Double-F-shaped fiber grating temperature sensor

A temperature sensor and fiber grating technology, applied in the field of optical sensing, can solve the problems that fiber grating temperature sensors are difficult to achieve large range and high sensitivity at the same time, and achieve the effects of avoiding chirp problems, improving sensitivity, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

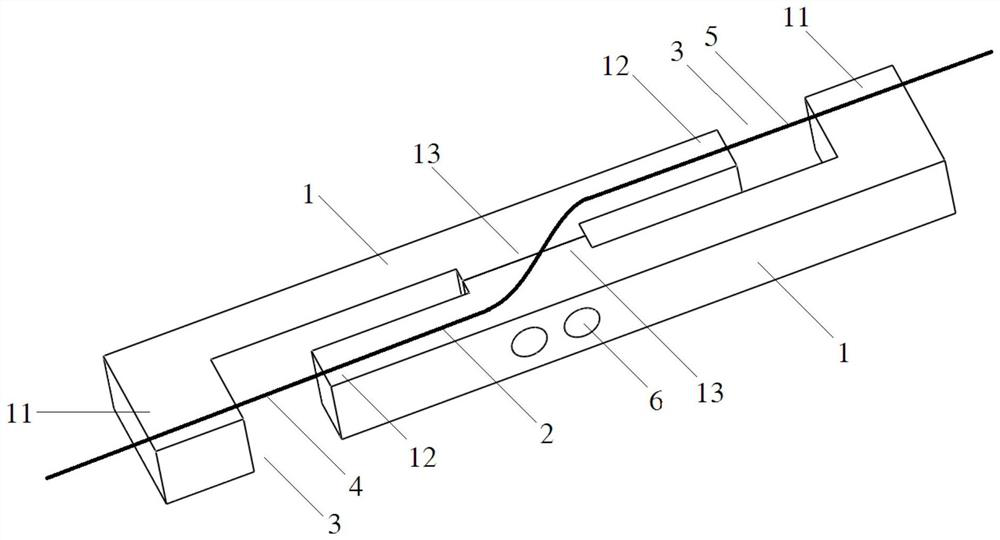

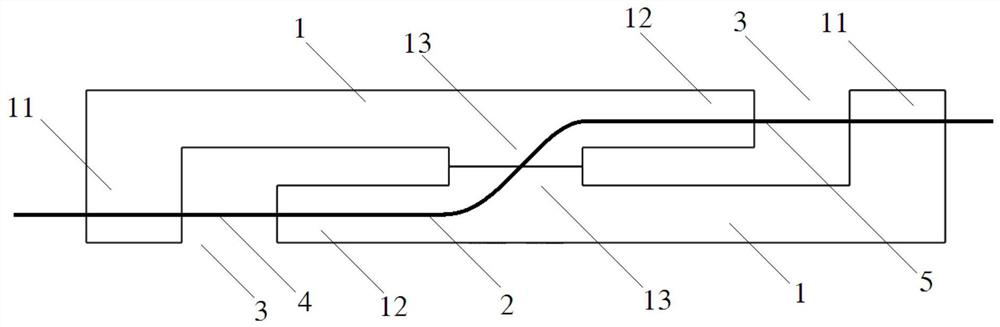

[0027] Such as Figure 1-Figure 3 As shown, the first fiber grating 4 and the second fiber grating 5 written on the same optical fiber 2 are slightly prestressed and then packaged between two adjacent pairs of end points of two F-shaped structural members 1 to form a double F-shaped fiber grating temperature sensor. The thermal expansion coefficients of the two F-shaped structural members 1 have a large difference. The two F-shaped structural members 1 are arranged symmetrically about the center, and the middle parts of the two F-shaped structural members 1 are fixedly connected. The head end beam 11 of one F-shaped structural member 1 A gap 3 is formed between a tail end 12 of another F-shaped structural member 1, and the first fiber grating 4 and the second fiber Bragg grating 5 are suspended in the gap 3, respectively.

[0028] When the temperature of the environment where the sensor is located changes, on the one hand, due to the thermal expansion effect of the fiber mate...

Embodiment 2

[0049] This embodiment further details the structure of embodiment 1. Specifically, in this embodiment, the double F-shaped fiber grating temperature sensor includes two F-shaped structural members 1, optical fibers 2, a first fiber grating 4, a second Fiber grating 5 and threaded joint 6.

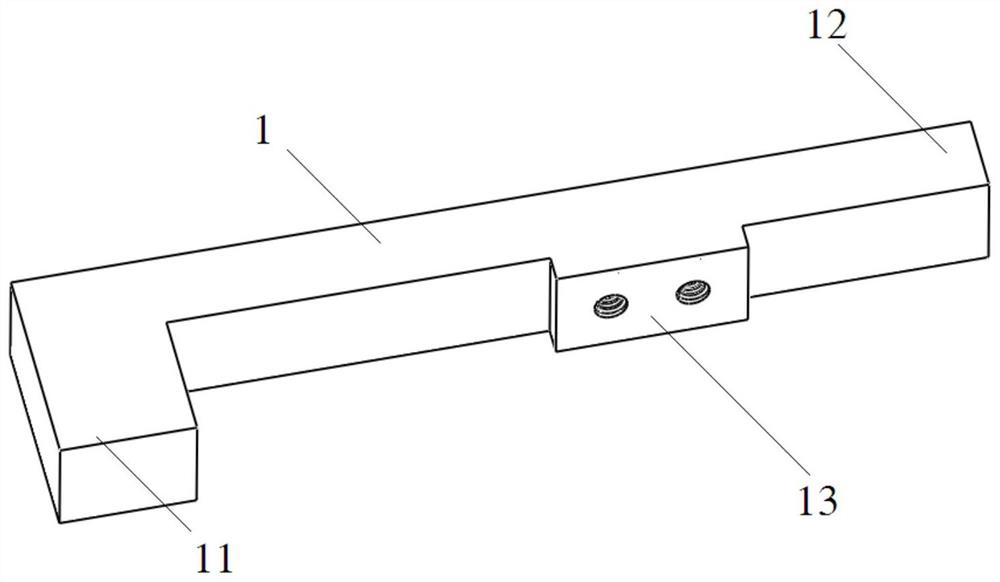

[0050] Such as image 3 As shown, the two F-shaped structural members 1 are both F-shaped structures with the same size, opposite end to end, but different materials. Each F-shaped structural member 1 includes a head end beam 11 , a tail end 12 and a middle beam 13 , wherein the tail end refers to the tail end point of the vertical bar connecting the head end beam 11 and the middle beam 13 . Wherein, gaps 3 are respectively formed between the head beam 11 of one F-shaped structural member 1 and the tail end 12 of the other F-shaped structural member 1 , and the lengths of the two gaps 3 are equal. The intermediate beams 13 of the two F-shaped structural members 1 are fixedly connected th...

Embodiment 3

[0056] In this embodiment, the F-shaped structural member 1 on the left is made of stainless steel, and the center wavelengths of the second fiber grating 5 and the first fiber grating 4 are 1550 nm and 1544 nm, respectively. Other components and the coupling relationship of the components are the same as in Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com