Medicine single-stamping tablet press

A medicine and voltage stabilizing technology, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as prone to splits, unstable pressurization, and cracks in tablets, so as to reduce the probability of splits and increase pressurization. The process is efficient and ensures the effect of stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

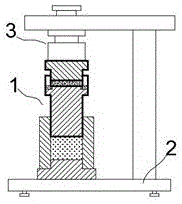

[0016] exist figure 1 Only image 3 In the shown embodiment, the pharmaceutical single-punch tablet press includes a mold 1, a machine body, a loading plate 2 and a pressurizing column 3; the mold 1 is detachably placed between the loading plate 2 and the pressing column 3;

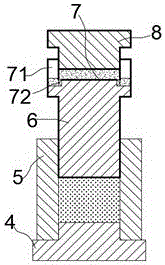

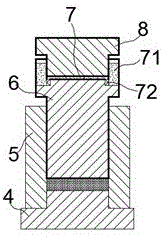

[0017] The mold 1 includes a bottom plate 4, a sleeve 5 and a pressure rod 6;

[0018] The top of the pressure rod 6 is provided with a buffer tank 7, the tank wall 71 of the buffer tank 7 is hollow, and the bottom of the buffer tank 7 is provided with a control valve 72 communicated with the tank wall 71; the buffer tank 7 is filled with a buffer solution, The buffer fluid is lubricating oil with high viscosity; when the pressure exceeds the threshold, the control valve 72 is opened; in the buffer tank 7, a stabilizing rod 8 is slidably arranged, and the stabilizing rod 8 and the buffer tank 7 are combined into a A liquid seal space with variable volume; a pressure scale value is engraved on the axis o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com