Method and special device for heterogeneous catalyzed synthesis of triacetonamine

A technology of heterogeneous catalysis and heterogeneous catalyst, applied in chemical instruments and methods, methods of chemically changing substances by atmospheric pressure, organic chemistry, etc. Alkali organic wastewater, low yield, etc., to reduce the difficulty of water treatment, avoid high salinity wastewater, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

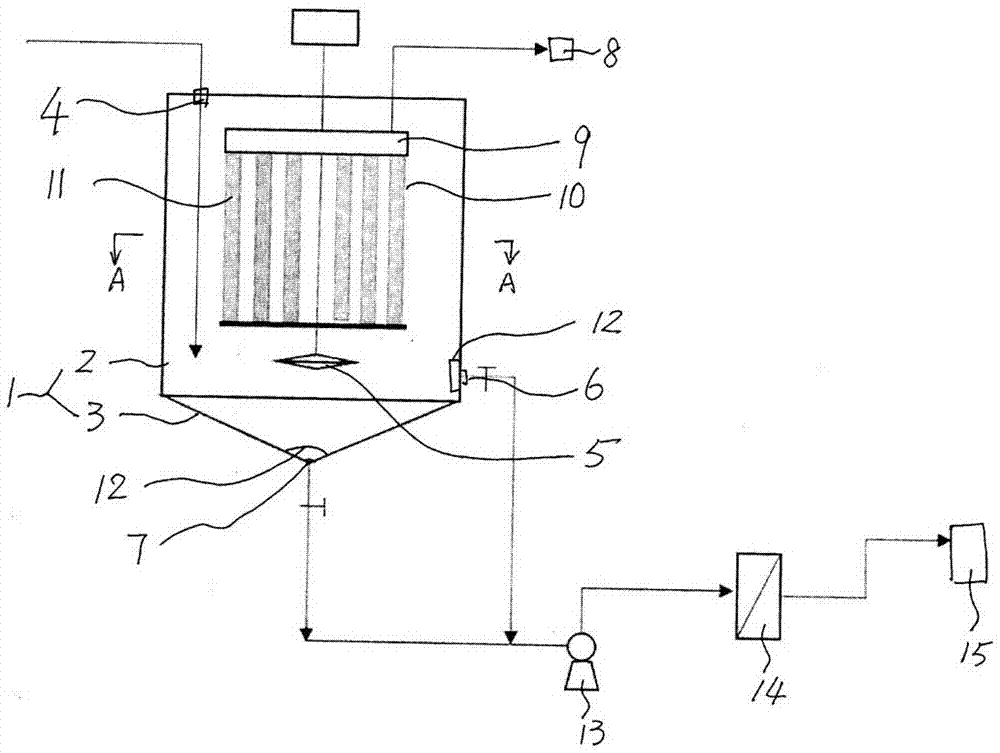

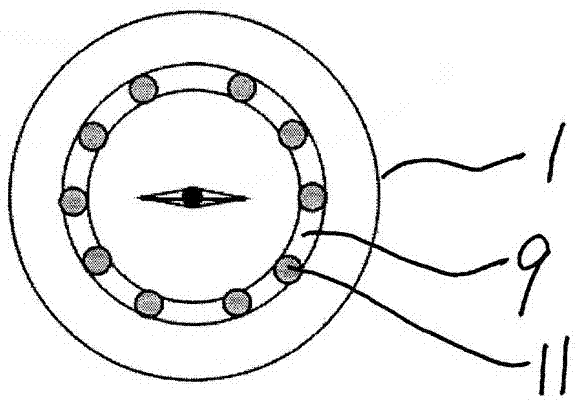

[0036] (1) Add 1000kg of organic sulfonic acid-modified ion exchange resin catalyst into the 5000L reactor, so that the catalyst enters the cone section reactor body 3 in the reactor;

[0037] (2) Add 2500kg of acetone to the reactor;

[0038] (3) Start the stirring mechanism and control the speed at 500 rpm, and heat the kettle to 45°C;

[0039] (4) Pass 122kg of ammonia gas into the kettle, and control the temperature of the kettle to 65°C;

[0040] (5) Open the water separator to divide the water, and keep the vacuum at -0.95MPa;

[0041] (6) Keep the kettle temperature at 65°C for 6 hours;

[0042] (7) Turn on the cooling water to reduce the temperature of the kettle to 45°C;

[0043] (8) Stop stirring and water separator, let it stand for 30 minutes, discharge the reaction liquid through the main and auxiliary discharge holes, and discharge through the pump 13 filter 14 to obtain the crude product of triacetone amine, which is analyzed by gas chromatography and the con...

Embodiment 2

[0046] (1) Add 500kg of ferric chloride-loaded molecular sieve catalyst into the 5000L reactor, so that the catalyst enters the cone section kettle body 3 in the reactor;

[0047] (2) Add 2500kg of acetone to the reactor;

[0048] (3) Turn on the stirring speed of 390 rpm, and heat the kettle to 45°C;

[0049] (4) Pass 183kg of ammonia gas into the kettle, and control the temperature of the kettle to 67°C;

[0050] (5) Open the water separator to separate the water, and keep the vacuum at -0.95MPa;

[0051] (6) Keep the kettle temperature at 67°C for 8 hours;

[0052] (7) Turn on the cooling water to reduce the temperature of the kettle to 45°C;

[0053](8) Stop stirring and water separator, let it stand for 30 minutes, discharge the reaction liquid through the main and auxiliary discharge holes, and discharge through the pump 13 and filter 14 to obtain the crude product of triacetone amine, which is analyzed by gas chromatography, and the conversion of acetone The rate is...

Embodiment 3

[0056] (1) Add 100kg of nano-alumina modified catalyst to the 5000L reactor;

[0057] (2) Add 2500kg of acetone to the reactor;

[0058] (3) Turn on the stirring speed of 250 rpm, and heat the kettle to 45°C;

[0059] (4) Pass 183kg of ammonia gas into the kettle, and control the temperature of the kettle to 62.5°C;

[0060] (5) Open the water separator to divide the water, and keep the vacuum at -0.95MPa;

[0061] (6) Keep the kettle temperature at 62.5°C for 4 hours;

[0062] (7) Turn on the cooling water to reduce the temperature of the kettle to 45°C;

[0063] (8) Stop stirring and water separator, let it stand for 30 minutes, discharge the reaction liquid through the main and auxiliary discharge holes, and discharge through the pump 13 and filter 14 to obtain the crude product of triacetone amine, which is analyzed by gas chromatography, and the conversion of acetone The rate is 45.1%, and the selectivity of triacetonamine is 67.9%;

[0064] (9) The crude product ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com