Method for realizing pressure tapping by using gas drainer and gas drainer for realizing pressure tapping

A drainer and gas technology, applied in gas/liquid distribution and storage, pipeline systems, mechanical equipment, etc., can solve the problem of single function of the gas drainer, and achieve the effect of expanding the scope of use, simple method, and efficient use of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

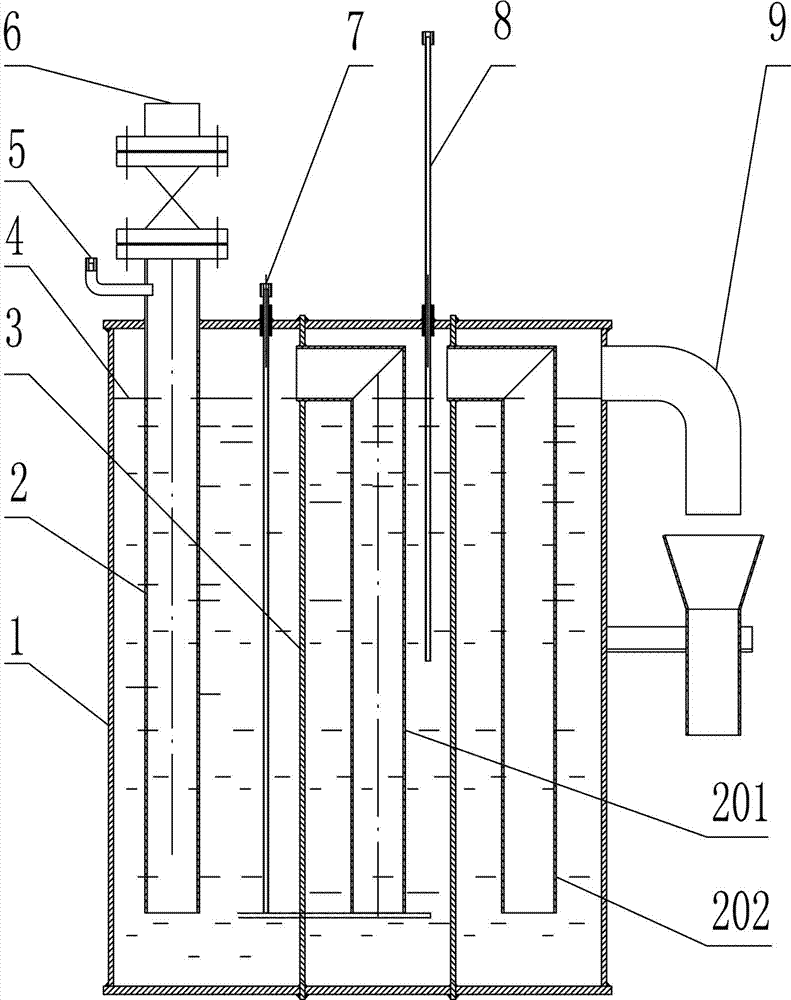

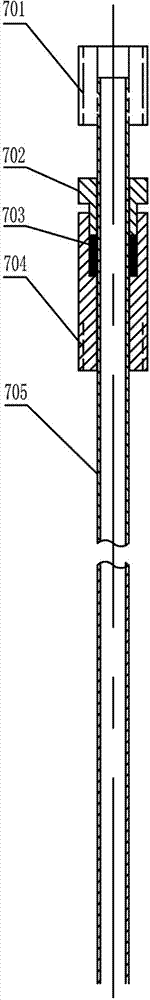

[0021] The gas drainer realizing the pressure taking method of the present invention can be composed of N horizontal connectors connected in series, the water seal chambers of each connector contain water for blocking gas, and a water seal pipe is erected in each water seal chamber , the lower end of each water-sealed tube is suspended, and the upper port of each water-sealed tube in the water-sealed chamber of the connector from the second stage to the last stage is connected with the water-sealed chamber of the previous stage; the upper port of the first-stage connector serves as a receiving port The inlet of the gas pressure, and the outlet connected to the atmosphere is opened on the last stage of the connector.

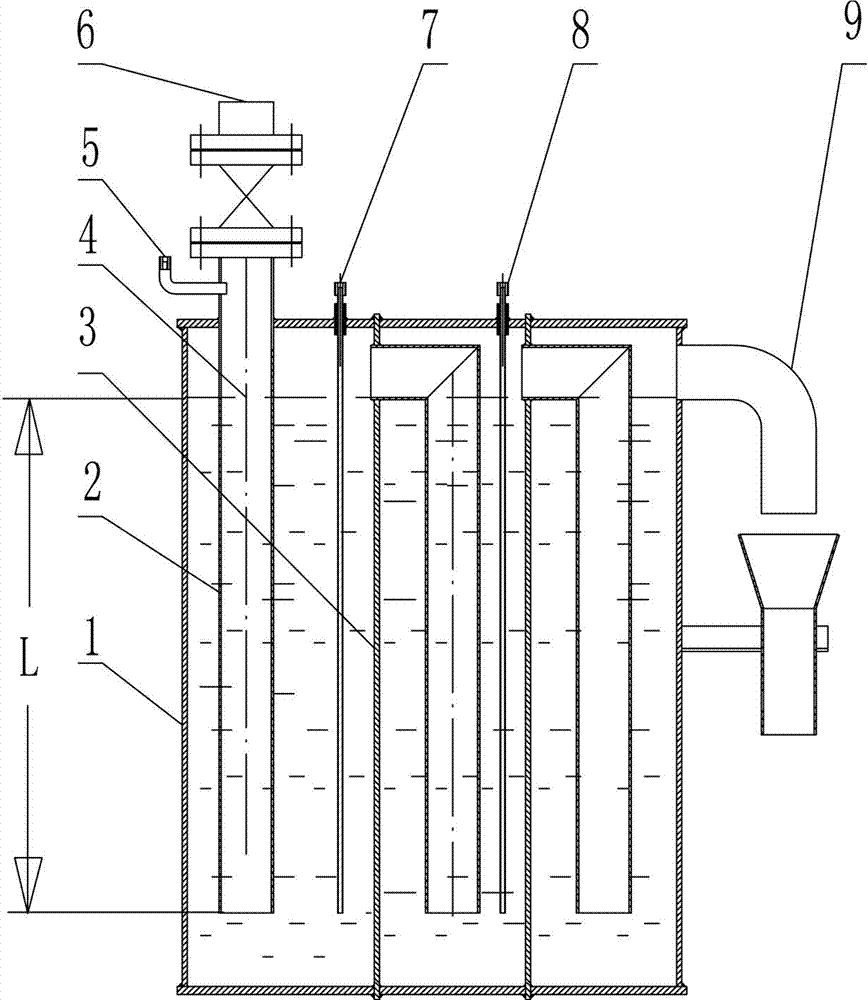

[0022] The gas drain can also be as figure 1 , figure 2 The form of the embodiment shown is integrated, that is, it includes an airtight drain housing 1, an inlet 6 is arranged on one side of the airtight drain housing 1 for communicating with the gas, and an o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com