Optical fiber temperature and pressure composite sensor

A composite sensor, optical fiber temperature technology, used in instruments, measuring devices, special recording/indicating devices, etc., can solve the problems of difficult high-precision measurement and signal quality degradation, and achieve the measurement and simplification of dynamic pressure and temperature signals. The steps of data processing and the effect of simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

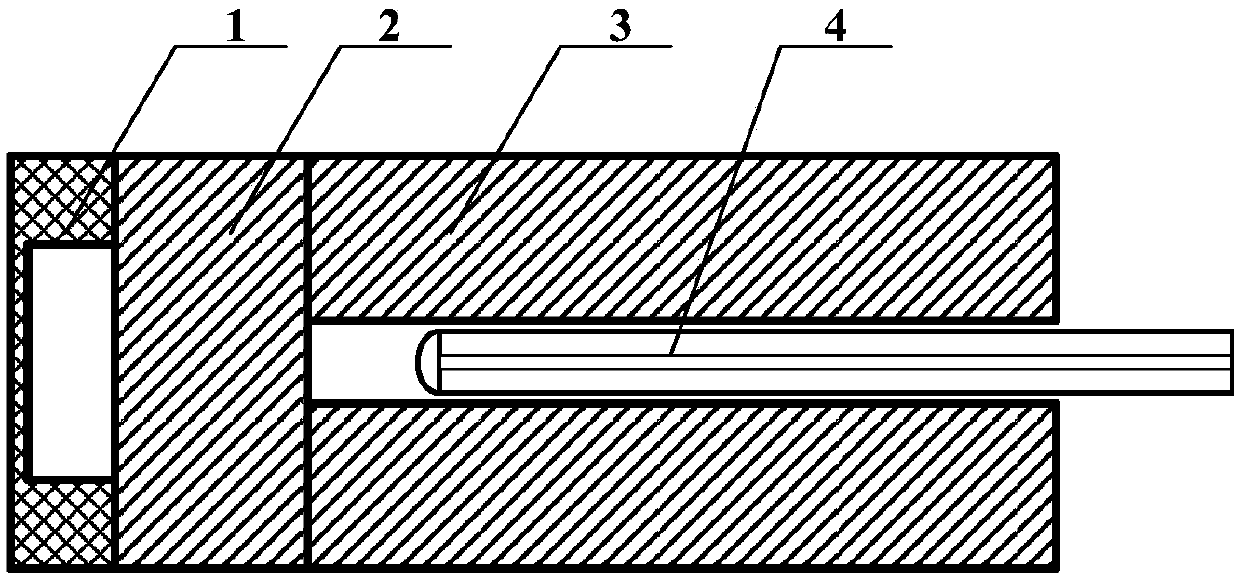

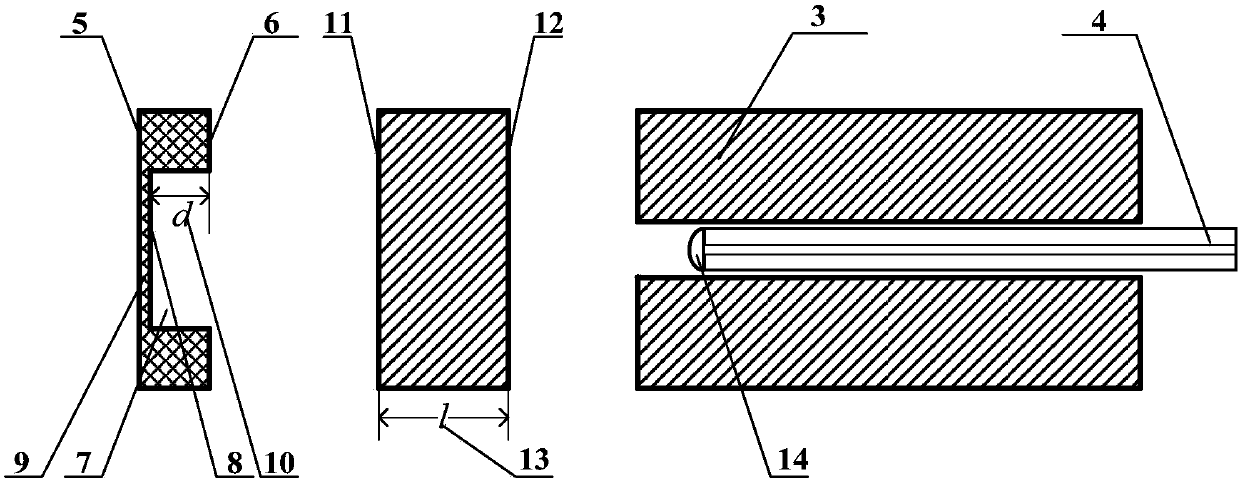

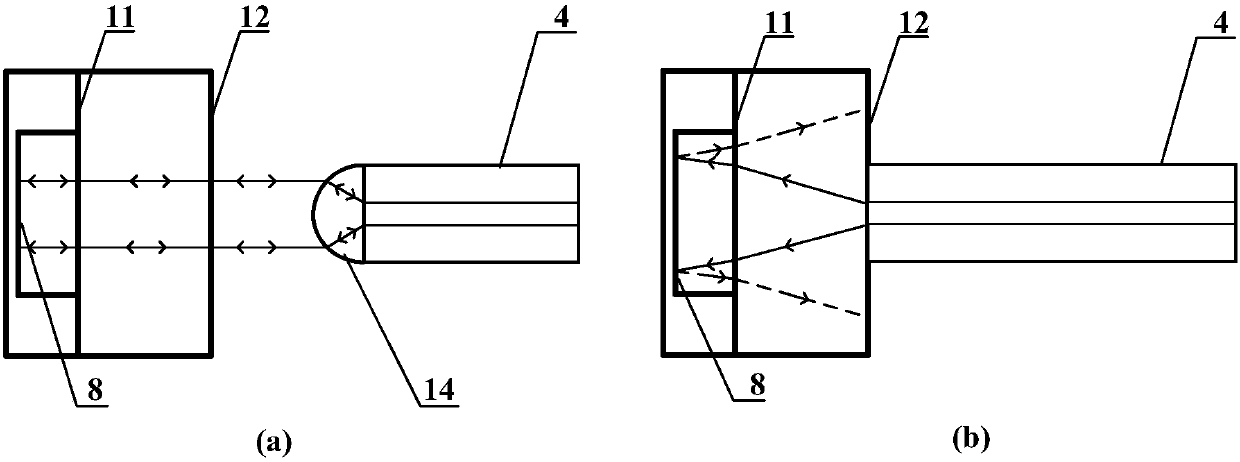

[0032] Such as figure 1 As shown, the optical fiber temperature and pressure composite sensor 26 is composed of a pressure sensing cavity 1 , a temperature sensing substrate 2 , a quartz hollow tube 3 and a transmission optical fiber 4 . Such as figure 2 As shown, the pressure sensing chamber 1 is made of single crystal silicon, which is a square piece of 1.8mm×1.8mm, the upper surface 5 of the pressure sensing chamber is a plane for diffuse reflection treatment, and the lower surface 6 of the pressure sensing chamber is The pressure-sensing cavity 7 is processed into a circular shallow pit with a radius of 650 μm. The upper surface 5 of the pressure-sensing cavity and the bottom surface 8 of the pressure-sensing cavity constitute the upper and lower surfaces of the pressure-sensing diaphragm 9. The thickness of the pressure-sensing diaphragm 9 is 50 μm. The depth d of the pressure cavity 7 is the length 10 of the pressure sensitive cavity, and d=20 μm. The temperature-sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com