Feeding frame mechanism of cutting machine for machining tamper mould of tablet press

A technology of cutting machine and tablet press, which is applied in metal processing and other directions, can solve the problems of uneven feeding speed and low work efficiency, and achieve the effects of improving work efficiency, simple production and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

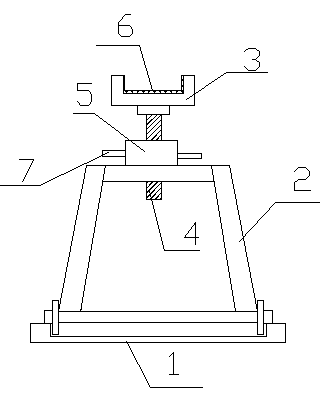

[0014] like figure 1 As shown: a feeding frame mechanism of a cutting machine for processing tablet press rod molds in this embodiment, including a feeding track 1 and a feeding cart 2, and the rollers on both sides of the bottom of the feeding cart 2 are respectively placed on the track 1 Above, a bolt 4 passes through the feeding cart 2 and fixes the collection frame 3 on the top, and a layer of wear-resistant backing plate 6 is fixed on the surface of the collection frame 3 .

[0015] Wherein the bolt 4 is fixed with an adjusting disc 5 , and two handles 7 are sequentially arranged radially along the circumference of the adjusting disc 5 .

[0016] The beneficial effect of this embodiment is that the design is reasonable, the function is perfect, and the pressing rod mold can be quickly sent into the cutting machine for cutting, thereby improving the working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com