Sealing surface free-grinding repairing method of slurry valve

A repair method and sealing surface technology, which is applied in the repair field of valves, can solve problems such as alumina slurry deposition, affecting valve performance, and valve unusability, and achieves the effect of a simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

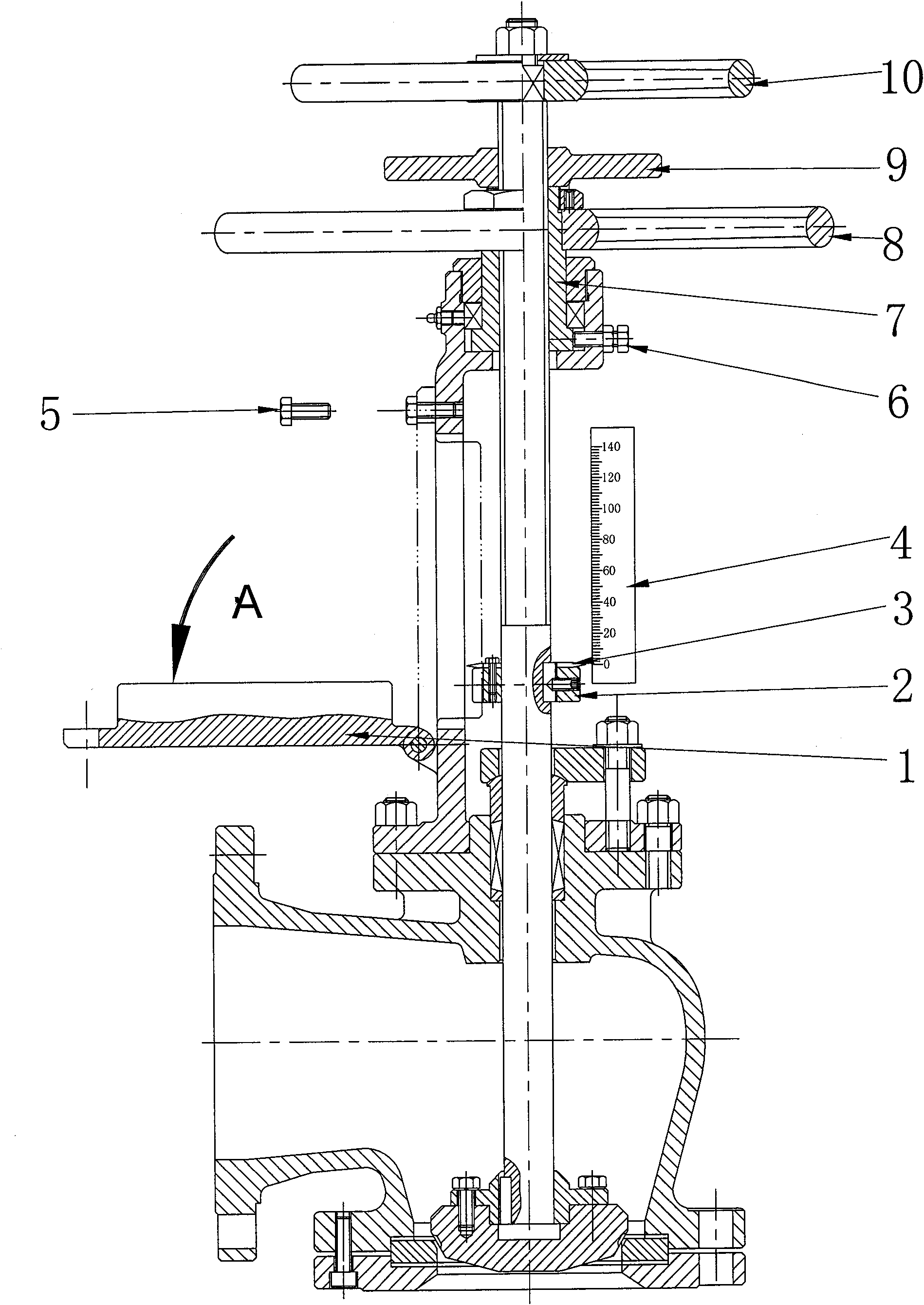

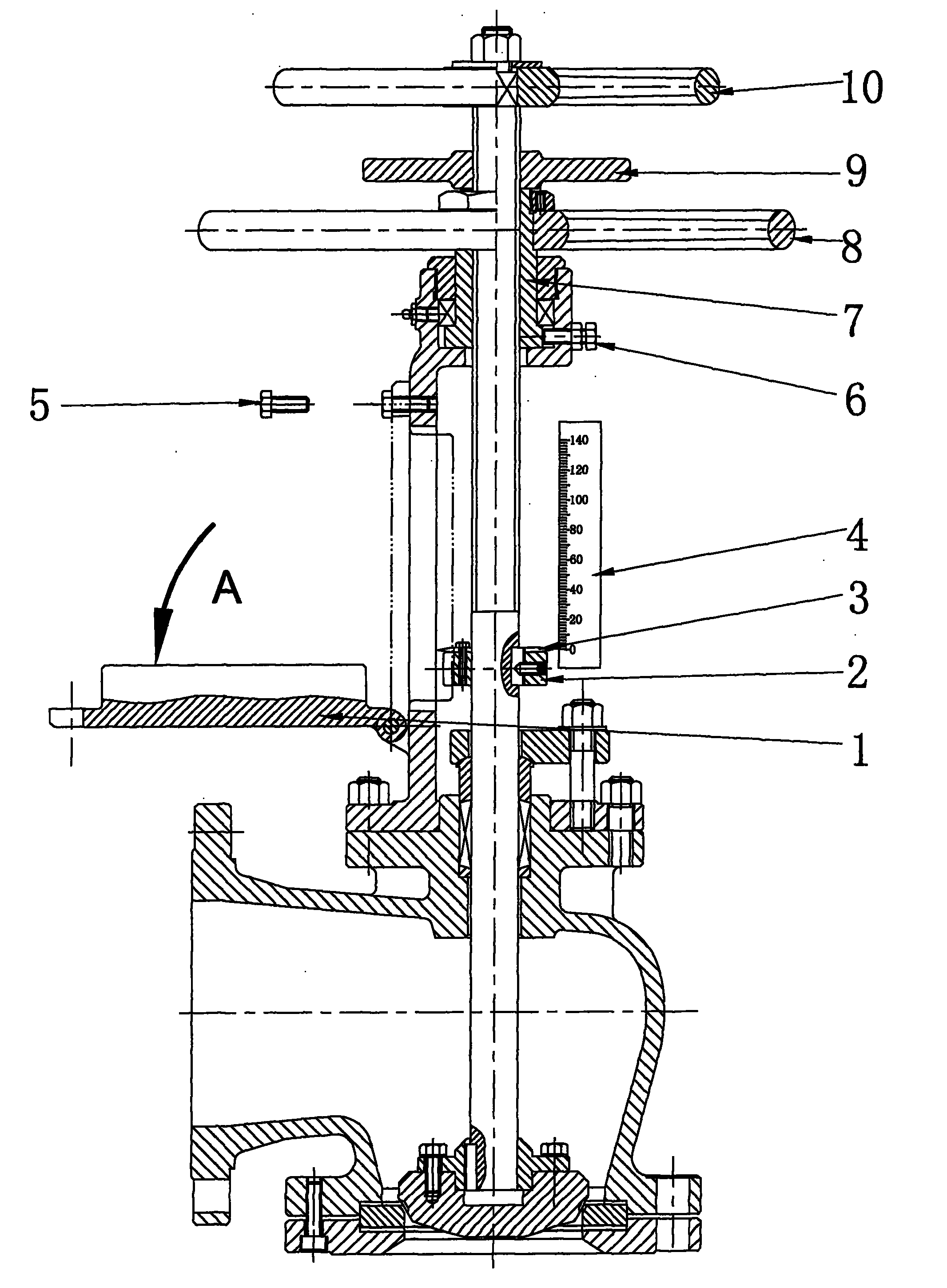

[0025] Shown in embodiment 1 is the handwheel transmission valve, and its grinding repair method is:

[0026] 1) Remove the guide plate fixing screw 5, turn the guide plate 1 to the left (direction indicated by arrow A), and make the guide rib on the guide plate separate from the guide groove on the anti-rotation plate 2.

[0027] 2) Loosen the lock nut on the stem nut 7 and set screw 6, and tighten the screw 6 to lock the stem nut.

[0028] 3) Turn the hand wheel 10 to make the valve disc contact with the valve seat, and pay attention to the contact pressure between the valve disc and the valve seat should be controlled at an appropriate level (too large contact pressure will cause the grinding not to be brisk, or even unable to grind; if the contact pressure is too small , resulting in low grinding efficiency).

[0029] 4) Tighten the valve stem lock nut 9 so that the valve stem and the valve stem nut 7 are tightly fixed to each other (they will not rotate freely).

[0030...

Embodiment 2

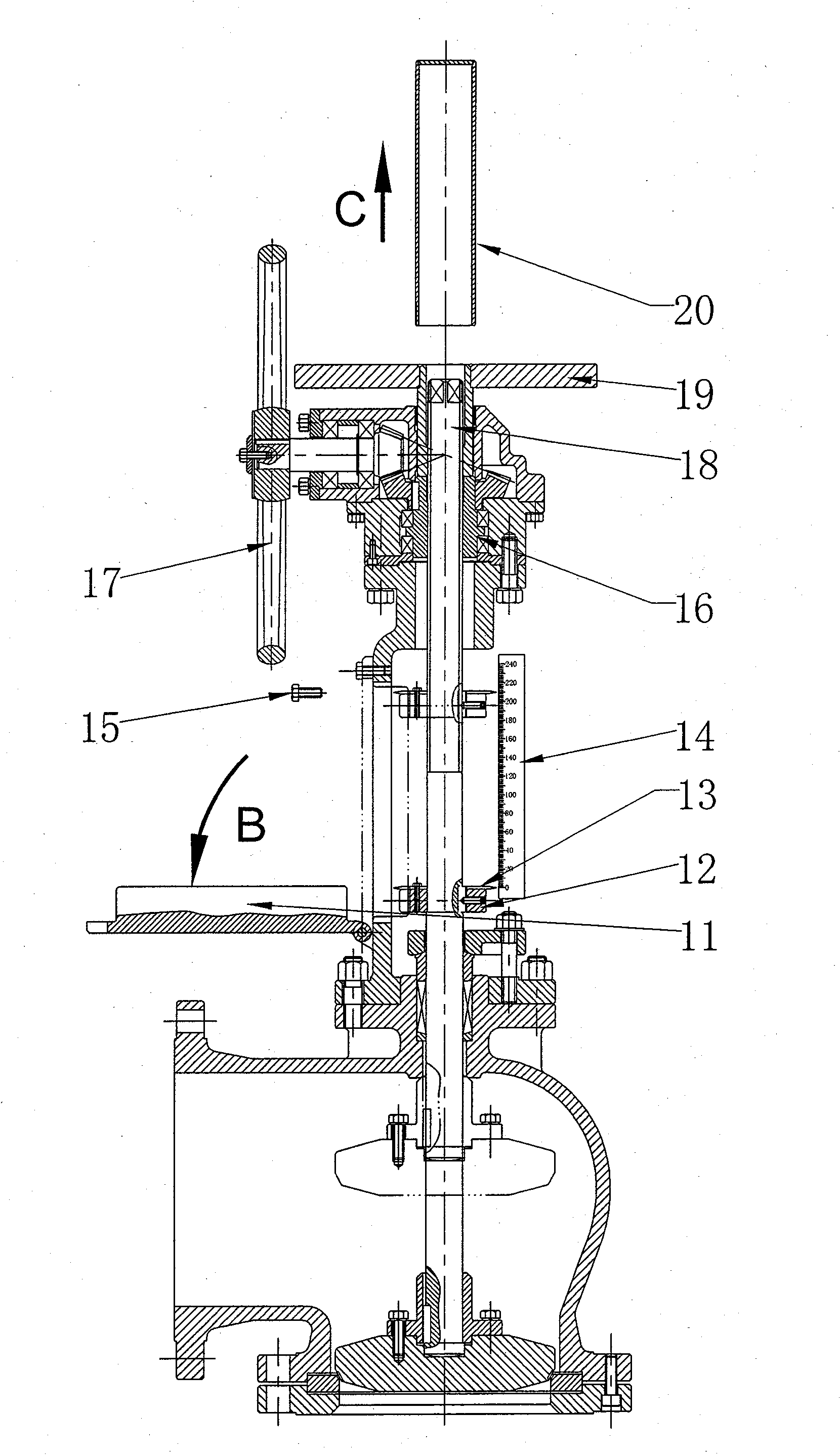

[0035] Shown in Example 2 is a gear drive valve whose grinding repair method is:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com