Convoluted diaphragm-type optical fiber Bragg raster liquid level sensor

A technology of liquid level sensor and corrugated diaphragm, which is applied in the direction of displaying liquid level indicator by pressure measurement, fluid pressure measurement using optical method, etc. problem, to achieve the effect of accurate pressure values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and examples, but the examples do not limit the present invention.

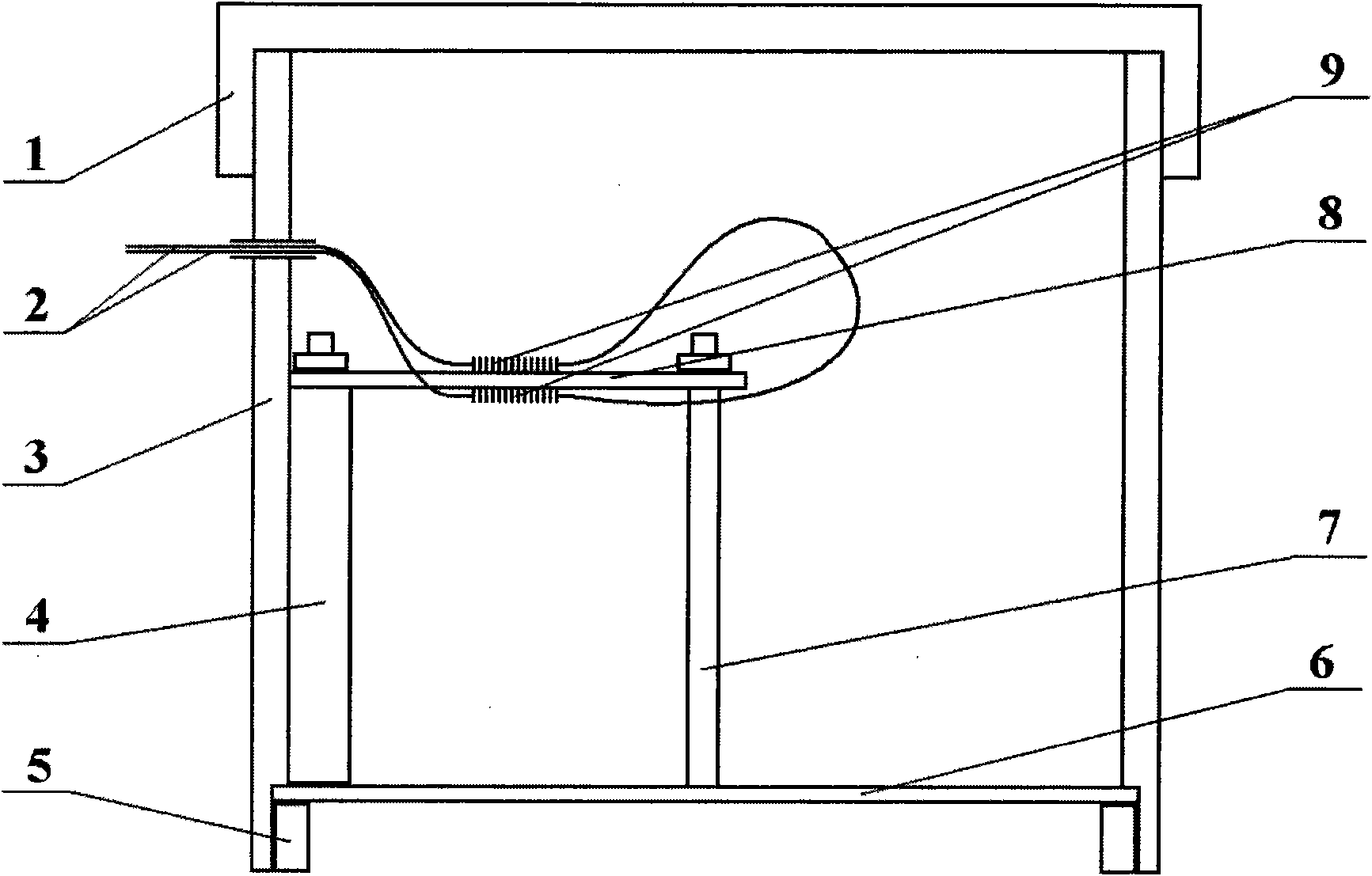

[0012] Such as figure 1 As shown, the corrugated diaphragm optical fiber Bragg grating liquid level sensor includes: optical fiber Bragg grating 9, corrugated diaphragm 6, transfer rod 7, cantilever beam 8 of equal strength; corrugated diaphragm 6 transmits deformation to equal strength cantilever beam 8, so that the fiber Bragg grating 9 pasted on the equal strength cantilever beam 8 produces a corresponding Bragg wavelength shift; in addition, the corrugated diaphragm type fiber optic Bragg grating liquid level sensor also includes: a fixing seat 4 for fixing Equal-strength cantilever beam 8; sealing ring 5, together with protective tube 3, corrugated diaphragm 6 is fixed, and leading and outgoing optical fibers 2 are respectively connected to two ends of two fiber Bragg gratings 9 connected in series....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com