Recombinant saccharomyces-fermentum-expressed hepatitis B surface antigen, production method of hepatitis B surface antigen, hepatitis B vaccine and production method of hepatitis B vaccine

A technology for recombining Saccharomyces cerevisiae and hepatitis B surface antigen, which is applied to the preparation methods of peptides, chemical instruments and methods, fermentation, etc., can solve the problems of high manual operation intensity, avoid manual operation, save equipment investment and maintenance costs, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Take the working seed batch of recombinant Saccharomyces cerevisiae expressing HBsAg constructed by Merck Company in the United States with DNA recombination technology, and culture it in a 0.25L conical flask at 27-29°C for 17-19 hours, and in a 2L conical flask at 27-29°C. Cultivate for 17-19 hours, ferment and cultivate for 16-22 hours at 27-29°C in 70L seed tanks, ferment and cultivate for 44-48 hours at 27-29°C in 800L production tanks, and harvest the yeast.

[0057] After crushing the yeast by a high-pressure homogenizer, add an equal volume of phosphate buffer containing Triton X-100, and filter the yeast fragments with a filter membrane during the addition process to extract HBsAg.

[0058] Triton was removed by XAD-4 column to prepare Triton Antigen (PBP).

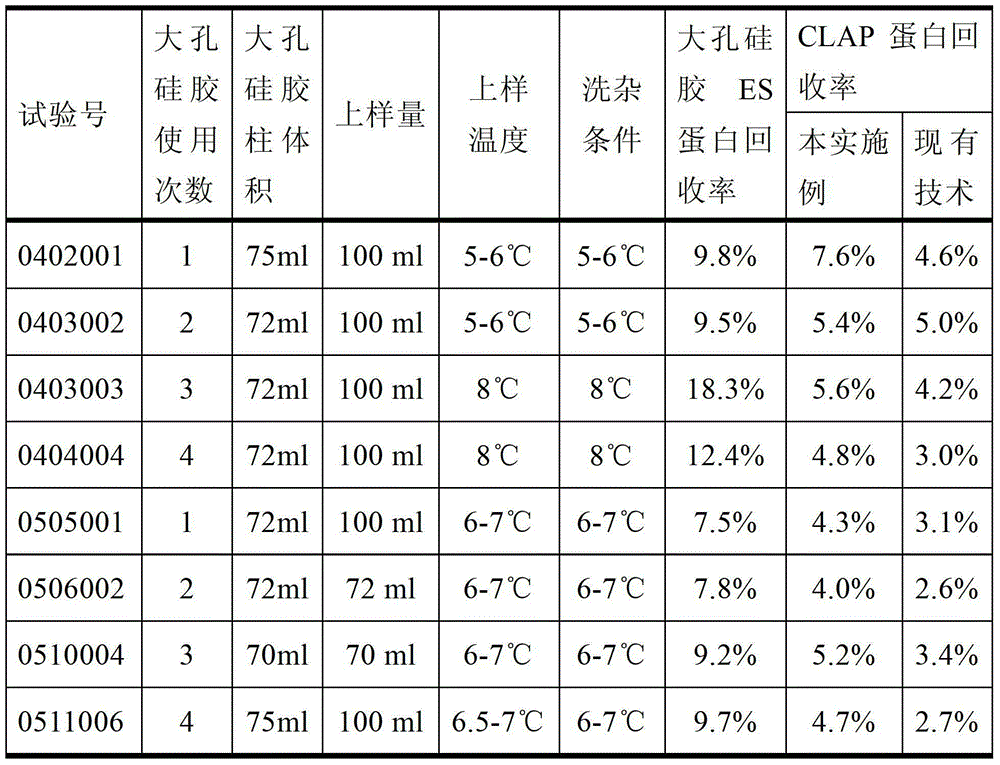

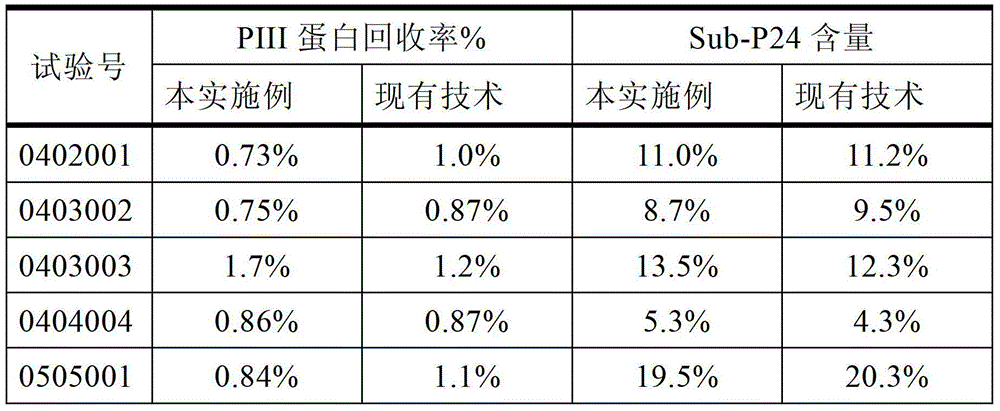

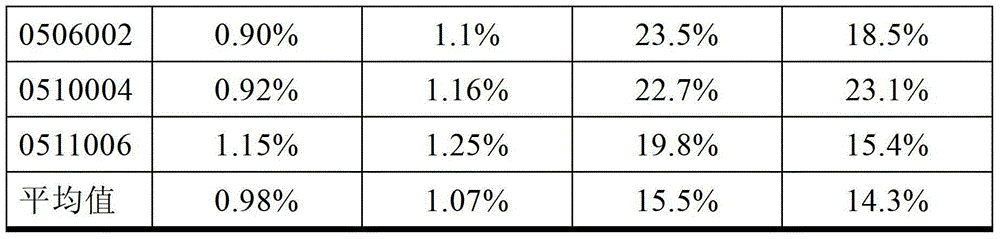

[0059] After loading macroporous silica gel with a pore diameter of 1000A and a particle size of 35 μm to 70 μm into a chromatography column to form a macroporous silica gel column, the macroporous silica ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com