Device for removing dust in tablets of tablet press

A technology of tablet press and dust, which is applied in the field of devices for removing dust from plain tablets of a tablet machine, can solve the problems of increasing the purification burden of central air conditioning, air pollution, packaging equipment and air pollution, and achieves benefits to health and air quality. The effect of little pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

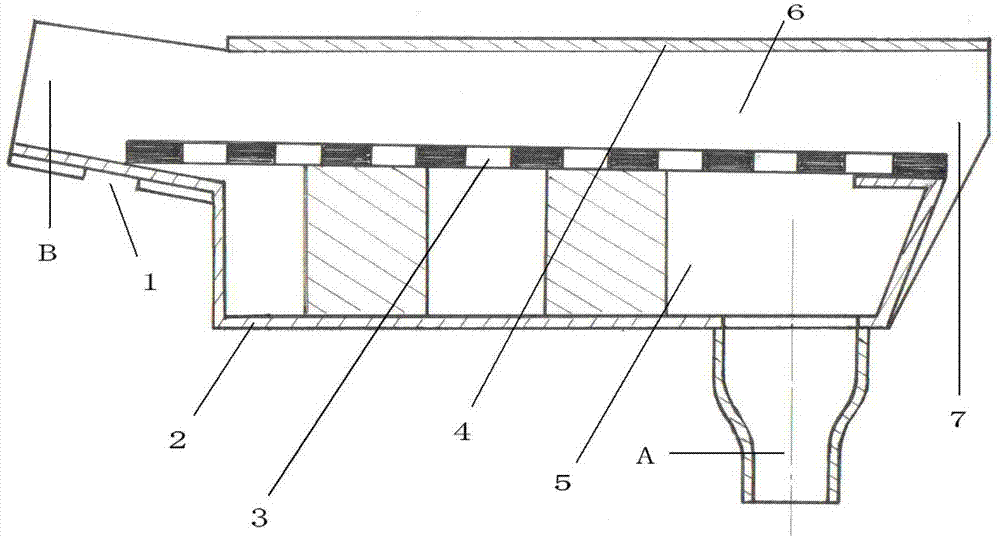

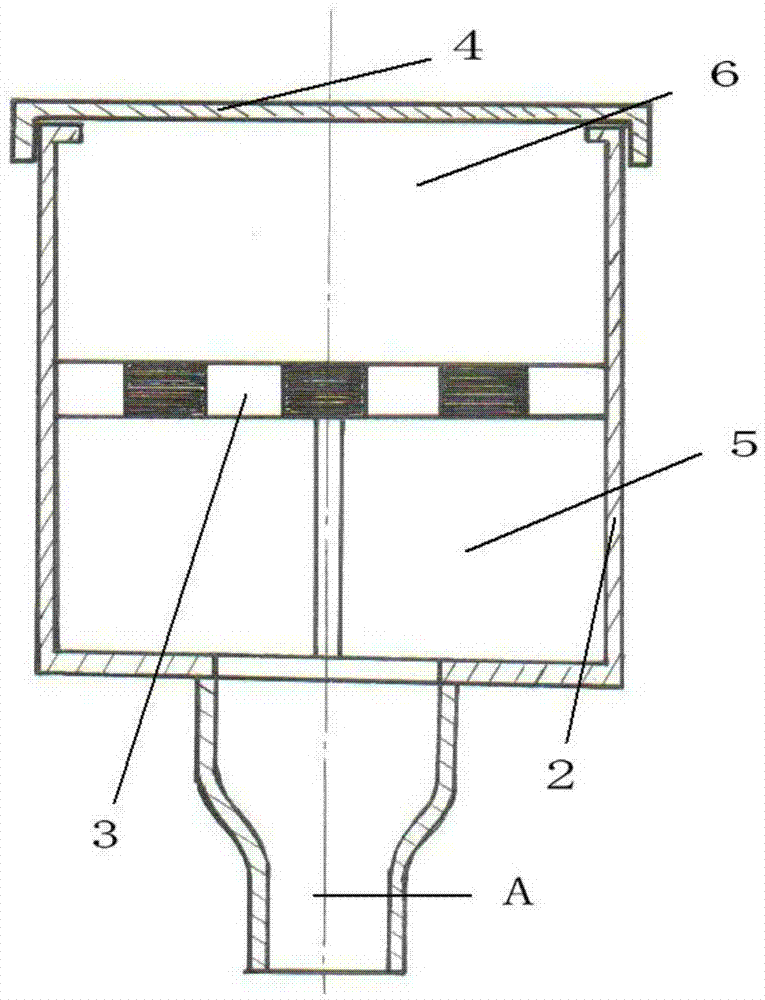

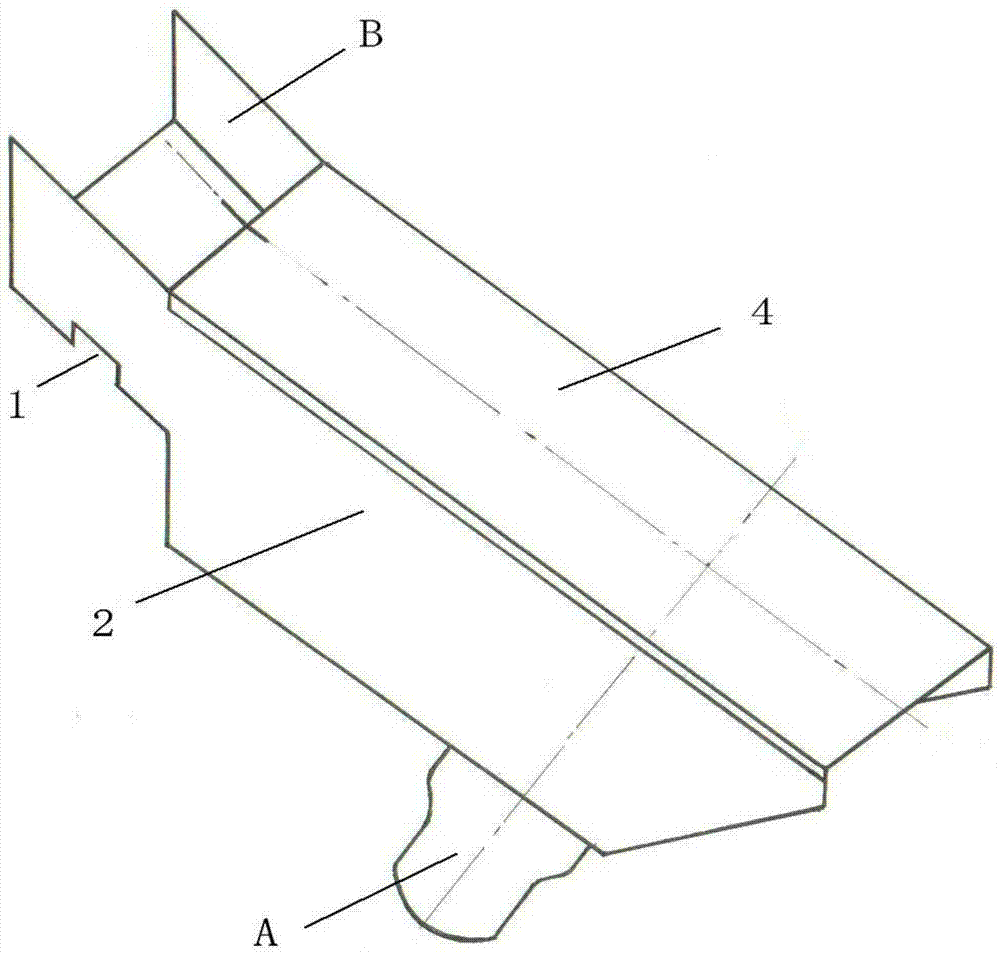

[0027] Such as figure 1 The present invention shown is a device for removing dust in plain tablets of a tablet machine. A partition 3 is installed in the middle of a rectangular tank body 2 of a stainless steel plate, and the partition layer 3 separates the rectangular tank body 2 into an upper chamber 6 and the lower chamber 5 are two parts, and the interlayer 3 is a 12-purpose stainless steel screen, such as figure 2 As shown, the upper chamber of the rectangular tank body 2 has a detachable stainless steel cover 4, the front end of the upper chamber 6 has a knuckle 1 and is made into an interface B connected with the tablet press, and the rear of the rectangular tank body 2 The end has a bevel 7, and the upper chamber 6 of the rectangular tank is longer than the lower chamber 5, as image 3 As shown, a stainless steel interface A is welded and fixed under the rear end of the lower chamber 5, and the interface is used to connect with the vacuum cleaner of the tablet press....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com