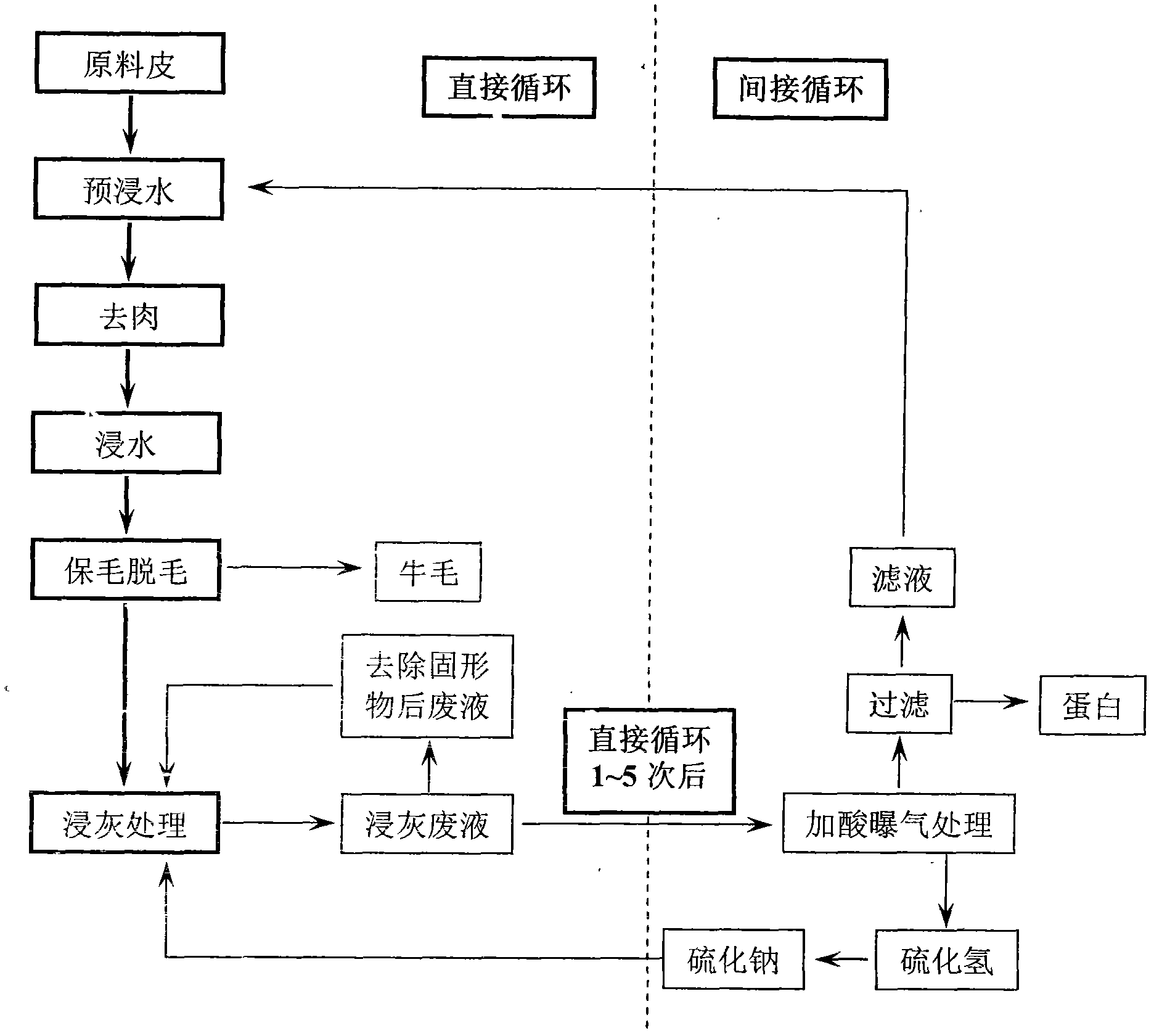

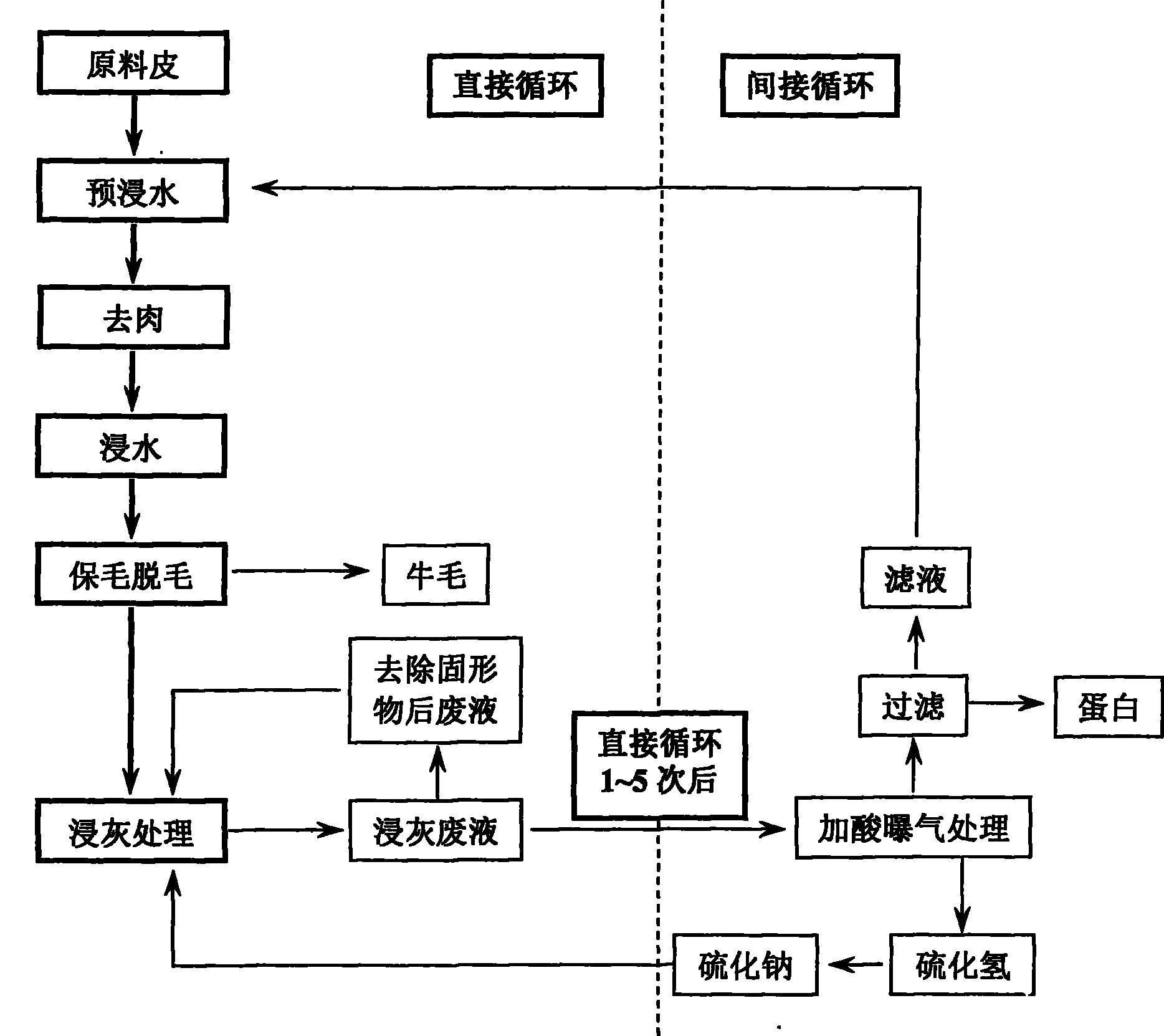

Hair-protection unhairing and liming waste liquor recycling method

A technology for hair preservation and depilation and waste liquid recycling, which is applied in the field of hair preservation and depilation and liming waste liquid recycling, which can solve the problems of high processing cost and low protein content, achieve low organic matter content, complete shape of shed hair, and overcome Cleansing effect with limited effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] (1) Weighing: Weighing the cow salt wet skin, which is used as the basis for the following materials;

[0051] (2) Pre-soaking water: 300wt% of water, the combination of rotating and stopping the drum for 8 hours, and controlling to dry;

[0052] (3) De-meat: remove the meat;

[0053] (4) Soaking in water: 200wt% of water, combined with the drum turning and stopping for 18 hours, and controlling to dry;

[0054] (5) Hair preservation and depilation, liming: water 150wt%, sodium thioglycolate 2%, rotate for 1 hour, add lime 1%, rotate for 30 minutes and start bath liquid circulation to filter and remove hair, stop bath liquid circulation after depilation for 1 hour , add 2% sodium sulfide, 2% lime and 100% water to carry out liming treatment, stop for a total of 15 hours, the gray skin comes out of the drum, collect liming waste liquid, filter to remove solid impurities, and set aside.

Embodiment 2

[0056] (1) Weighing: Weighing the cow salt wet skin, which is used as the basis for the following materials;

[0057] (2) Pre-soaking water: 250wt% of water, the combination of rotating and stopping the drum for 10 hours, and controlling to dry;

[0058] (3) De-meat: remove the meat;

[0059] (4) Soaking in water: 250wt% of water, combined with the rotating and stopping of the drum for 20 hours, controlled to dry;

[0060] (5) Hair preservation and depilation, liming: water 150wt%, mercaptoethanol 1.5%, rotate for 1 hour, add lime 1.5%, rotate for 30 minutes and start bath circulation to filter hair removal, stop bath circulation after depilation for 1 hour, Add 1% sodium sulfide, 1% lime and the liming waste liquid in 100% embodiment 1 and carry out liming process, stop for 18 hours altogether, the gray skin goes out drum, collect liming waste liquid, filter and remove solid matter impurity, wait use.

Embodiment 3

[0062] (1) Weighing: Weighing the cow salt wet skin, which is used as the basis for the following materials;

[0063] (2) Pre-soaking water: 250wt% of water, the combination of rotating and stopping the drum for 10 hours, and controlling to dry;

[0064] (3) De-meat: remove the meat;

[0065] (4) Soaking in water: 250wt% of water, combined with the rotating and stopping of the drum for 20 hours, controlled to dry;

[0066] (5) Preservation and depilation, liming: 150wt% water, 1.5% mercaptoethanol, rotate for 1 hour, add 1.5% lime, rotate for 30 minutes and start bath circulation to filter and remove hair, stop bath circulation after 1 hour of depilation, Add 1% sodium sulfide, 1% lime and 100% liming waste liquid in Example 1 to carry out liming treatment, stop for a total of 18 hours, the gray skin will go out of the drum, collect liming waste liquid, and filter to remove solid impurities.

[0067] (6) Reuse the liming waste liquid collected in (5) for the second time in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com