Optical fiber temperature and pressure sensor for double-cavity structure and a preparation method thereof

A technology of pressure sensor and optical fiber temperature, which is applied in the direction of physical/chemical change thermometer, thermometer, and measurement of the change force of the optical property of the material when it is stressed, which can solve the problem of complex sensor structure and high sensor packaging requirements , difficult to manufacture and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] A method for preparing an optical fiber temperature and pressure sensor with a dual-cavity structure, said method comprising the following steps:

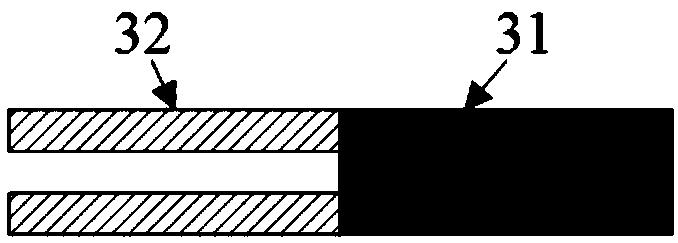

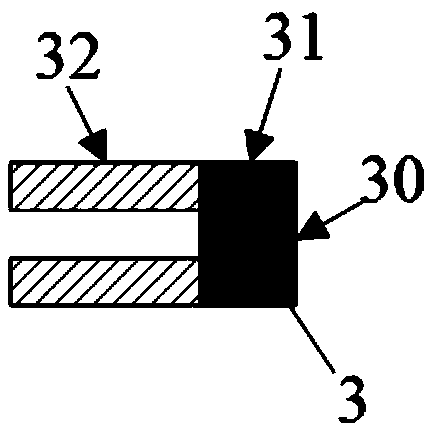

[0063] The second capillary 32 and a section of optical fiber 31 are fused together, and the optical fiber 31 is thinned and ground to a required length to form an intrinsic type F-P cavity 3;

[0064] Insert the incident component 1, the intrinsic F-P cavity 3, and the reflective component 2 into the first capillary 5, and reasonably control their distance to form an extrinsic F-P cavity 4, which is fixedly connected to form a dual-cavity optical fiber temperature and pressure sensor.

[0065] The way of the fixed connection is glue or welding.

[0066] The technical solution for inserting the incident component 1, the intrinsic F-P cavity 3, and the reflective component 2 into the first capillary 5, reasonably controlling the distance thereof, and forming the extrinsic F-P cavity 4 includes the following steps: The incide...

Embodiment 1

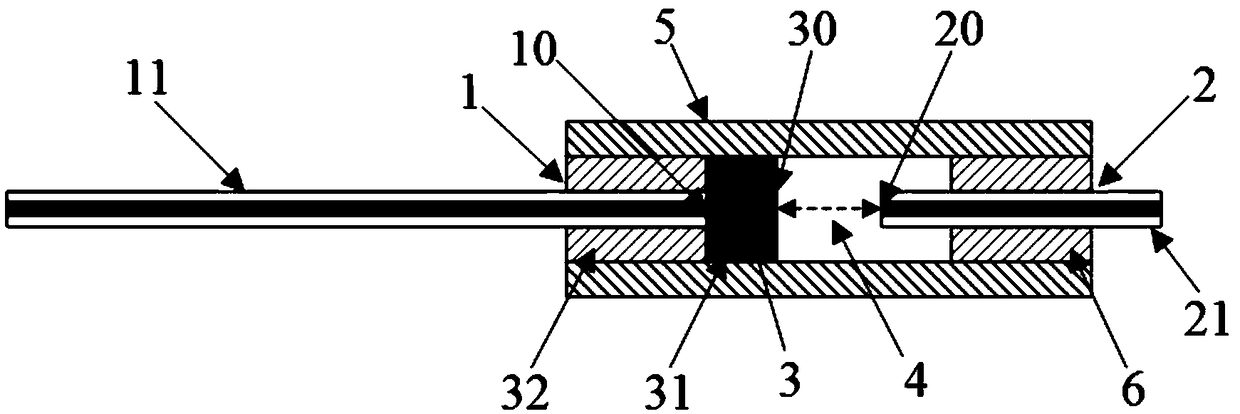

[0072] Embodiment 1 provides an optical fiber temperature and pressure sensor with a dual-cavity structure. Such as figure 1 as shown, figure 1 It is a structural schematic diagram of an optical fiber temperature and pressure sensor with a dual-cavity structure in Embodiment 1 of the present invention, Figure 2A to Figure 2E It is a schematic diagram of the sensor preparation process in Example 1 of the present invention.

[0073] The optical fiber temperature and pressure sensor with dual cavity structure includes: an intrinsic F-P cavity 3 , an incident component 1 , a reflective component 2 , an extrinsic F-P cavity 4 , and a first capillary 5 .

[0074] The intrinsic type F-P cavity 3 is formed by fusing a second capillary 32 and a section of optical fiber 31; the incident component 1 includes an incident optical fiber 11 for guiding the incidence of coherent light beams; the incident optical fiber 11 is inserted into the intrinsic type F-P cavity 3 The second capillar...

Embodiment 2

[0084] Embodiment 2 provides an optical fiber temperature and pressure sensor with a dual-cavity structure. Such as image 3 as shown, image 3 It is a structural schematic diagram of an optical fiber temperature and pressure sensor with a dual-cavity structure in Embodiment 2 of the present invention. Figure 4A to Figure 4EIt is a schematic diagram of the sensor preparation process of Example 2 of the present invention.

[0085] The optical fiber temperature and pressure sensor with dual cavity structure includes: an intrinsic F-P cavity 3 , an incident component 1 , a reflective component 2 , an extrinsic F-P cavity 4 , and a first capillary 5 .

[0086] The intrinsic type F-P cavity 3 is located between the incident component 1 and the reflective component 2, and is formed by fusing a second capillary 32 and a section of optical fiber 31; the incident component 1 includes an incident optical fiber 11 for guiding coherent The incidence of the light beam, the incident opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com