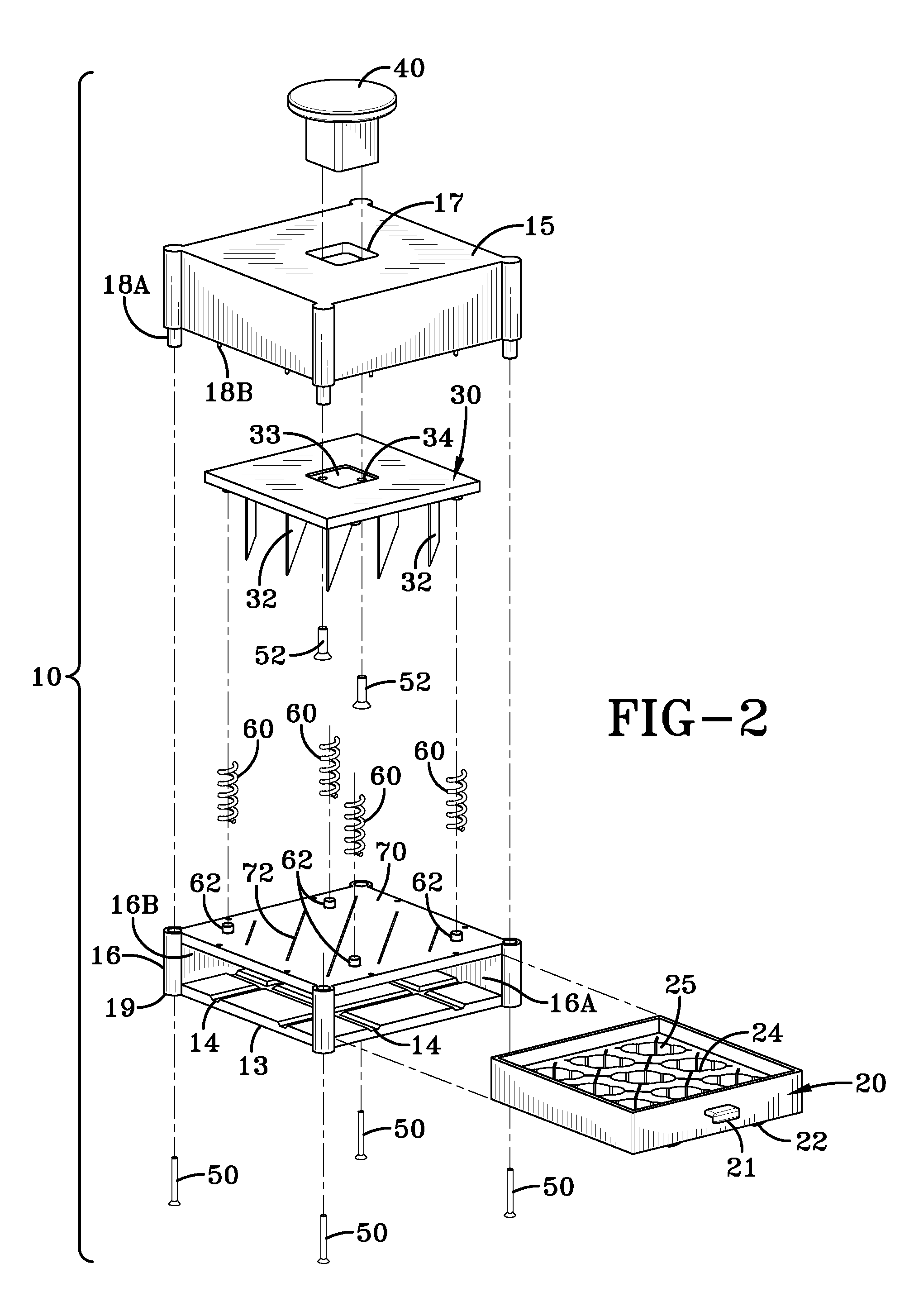

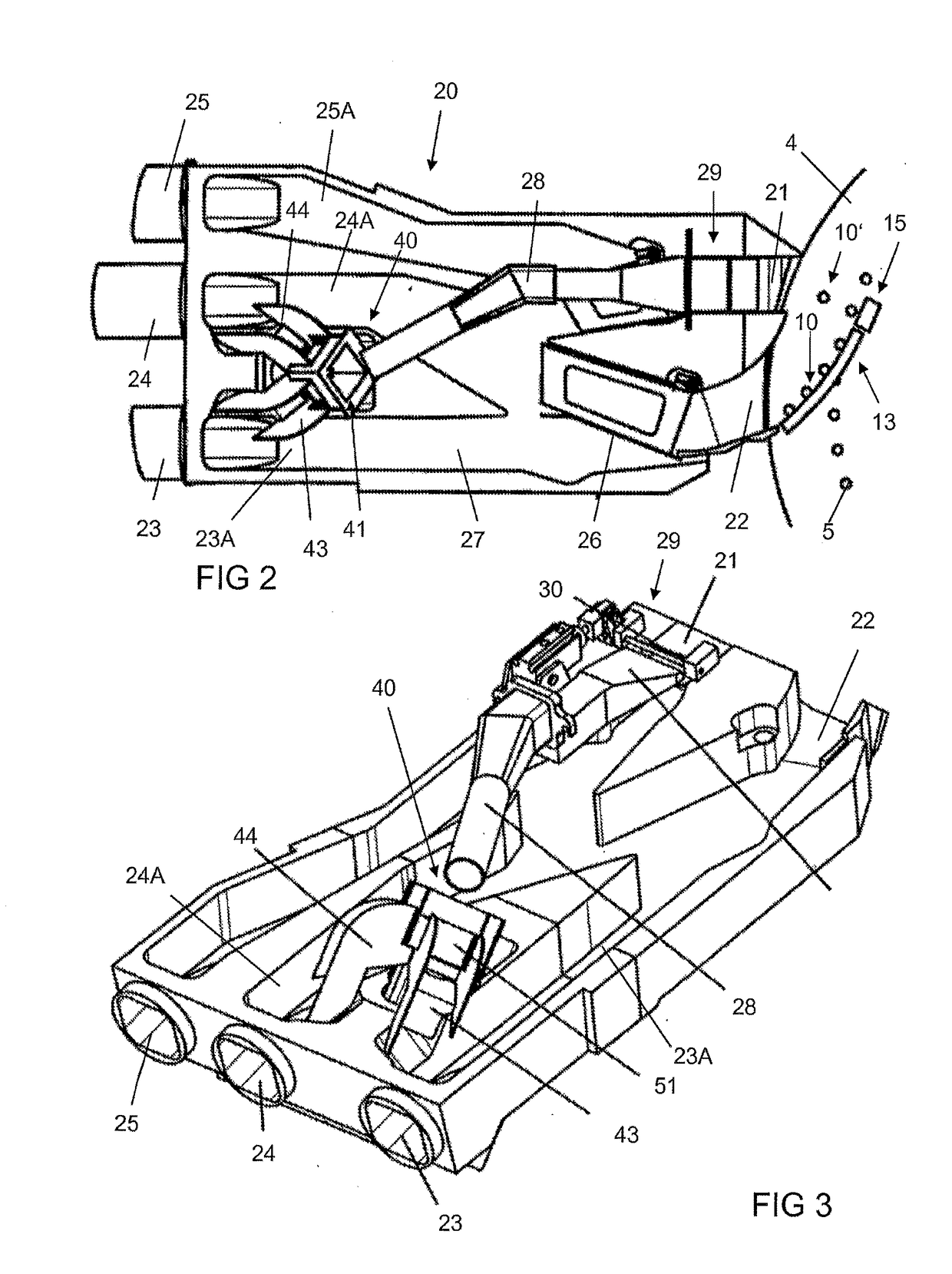

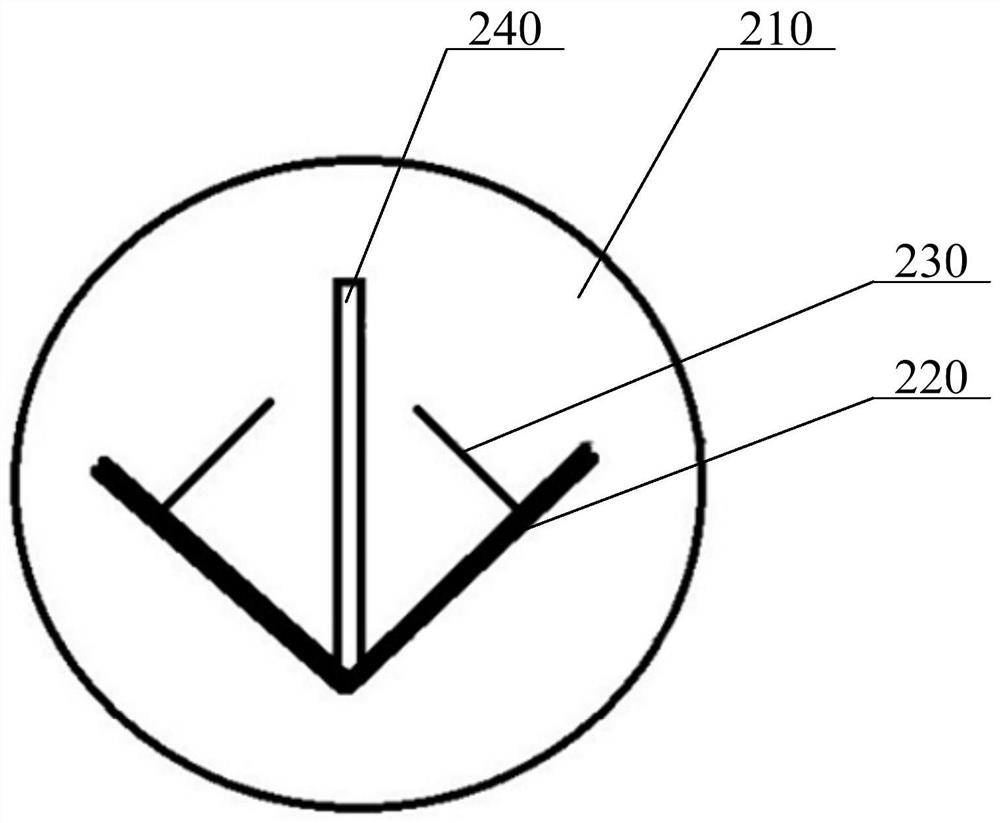

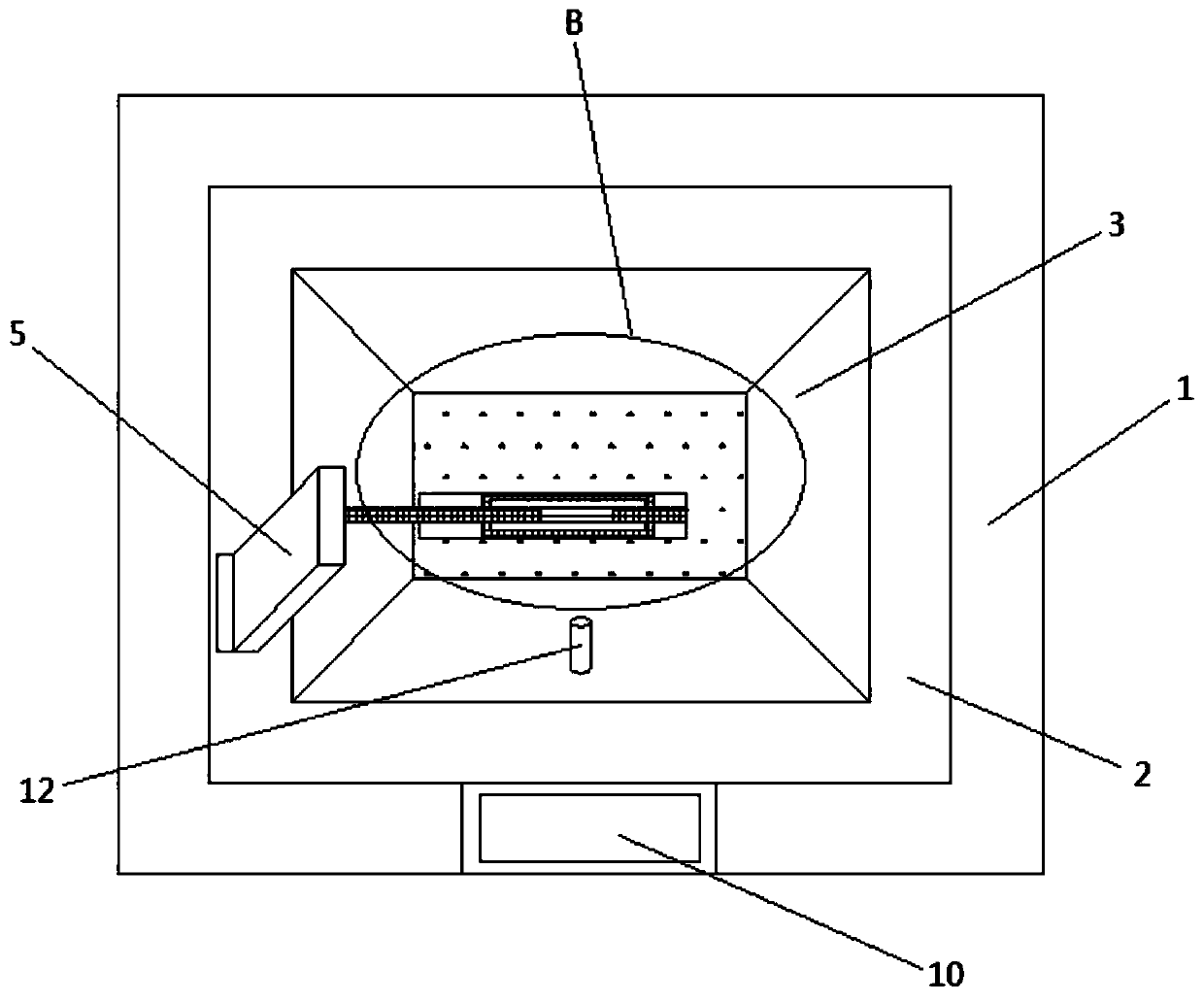

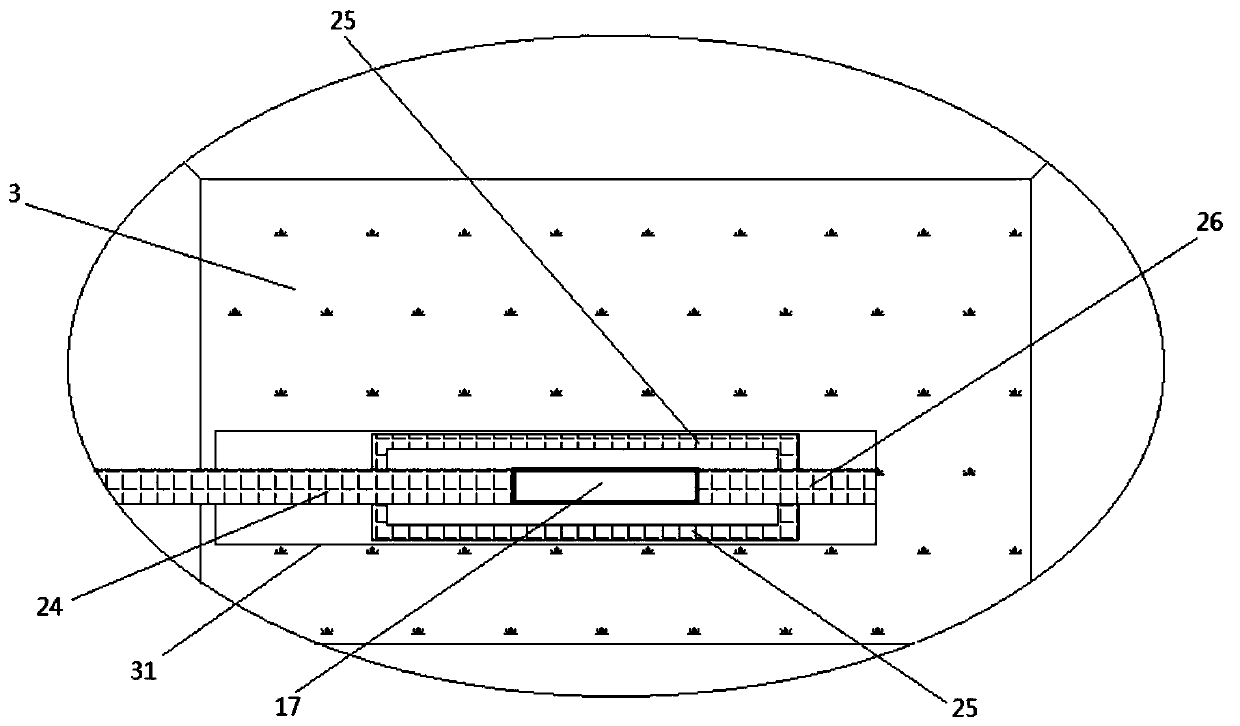

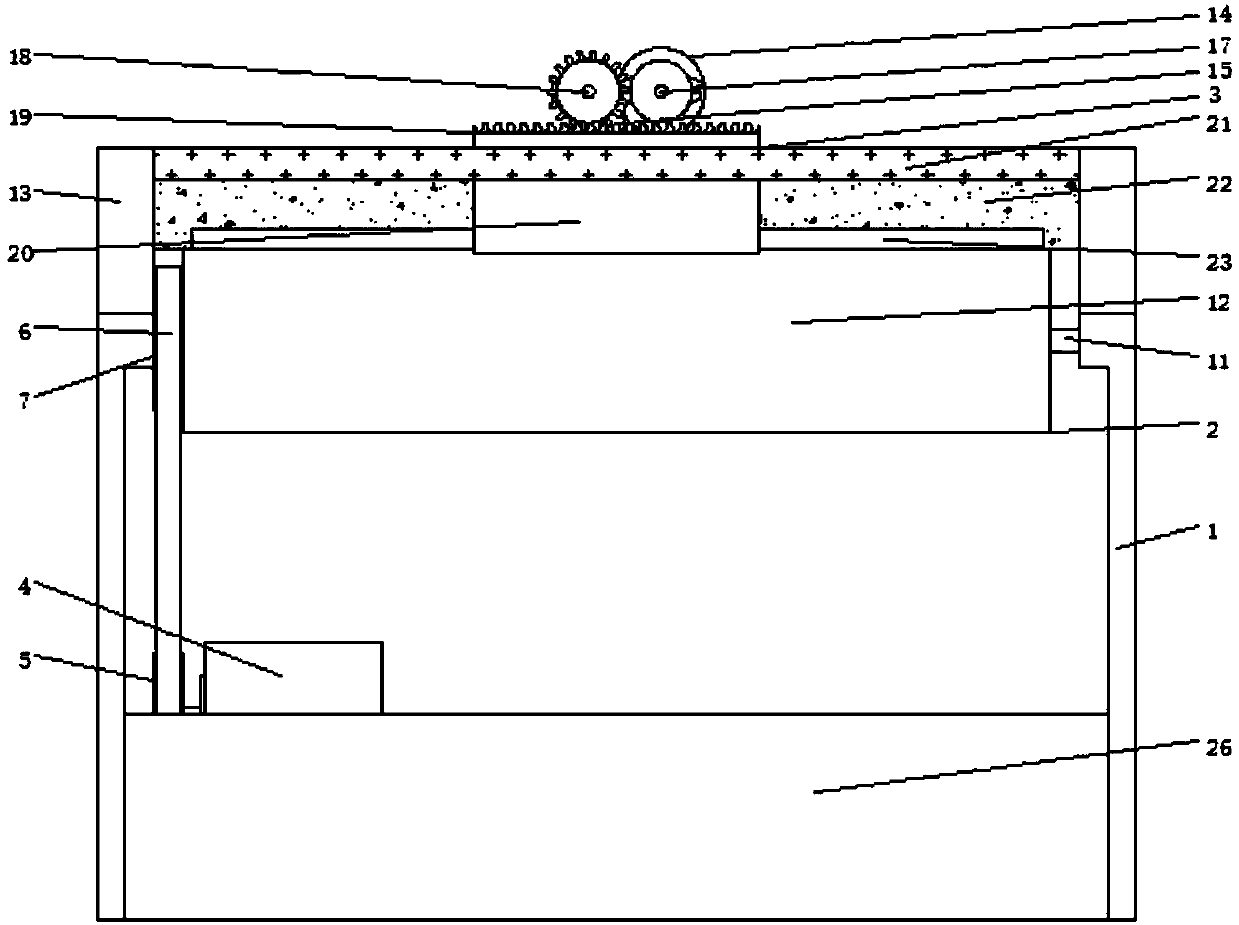

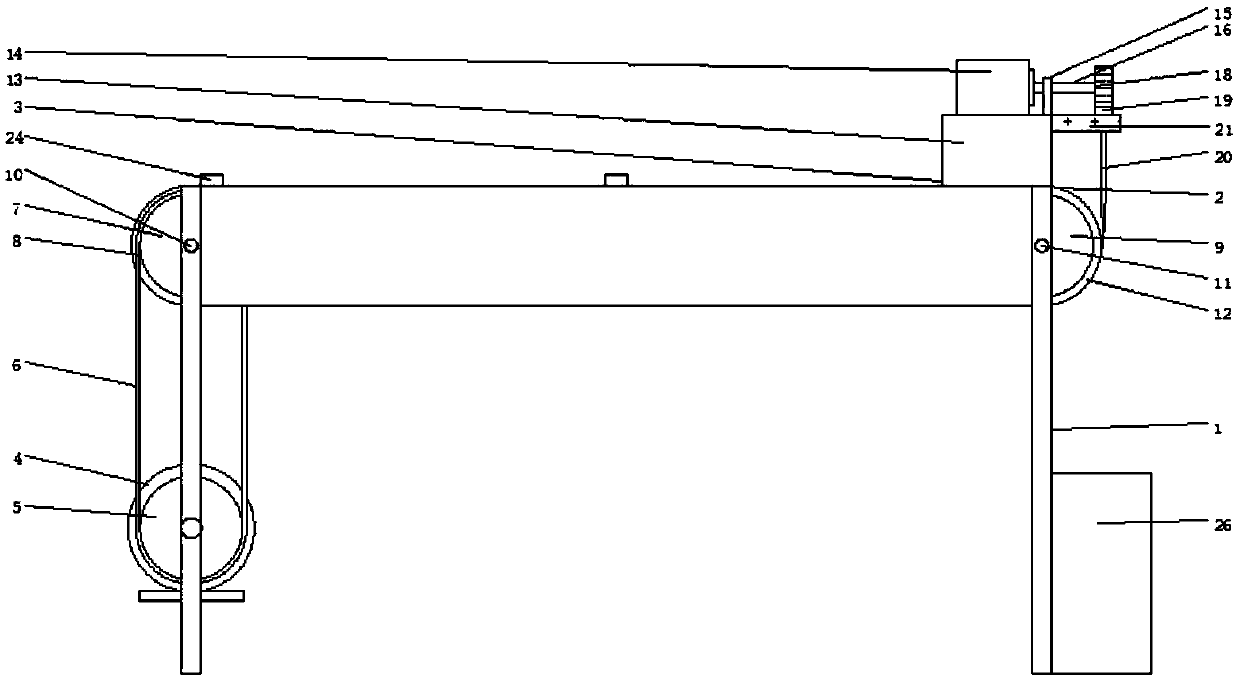

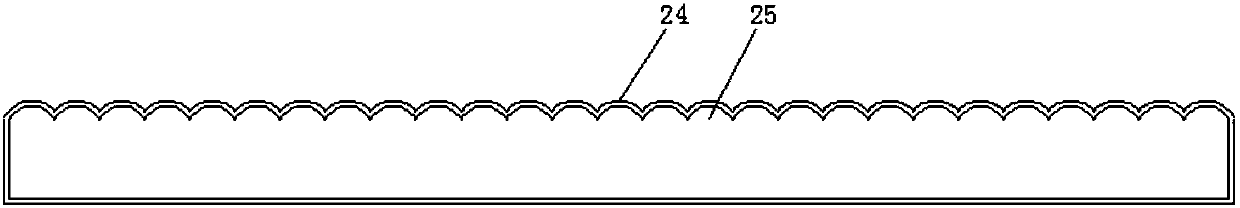

Multiple tablet cutter

A multi-tablet cutting device has a removable tablet holding tray, a housing structure and a plurality of vertically movable cutting blades. The removable tablet holding tray has a plurality of tablet nests. Each nest has two or more levels of beds sized to hold tablets of different sizes or shapes. The housing structure has at least one opening to receive the removable tablet holding tray. The plurality of vertically movable cutting blades is mounted on a support structure on the inside of the housing above the tablet holding tray above a location where the tablet holding tray is stored. The plurality of cutting blades is aligned above the tablet nests and upon a downwardly directed vertical movement the plurality of cutting blades passes through first slots in the nests aligned with the cutting blades to cut the tablets held in the nests into halves.

Owner:RAGHUPRASAD PUTHALATH KOROTH

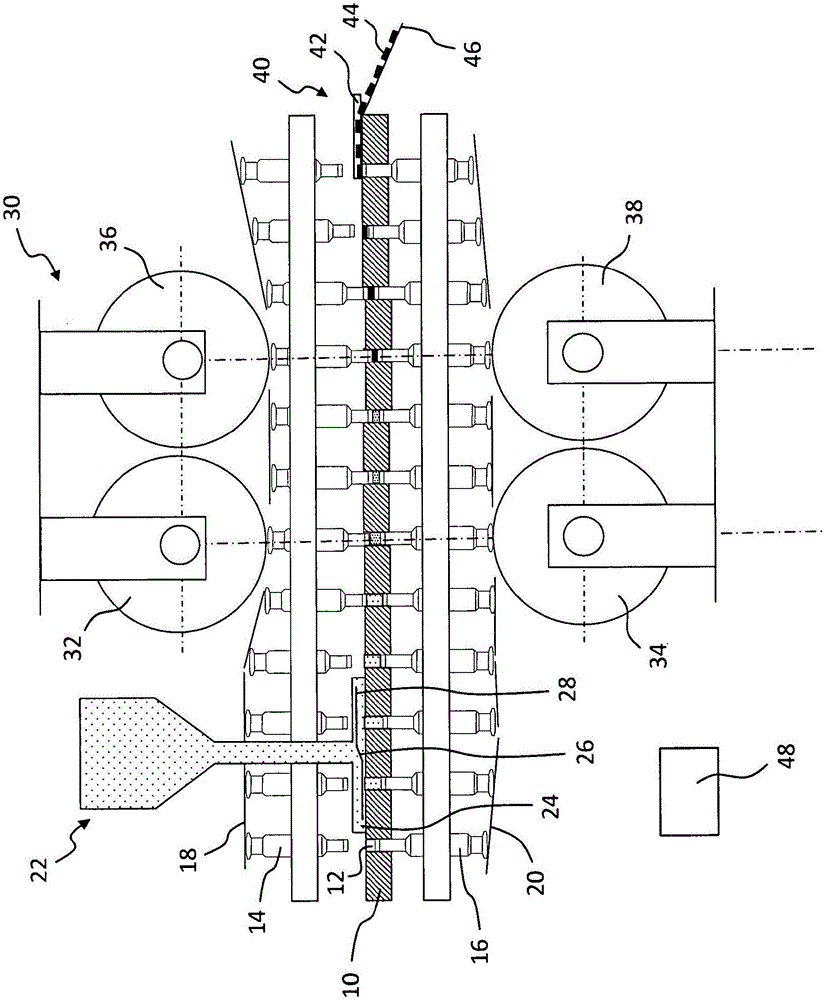

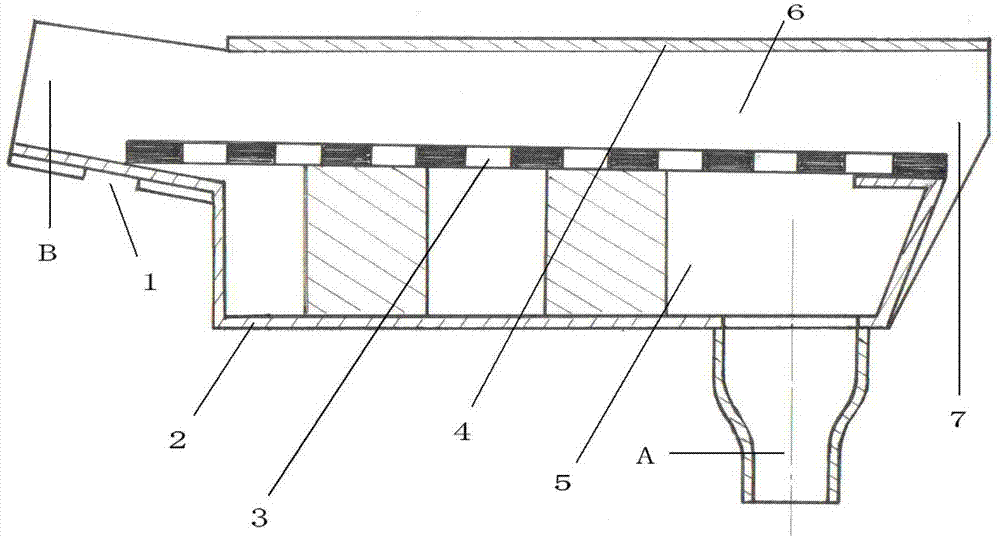

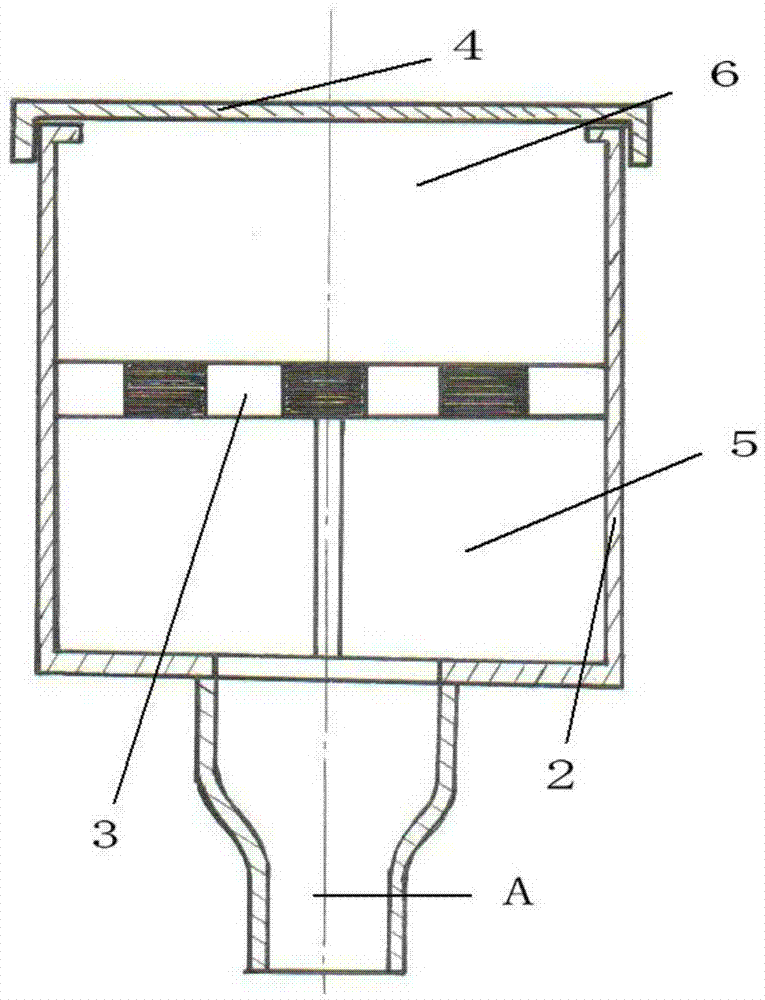

Rotary tablet press with tablet outlet, tablet outlet for said rotary tablet press and method for producing tablets on a tablet press

ActiveUS20170080662A1Increase production outputImprove adhesionSortingShaping pressControl signalTABLET CUTTER

A rotary tablet press, having a rotor, which is driveable about a vertical axis of rotation and has a die plate with die bores for producing tablets inside the die bores by means of punch pairs, having at least one filling station, having at least one pressing station, and having at least one tablet outlet for removing the produced tablets out of the rotary tablet press, with which is associated a discharging device, by way of which tablets, in dependence on a control signal, can be supplied as single tablets to a first channel or as a tablet stream to a second channel in the tablet outlet. In order to enable increased production output with improved adherence to the demands on the tablets, a weighing device with a weighing cell is incorporated into the tablet outlet, tablets from the first channel being suppliable to the weighing device by means of a supply channel.

Owner:ROMACO KILIAN GMBH

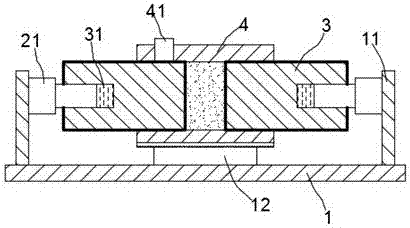

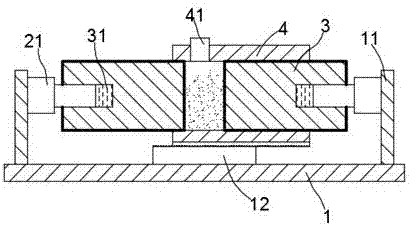

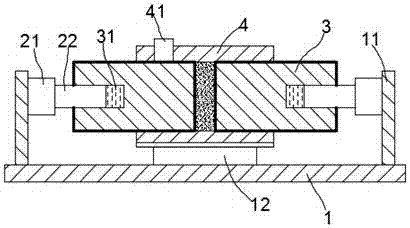

Tablet cutter

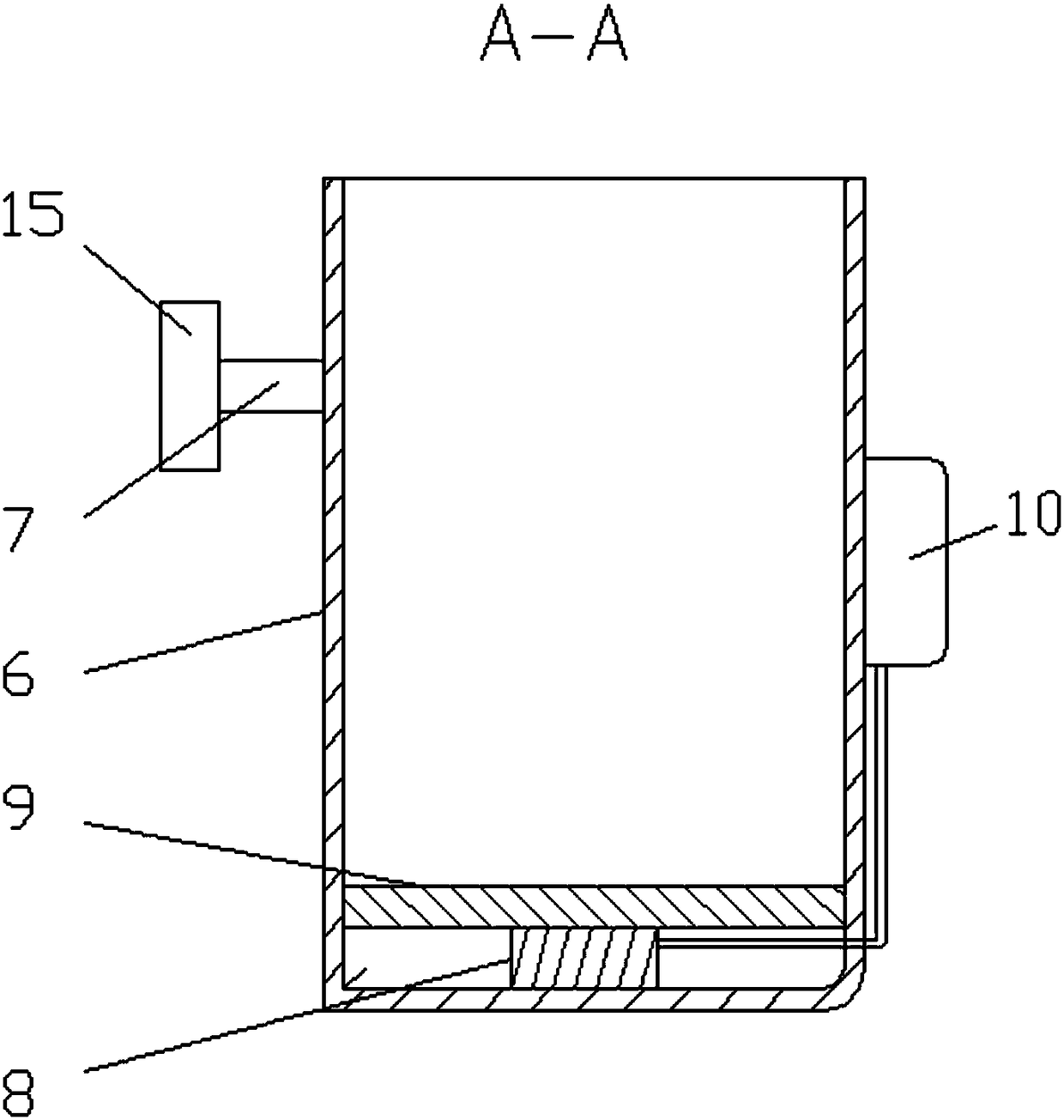

A tablet cutter is formed by a cutting edge mounted on the bottom of a hollow column in perpendicular thereto and a transparent top plate mounted on the top of the hollow column to close the top thereof, a convex edge fixing head and an edge bearing head on a concave side surface of the hollow column which conforms to the head so that the contacting area of the head and the edge bearing head to which impact is transferred upon cutting action. The width in a horizontal direction of the edge bearing head and the edge fixing head is larger than that of the edge bearing body and the edge fixing body, and these elements are covered with a cover having an inner diameter equal to the outer diameter of the hollow column.

Owner:IWASAKI

Tablet cutter

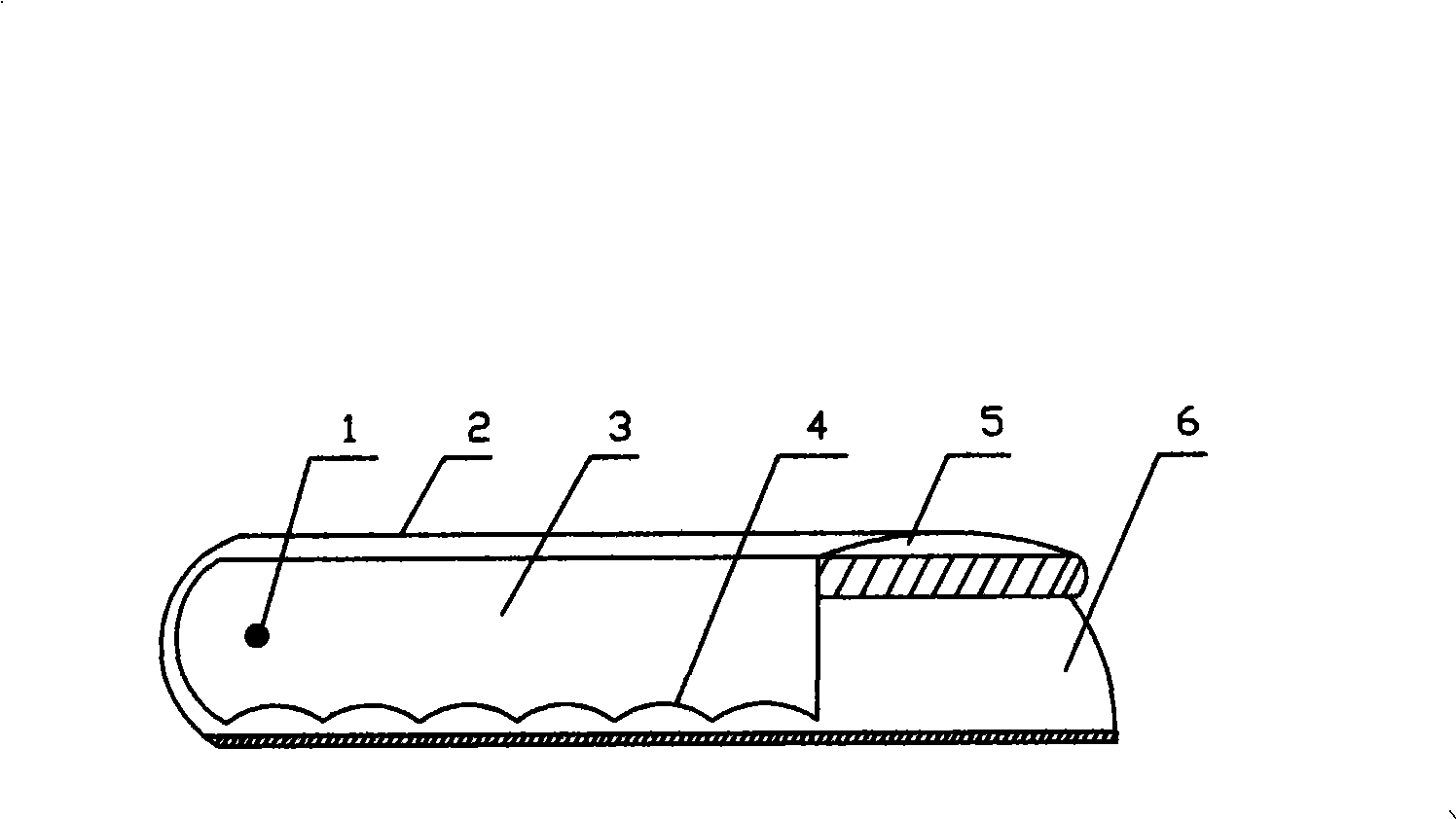

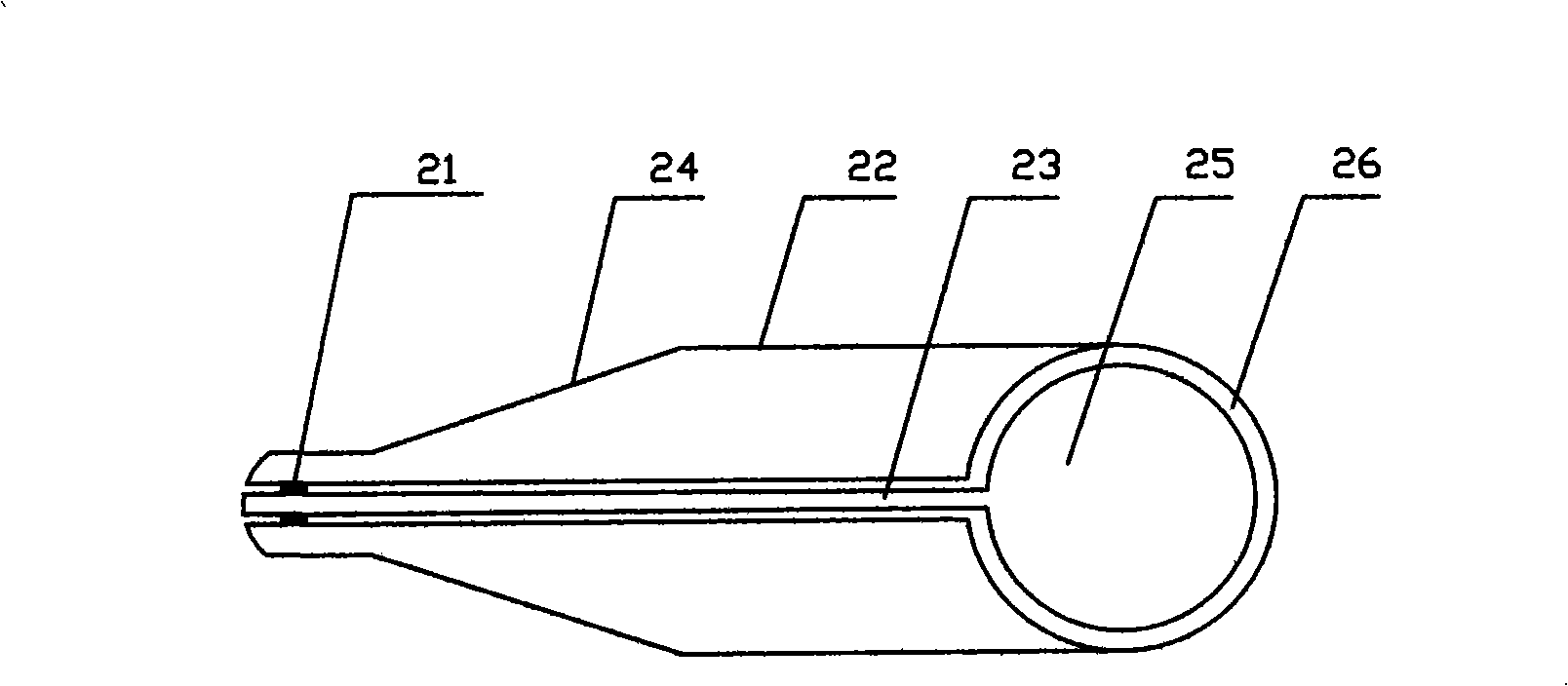

The invention discloses a tablet divider which comprises a parent body and a knife body. The tablet divider is characterized in that one end of the knife body is connected with one end of the parent body by an axis, and the other end of the knife body is provided with a knife handle while the middle part of the knife body is provided with a knife edge which is wave-shaped (including zigzag shape, arc and straight line shape), and the other end of the parent body is provided with a tablet passageway, and the parent body is flat infundibulate. When in use, the parent body of the tablet divider is grasped by hands to open the knife body from the knife handle, and the tablet is placed from the position of the passageway of the parent body, and the tablet can be divided into two parts evenly when the knife handle is pressed. As the parent body is flat infundibulate, the tablets can be divided regardless of tablet sizes; as the knife edge is wave-shaped, the tablets can be divided no matter the tablets are flat-shaped or round convex. The tablet divider has the advantages of simple structure, convenient operation, being healthy, standard and fast.

Owner:宫锡和

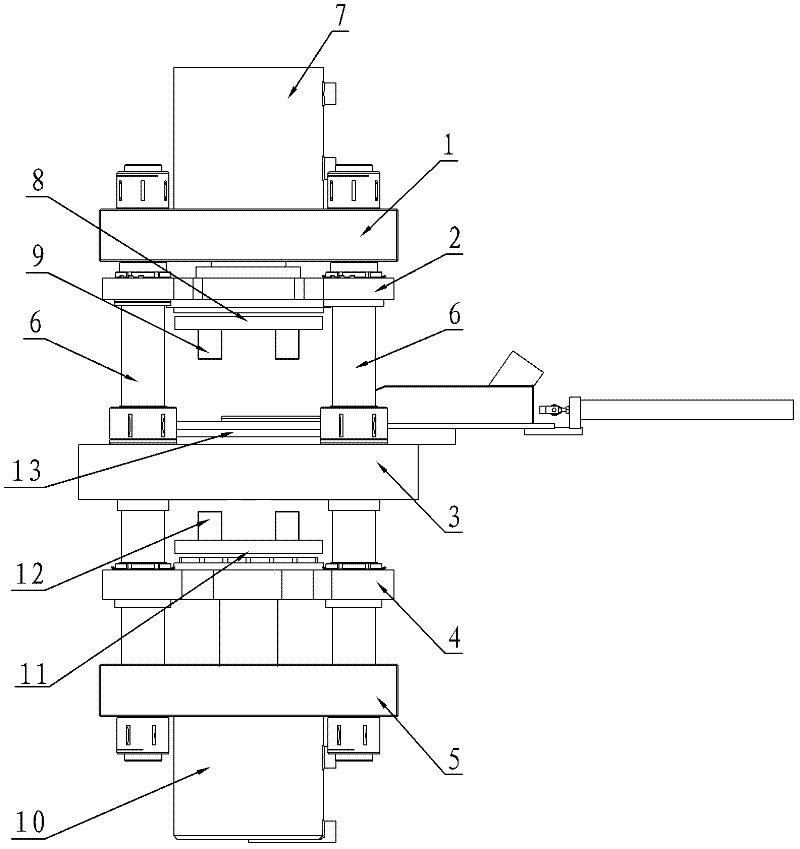

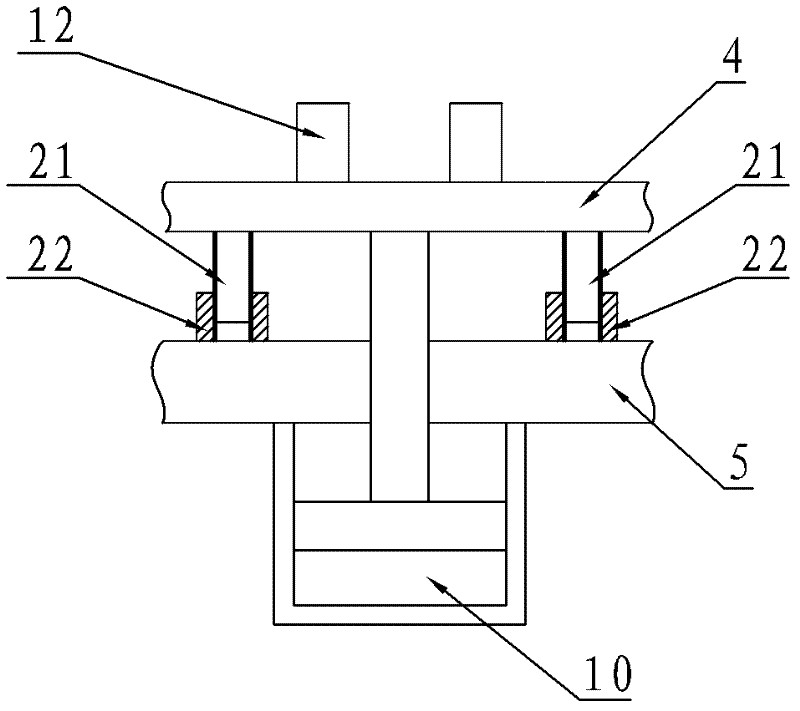

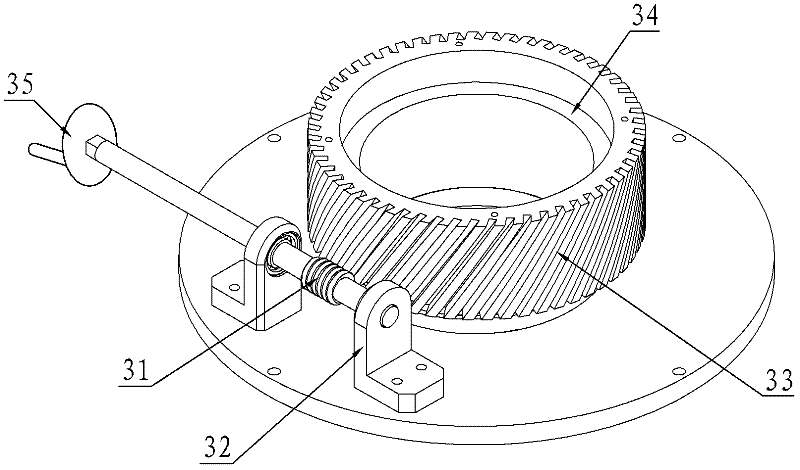

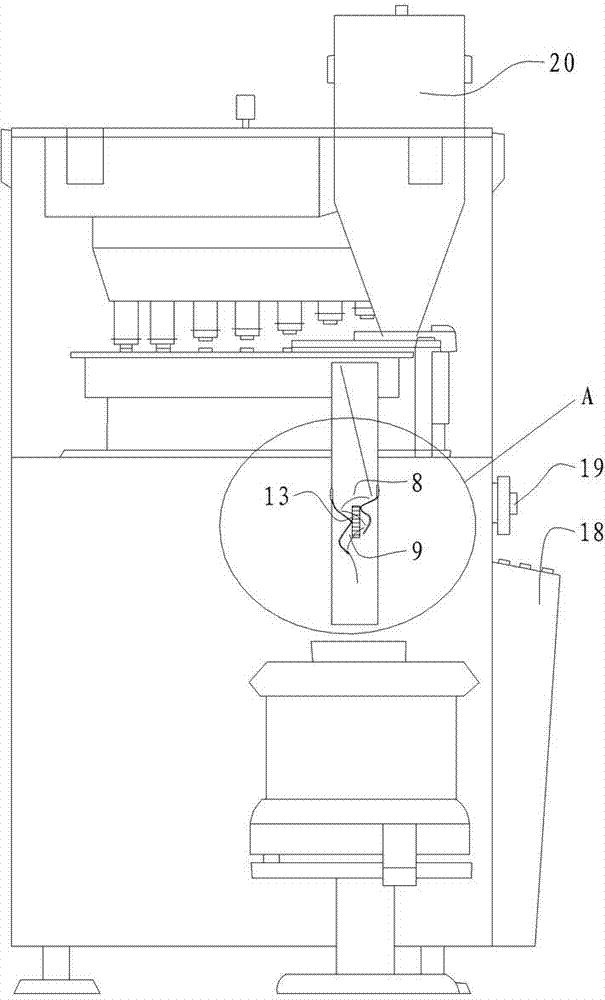

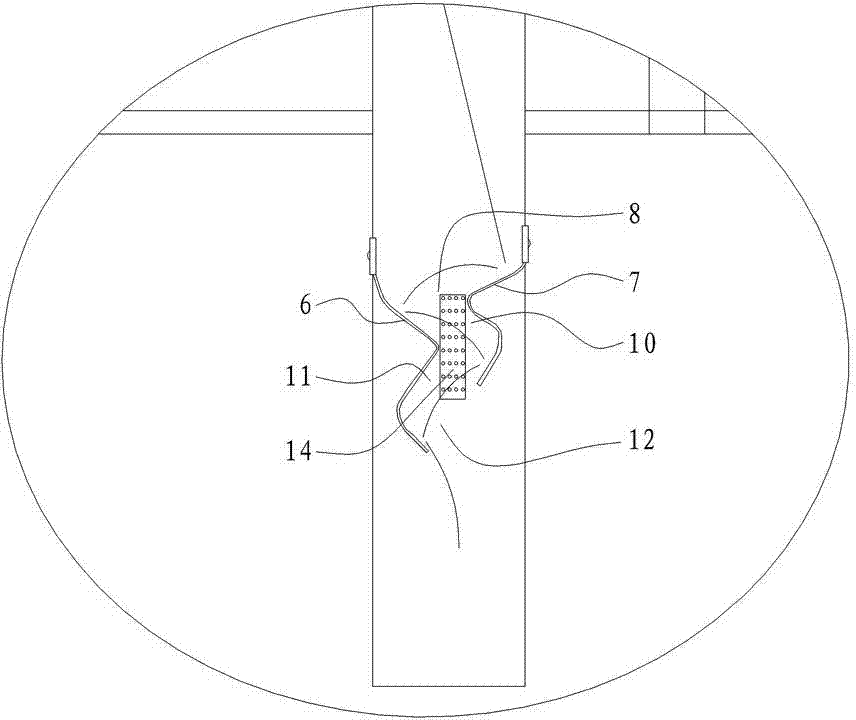

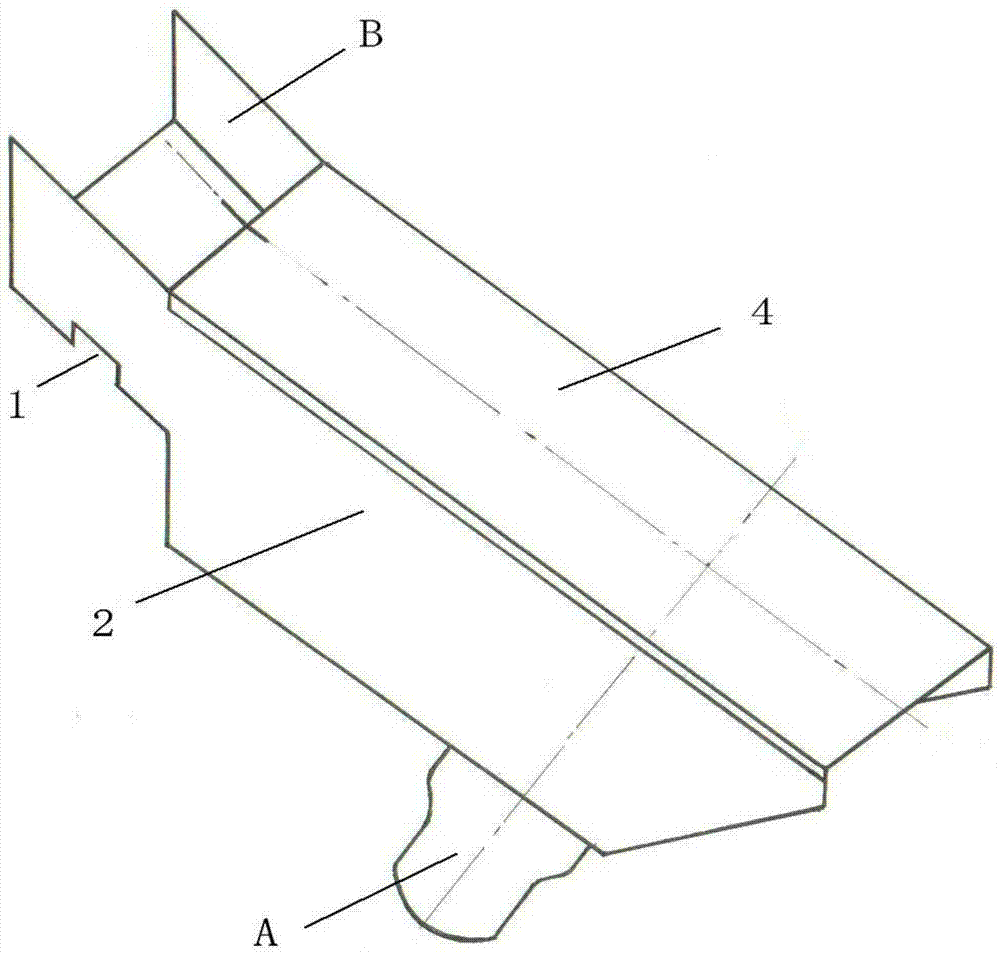

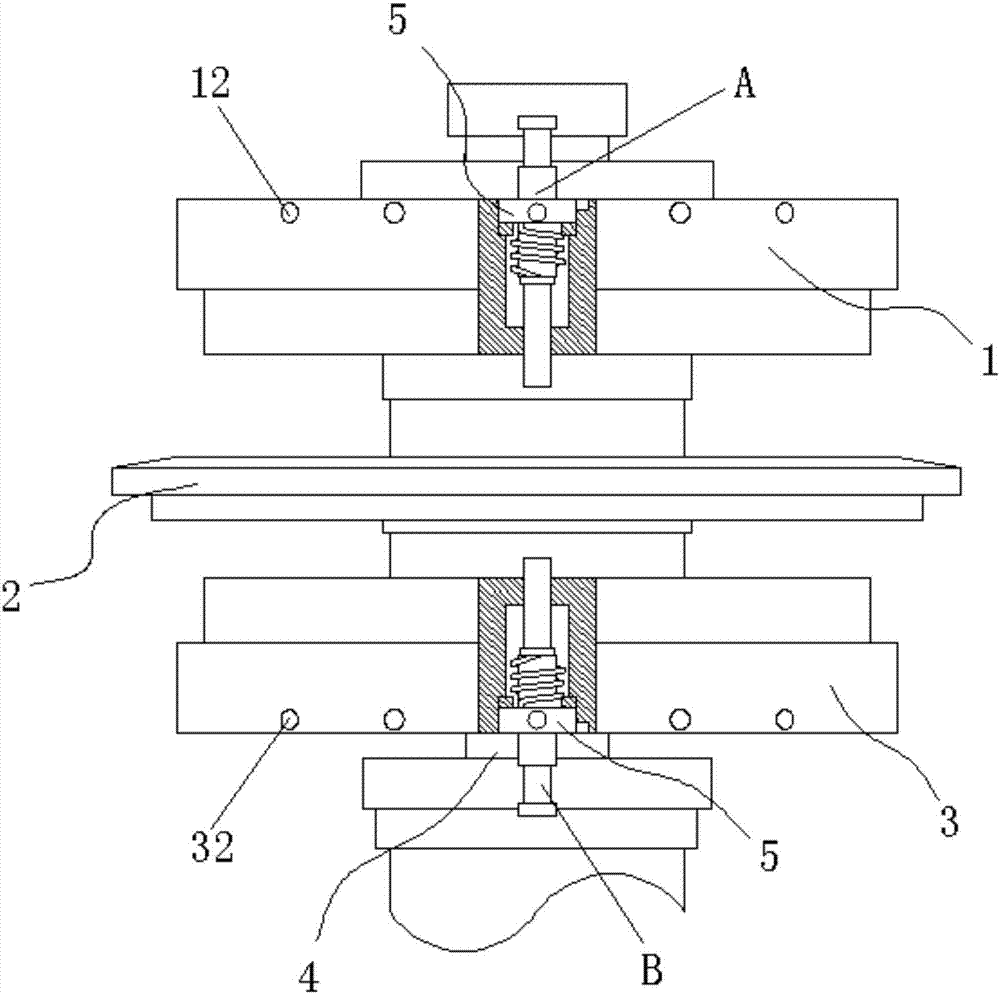

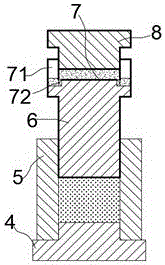

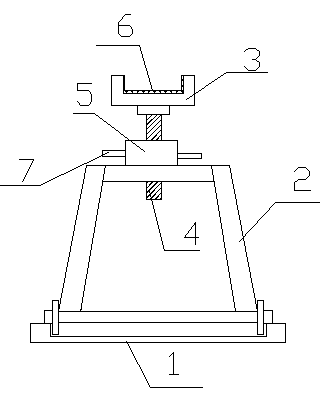

Loading depth fine adjusting device for tablet press

A loading depth fine adjusting device for a tablet press comprises a worm, a worm support, a helical gear and a fixed thread bushing. The fixed thread bushing is sleeved on a piston rod of a lower hydraulic cylinder and fixedly mounted on the upper end face of a lower fixed plate, the outer periphery of the fixed thread bushing is provided with an external thread, an inner hole of the helical gear is provided with an internal thread, and the helical gear is screwed onto the fixed thread bushing through the internal thread on the helical gear. The worm is fixed onto the worm support which is fixedly mounted on the lower fixed plate, the worm is meshed with the helical gear, and the height of the helical gear is larger than or equal to that of the fixed thread bushing. The fine adjusting device is capable of precisely fine adjusting the distance between a lower moving plate and the lower fixed plate, and is simple in structure, reasonable in stress, simple and feasible in adjustment, high in control precision, wide in adjusting range, economical practical, and capable of overcoming the defects of the prior art.

Owner:常州金坛威克压片机械制造有限公司

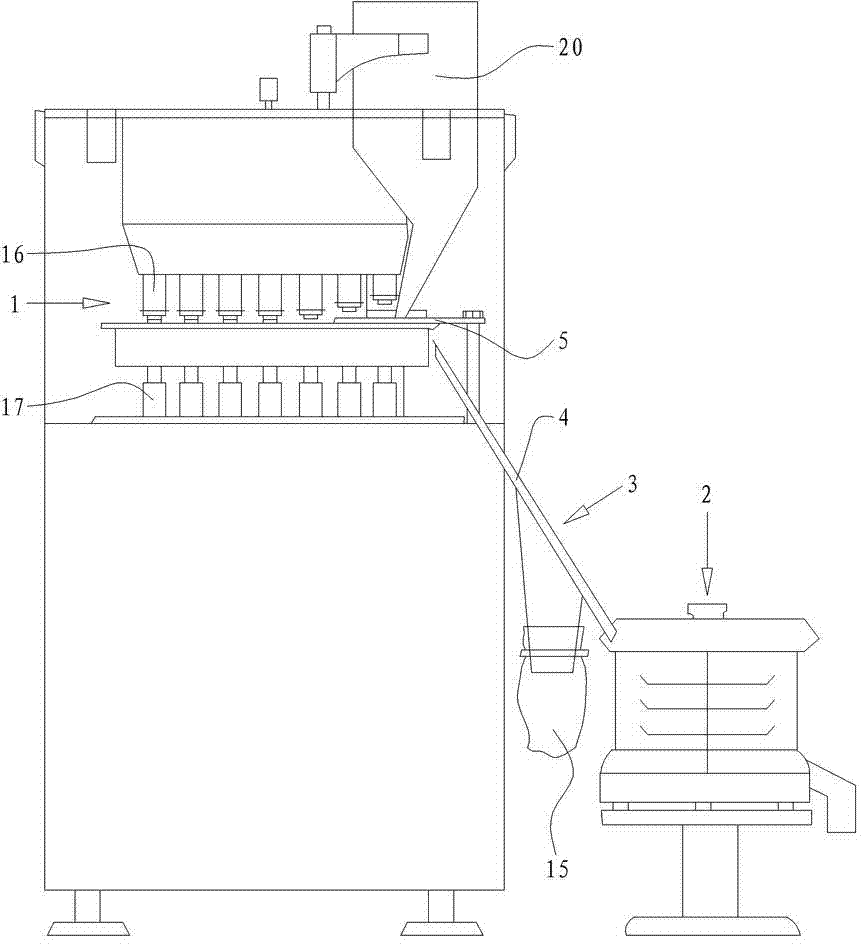

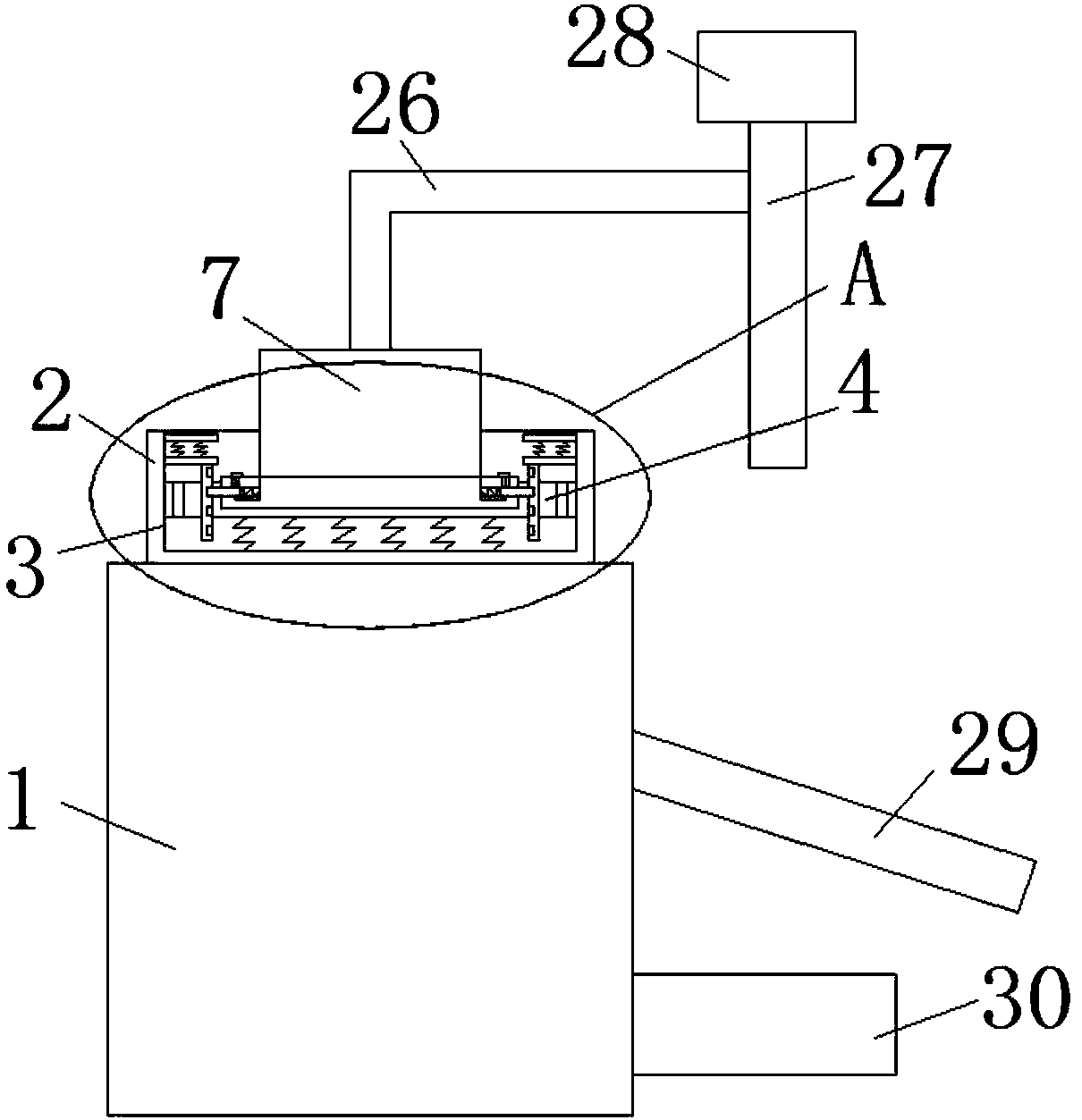

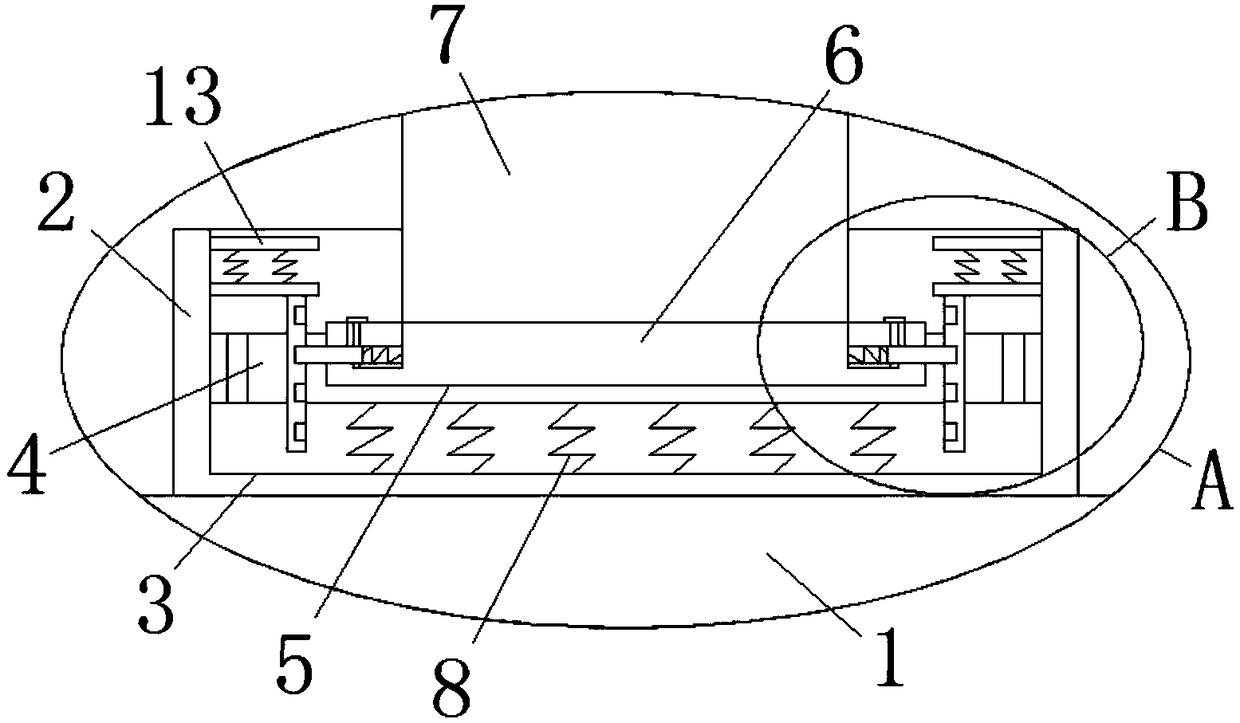

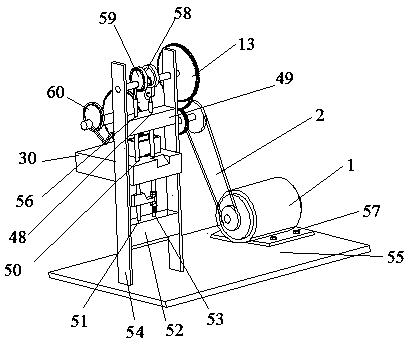

Tablet machine

The invention relates to a tablet machine, and belongs to the technical field of press machines. The tablet machine comprises a tablet pressing forming device, a tablet collecting device and a tablet output device. The tablet output device comprises a tablet falling groove which is obliquely placed and a tablet scraper. An adjusting piece used for adjusting the falling angle of tablets is arranged in the inlet of the tablet falling groove, a left vibration piece and a right vibration piece opposite to the left vibration piece are arranged in the tablet falling groove, the upper portion of the left vibration piece and the upper portion of the right vibration piece are close to each other to form an arc tablet collecting portion, the lower portion of the left vibration piece and the lower portion of the right vibration piece form a tablet falling channel where the tablets fall after the tablets hit back and forth between the left vibration piece and the right vibration piece, the bottom face inside the tablet falling groove is provided with powder collection holes and a powder falling groove which is obliquely formed relative to the axial direction of the tablet falling groove and communicated with the powder collection holes, the width of the powder falling groove is smaller than the thickness of each tablet, the powder falling groove is located in the tablet falling channel, the powder collection holes are formed in the side, away from the right vibration piece, of the left vibration piece, and formed in the side, away from the left vibration piece, of the right vibration piece, and a powder collection container connected with the powder collection holes is arranged outside the tablet falling groove. The tablet machine has the advantage of recycling powder stock.

Owner:SUZHOU RUNHONG TRADING

Portable tablet cutter for obstetrical department

PendingCN113425601AAchieve clampingEasy to cutOral administration deviceTABLET CUTTERBiomedical engineering

The invention relates to a cutter, in particular to a portable tablet cutter for the obstetrical department. The portable tablet cutter for the obstetrical department can realize automatic cutting and automatic collection. According to the technical scheme, the portable tablet cutter for the obstetrical department comprises a base, supporting frames, a fixing block, an outer frame, a storage bottle, a cutting mechanism and a correcting mechanism, the supporting frames are arranged on the three sides of the top of the base, the fixing block is connected between the upper parts of the supporting frames, the outer frame is arranged on the fixing block, the storage bottle is connected to the bottom of the outer frame in a threaded mode, the cutting mechanism is arranged on the outer frame, and the correcting mechanism is arranged on the outer frame. Through cooperation between the cutting mechanism and the correcting mechanism, the effects of clamping the tablets and cutting the tablets at the same time can be achieved.

Owner:赖招娣

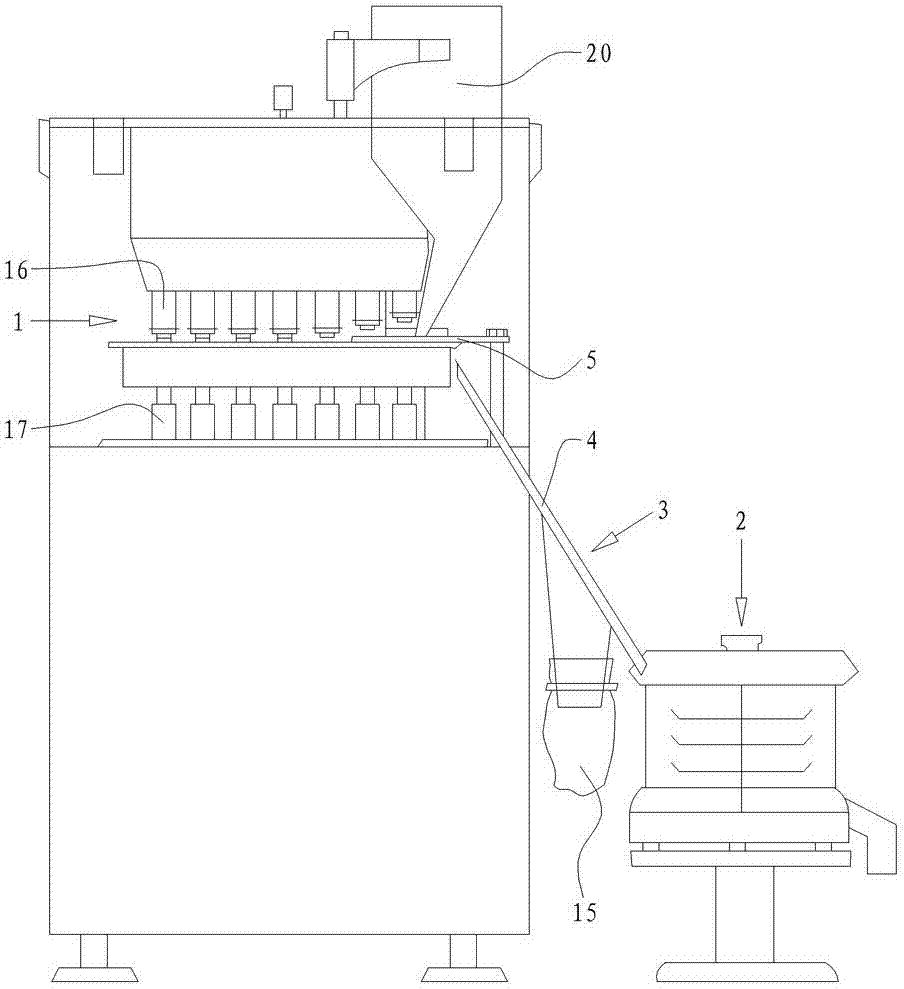

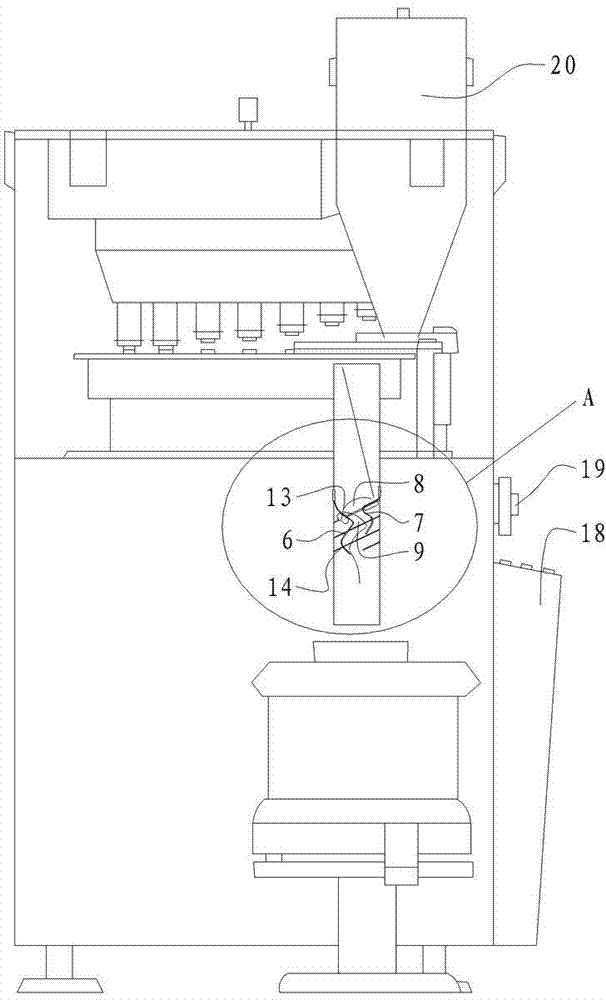

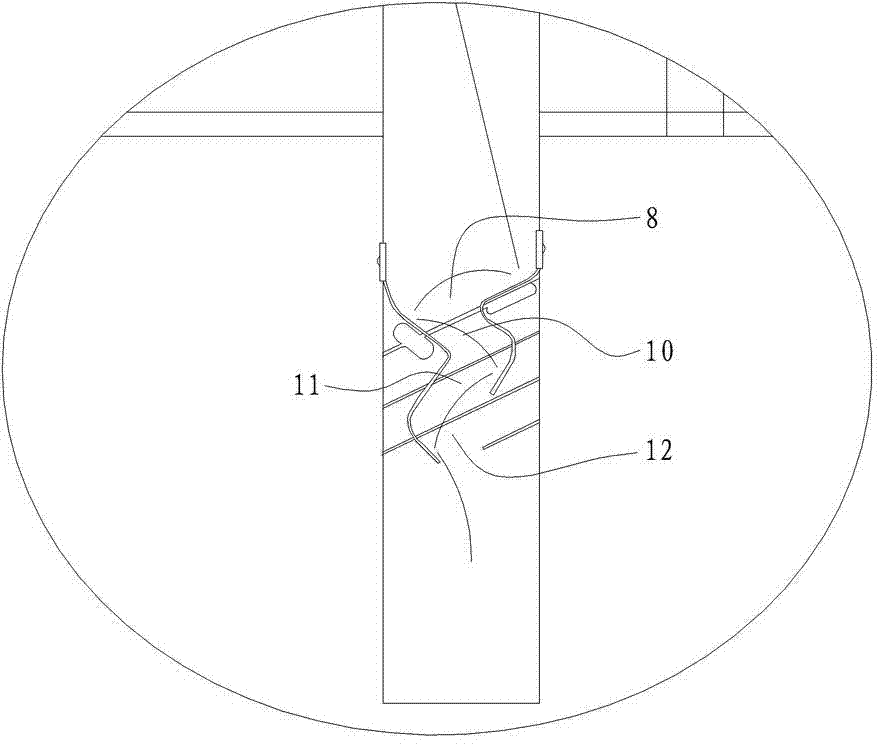

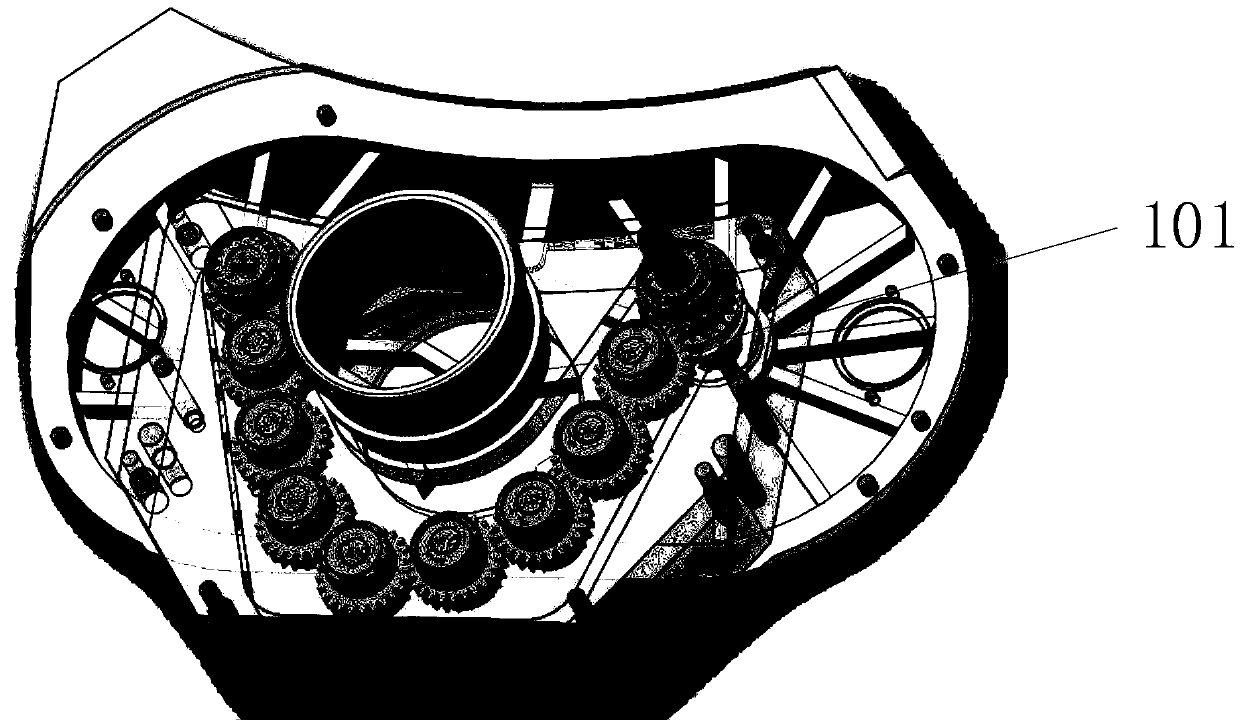

Multi-vibrating-reed rotary tablet press

The invention relates to a multi-vibrating-reed rotary tablet press, and belongs to the technical field of presses. The rotary tablet press comprises a tablet compression molding device, a tablet collecting device and a tablet discharging device, the tablet discharging device comprises a tablet discharging groove arranged in a slant mode and a tablet scraping plate, an adjusting sheet for adjusting the falling angles of tablets is arranged at an inlet of the tablet discharging groove, a left vibrating reed and a right vibrating reed which are opposite are arranged in the tablet discharging groove and are respectively composed of at least two vibrating reeds vertically arranged in a line, the upper portions of the left vibrating reed and the right vibrating reed get close to each other to form a collecting part of the arc-shaped tablets, tablet discharging channels are formed in the lower portions of the left vibrating reed and the right vibrating reed respectively, a powder outlet hole is formed in the position, located in the tablet discharging channels, on the bottom face of the tablet discharging groove, a filtering net is fixed on the powder outlet hole, and the hole diameters of filtering holes of the filtering net are smaller than the diameters of the tablets. A powder accumulated container used for being connected with the powder outlet hole is arranged outside the tablet discharging groove. The multi-vibrating-reed rotary tablet press has the advantage of recycling powder raw materials.

Owner:SUZHOU RUNHONG TRADING

Dust removal device for tablet press

Owner:罗厚镇

Air blast type tablet discharging tablet press

The invention discloses an air blast type tablet discharging tablet press. The air blast type tablet discharging tablet press comprises a rack, a pressing block, an upward pressing oil cylinder and an upper die box. The upper die box is fixedly connected to the rack. The upper die box is provided with a top cover and a bottom opening. The pressing block is driven by the upward pressing oil cylinder to be upwards pressed into the upper die box. An air hole corresponding to a swing plate is formed in the pressing block. Compressed air can be led into the air hole. According to the tablet press, tablets are pressed and formed in an upward pressing forming manner, the tablets are downwards disengaged from the upper die box under gravity, and therefore the tablets can be conveniently taken out. In addition, the lower portions of the two side walls of the upper die box can swing outwards, the pressure exerted by the side wall of the upper die box on the tablets can be released, the tablets can conveniently leave the upper die box, and the tablets can be conveniently taken out.

Owner:重庆市扬昇药业有限公司

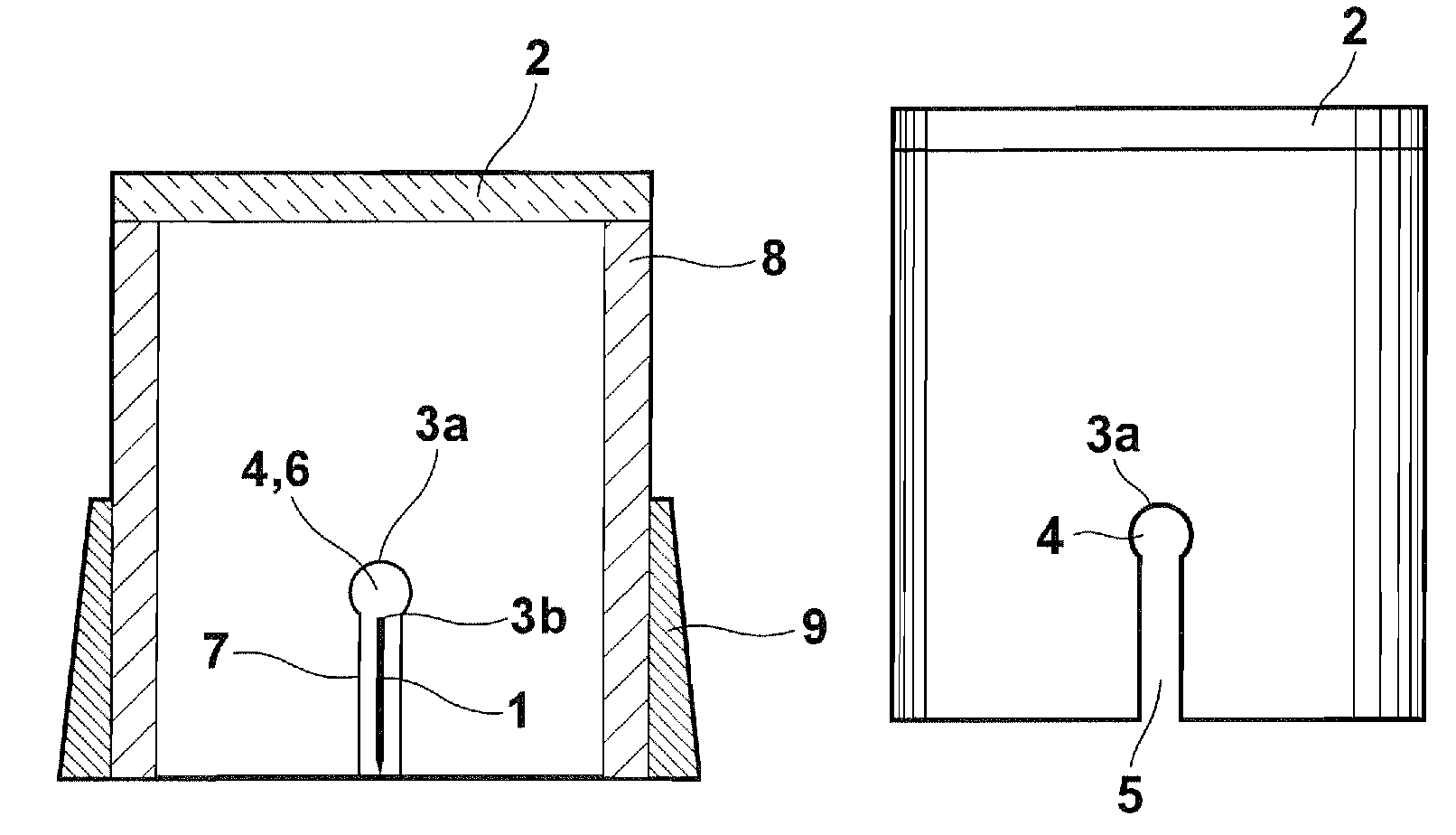

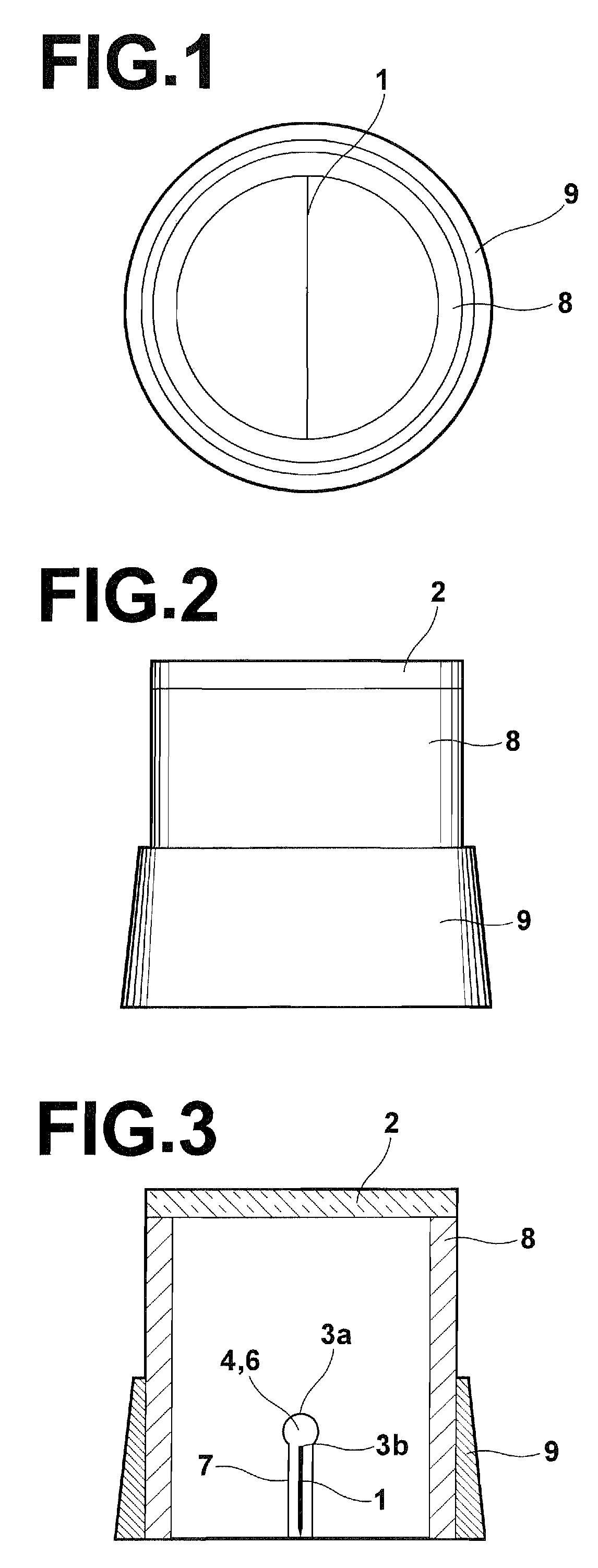

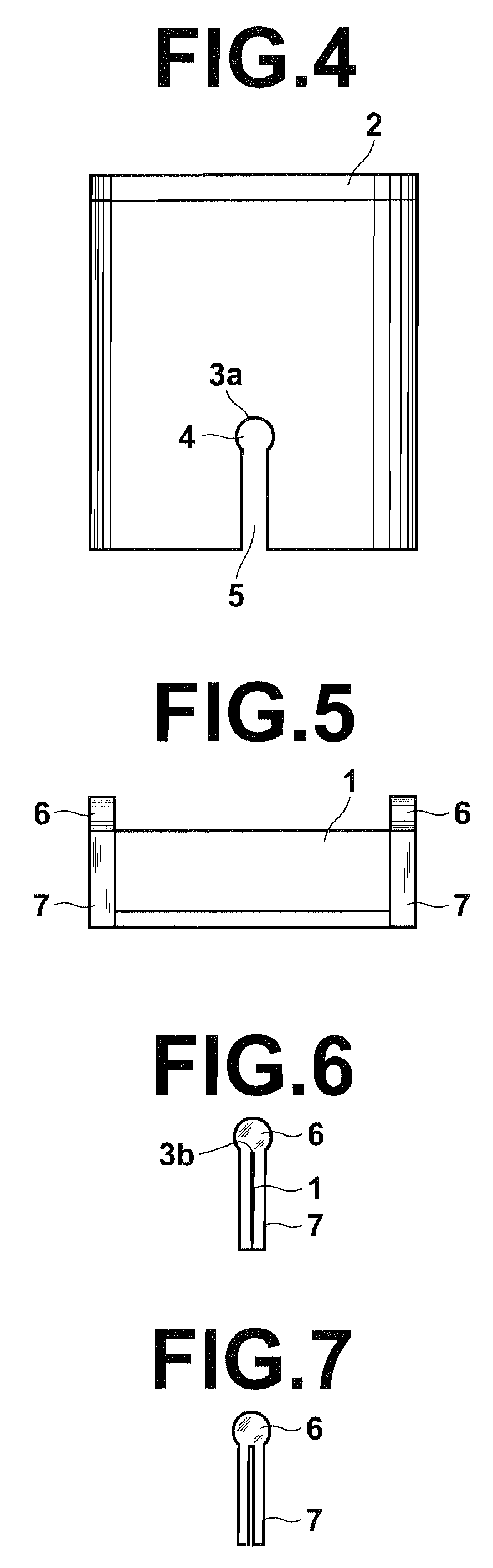

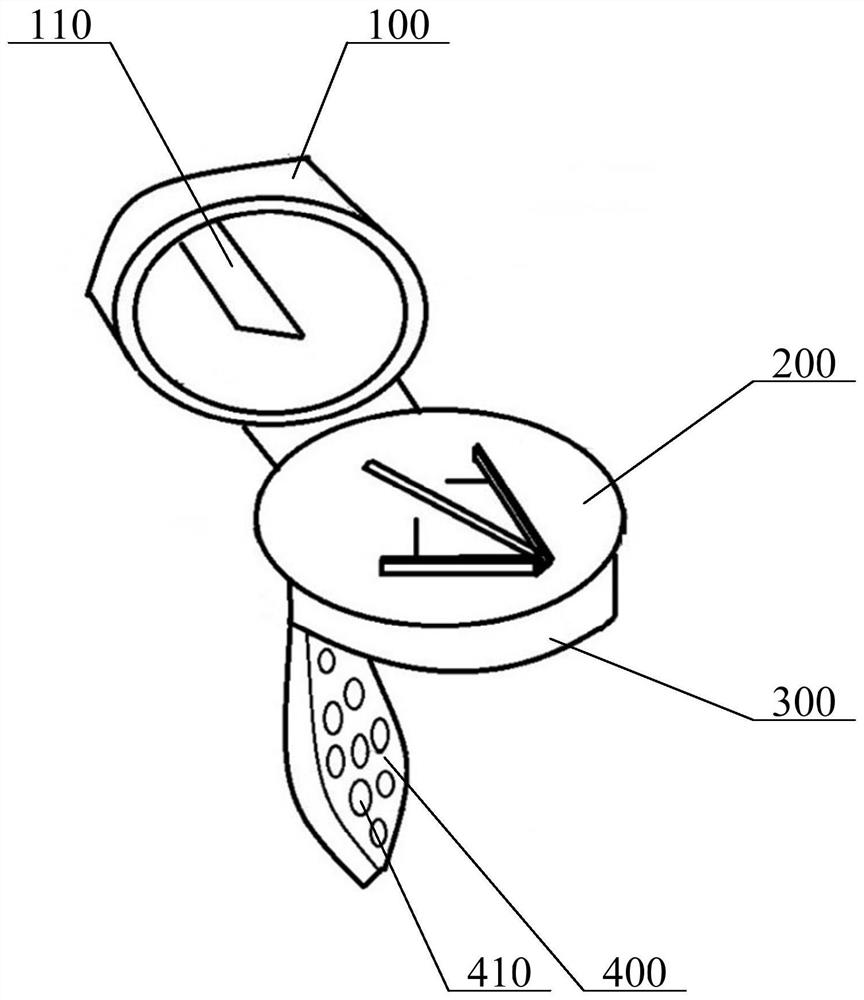

Medicine cutting device and medicine storage device

The invention provides a medicine cutting device and a medicine storage device, and relates to the technical field of medical supplies. The medicine cutting device comprises a flip cover main body anda fixing component, wherein the fixing component is used for fixing tablets, the flip cover main body is provided with a cutter, and the flip cover main body is configured to be capable of rotating relative to the fixing component so as to enable the cutter to cut the tablets. According to the medicine cutting device and the medicine storage device, the cutter is arranged on the flip cover main body, the flip cover main body rotates to enable the cutter to cut the tablets located on the fixing component, the medicine is cut, the whole tablet is accurately split, the technical problems that inthe prior art, the medicine is broken off by hands, labor is wasted, the operation is inaccurate, and the uneven dose splitting is easily caused are solved, and the technical effects that the medicine splitting is labor-saving and accurate are achieved.

Owner:BEIJING JISHUITAN HOSPITAL

Tablet collecting device for tablet press

The invention discloses a tablet collecting device for a tablet press, and relates to the field of medicine production equipment. The tablet collecting device comprises a base plate, a slide way, collecting barrels and weighing mechanisms, wherein the base plate is arranged on the side surface of a machine body of the tablet press through bolts and is located below discharge ports of the tablet press, the slide way is horizontally welded and fixed to the base plate, supporting rods are connected to the side surfaces of the collecting barrels, sliding blocks are connected to the tail ends of the supporting rods and are connected in the slide way in a sliding mode, a notch used for taking out the sliding blocks is formed in the middle of the slide way, and the weighing mechanisms are furtherarranged in the collecting barrels. The tablet collecting device has the advantages that an existing collecting mode of the tablet press is improved, the slide way and the detachable collecting barrels are arranged on the side surface of the machine body of the tablet press, the multiple collecting barrels can be placed in the slide way, when one collecting barrel is full, the collecting barrel is directly replaced with another empty collecting barrel, then the full collecting barrel is taken out from the notch, shutdown is not needed, and therefore the production efficiency is improved, andthe operation is flexible.

Owner:WUHU NOKAN BIOTECH

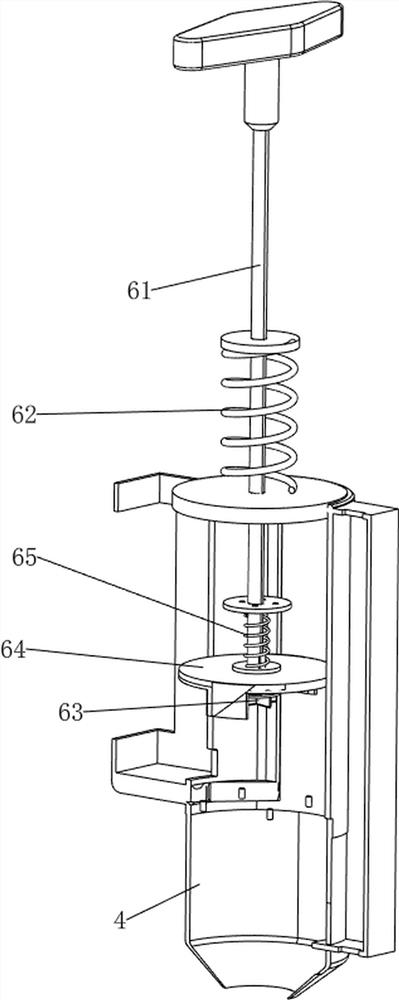

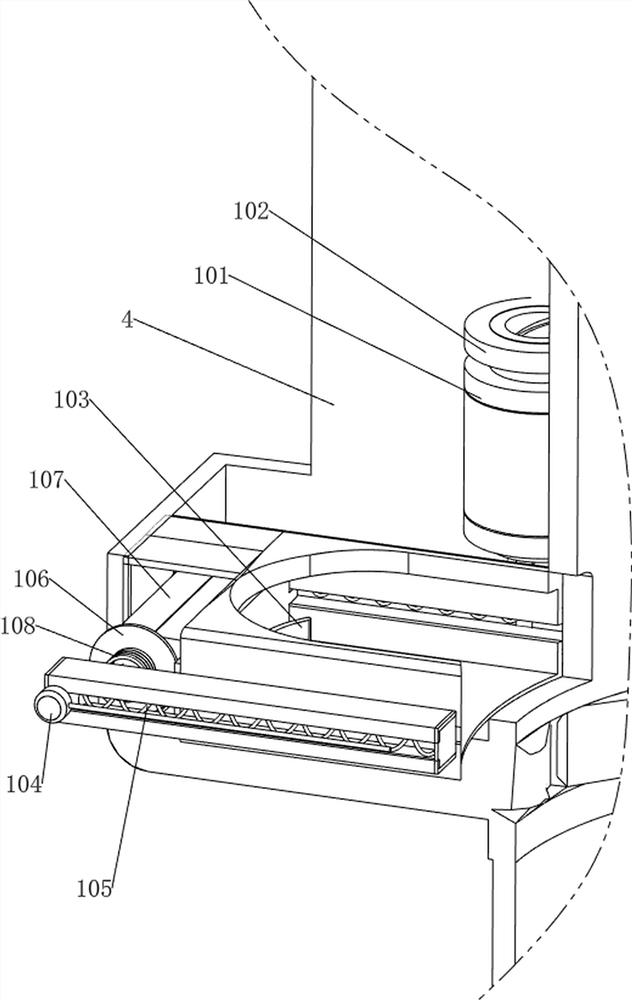

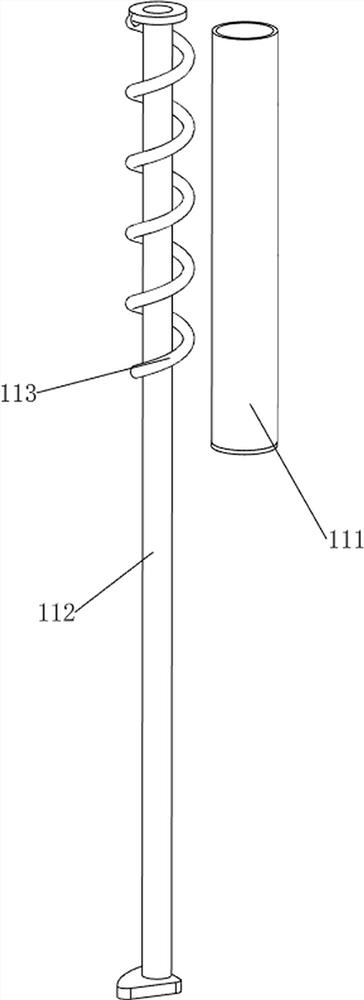

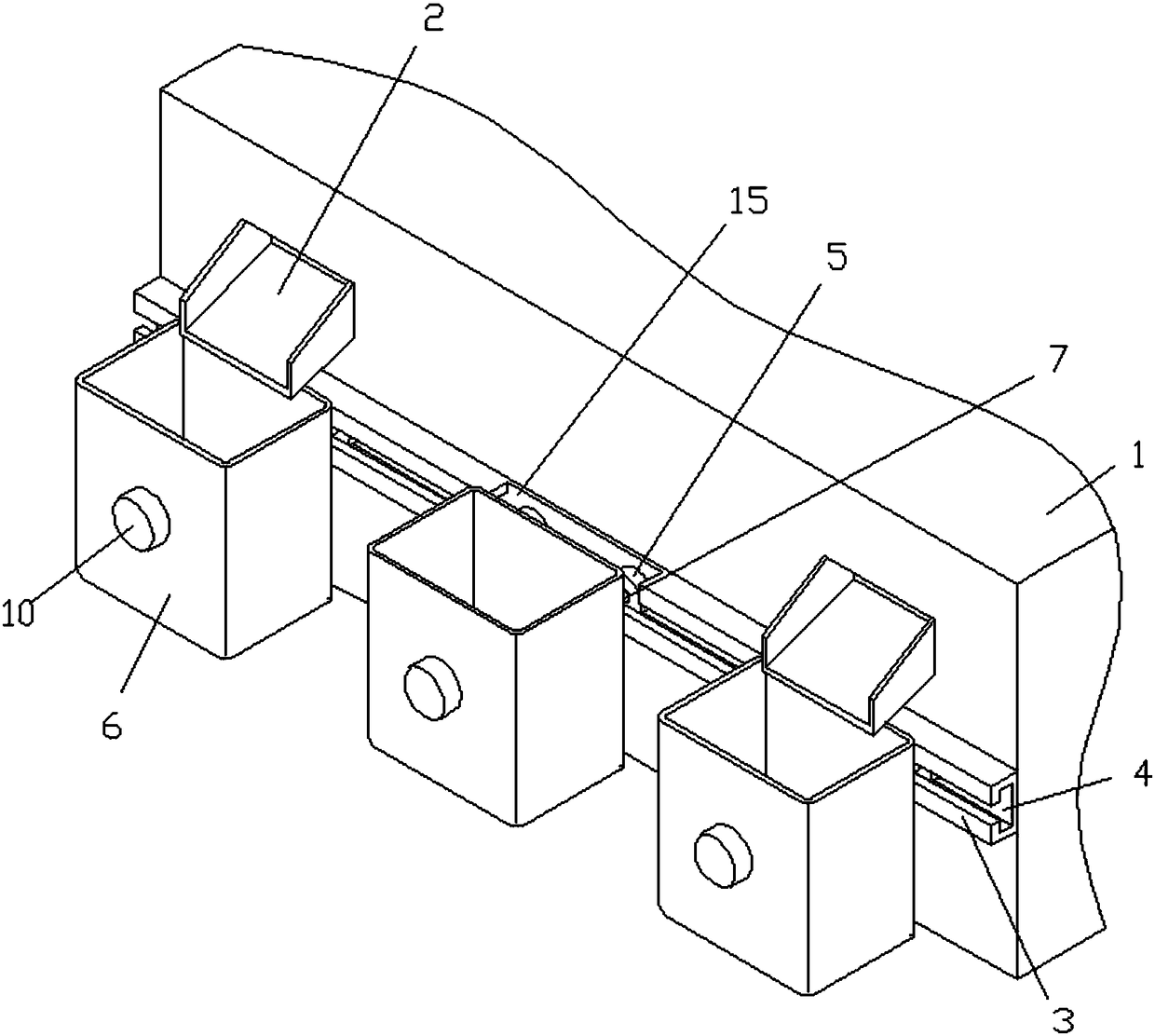

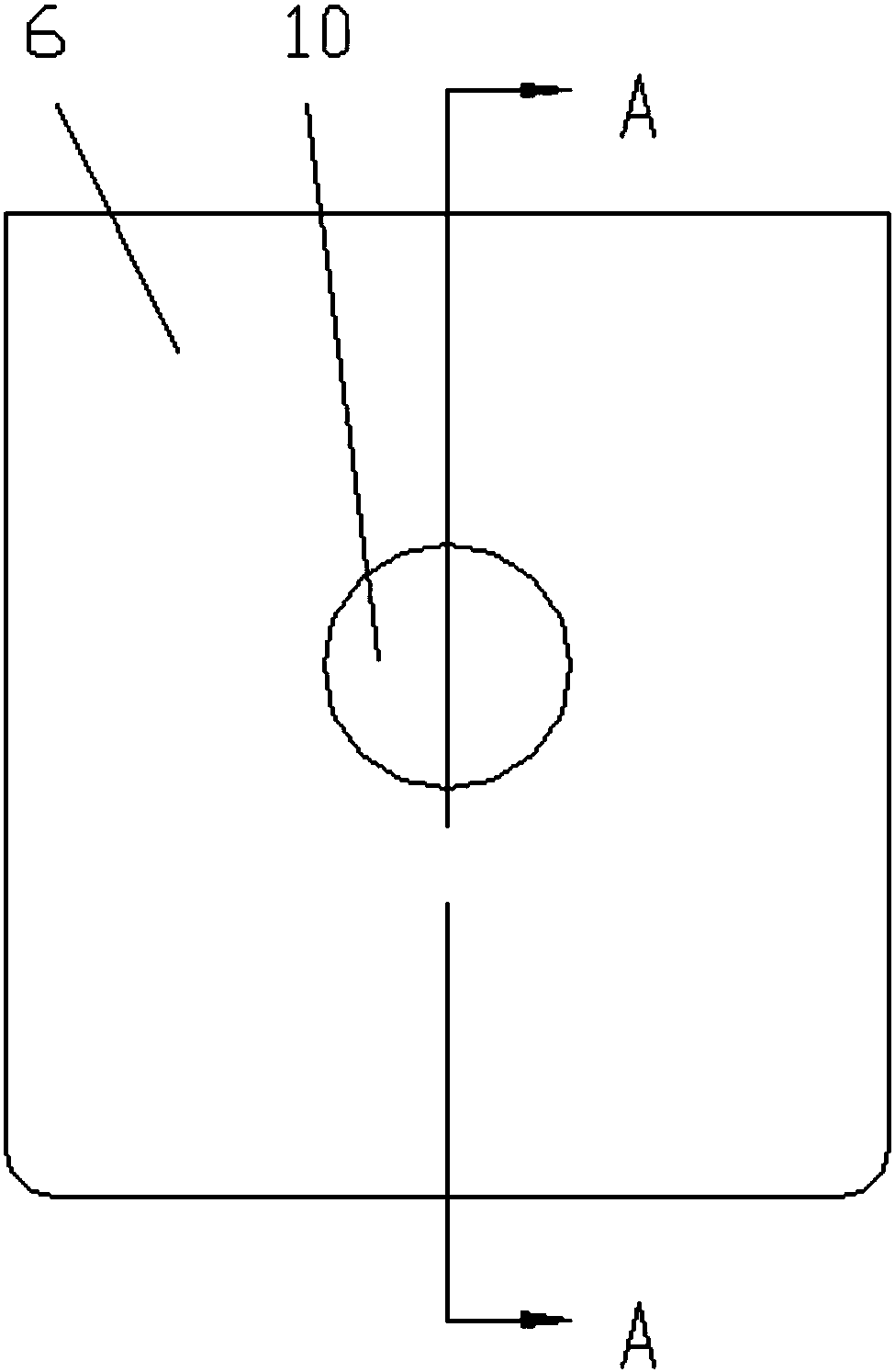

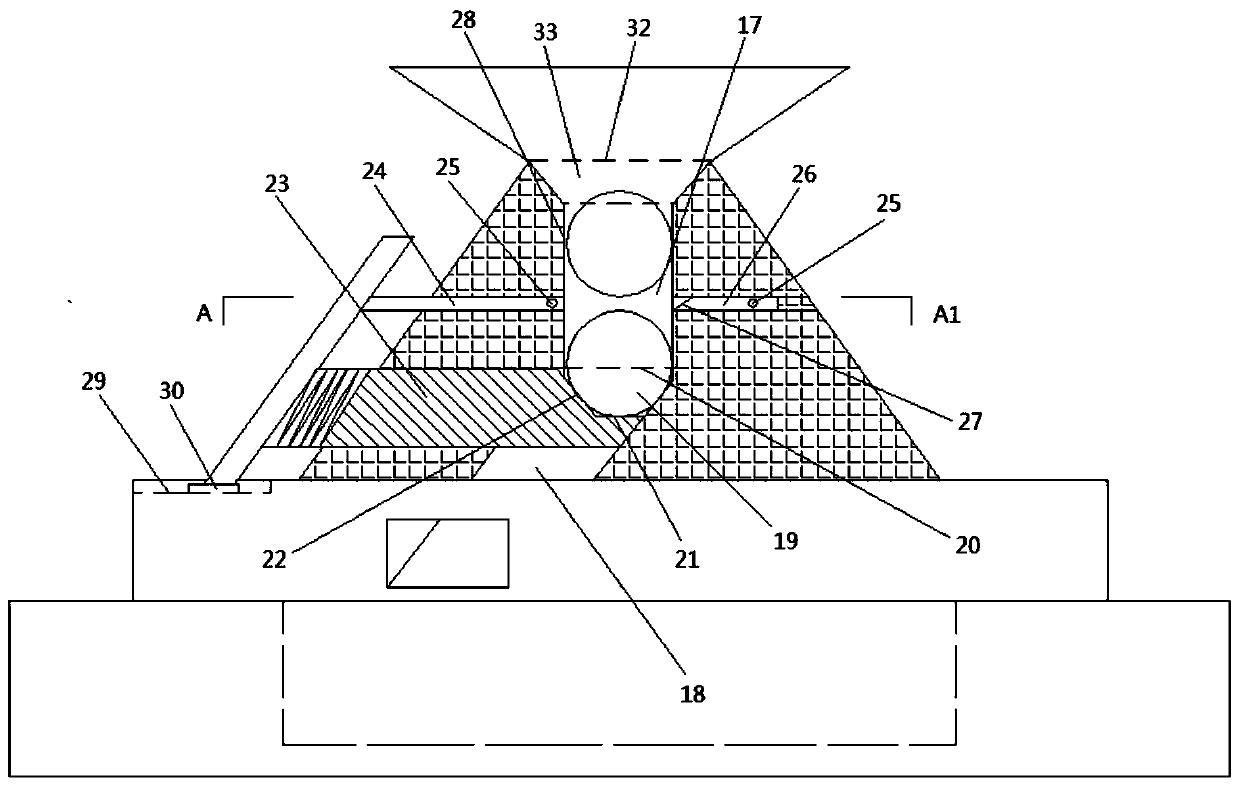

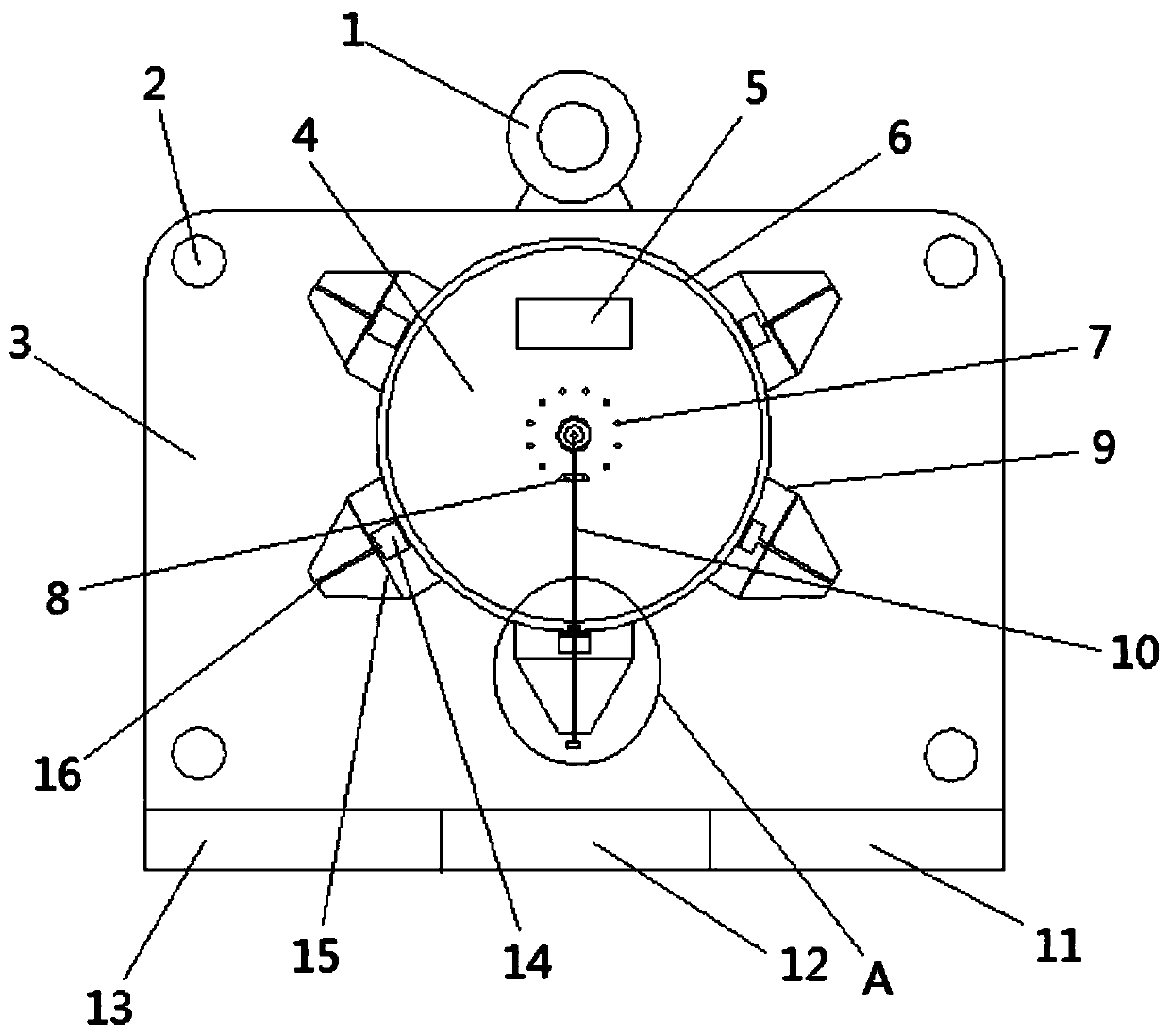

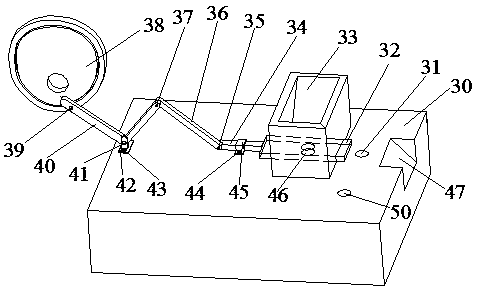

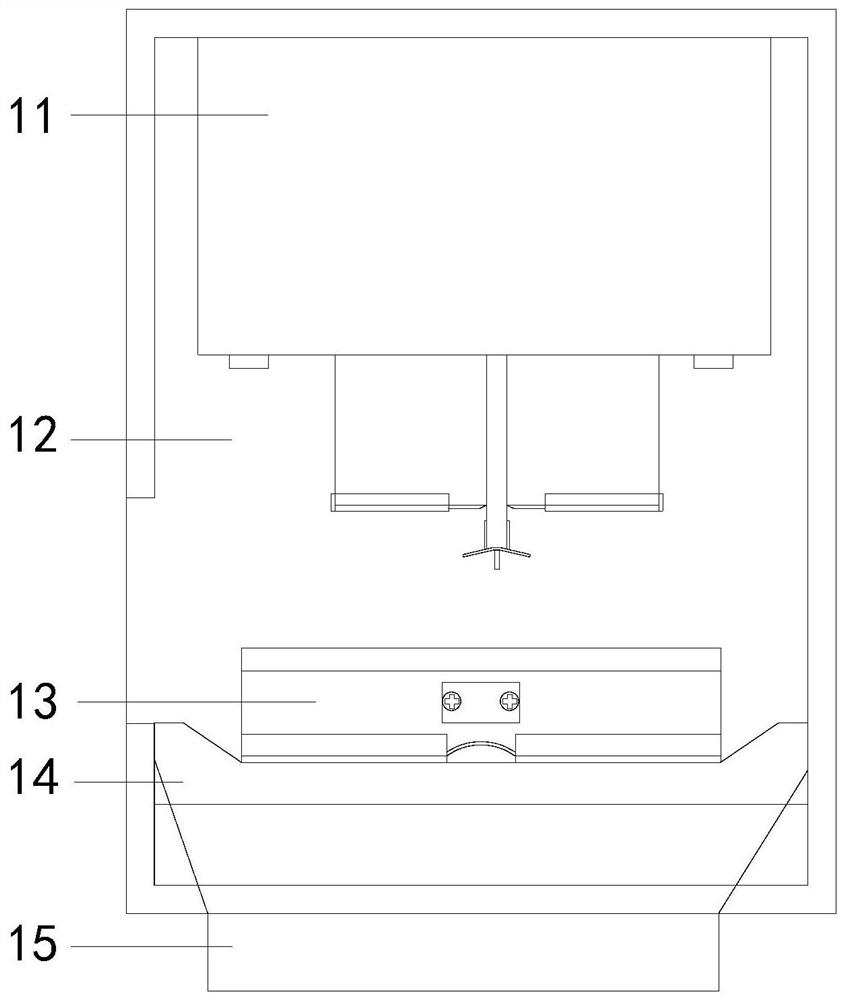

Easy-to-operate medicine dividing device for round tablets

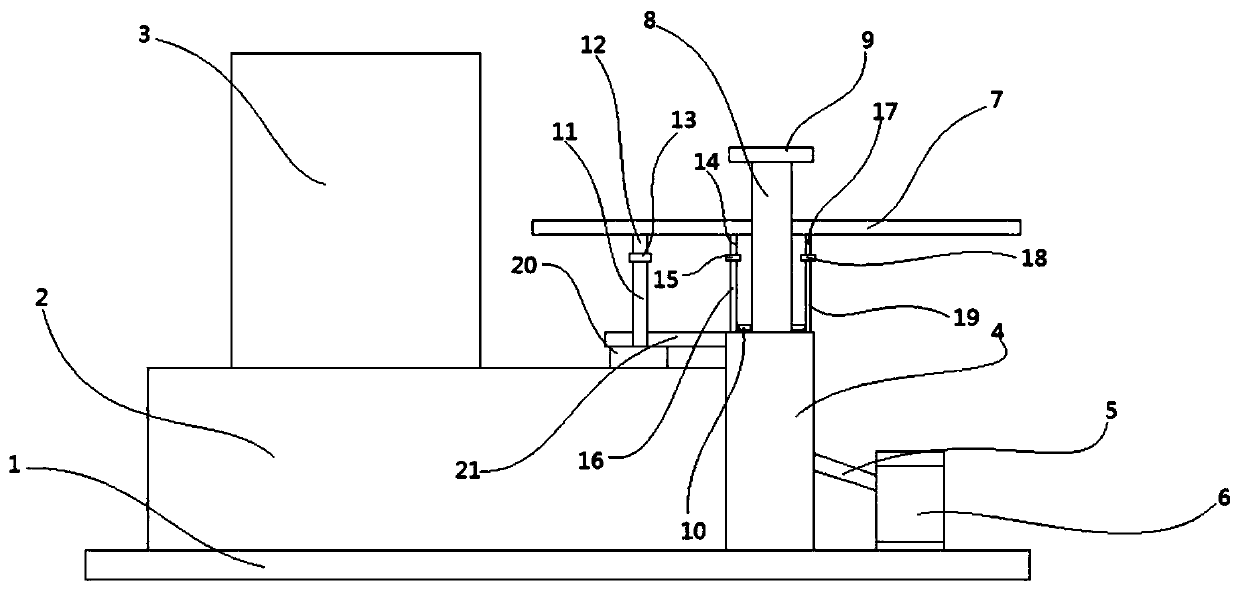

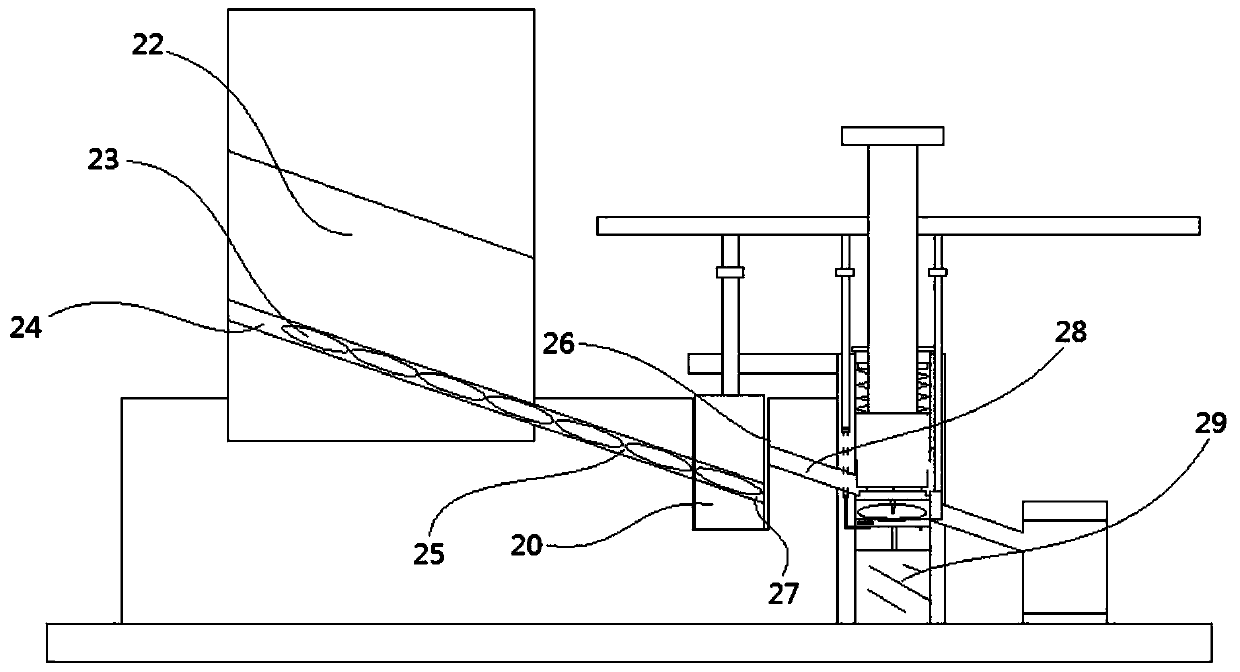

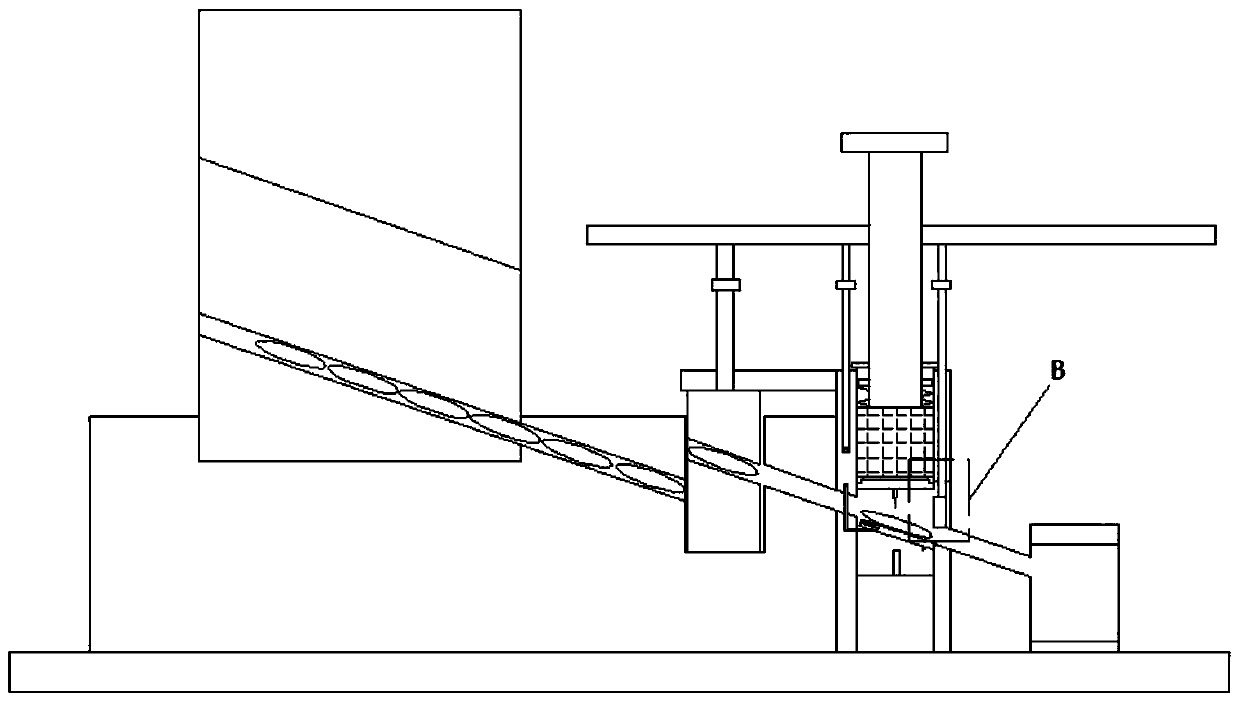

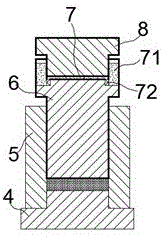

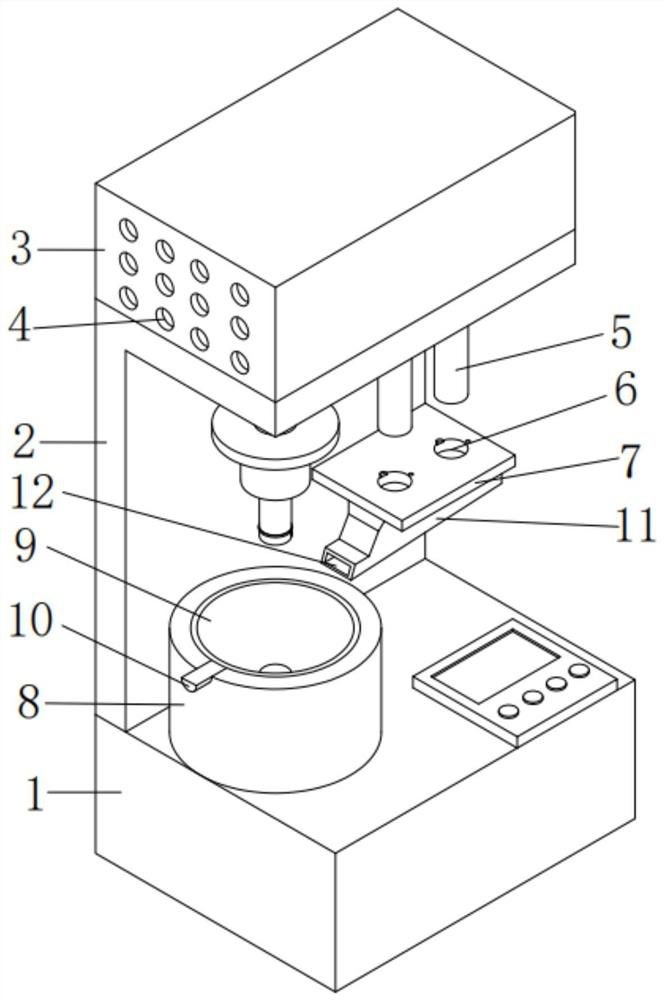

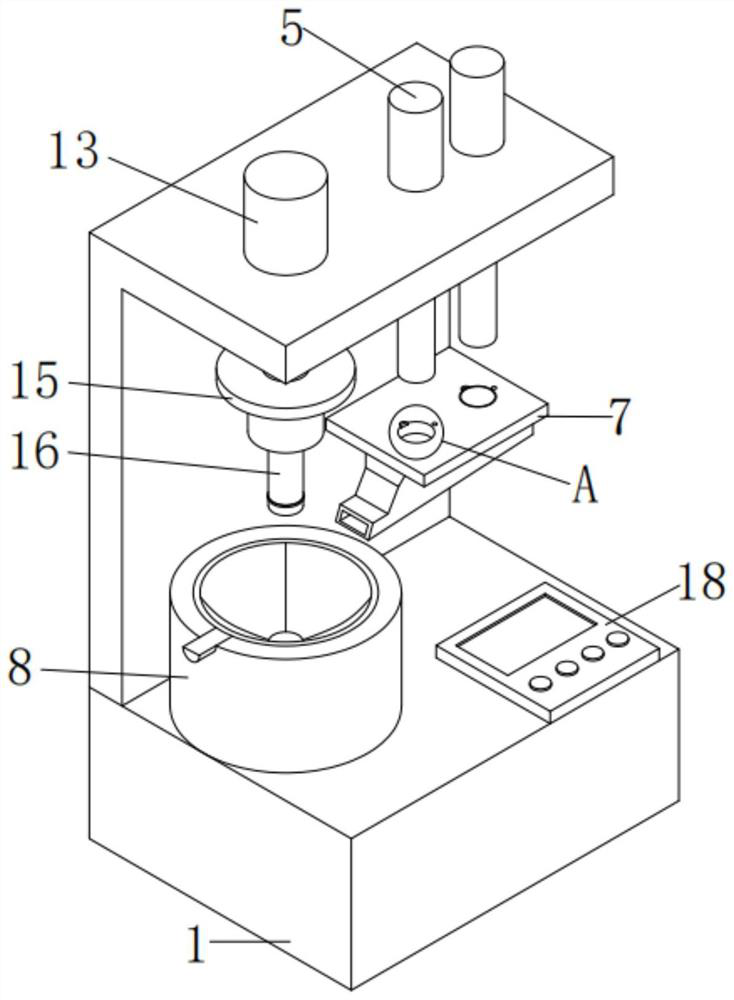

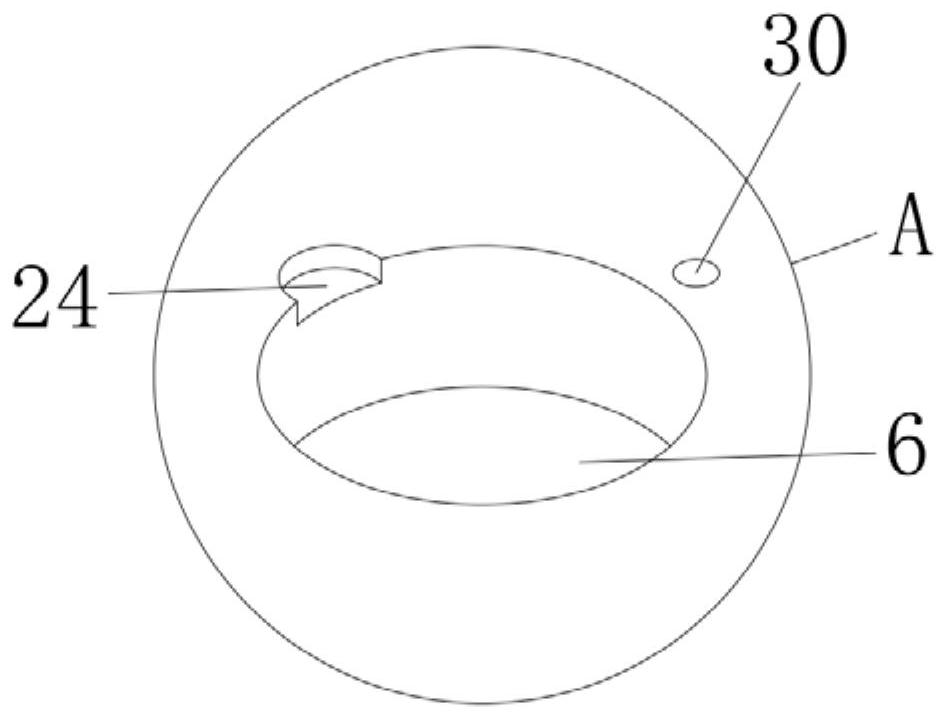

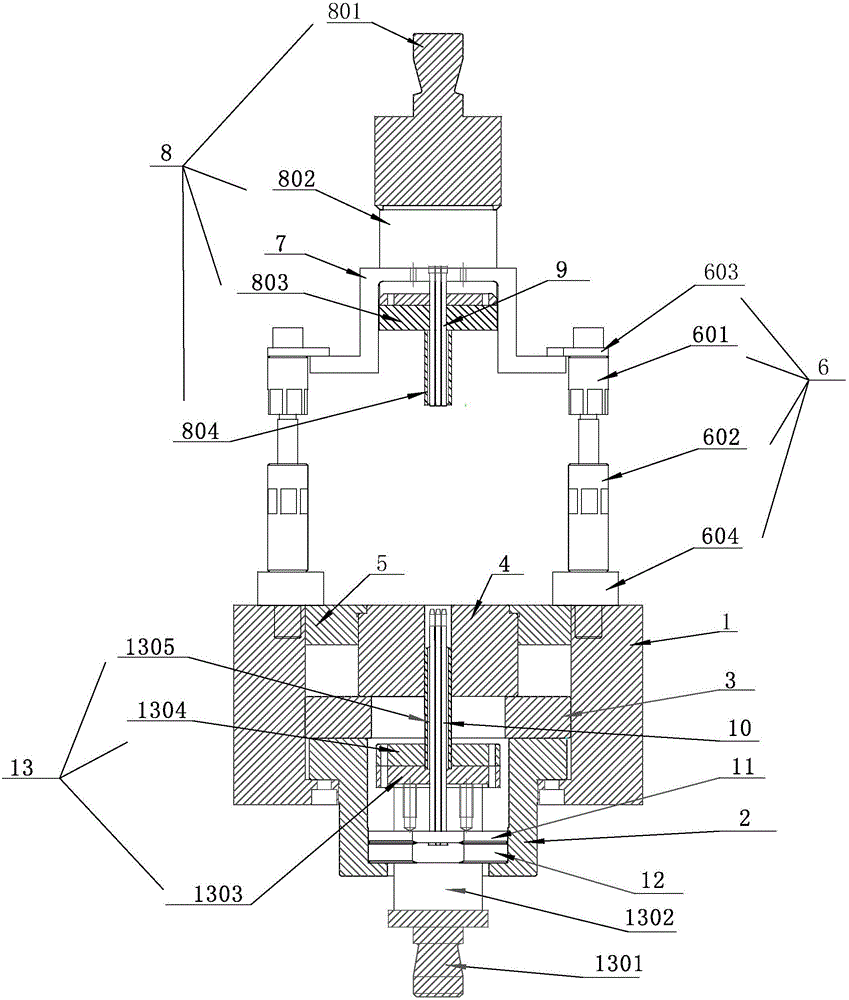

ActiveCN111514027AEasy to operateRealize continuous segmentationOral administration deviceTABLET CUTTERMechanical engineering

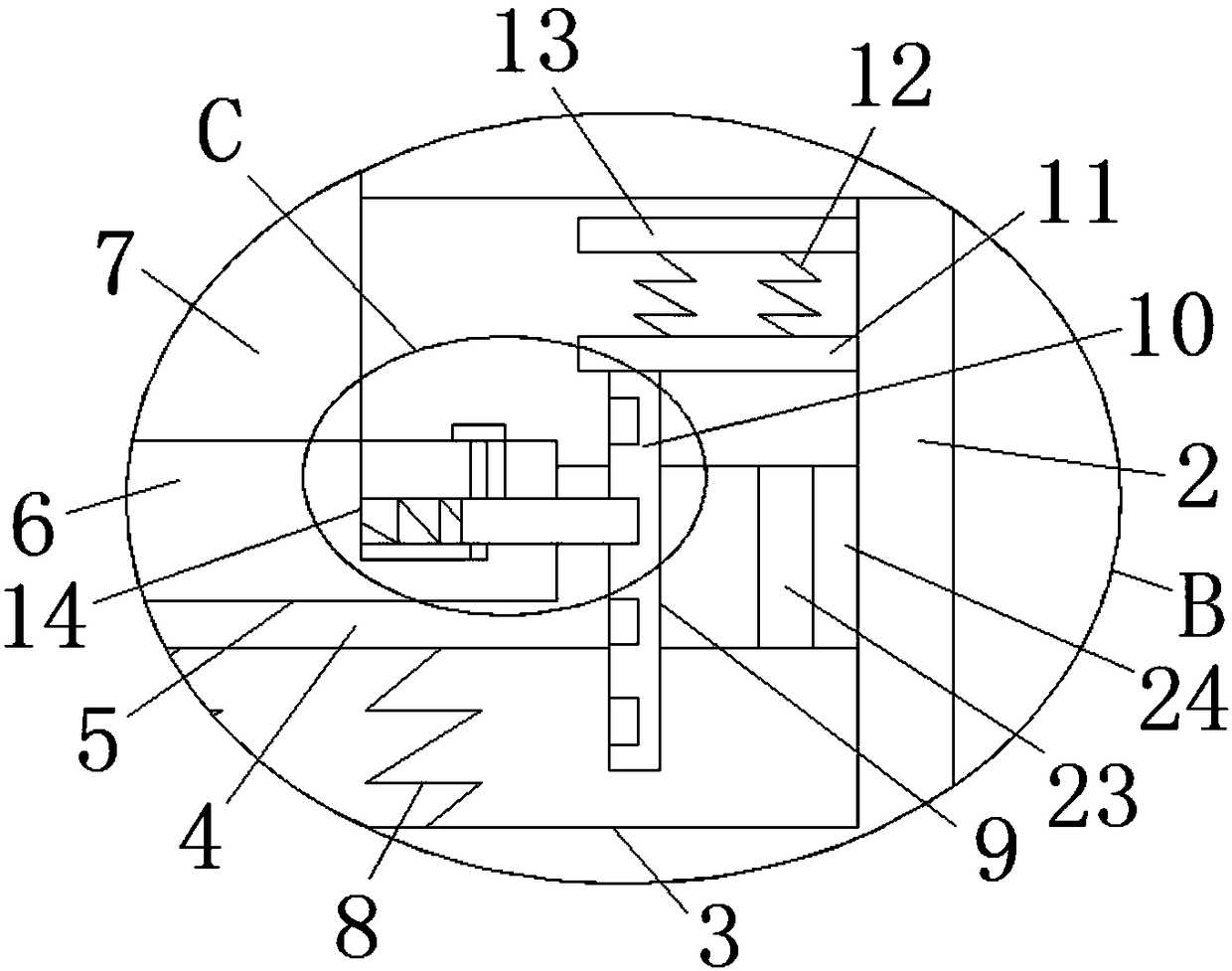

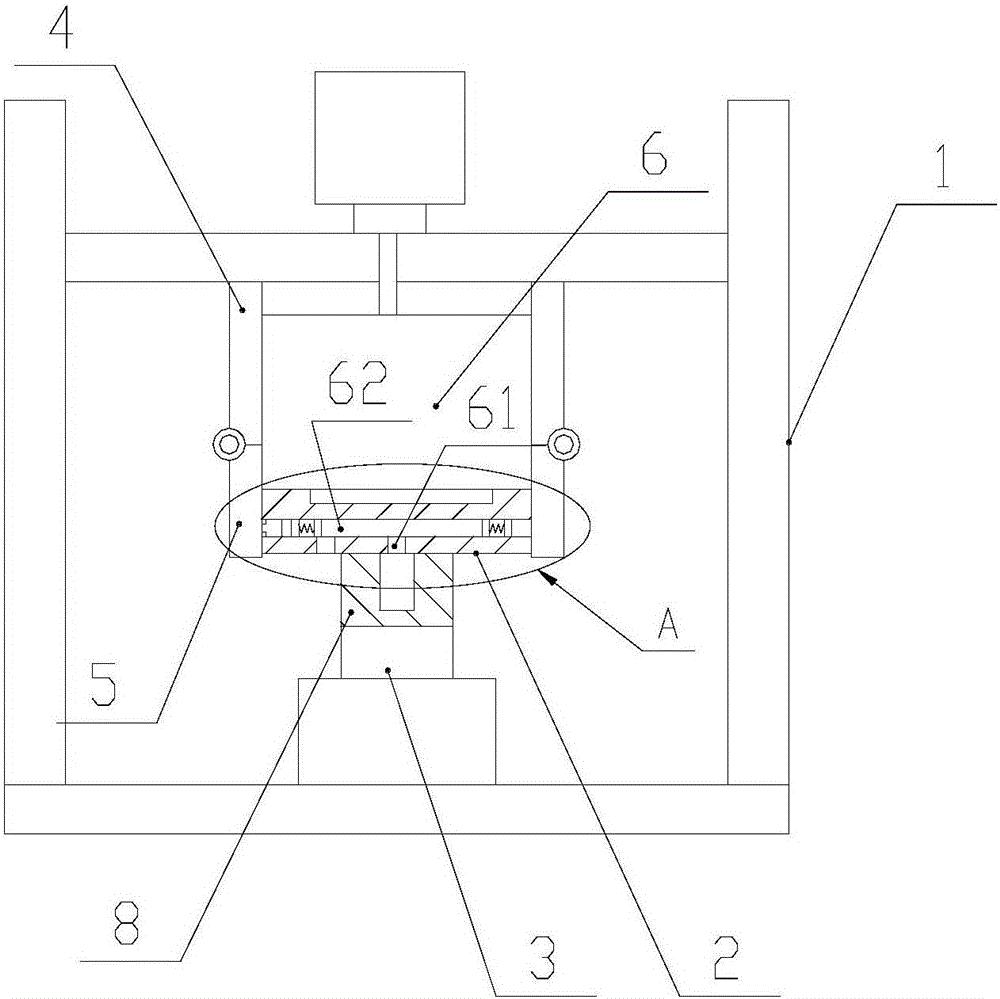

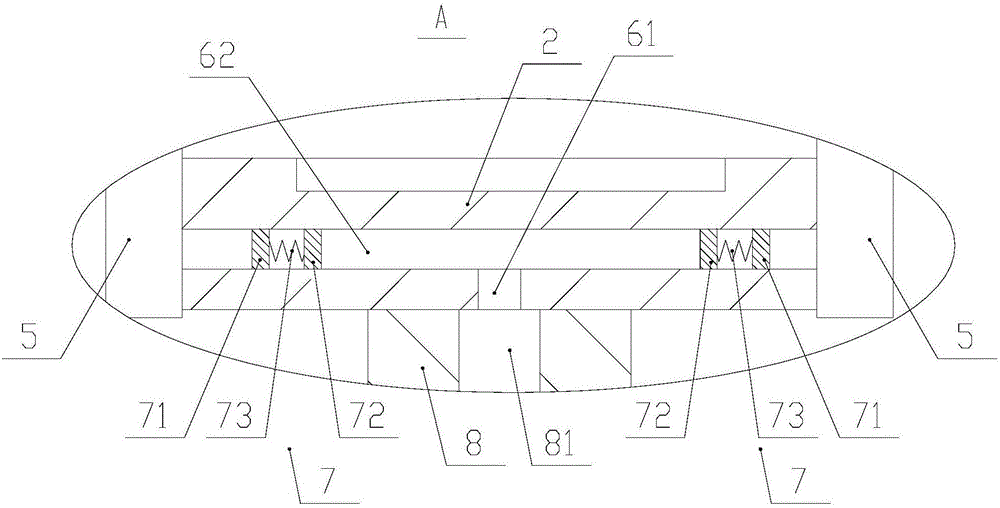

The invention relates to an easy-to-operate medicine dividing device for round tablets, and relates to the technical field of medical treatment. The device comprises a base, a solid block A, a tabletconveying box, a tablet collecting barrel and a tablet dividing mechanism. Extremely simple operation of splitting the round tablets is achieved, and continuous splitting of the round tablets can be achieved only by moving one hand up and down; the device is high in round tablet splitting efficiency and suitable for batch round tablet splitting operation; round tablets are simply positioned, and positioning is naturally achieved through a mechanical process; by replacing blades, the device can be suitable for splitting round tablets in various modes.

Owner:青岛市市北区蓝天心理研究所

Double-shaft medicine tablet pressing machine

The invention relates to a double-shaft medicine tablet pressing machine. The double-shaft medicine tablet pressing machine comprises a base, support arms and driving parts, wherein the support arms and the driving parts are symmetrically arranged at two ends of the base; each driving part comprises a driving motor and a driving rod; the driving rods can screw in and screw out along the self axes under driving of the driving motors; a pressing column is detachably mounted on each driving rod; an acceleration gear set is arranged between each pressing column and each driving rod; an adjusting rod is also arranged on the base; a pressing cylinder is arranged on the adjusting rod; the pressing cylinder is in threaded matching connection with the adjusting rod; the pressing cylinder is coaxial with the pressing columns; a medicine feeding hole is formed in the cylinder wall of one end of the pressing cylinder. The tablet pressing machine is capable of balancing pressure of medicine tablets, uniformly pressing the medicine tablets, reducing the occurrence of tablet cracking phenomenon, saving time and providing convenience for subsequent research.

Owner:王莉

Round tablet slitting device

The invention discloses a round tablet slitting device, and relates to the technical field of medical instruments. The round tablet slitting device comprises a base, a mounting plate, a solid block, atablet hopper, a pull plate, a slide plate, a guide box, a rectangular tablet guide passage, a trapezoidal positioning tablet hopper and a cutter mechanism. When the round tablet slitting device is used, only a cutter mechanism needs to be pressed to cut a round tablet into two halves, then the pulling plate is pulled, and the cut round tablet can slide into a tablet collecting groove from a tablet outlet sliding groove. Meanwhile, after the round tablets on the upper portion are isolated and the pulling plate is loosened, communication of a rectangular tablet guiding channel is achieved, a trapezoidal positioning tablet hopper restores, a round tablet on the upper portion are rapidly positioned, and then the cutting knife mechanism is pressed to cut the round tablet again. The round tablet slitting device is simple in structure, is convenient to use, can achieve continuous slitting of round tablets and is high in slitting efficiency.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

Device for removing dust in tablets of tablet press

InactiveCN103879019AComply with GMP requirementsMeet environmental protection requirementsSievingScreeningEngineeringTABLET CUTTER

The invention relates to a device for removing dust in tablets of a tablet press. An interlayer is arranged in the middle of a rectangular tank body formed by stainless steel plates and divides the rectangular tank body into an upper cavity and a lower cavity. The interlayer is a 12-mesh stainless steel screen, and a detachable stainless steel cover is arranged on the upper cavity of the rectangular tank body. A bevel is arranged at the front end of the upper cavity, and the front end of the upper cavity is manufactured into a connector connected with the press, the rear end of the rectangular tank body is provided with a bevel, the upper cavity of the rectangular tank body is longer than the lower cavity, a stainless steel connector is welded and fixed to the lower portion of the rear end of the lower cavity, and the connector is used for being connected with a tablet press dust collector. The device has a good dust moving effect and is low in noise, low in cost, free of occupied area and low in fault rate, pollution caused by dust to air is effectively controlled, and cross contamination between medicines is effectively controlled.

Owner:哈药集团三精制药四厂有限公司

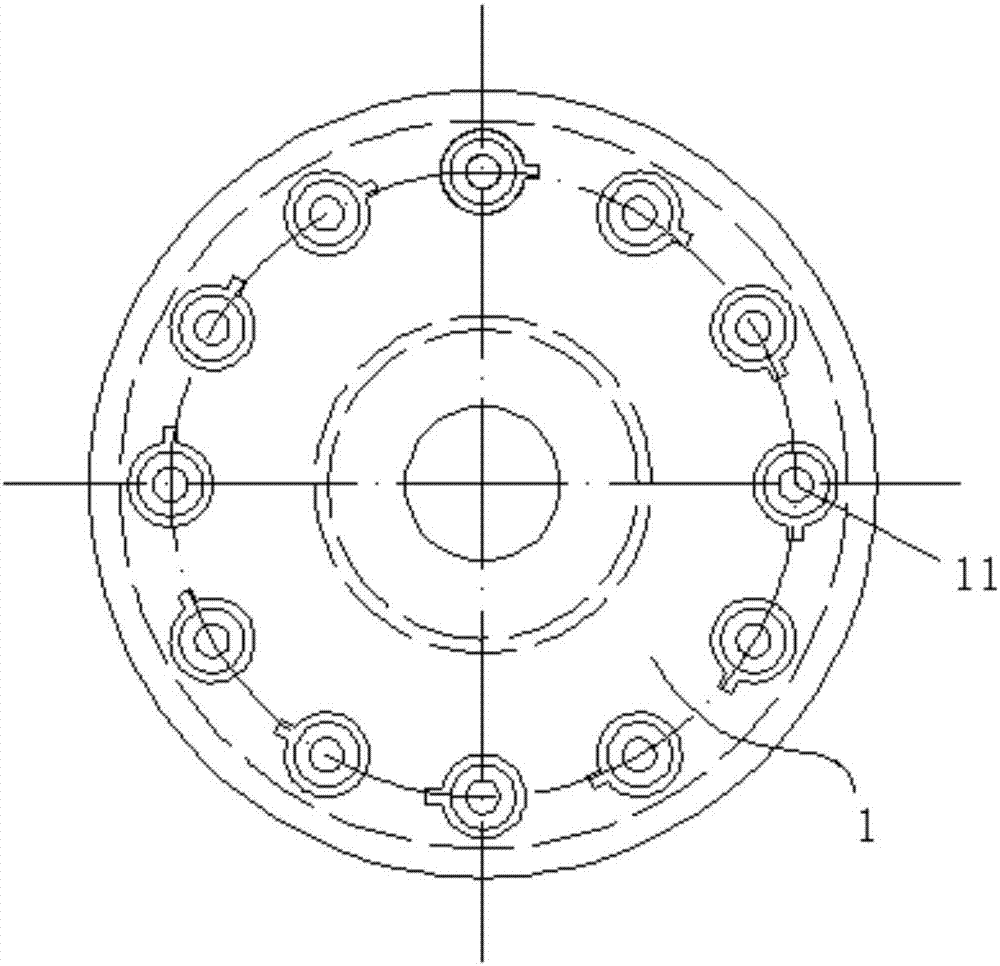

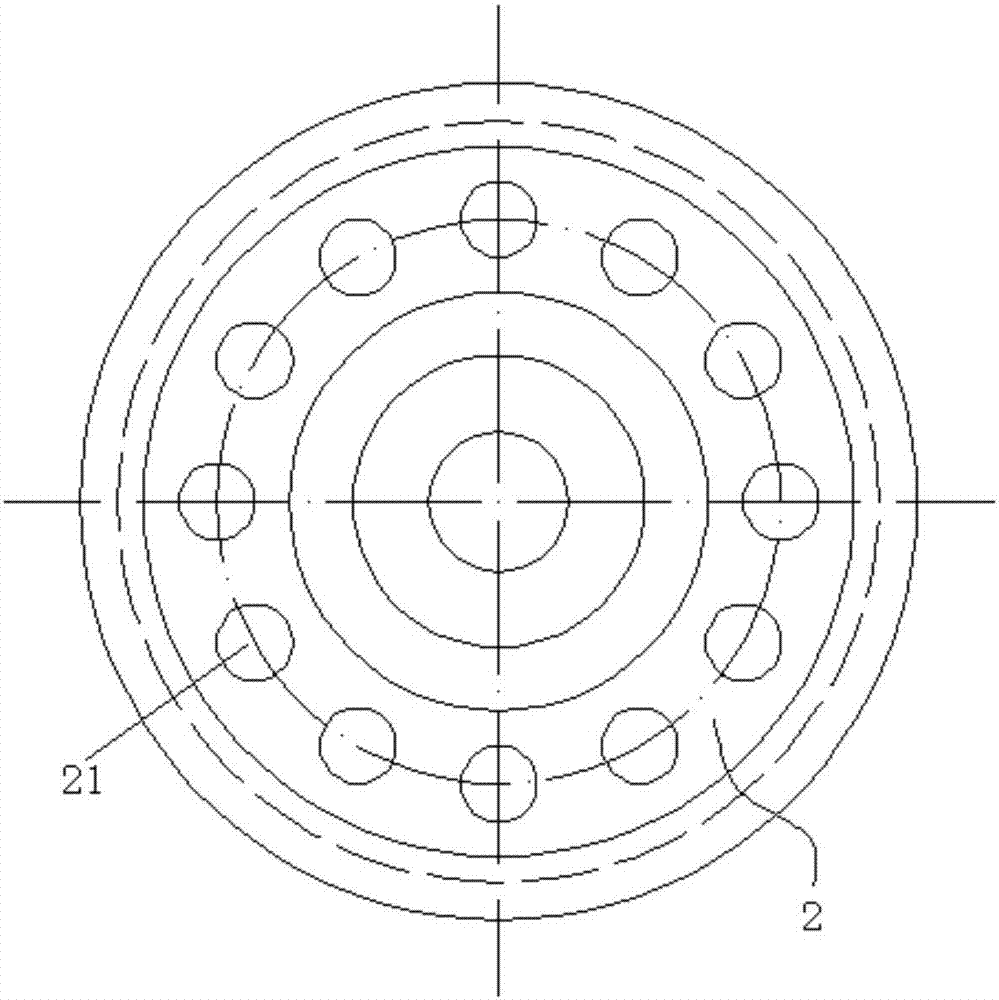

Rotary table device of rotary tablet machine

The invention discloses a rotary table device of a rotary tablet machine, and relates to the technical field of pharmaceutical machinery. The rotary table device comprises an upper rotary table, a middle rotary table, a lower rotary table, a vertical shaft and punching rod sleeving devices, the upper rotary table, the middle rotary table and the lower rotary table are sequentially and fixedly installed on the vertical shaft from top to bottom, the upper rotary table is provided with twelve vertical upward punching installing holes along the center in an annular arrayed distribution manner, thelower twelve rotary table is provided with twelve vertical downward punching installing holes along the center in an annular arrayed distribution manner, the number of the punching rod sleeving devices is twenty four, twelve punching rod sleeving device are embedded into the upward punching installing holes and fastened and connected through screws, and the other twelve punching rod sleeving device are embedded into the downward punching installing holes and fastened and connected through screws. By means of the rotary table device of the rotary tablet machine, upward punching, downward punching, dismounting and mounting are convenient, and meanwhile, a puncher pin moves more smoothly.

Owner:上海天和制药机械有限公司

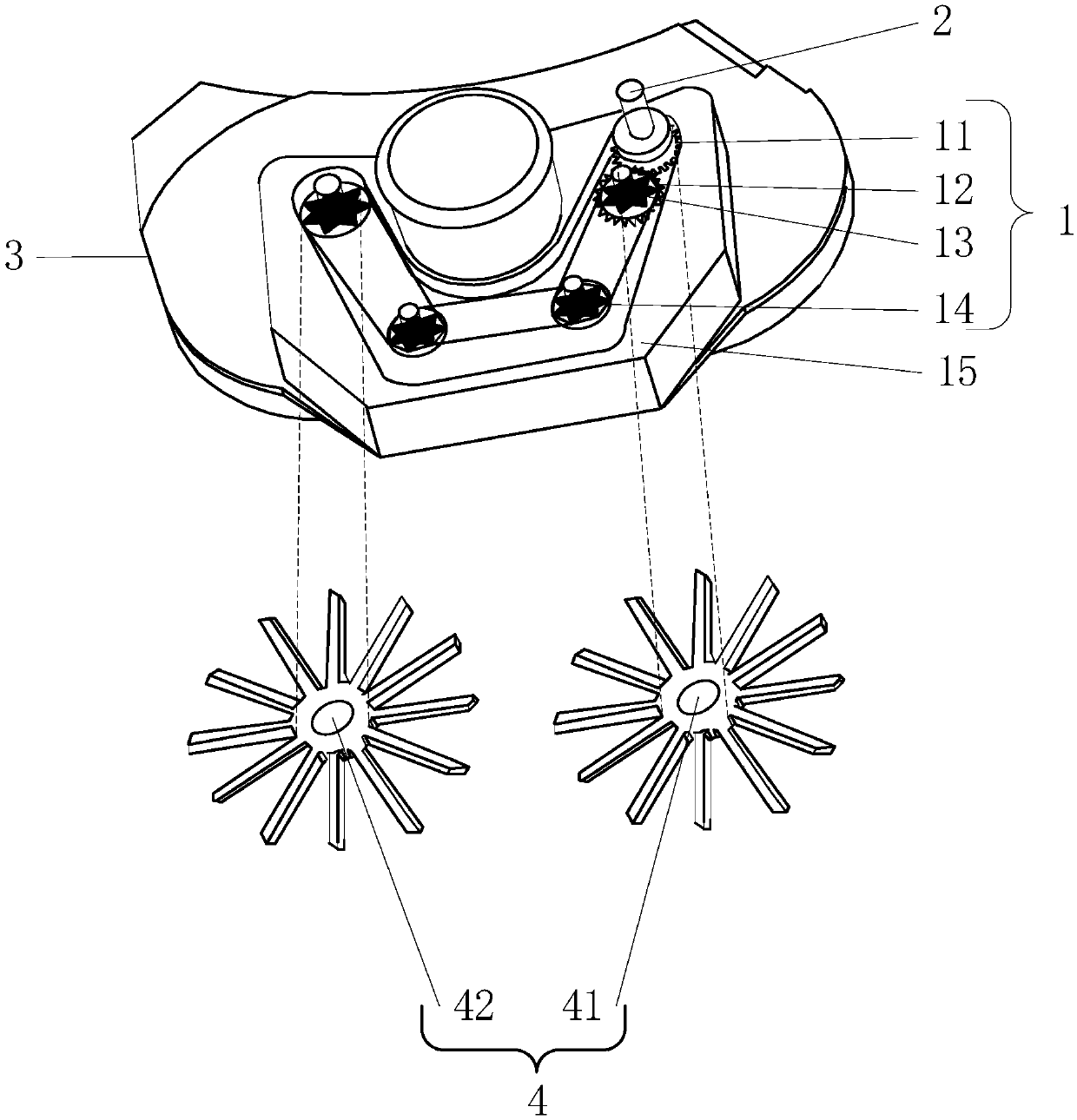

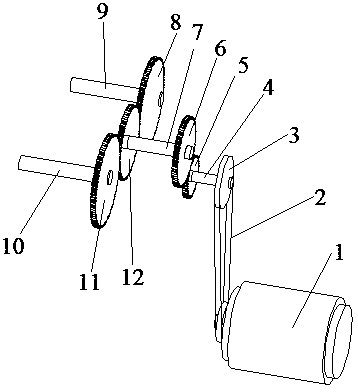

Tablet press feeder

The invention discloses a tablet press feeder which solves the problems that an existing tablet press feeder is large in weight and inconvenient to operate. The tablet press feeder comprises a transmission mechanism, an input shaft, a feeding bottom shell and an impeller set, wherein the transmission mechanism is in transmission connection with a second impeller and the input shaft through an odd-number gear meshing connection relay chain wheel; one end of the input shaft is in linkage connection with an external motor, the other end of the input shaft is in linkage connection with a first impeller, and the middle of the input shaft penetrates through the transmission box; and the feeding bottom shell is used for containing the first impeller and the second impeller, and the impeller set comprises the first impeller and the second impeller and is used for pushing materials entering the feeding bottom shell out of the feeding bottom shell. The weight of the feeder transmission mechanismis reduced, the labor intensity is reduced, and loading and unloading are convenient for operators. Chain wheels are easy to machine and can be automatically machined, so that the cost is saved, andthe economic efficiency is better. Compared with the gear meshing transmission, the chain wheel transmission has the advantages that the space is saved, and the condition of reducing the weight in design of a transmission box is met.

Owner:北京新龙立智能科技有限公司

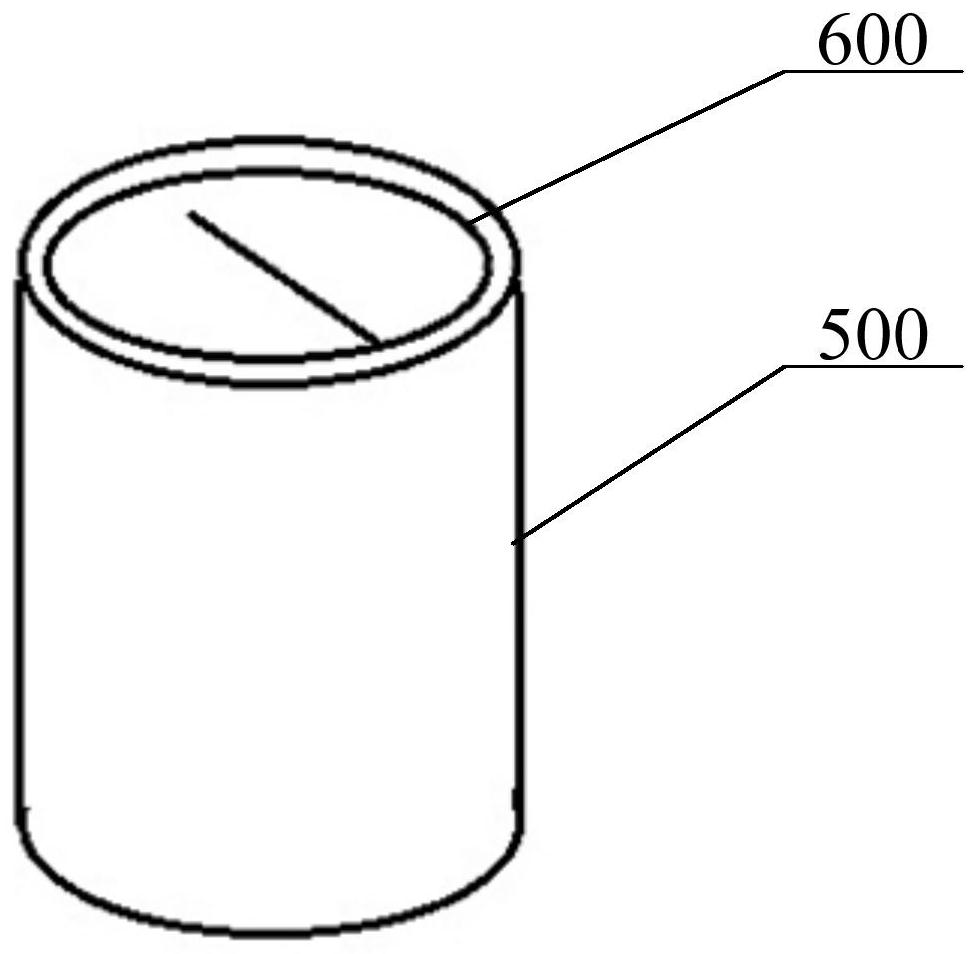

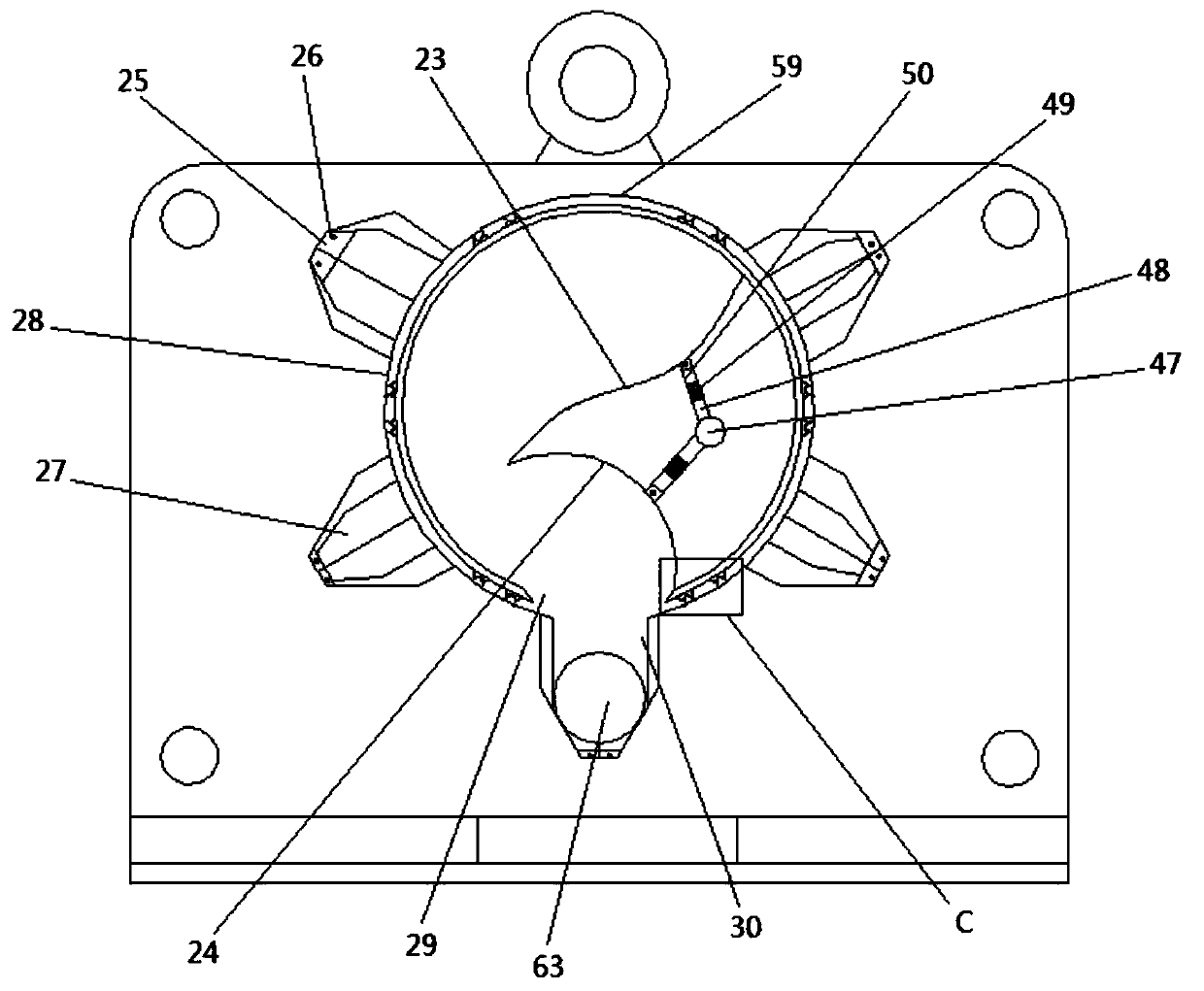

Round tablet cutter convenient for continuous cutting

InactiveCN111557854AAdapt to the needs of position adjustmentImprove segmentation efficiencyOral administration deviceStructural engineeringTABLET CUTTER

The utility model discloses a round tablet cutter convenient for continuous cutting and relates to the technical field of medical instruments. The round tablet cutter comprises a supporting part, a bottom plate and a flat cylindrical shell, wherein the supporting part is used for enabling the bottom plate to keep an inclined angle towards the rear side; a medicine feeding opening is formed in thefront end surface of the shell; a tablet slideway for guiding the trend of the round tablets is also arranged in the shell below the medicine feeding opening; a medicine outlet is further formed in the bottom of the side wall of the shell; a sliding sleeve A is further rotationally connected to the outer surface of the side wall of the shell; a plurality of medicine cutting boxes used for cuttinground tablets of different sizes are arranged on the outer side of the sliding sleeve A; the inner side end of any medicine cutting box is open and forms a medicine inlet; and a blade seam is formed in the front end face of each medicine cutting box. The round tablet cutter can conveniently, rapidly and continuously cut round tablets, the round tablet positioning speed is high, operation is easy,and the cutting efficiency is high.

Owner:青岛市市北区蓝天心理研究所

A tablet forming machine

The invention discloses a tabletting forming machine. The tabletting forming machine comprises a base, a feeding mechanism, an upper punch mechanism, a lower punch mechanism and a drive mechanism. Anelectromotor and a rack are fixed to the base, the electromotor is in drive connection with the feeding mechanism, the upper punch mechanism and the lower punch mechanism through the drive mechanism,the upper punch mechanism and the lower punch mechanism are combined to carry out punching to enable blanks to be formed by tabletting, and finished products are pushed out of a first cavity through the lower punch mechanism. According to the tabletting forming machine, the electromotor serves as primepower, the power is transmitted to the feeding mechanism, the upper punch mechanism and the lowerpunch mechanism, feeding is achieved through the feeding mechanism, tabletting is achieved through the upper punch mechanism and the lower punch mechanism jointly, discharging is achieved by pushinga feeder to extrude workpieces to enter a discharging sliding way groove, and the functions of feeding, positioning, tabletting, pushing-out and the like are integrated. The tabletting forming machineis simple and compact in structure, high in efficiency and stable in work, and the problems that an existing tabletting machine is unstable in pressure maintenance, high in environmental pollution, high in noise and vibration, low in production efficiency and the like are solved.

Owner:HOHAI UNIV CHANGZHOU

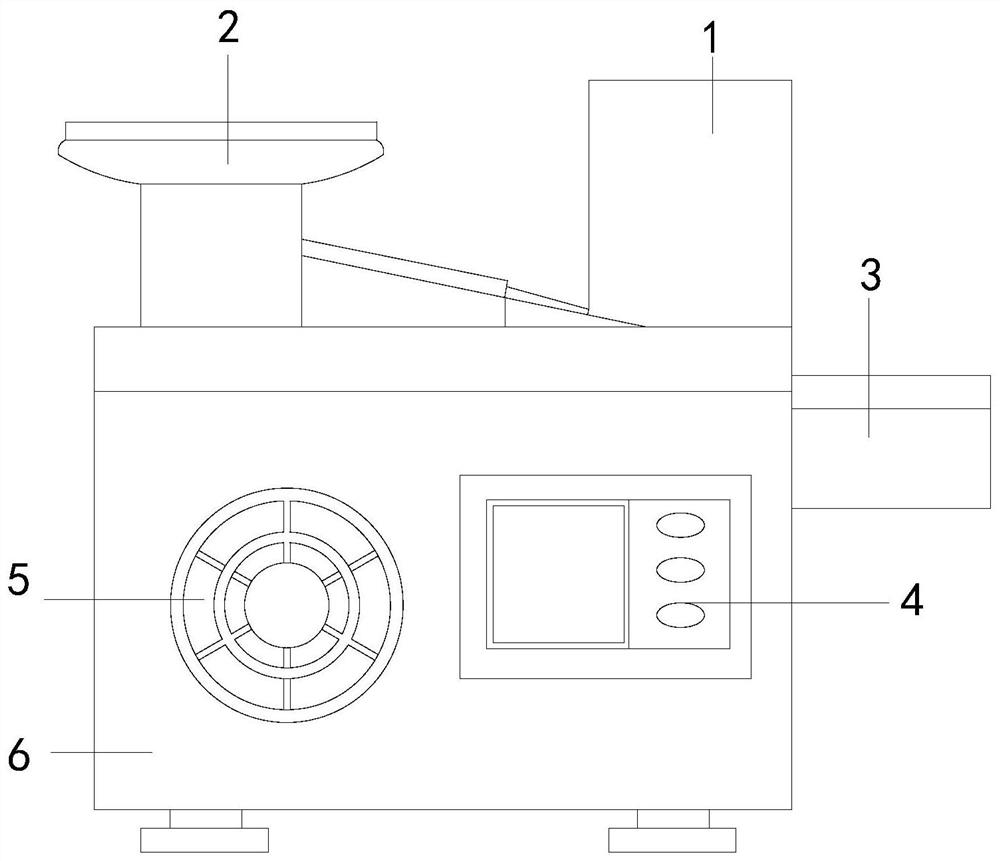

Tablet distributor for pediatric department

InactiveCN112022714AProtect from moistureHigh precisionOral administration deviceTABLET CUTTERSurgery

The invention discloses a tablet distributor for the pediatric department. The tablet distributor structurally comprises a tablet distributing tool bit, a tablet containing hopper, a tablet taking box, a control panel, a radiator and a machine body, wherein the tablet distributing tool bit is arranged on the right side of the tablet containing hopper, and the middle of the tablet distributing toolbit is connected with the tablet containing hopper through a sliding groove; the tablet taking box is vertically fixed to the top of the machine body; the radiator is fixed in a groove in the front end of the machine body through a bolt; and a motor in the tablet distributing tool bit is connected with a terminal in the control panel through a wire. The tablet distributor has the beneficial effects that cutting is conducted by controlling displacement of a first-order cutting plate and a second-order cutting plate, an anti-skid pressing plate hoops tablets, the tablets are cut in a one-to-twomanner and in a one-to-four manner, the tablet distributing precision is improved, and the situation that the tablets are affected with damp due to hand holding is avoided; and a cross protrusion isarranged at the bottom of a supporting plate, the anti-skid pressing plate is matched when the cutting plates are pressed downwards, the tablets are jacked from the middle and separated from the middle under extrusion of the corners on the two sides of the anti-skid pressing plate, efficiency is improved, and tablet fines generated during cutting are reduced.

Owner:吴宗妹

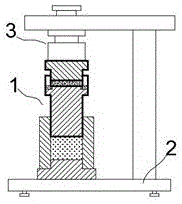

Medicine single-stamping tablet press

ActiveCN107433729AKeep the pressure steadyStable under pressureShaping pressTABLET CUTTEREngineering

The invention relates to a medicine single-stamping tablet press. The medicine single-stamping tablet press comprises a die, a press body, a bearing plate and a pressed column. The die is detachably placed between the bearing plate and the pressed column and comprises a bottom plate, a sleeve and a pressed rod; a buffer groove is formed in the top end of the pressed rod, and the groove wall of the buffer groove is hollow; a control valve communicating with the groove wall is arranged at the bottom of the buffer groove, and the buffer groove is filled with a buffer solution; when the pressure exceeds a threshold value, the control valve is opened; a pressure stabilizing rod is slidably arranged in the buffer groove and can keep on sliding back and forth in the buffer groove in a solution-sealed mode; the pressure stabilizing rod and the buffer groove are made of permanent magnet materials which are repellent and have the same pole; and the medicine single-stamping tablet press can buffer pressure changing, so that pressure transmitting is more stable, and cracking pieces are effectively prevented.

Owner:江苏绿途环保科技有限公司

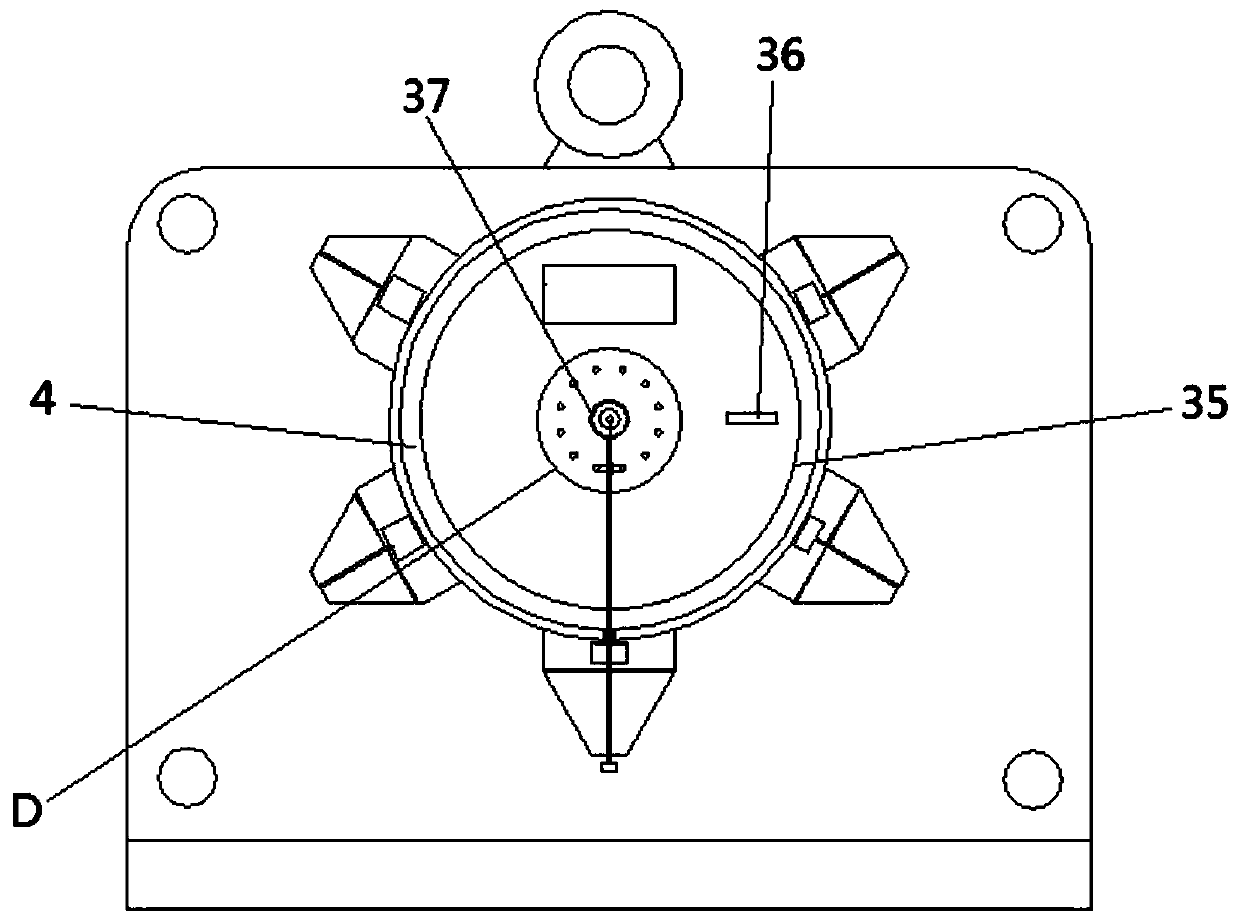

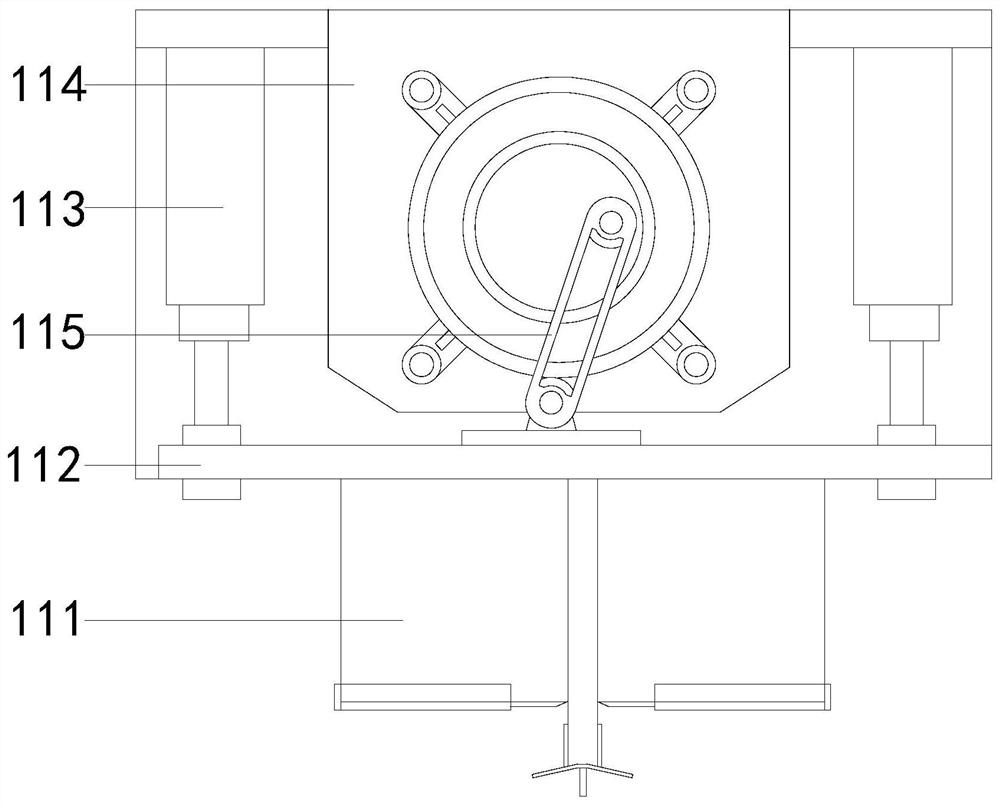

Tablet machine and full-automatic slag producing machine

ActiveCN105946273AImprove processing efficiencyHigh movement precisionSortingShaping pressSlagTABLET CUTTER

The invention provides a tablet machine and a full-automatic slag producing machine and belongs to the field of steel mill slag detection. The tablet machine comprises a rack, a mounting portion, a steel ring and a machining device used for machining slag. The steel ring is mounted on the mounting portion. The steel ring is used for containing the slag. The mounting portion is movably connected with the rack. The machining device is mounted on the rack. The full-automatic slag producing machine comprises a frame body, a center manipulator, a detection device, a breaking and grinding functional module and the tablet machine. The center manipulator, the breaking and grinding functional module and the tablet machine are mounted on the frame body. The center manipulator is used for putting the steel ring into the detection device. The detection device is used for detecting whether the steel ring cracks or not. The breaking and grinding functional module is used for breaking the slag and conveying the broken slag into the tablet machine. By the adoption of the tablet machine, when tabletting is conducted, the mounting portion slides on the rack and carries the steel ring into the machining device, after machining is completed, the mounting portion with the steel ring leaves the machining device, and thus treatment efficiency is improved.

Owner:上海美诺福科技有限公司

Tablet cutter

InactiveCN107584546APrevent slidingAvoid entanglementMetal working apparatusEngineeringTABLET CUTTER

The invention discloses a tablet cutter which comprises a bracket, a conveying table and a slicing device, wherein the slicing device is arranged above the bracket; the conveying table is arranged inthe bracket under the slicing device; the conveying table comprises a first motor, a driving wheel, a belt, a driven wheel, a first linking roller, a second linking roller, a first driving rod, a second driving rod and a conveyer belt; the first motor is fixedly connected with a platform at the bottom of the bracket; the first motor is fixedly connected with the driving wheel through a rotating shaft. The tablet cutter is capable of solving the problems of complex equipment structure, inconvenience in operation and winching in cutting process in the prior art; the conveyer belt is adopted forsupplying power to convey the medicinal material to a slicing port; the slicing device is used for quickly slicing, so that the slicing volume is greatly increased, the output is effectively increased, the labor capacity of the worker is reduced and the production cost is lowered; the structure is simple; the use is convenient and safe.

Owner:安徽延寿堂药业有限公司

Full-automatic medicine grinding device

ActiveCN112973923AExtended service lifeSave human effortPharmaceutical product form changeGrain treatmentsPharmacy medicineElectric machinery

The invention discloses a full-automatic medicine grinding device. The full-automatic medicine grinding device comprises a base, an L-shaped vertical plate is fixedly connected to one side of the upper surface of the base, an electric cylinder is fixedly mounted on the upper surface of the L-shaped vertical plate, a mounting plate is fixedly connected to the lower end of a telescopic rod of the electric cylinder, and a grinding motor is fixedly connected to the lower surface of the mounting plate. According to the full-automatic medicine grinding device, grinding work is automatically completed through the electric cylinder, the grinding motor, a conical grinding groove and a controller, manpower is greatly saved, the grinding efficiency is improved, a grinding pad and a sleeve pad are arranged, after grinding is completed, medicine is prevented from being adhered to a grinding instrument, cleaning is convenient, when medicine of different patients is ground, only the grinding pad and the sleeve pad need to be replaced, the problems that medicine residues exist and medicines of different patients are mixed are effectively avoided, a pressure sensor, an electric push rod and a tablet cutter are matched with the controller, the medicine needing to be cut can be rapidly and accurately cut, and manual cutting is not needed.

Owner:GENERAL HOSPITAL OF NINGXIA MEDICAL UNIV

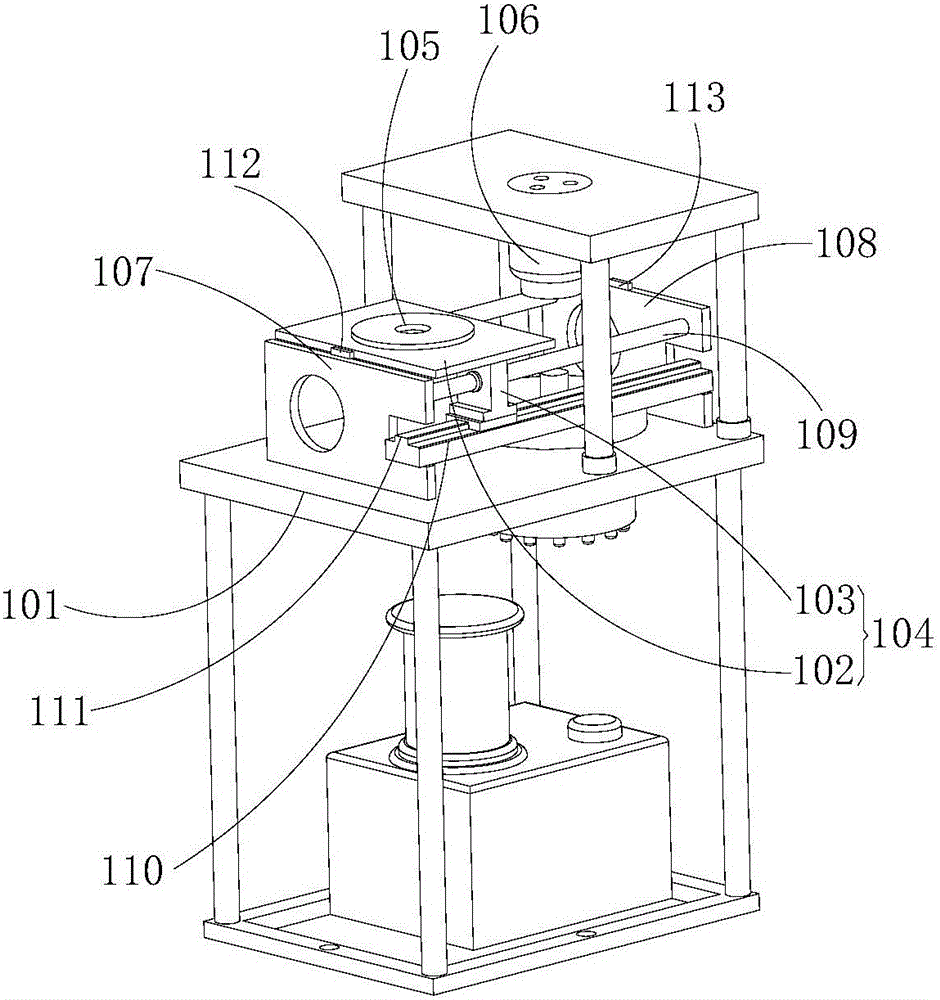

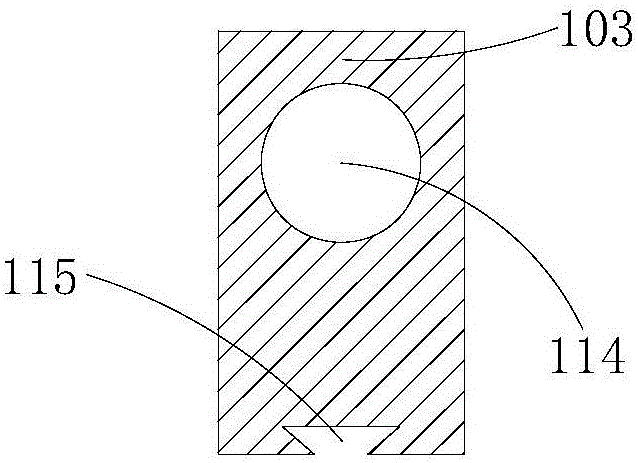

Small-hole-diameter porous die device for tablet press

The invention discloses a small-aperture porous mold device for a tablet press, comprising a mold base, a core rod base, a middle mold gasket, a middle mold, a middle mold pressing ring, a support column, a gantry frame, an upper punch, an upper punch core rod, Lower punch, lower punch panel, lower punch backing plate and lower punch; the porous mold device can press porous tablets, and has the advantages of simple structure, reasonable design, stable and efficient operation, flexible adjustment of parts, The produced tablets are characterized by good molding, and are suitable for preparing tablets of various specifications and types.

Owner:LIAOCHENG WANHE IND MFR

Feeding frame mechanism of cutting machine for machining tamper mould of tablet press

InactiveCN103831658AAvoid it happening againAvoid scratchesMetal working apparatusTABLET CUTTEREngineering

The invention discloses a feeding frame mechanism of a cutting machine for machining a tamper mould of a tablet press. The feeding frame mechanism of the cutting machine for machining the tamper mould of the tablet press comprises feeding tracks and a feeding trolley, wherein idler wheels on the two sides of the feeding trolley are placed on the tracks; a bolt penetrates through the feeding trolley; a collection frame is fixed to the top of the bolt. The bolt is fixedly provided with an adjusting disc. The feeding frame mechanism of the cutting machine for machining the tamper mould of the tablet press has the advantages of being reasonable in design, easy to manufacture, and capable rapidly feeding the tamper mould into the cutting machine to be cut and improving the working efficiency.

Owner:XINGHUA CITY XIANGHE PHARMA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com