Dust removal device for tablet press

The technology of a dust removal device and a tablet press is applied to presses, dust removal, cleaning methods and appliances, etc. It can solve the problems of inconvenient suction fan buffer protection, easy damage to the suction fan, and inconvenient installation of the suction fan, etc., and achieves a simple structure , easy operation and high practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

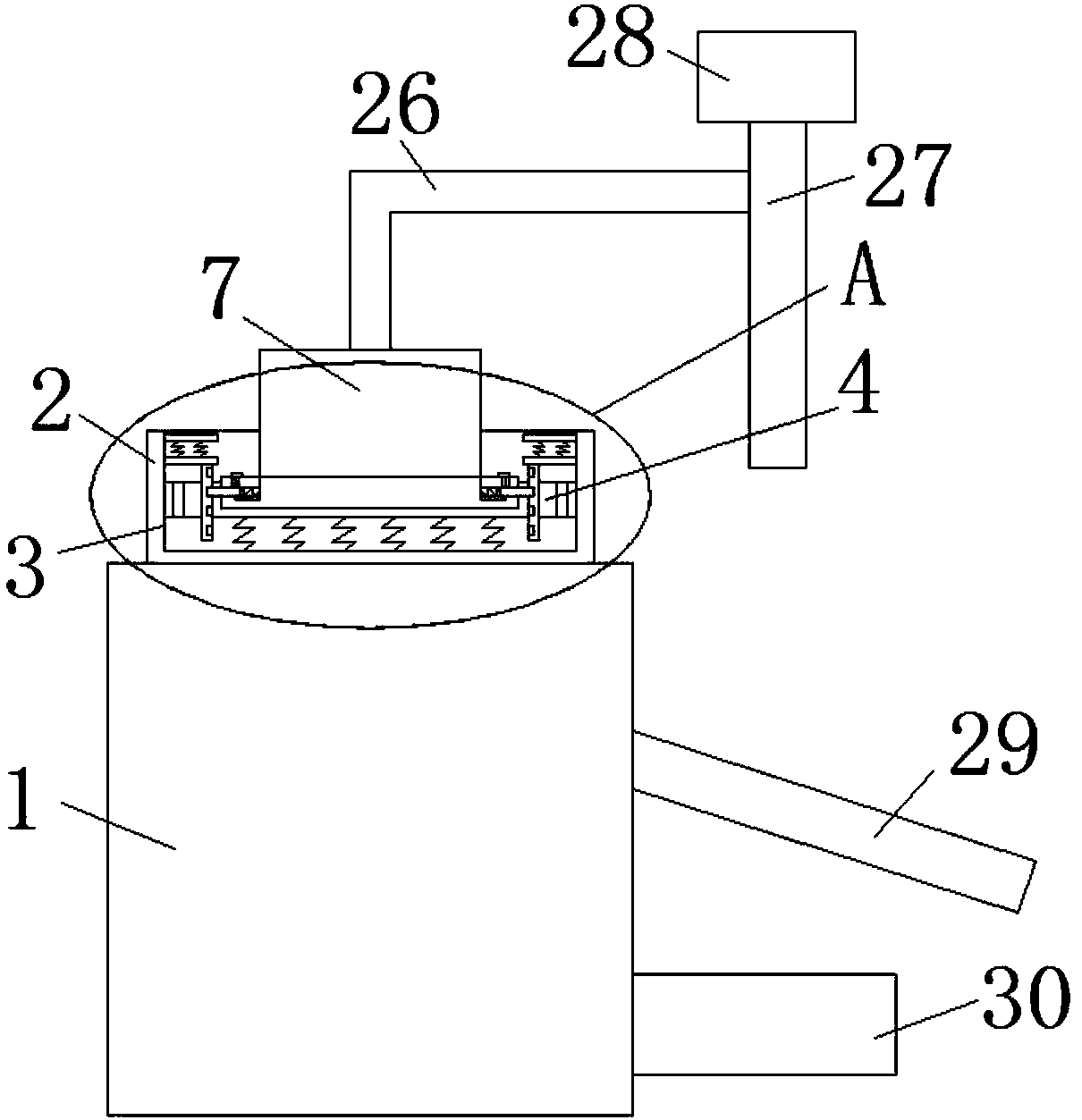

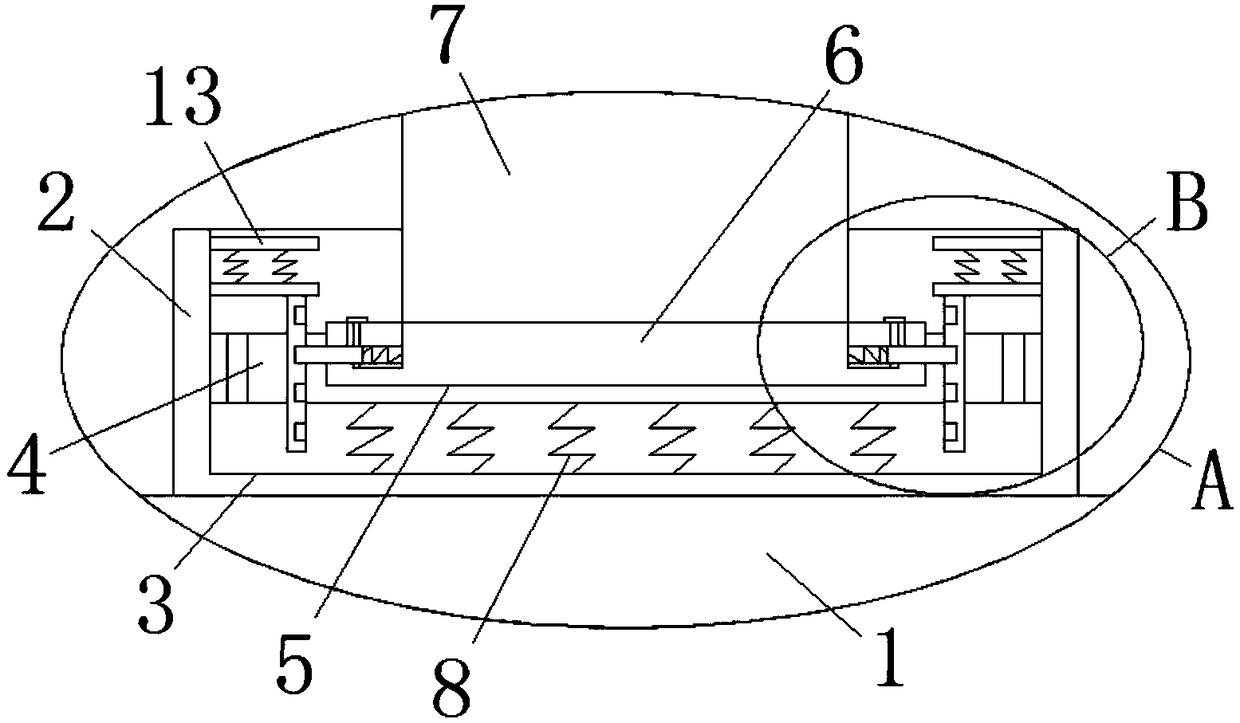

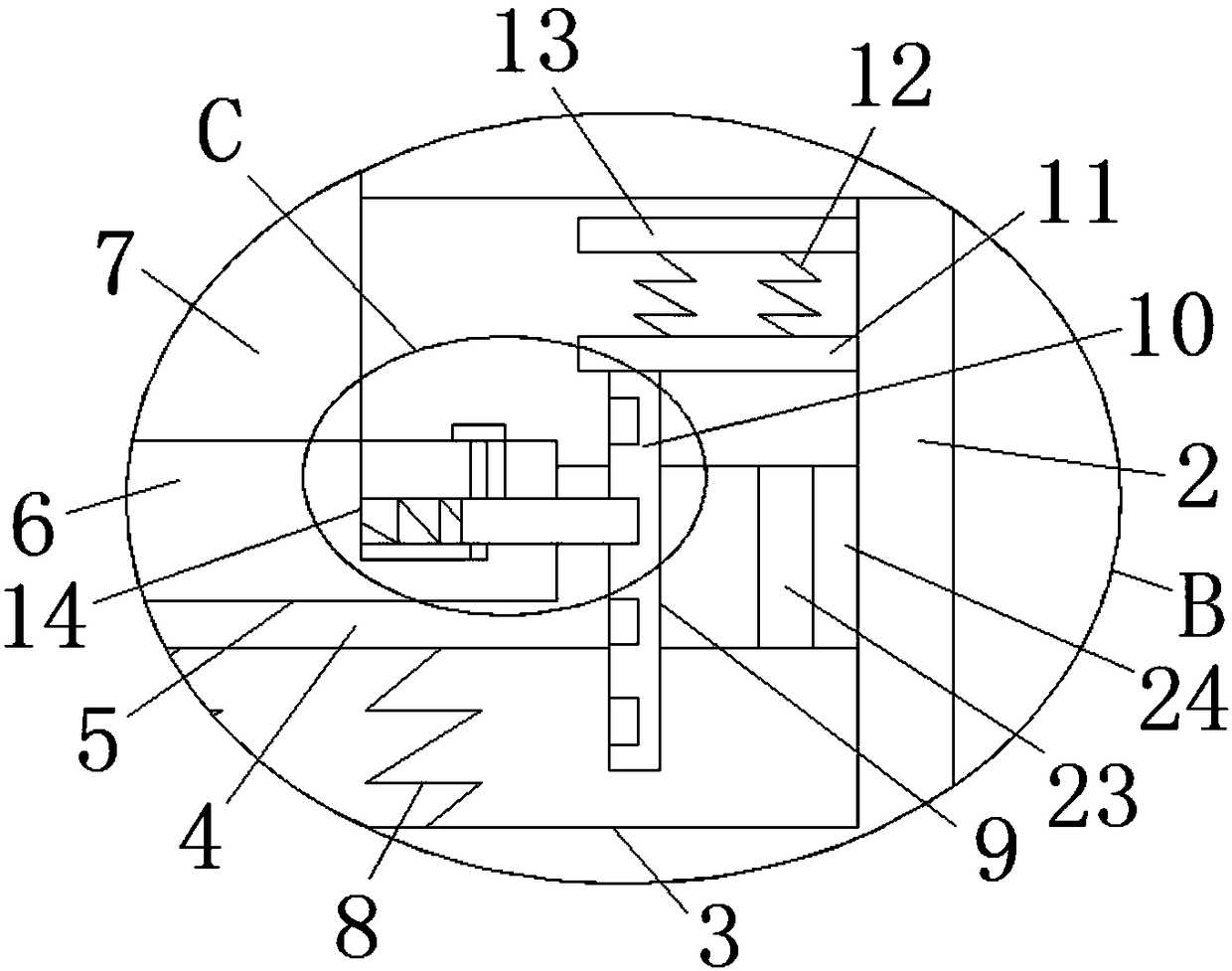

[0027] refer to Figure 1-5 , a dust removal device for a tablet press is proposed in this embodiment, comprising a worktable 1, a mounting table 2 is fixedly installed on the top of the working table 1, and a first groove 3 is opened on the top of the mounting table 2, and the first groove 3 A slide plate 4 is movable inside, and the top of the slide plate 4 is provided with a mounting groove 5, and a mounting plate 6 is movably installed in the mounting groove 5, and the top of the mounting plate 6 extends to the top of the slide plate 4 and is fixedly installed with a suction fan 7, the first groove The bottom inner wall of 3 is welded with a plurality of first springs 8, the top of the first spring 8 is welded to the bottom of the slide plate 4, and both sides of the bottom of the slide plate 4 are provided with sliding holes 9, and the plurality of first springs 8 are located on both sides. Between two sliding holes 9, a sliding rod 10 is slidably installed in the sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com