Tablet machine

A tablet press and tablet technology, applied in the field of presses, can solve the problem that powder can no longer be reused, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

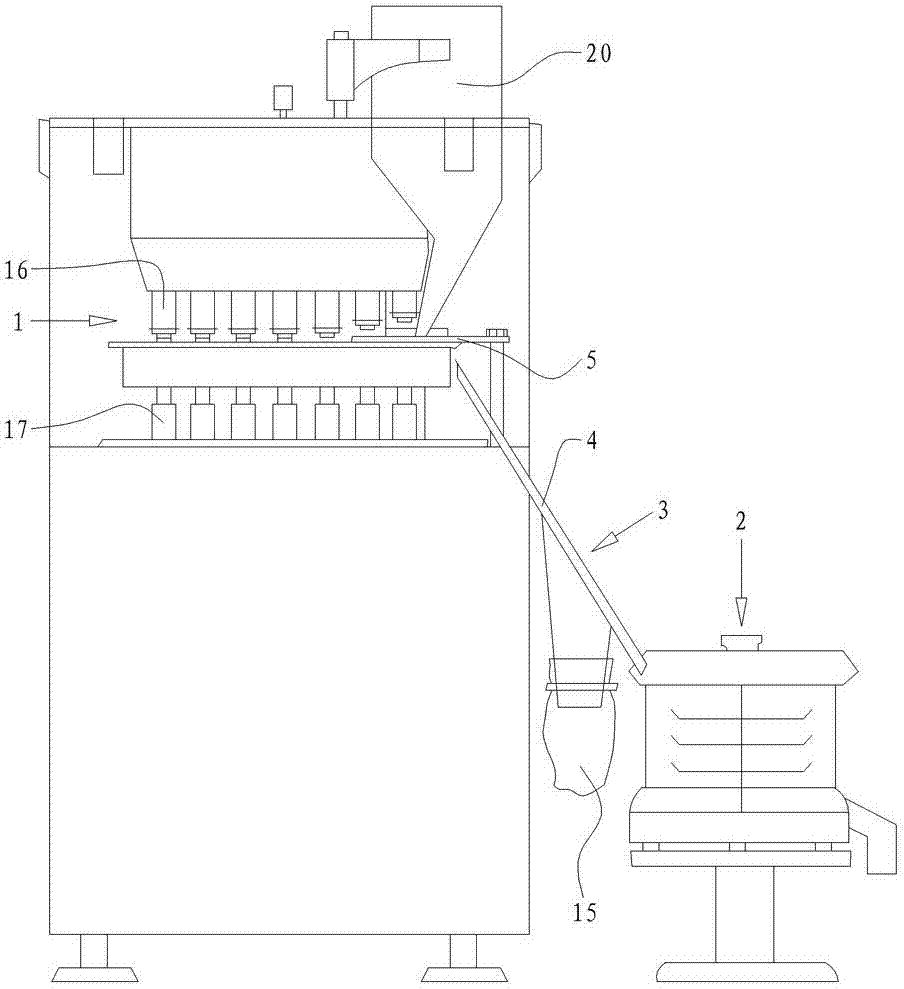

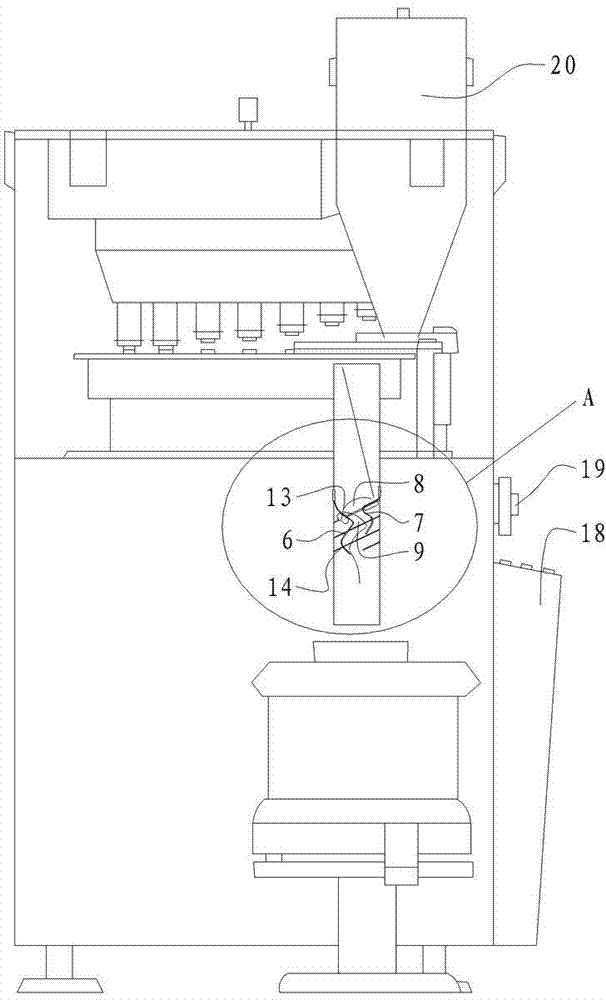

[0015] The tablet press of this embodiment, such as figure 1 and figure 2 As shown, it includes a sheet compression molding device 1 and a sheet collection device 2 located below the sheet compression molding device 1 . A sheet discharging device 3 is arranged between the sheet pressing and forming device 1 and the sheet collecting device 2 . The film output device 3 includes a lower film groove 4 placed obliquely and a scraper plate 5 for scraping the formed sheet into the lower film groove.

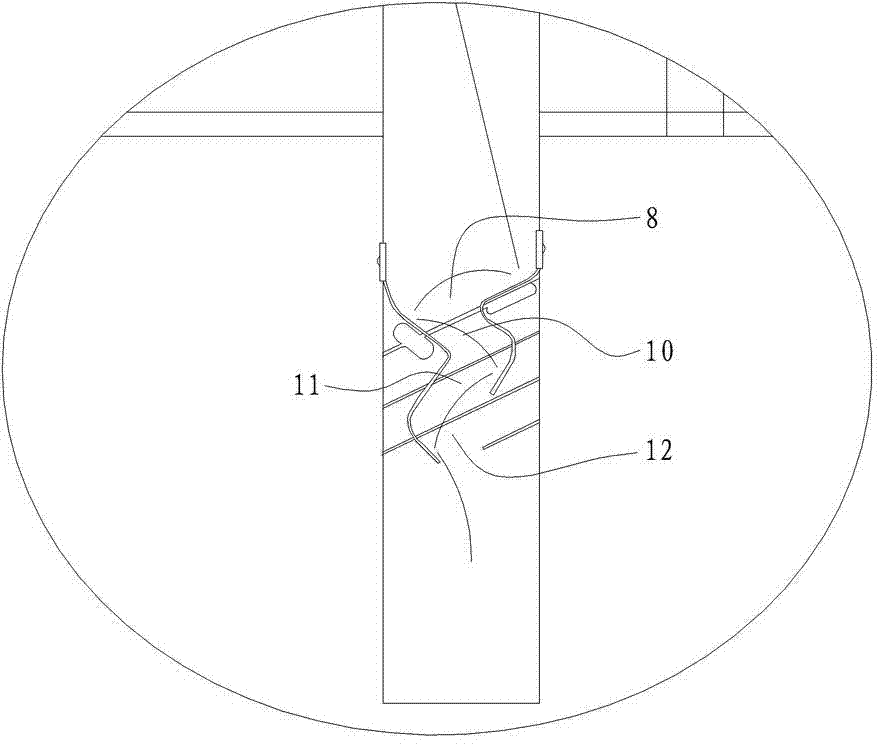

[0016] like image 3 As shown, the entrance of the lower film groove 4 is provided with an adjusting piece (not marked on the figure) for adjusting the falling angle of the film. A left vibrating plate 6 and a right vibrating plate 7 are arranged in the lower plate groove 4 opposite to each other. The upper parts of the left vibrating plate 6 and the right vibrating plate 7 are close to each other to form an arc-shaped chip collecting portion 8 . The lower part of the left vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com