Cache type non-stop PCB feeding device

A feeding device and PCB board technology, applied in the field of PCB board manufacturing, can solve the problems of affecting production efficiency and low feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

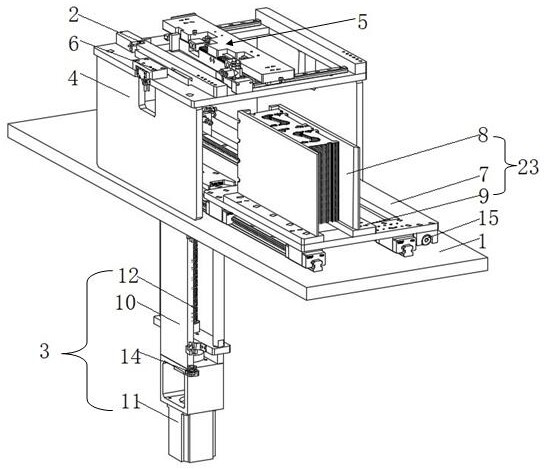

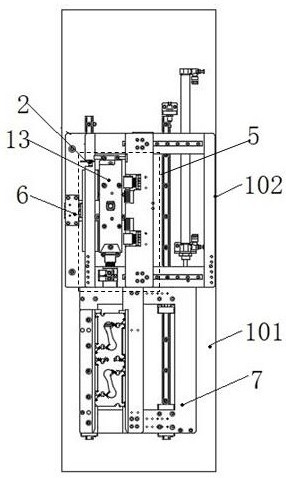

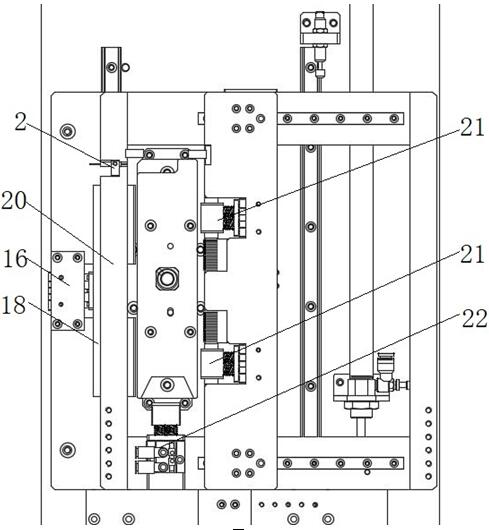

[0028] Such as figure 1 , figure 2 Shown is a buffer type non-stop PCB feeding device provided by the present invention, including a workbench 1 and a PCB silo 23 for placing PCB boards. The PCB silo 23 is located above the workbench 1, and the PCB silo 23 The bottom of the bottom is slidingly connected along the length direction of the workbench, and the workbench is divided into a feeding station 101 and a feeding station 102; the bottom of the feeding station 101 is used to lift the PCB in the PCB silo 23 upwards to The jacking mechanism 3 of the feeding position; a positioning frame 4 is set on the feeding station 101, a positioning assembly 5 for positioning the PCB board circumferential direction is set on the positioning frame 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com