A tablet forming machine

A forming machine and tableting technology, which is applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of affecting the quality of tablet forming products, unstable pressure holding process, low processing efficiency, etc. The effect of unstable pressure, simple structure and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

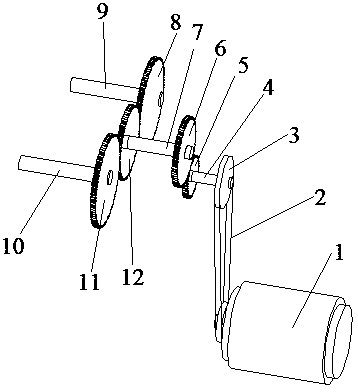

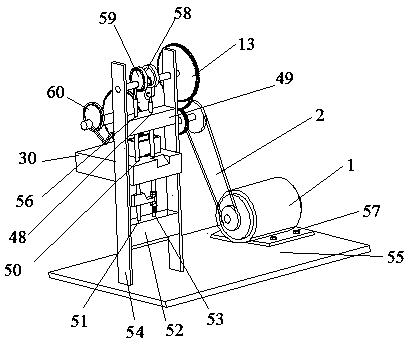

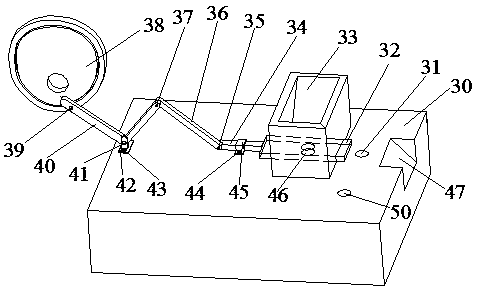

[0029] Such as Figure 1-5 As shown, a tablet molding machine includes a base 55, a punch mechanism, a feeding mechanism 60 and a transmission mechanism. The base 55 is fixedly provided with a motor 1 and a frame 54. The base 55 provides positioning for the motor 1 and the frame 54. The motor 1 is fixed on the base 55 by a third bolt group 57 composed of four hexagon bolts. A first guide block 49, a table 30 and a second guide block 52 are fixedly arranged on the frame 54. The first guide block 49 is provided with a first guide hole 56 and a fourth guide hole 48, the table 30 is provided with a second guide hole 50 and a first cavity 31, the second guide block 52 is provided with a third guide hole 51 and a fifth guide hole 51 in parallel. Guide hole 53.

[0030] The punch mechanism includes an upper punch mechanism 58 and a lower punch mechanism 59. The upper punch mechanism 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com