Double-shaft medicine tablet pressing machine

An axial compression and medicine technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as top cracking, waist cracking, tablet cracking, compression rod deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

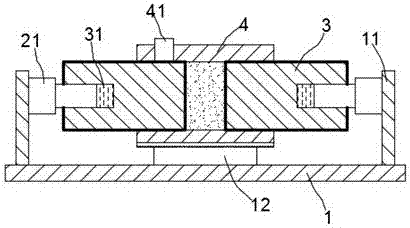

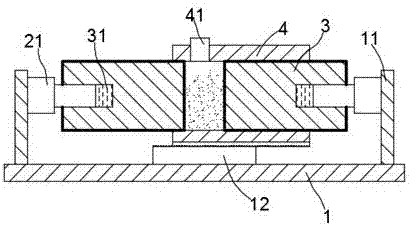

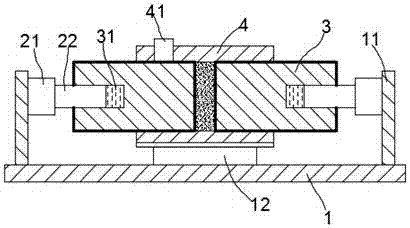

[0017] exist Figure 1 to Figure 3 In the shown embodiment, the pharmaceutical biaxial tablet press includes a base 1, support arms 11 and driving components symmetrically arranged at both ends of the base 1,

[0018] The driving part includes a driving motor 21 and a driving rod 22. Driven by the driving motor 21, the driving rod 22 can be screwed in and out along its own axis; the rotation directions of the two driving rods 22 are opposite;

[0019] A pressure column 3 is detachably installed on the drive rod 22, and an acceleration gear set 31 is arranged between the pressure column 3 and the drive rod 22;

[0020] An adjustment rod 12 is also arranged on the base 1, and a pressure cylinder 4 is arranged on the adjustment rod 12, and the pressure cylinder 4 and the adjustment rod 12 are connected by thread matching;

[0021] The pressurized cylinder 4 is coaxial with the pressurized column 3; a drug inlet hole 41 is opened on the cylinder wall at one end of the pressurized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com