Optical fiber sensing array-type collecting system for coal-bed gas dynamic pressure measuring

An optical fiber sensing and dynamic pressure technology, which is used in measurement, earthmoving, wellbore/well components, etc., can solve the problem of single data point acquisition, difficult gas dynamic pressure distribution monitoring technology, and poor indication accuracy. to guarantee and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

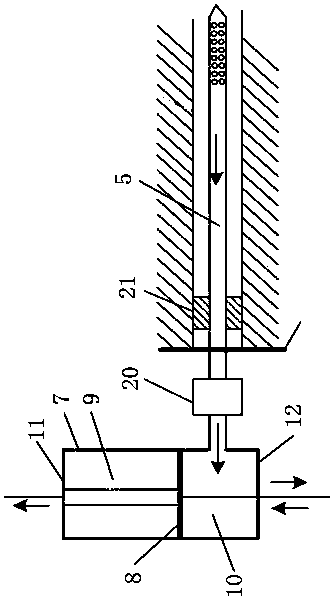

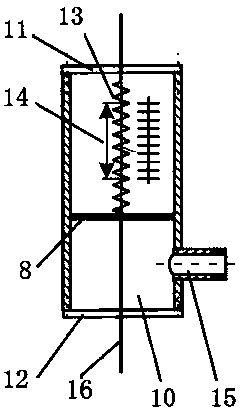

[0055] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

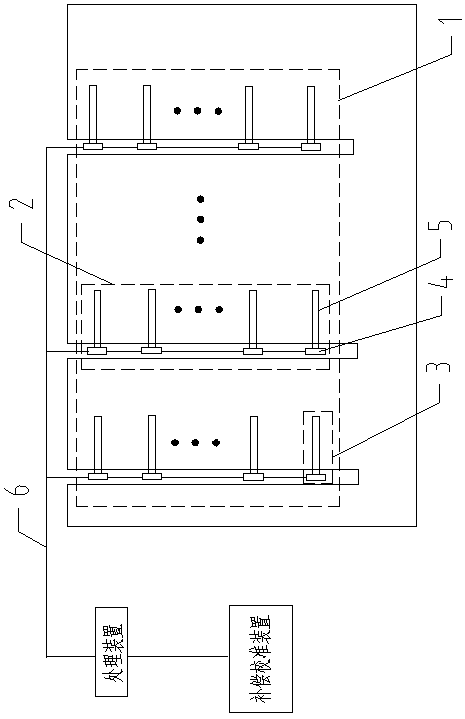

[0056] Such as figure 1 As shown, the optical fiber sensing array acquisition system for coal seam gas dynamic pressure measurement according to the present invention includes an optical fiber sensing array 1 and a processing device connected to the optical fiber sensing array 1 and a compensation calibration device connected to the processing device ;

[0057] The optical fiber sensing array 1 is used for real-time acquisition of gas pressure signals at various detection points or specified detection points in the measurement area, and converting the detected gas pressure signals into optical measurement signals and sending them to the processing device;

[0058] The processing device is used to receive the optical measurement signal corresponding to the gas pressure information of each or designated detection point in the measurement area sent by the optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com