Full-function osmotic pump controlled-release tablet laser-beam drilling machine

An osmotic pump controlled release, tablet laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as inability to ensure products, reduced feeding speed, and reduced tablet conveying speed, to overcome poor adaptability, Enhanced adaptability and good punching consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

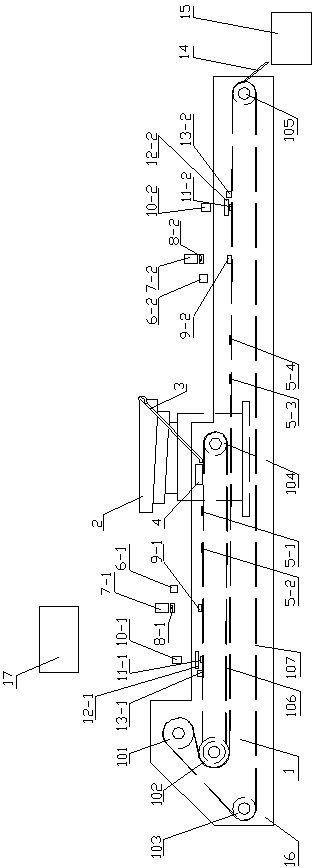

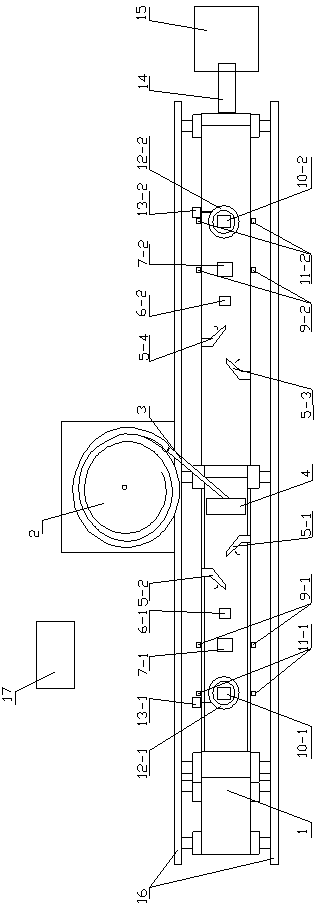

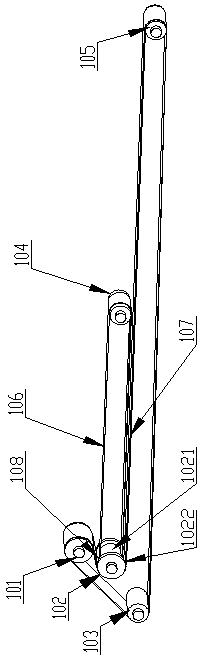

[0021] Below in conjunction with accompanying drawing, the present invention will be further described: with reference to figure 1 , figure 2 and image 3 A full-featured osmotic pump controlled-release tablet laser punching machine includes a tablet delivery device, a tablet carding board, a color recognition sensor, a punching positioning sensor, a laser, a high-speed scanning galvanometer, a computer, and a visual detection and rejection system, The tablet conveying device includes a double-layer flat belt conveyor 1 and a double-track tablet vibrating plate feeder 2. The double-track tablet vibrating plate feeder 2 is connected to the double-layer flat belt conveyor 1 through the connecting track 3 and the mounting bracket 4. Convergence, the double-layer flat belt conveyor 1 includes a first follower shaft 101, a drive shaft 102, a second follower shaft 103, a third follower shaft 104, a fourth follower shaft 105, an upper conveyor belt 106 and a lower conveyor belt Be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com