Cotton picker cleaning device and cotton picker

A technology for cleaning devices and cotton pickers, which is applied in the direction of picking machines, agricultural machinery and implements, harvesters, etc. It can solve the problems of water pump damage, inconvenient maintenance, and internal space occupation, so as to prevent damage, work stably, and maintain stable pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

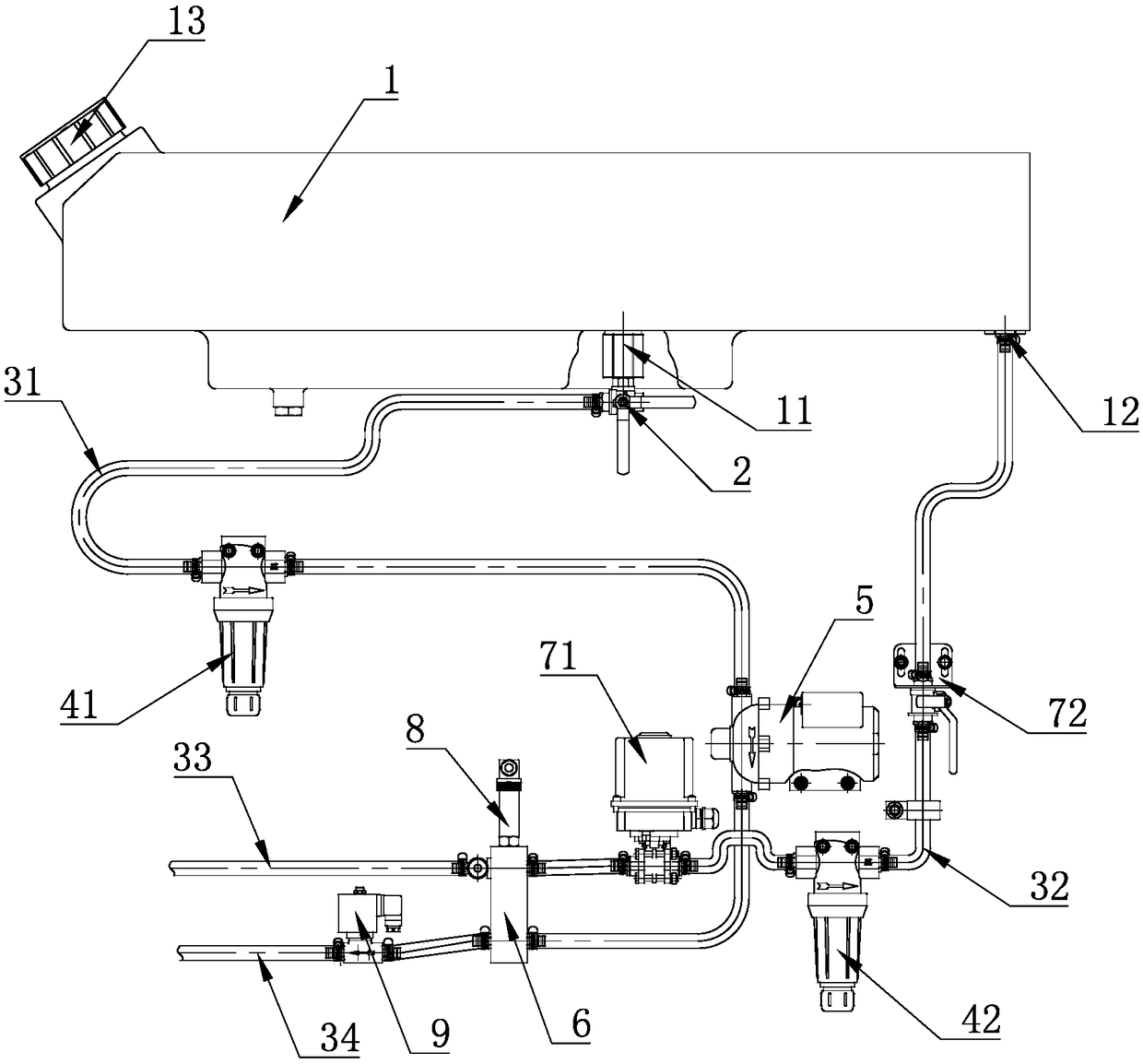

[0030] A cotton picker cleaning device, such as figure 1 As shown, it includes a water tank 1 containing cooling water, a transmission channel for transferring the cooling water to the ingot picking assembly, and a power assembly 5 for extracting cooling water in the water tank 1. The water tank 1 includes a water outlet 11, a water return port 12 and a water injection port 13. The water port 13 is arranged on the top of the water tank 1 for supplementing cooling water into the water tank 1, the water outlet 11 and the water return port 12 are arranged at the bottom of the water tank 1, and the transmission channel includes the water outlet pipe 31 connected with the water outlet 11 and the water return port 12. The connected return pipe 32, the distributor 6 is connected between the outlet pipe 31 and the return pipe 32, and the distributor 6 is provided with an accommodation chamber for accommodating cooling water, the outlet pipe 31 and the return pipe 32 communicate with th...

Embodiment 2

[0046] A cotton picker, including the cotton picker cleaning device in Embodiment 1, adjusts the opening and closing degree of the first control valve 71 according to the detection value of the pressure sensor 8, and then adjusts the amount of water flowing back into the water tank 1, that is, adjusts the distribution The water pressure in the device 6 stabilizes the water pressure inside the distributor 6 and out of the water spray pipe 33 at a certain value, so that the cleaning device of the cotton picker can more stably moisten and cool down the picking spindle assembly, ensuring that the cotton picking The machine works stably for a long time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com