A cementing cement bonding strength testing device and method

A technology of cementing strength and cementing cement, applied in the field of drilling, can solve problems such as low accuracy of cementing strength test, and achieve the effect of solving the problems of low accuracy of cementing strength test, accurate cementing strength and avoiding mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the technical solution provided by the embodiment of the present application, through the collected accurate pressure value, the cementation strength of the cemented sample can be calculated, thereby accurately evaluating the cementation strength between the cement and the well wall (or casing), and avoiding the need to test the cementation strength The interaction between the surface of the inner ring and the surface of the outer ring solves the technical problem of low accuracy of the bond strength test in the prior art, and improves the accuracy of the bond strength test.

[0039] The main realization principles, specific implementation methods and corresponding beneficial effects that can be achieved of the technical solutions of the embodiments of the present application will be described in detail below in conjunction with the accompanying drawings.

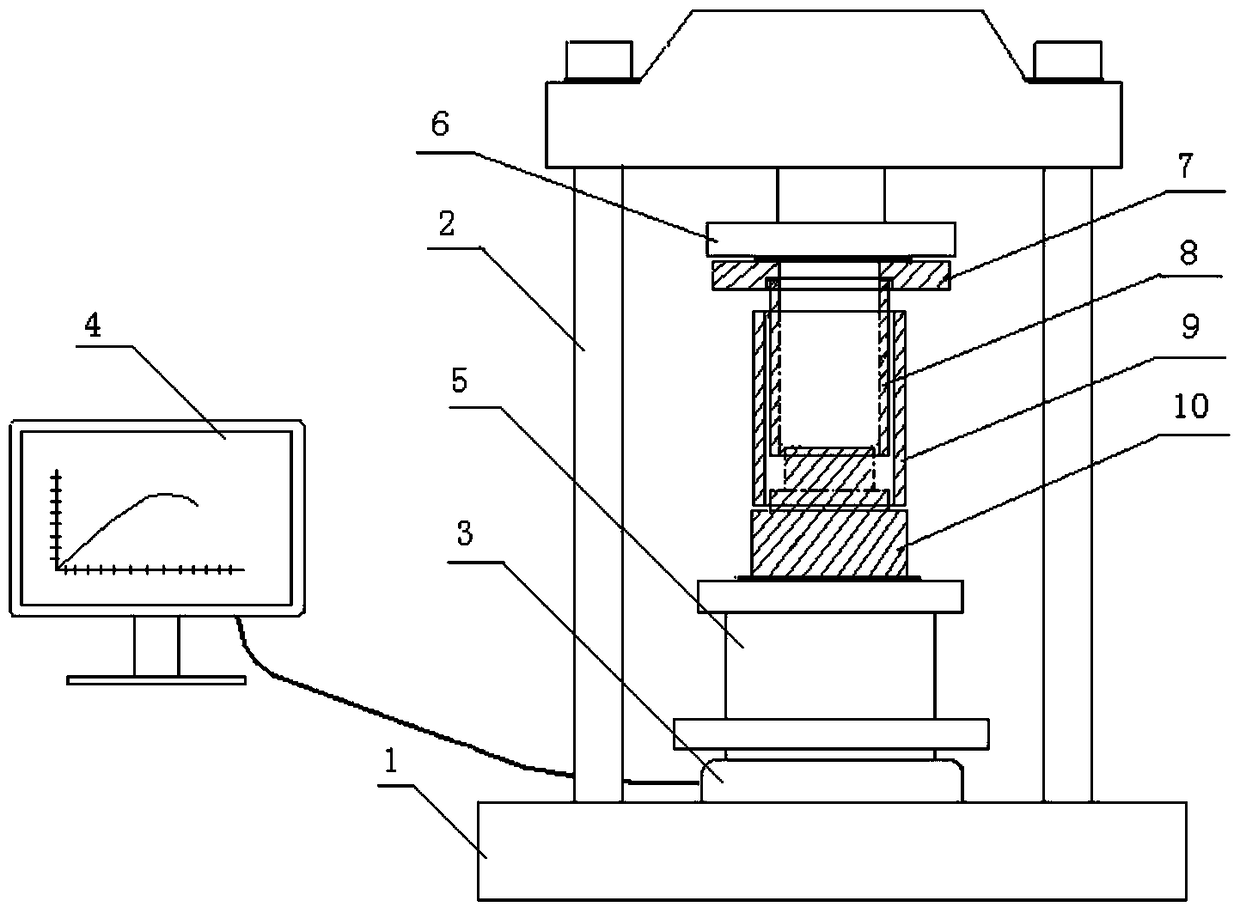

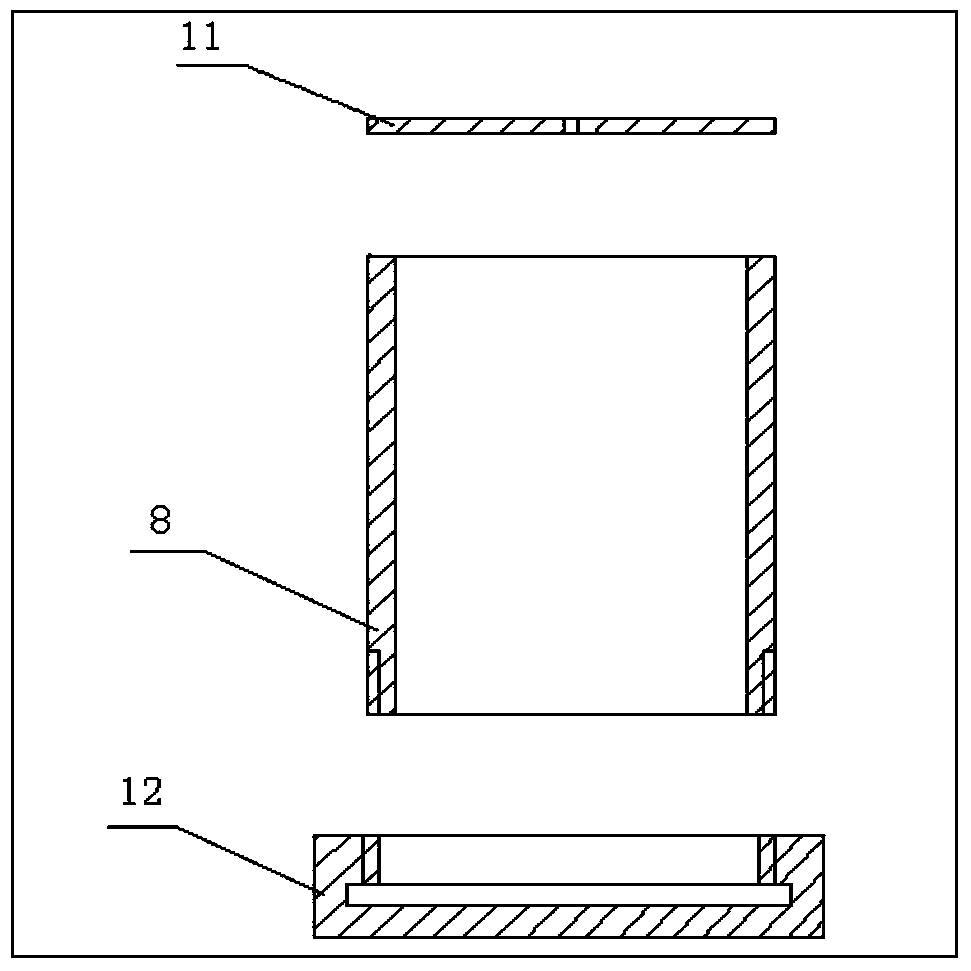

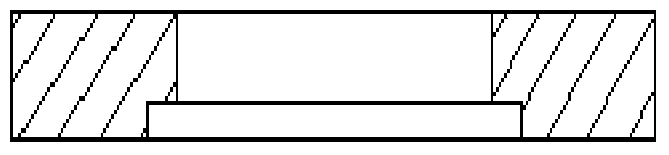

[0040] Please refer to figure 1 , the embodiment of the present application provides a cement bond strength tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com