Method of operating a rotary tablet press and rotary tablet press

A tablet press, rotary technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve problems such as the adverse effect of machine power on the quality of pressed products, and achieve the effect of simple production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

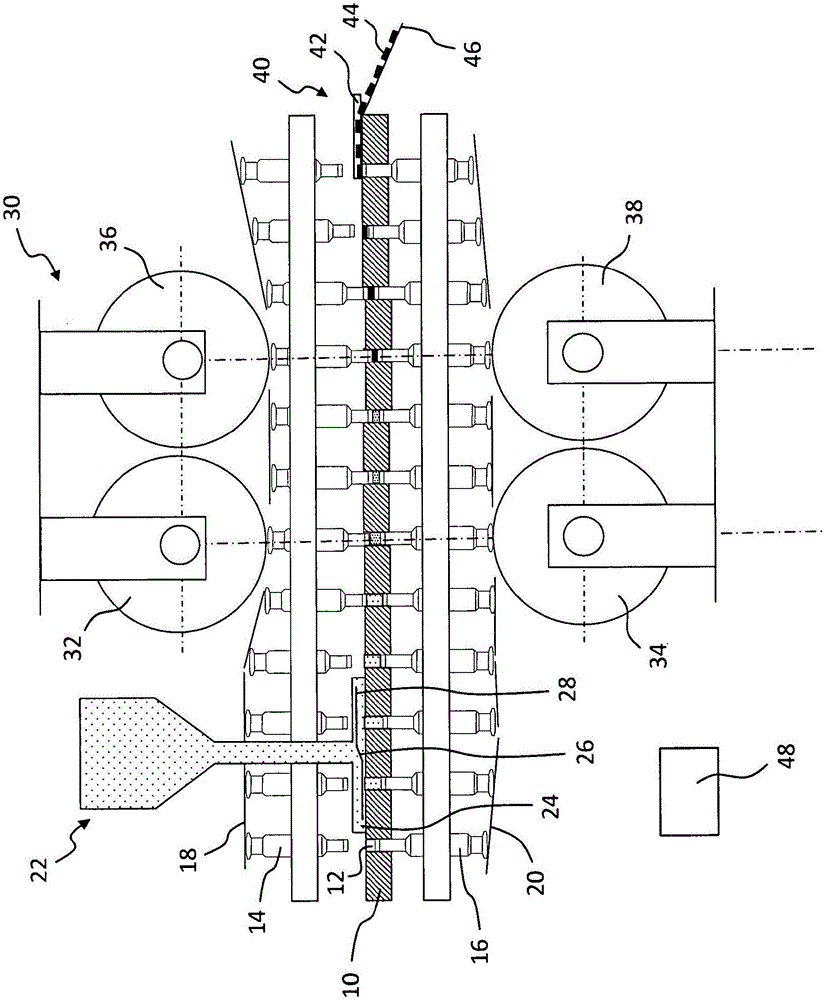

[0019]The rotary tablet press comprises a rotor which is driven in rotation at the rotor speed by a rotary drive (not shown in detail), said rotor having a die plate 10 with a plurality of openings 12 . Furthermore, the rotor includes a plurality of upper punches 14 and lower punches 16 which rotate synchronously with the die plate 10 . A pair of punches consisting of an upper punch 14 and a lower punch 16 is associated here with a hole 12 in each case. The axial movement of the upper punch 14 and the lower punch 16 during rotation of the rotor is controlled by an upper control cam element 18 and a lower control cam element 20 . The rotary tablet press also includes a filling station 22 with a filling device having a filling chamber 24 in which a filling wheel 26 is arranged, which has a plurality of agitating wheels arranged on the circumference. Blade 28. The filler wheel 26 is driven in rotation at the filler wheel speed by a rotary drive (not shown in detail). Furthermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com