Patents

Literature

54results about How to "No stay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

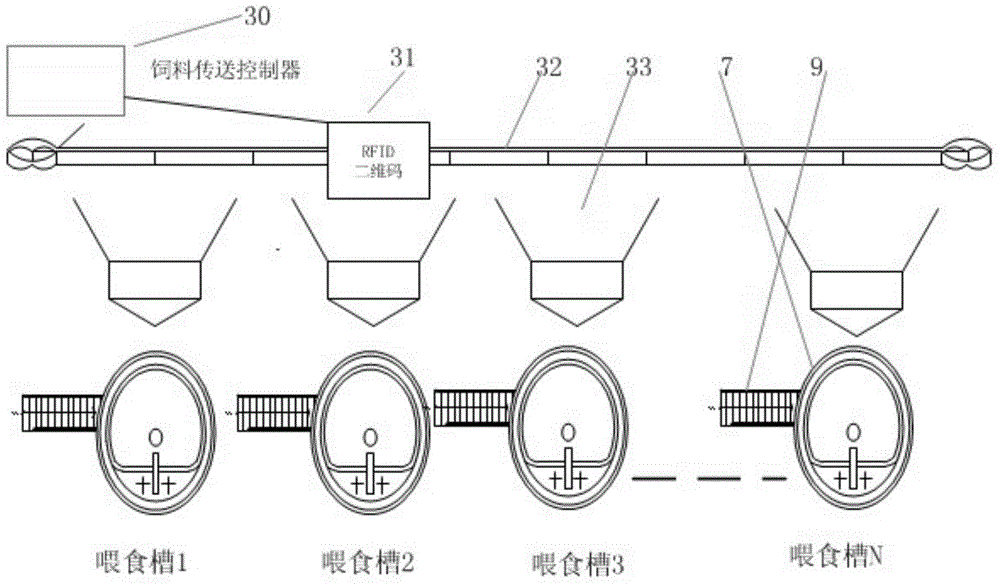

Traceable livestock breeding method

InactiveCN104700314AReduce farming personnelReduce farming labor costsData processing applicationsAnimal husbandryLivestockEngineering

The invention discloses a traceable livestock breeding method which includes the steps: (1) building a traceable management cloud service platform; (2) marking ear tags capable of recognizing individual information and attaching a leg ring to each livestock; (3) building a traceable unit feeding system; (4) building a traceable livestock farm; (5) building a traceable slaughtering system; (6) building a traceable logistic transportation system. The livestock is traceable in the whole process from young selection to breeding, slaughtering, transportation and consumers, livestock quality safety and breeding benefits are improved, and environmental management and supervision are more perfect.

Owner:牛光涛

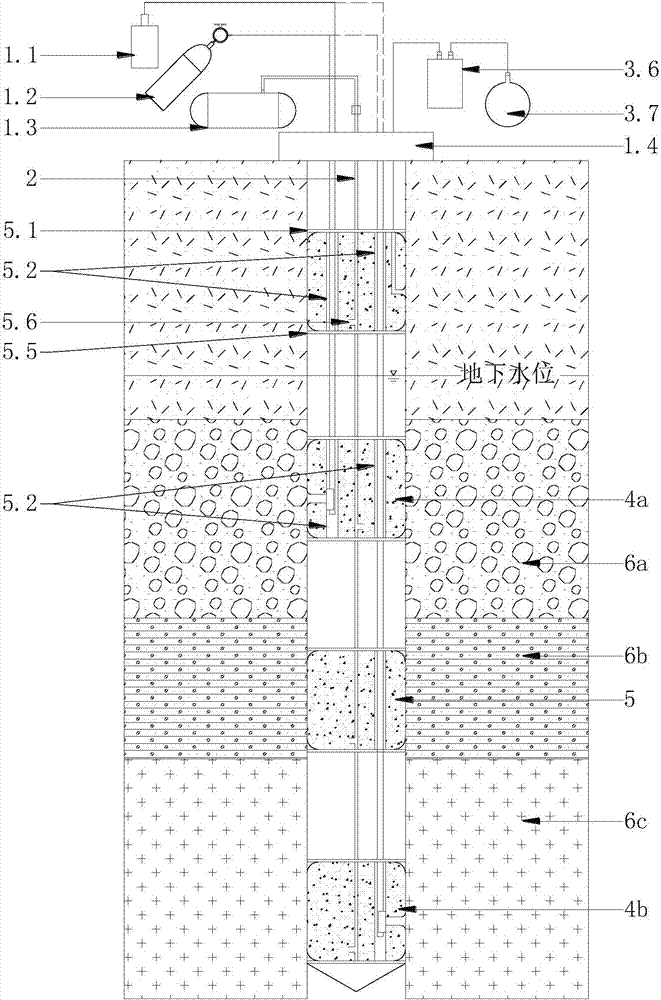

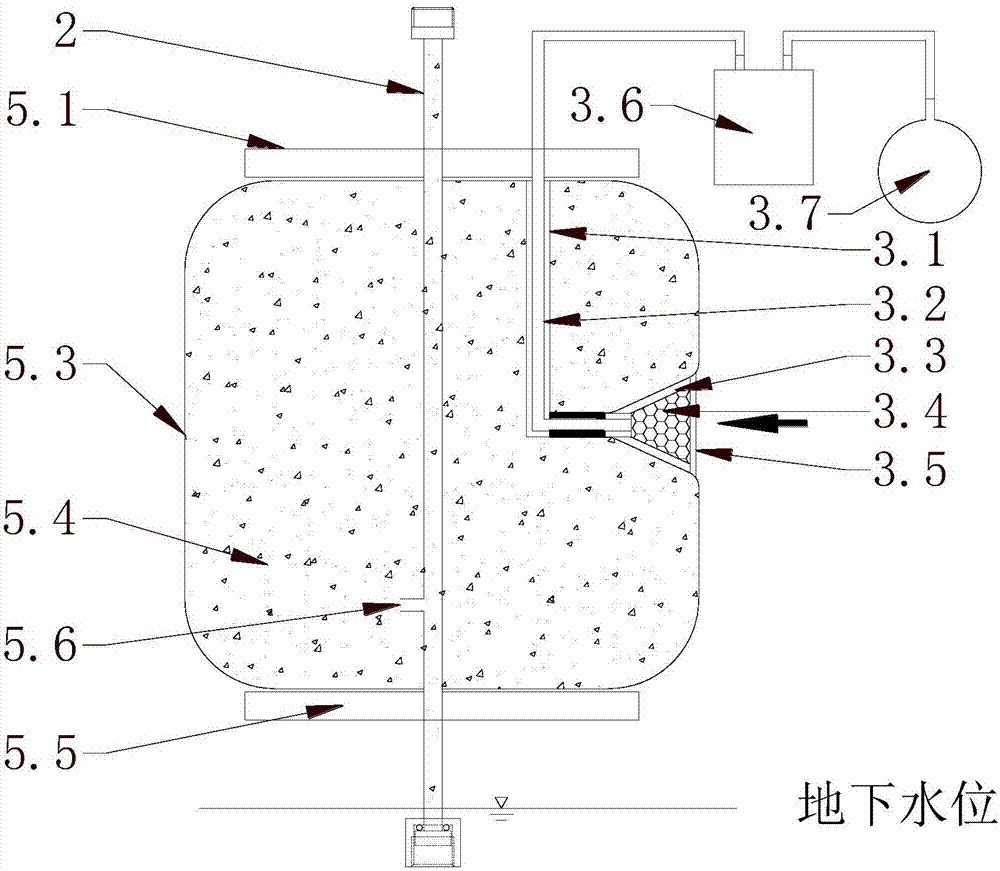

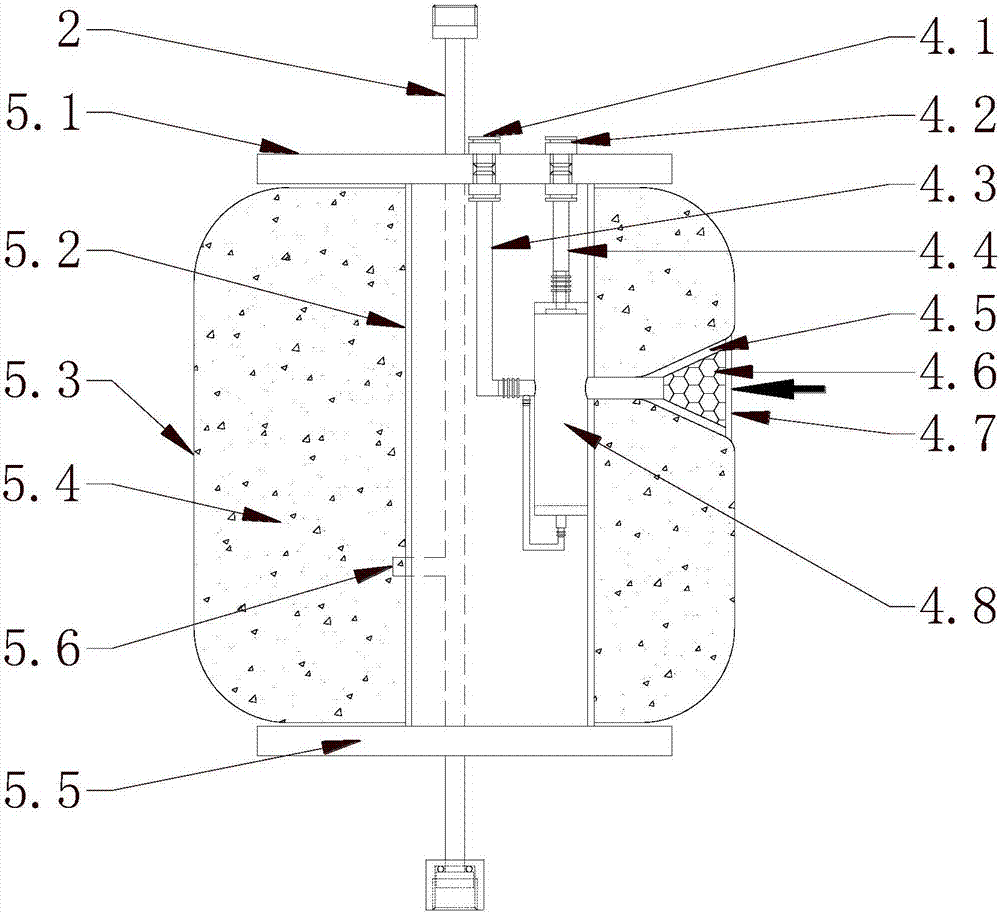

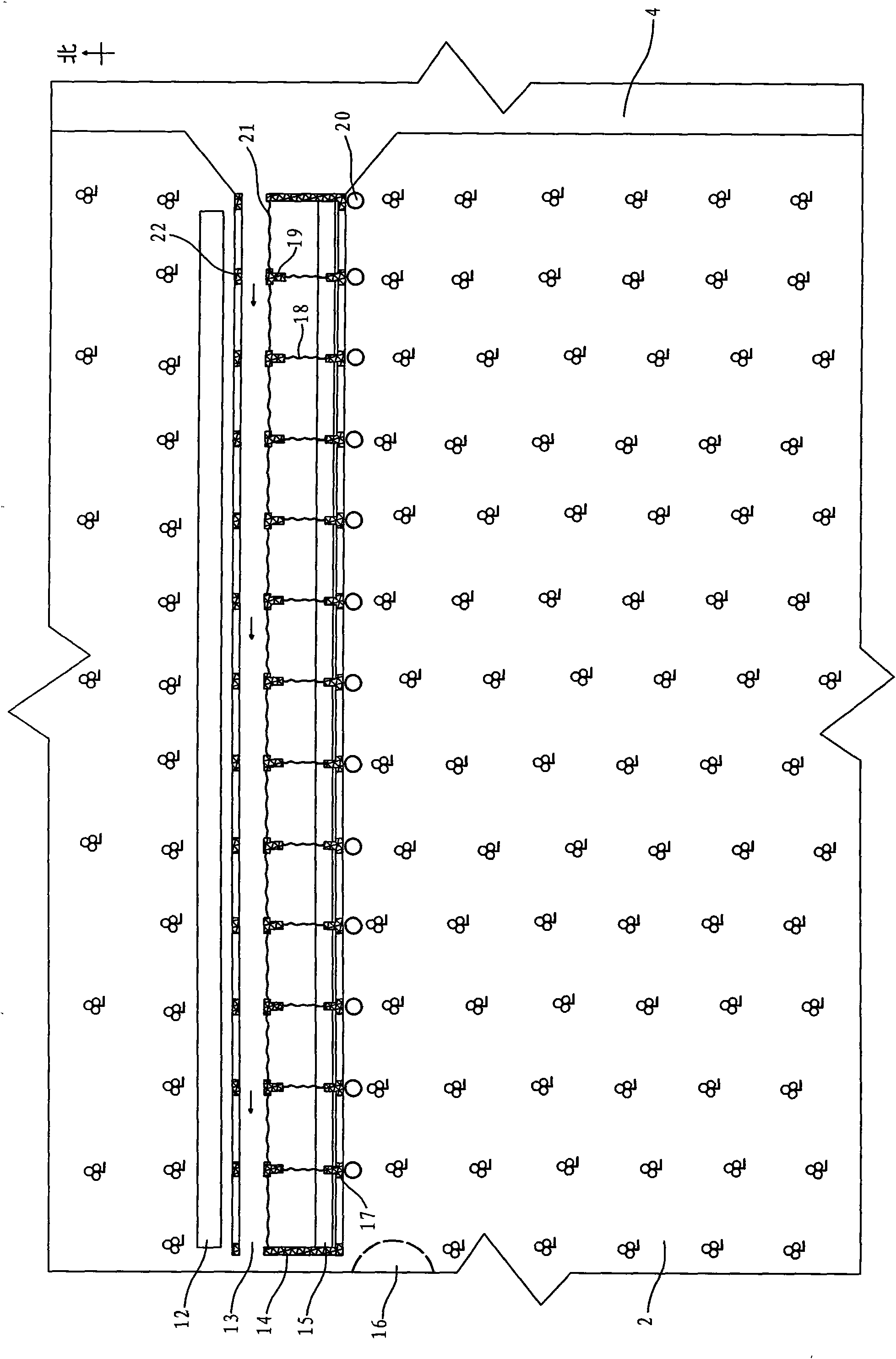

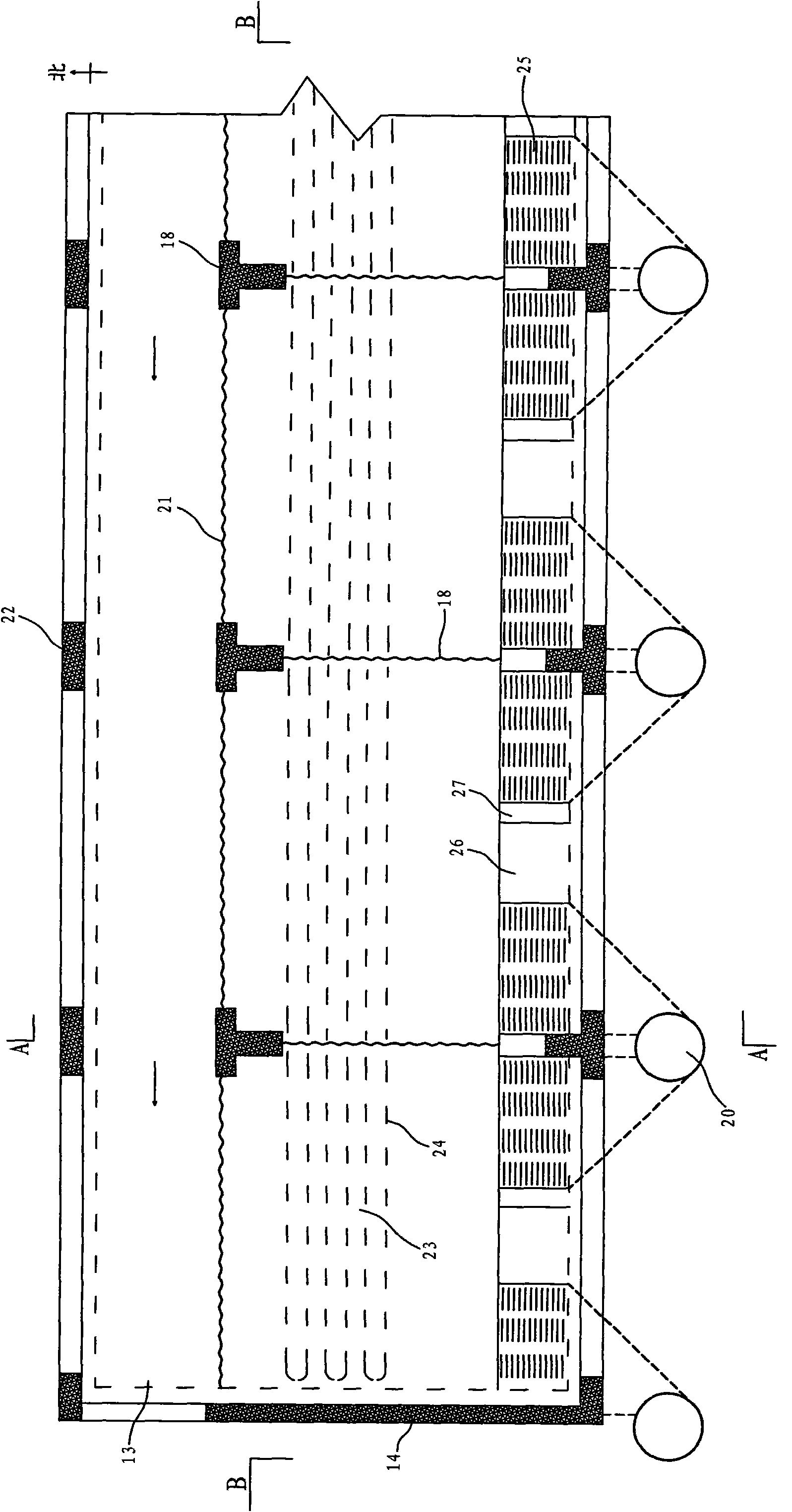

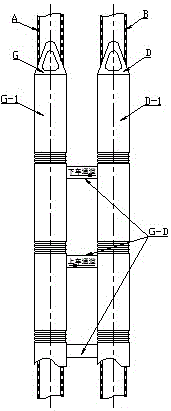

U-shaped pipe underground fluid multilayer sampling device

ActiveCN107023289ADisadvantages of avoiding reverse pressure overloadAvoid enteringBorehole/well accessoriesSupporting systemUnderwater

The invention provides a U-shaped pipe underground fluid multilayer sampling device. The U-shaped pipe underground fluid multilayer sampling device comprises a ground auxiliary system, a supporting system, a gas getting unit, water getting units and interlayer packers. The gas getting unit, the water getting units and the packers are arranged on a supporting connection rod of the supporting system. The gas getting unit is arranged in an aeration zone above a water table, the water getting units are arranged below the water table, the packers are mixed with the gas getting unit and the water getting units, waterpower incontinuity of upper parts and lower parts of sampling units in sampling layers of different aquifers or the same aquifer is achieved, and underwater of the different aquifers is sealed and cannot be mutually disturbed by drilled channels. The U-shaped pipe underground fluid multilayer sampling device is simple and novel in structural design and free of starting pressure, the service life of equipment is prolonged, the sample introduction speed is increased, the cost is reduced, and the application range is wider.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

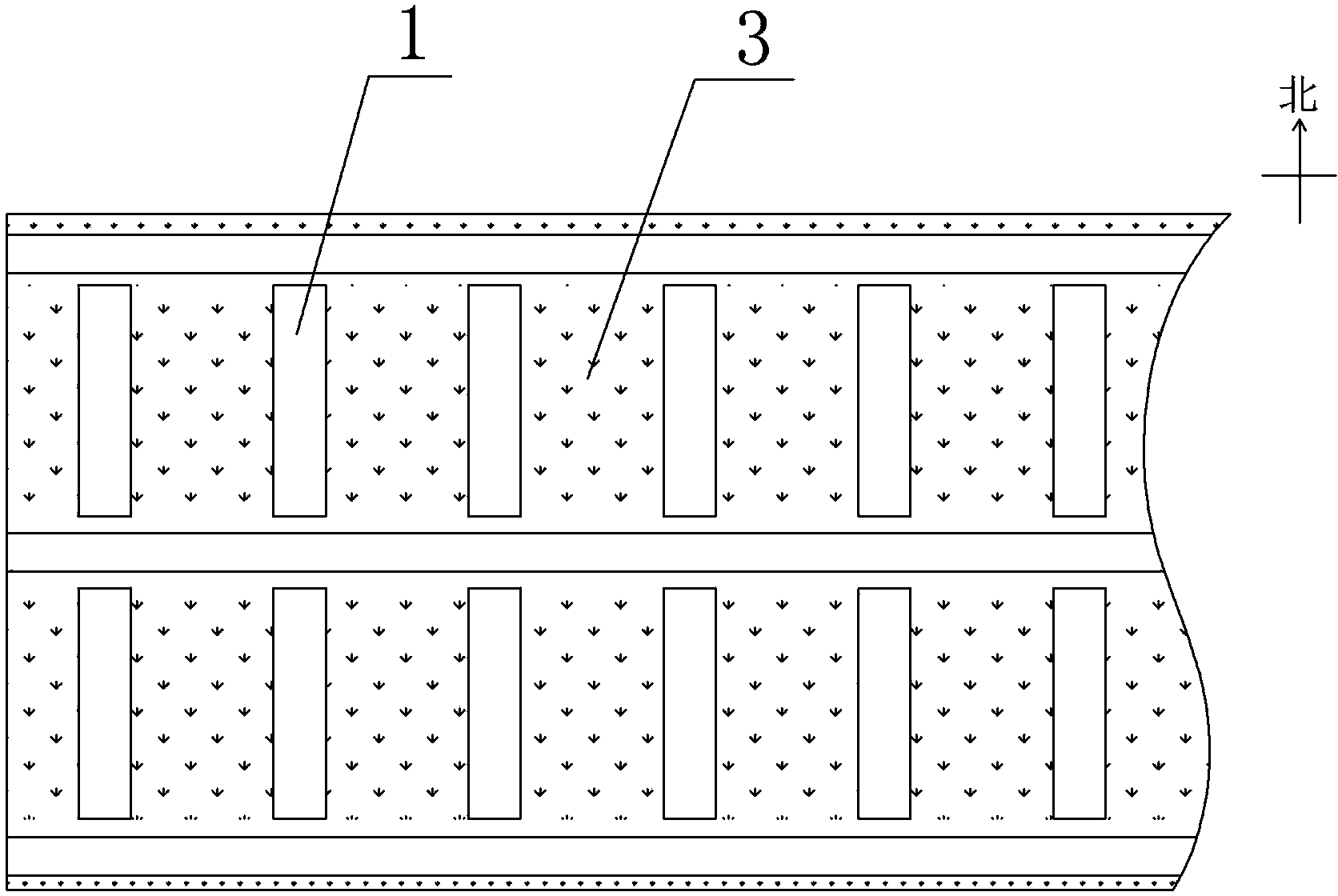

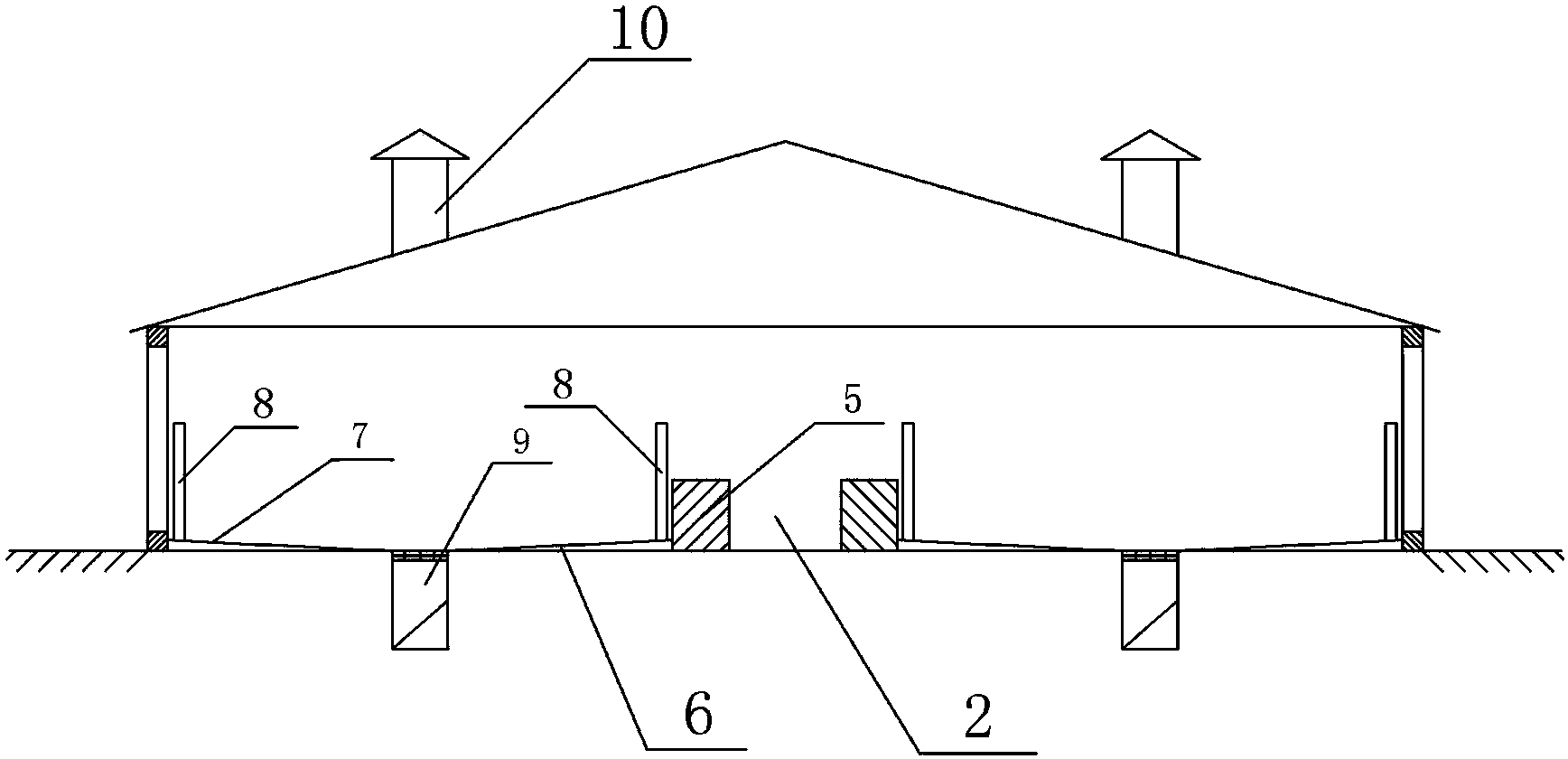

Healthy cattle farm and cattle raising method

ActiveCN103918562AClean and comfortable environmentFresh airAnimal feeding stuffAnimal housingEnvironmental hygieneAgricultural science

The invention discloses a healthy cattle farm and a cattle raising method. The healthy cattle farm and the cattle raising method aim at solving the technical problems that an existing intensive type cattle farm is unreasonable in layout, poor in environment sanitary condition and not favorable for organic ecological breeding. The healthy cattle farm is characterized in that feed troughs, feeding areas and rest areas are arranged in each cattle housing; a urine collection blind channel is arranged between each feeding area and the corresponding rest area, the ground in each feeding area inclines upwards gradually from one end close to the urine collection blind channel to the corresponding other end, and the ground in each rest area inclines upwards gradually from one end close to the urine collection blind channel to the corresponding other end; embedded type urine storage pools communicated with the corresponding urine collection blind channels are arranged outside the cattle housings. The two ends, communicated with the outside, of each urine collection channel are provided with air draft chimneys which are higher than roofs of the cattle housings. According to the cattle raising method, the healthy cattle farm is adopted as a raising place for originally ecological and healthy breeding. The healthy cattle farm is reasonable in structural layout, clean, tidy and comfortable in environment, beneficial for reducing germ breeding so that cattle can grow healthily, and beneficial for increasing benefits of the cattle raising industry, and has a wide market prospect.

Owner:郭群然

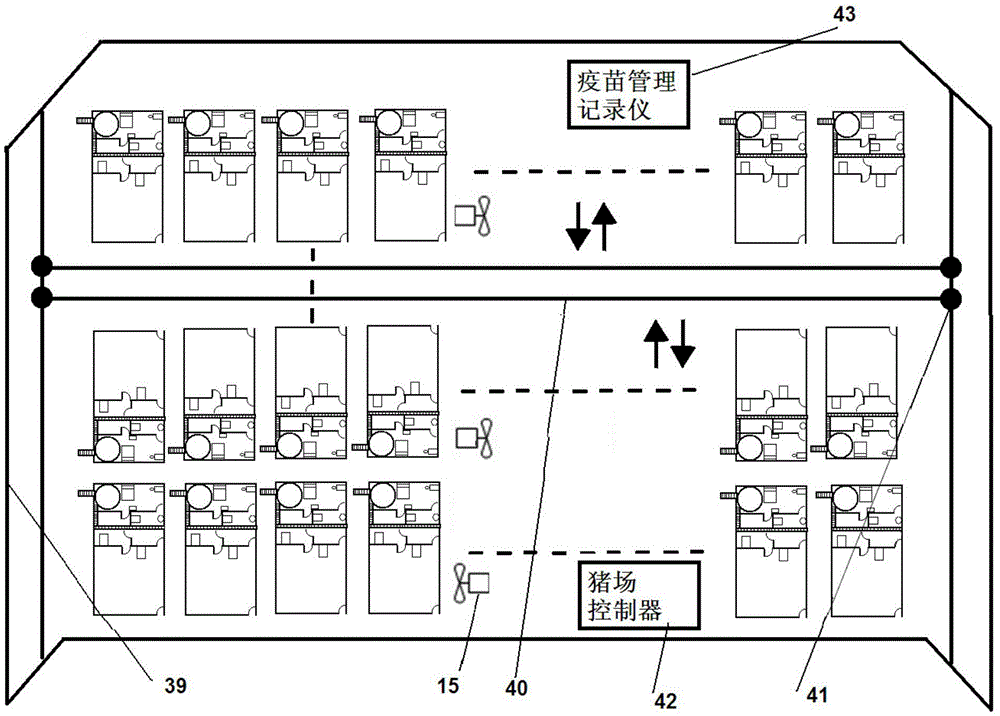

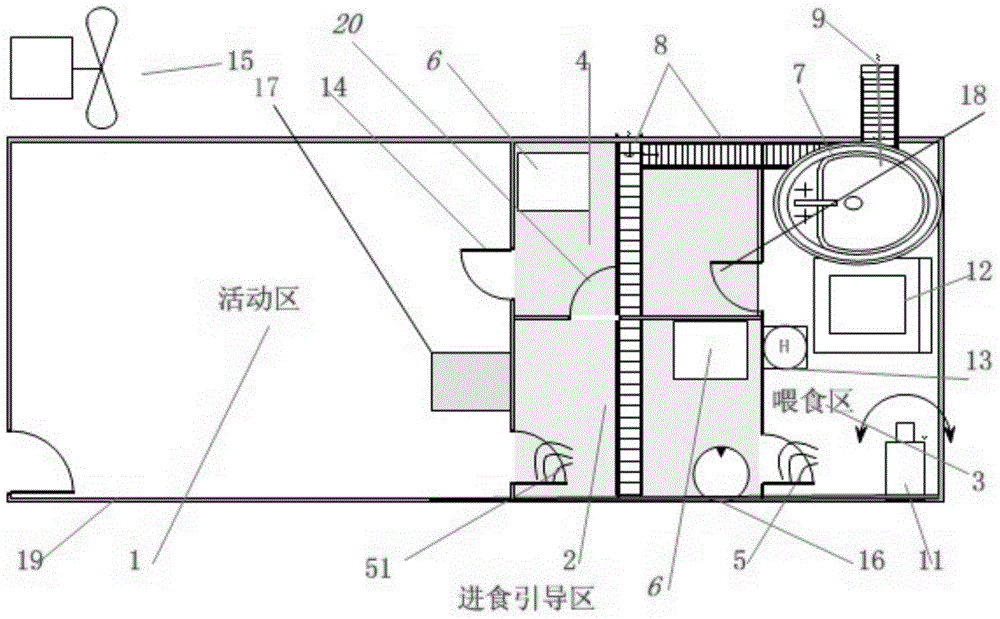

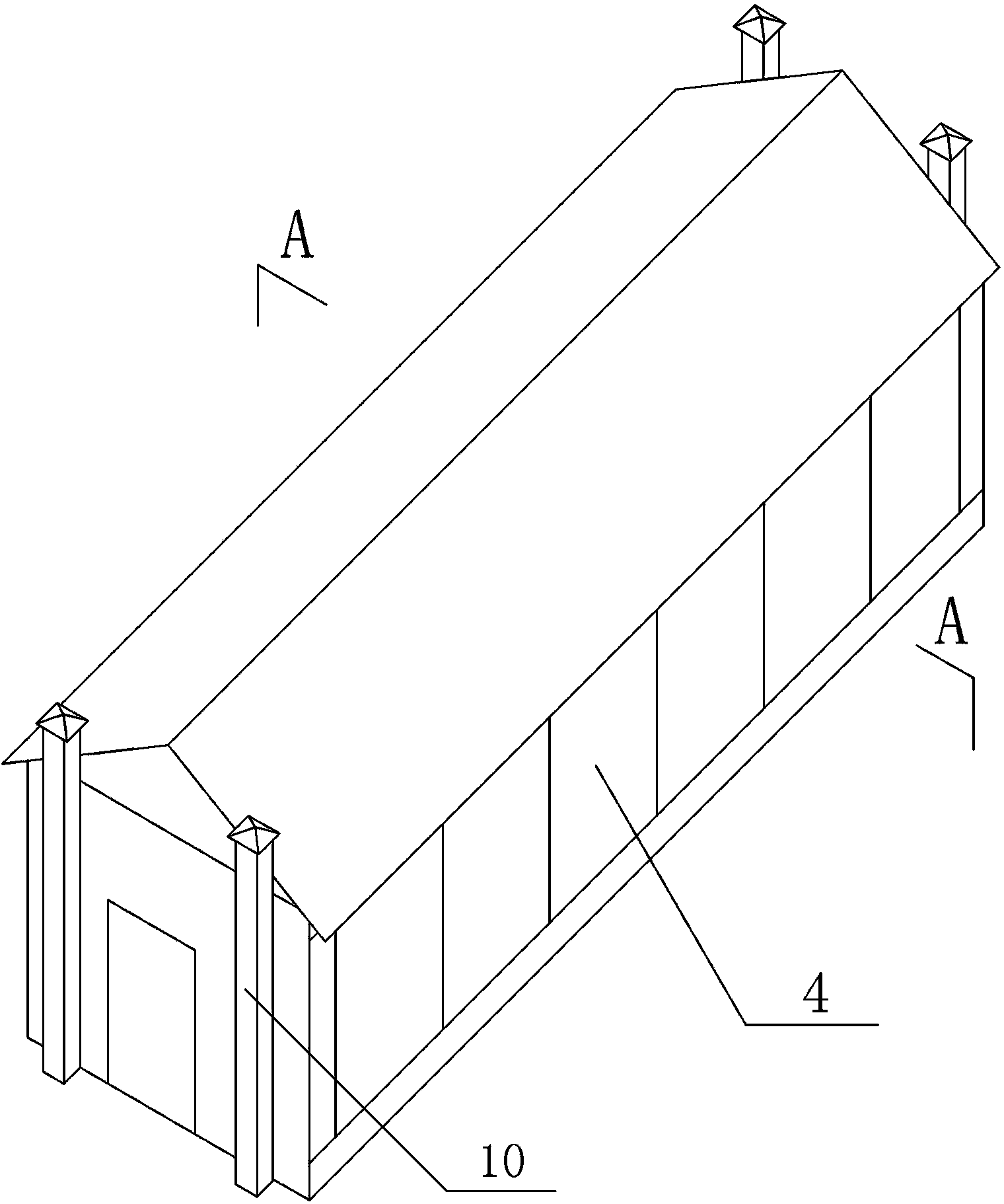

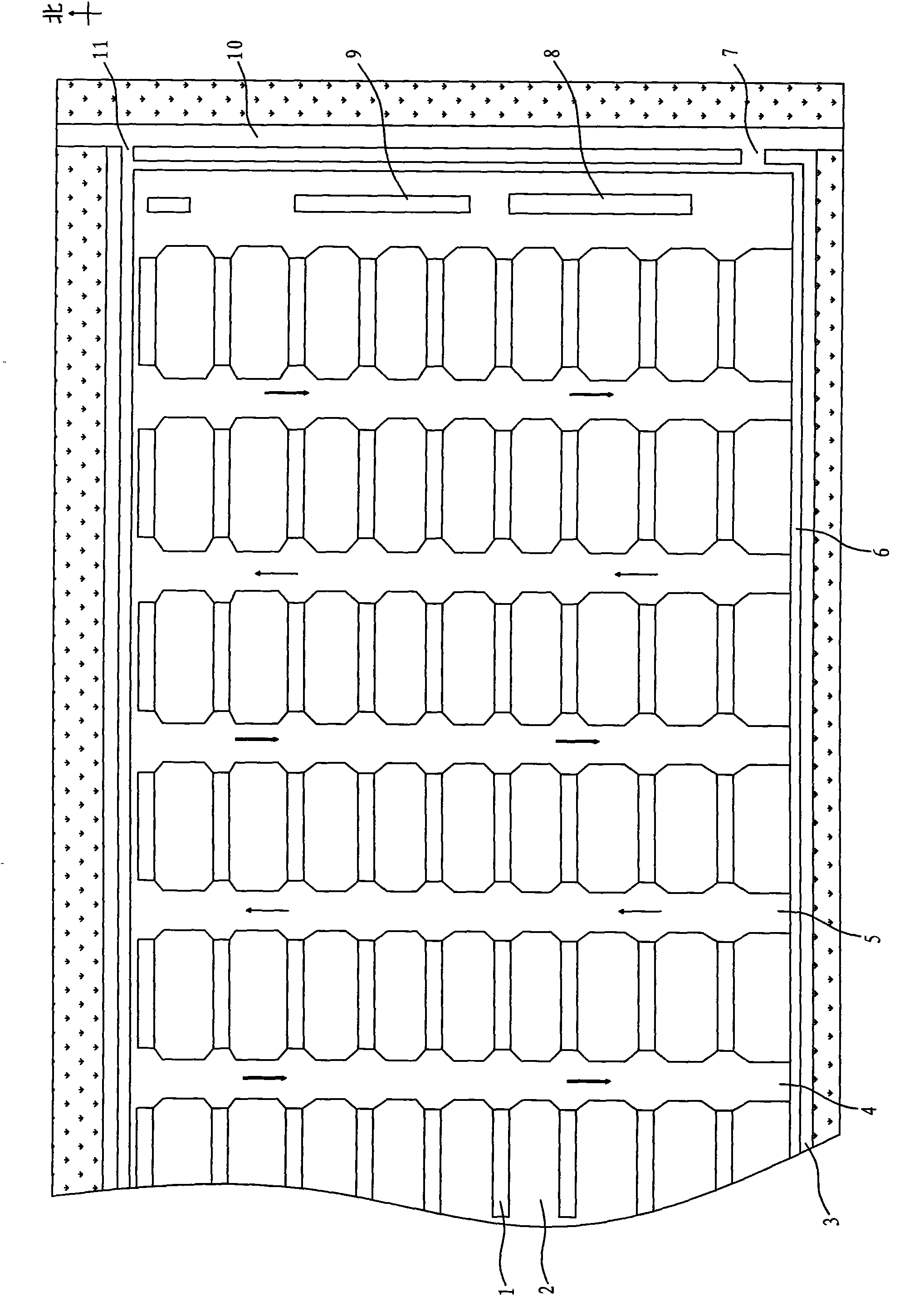

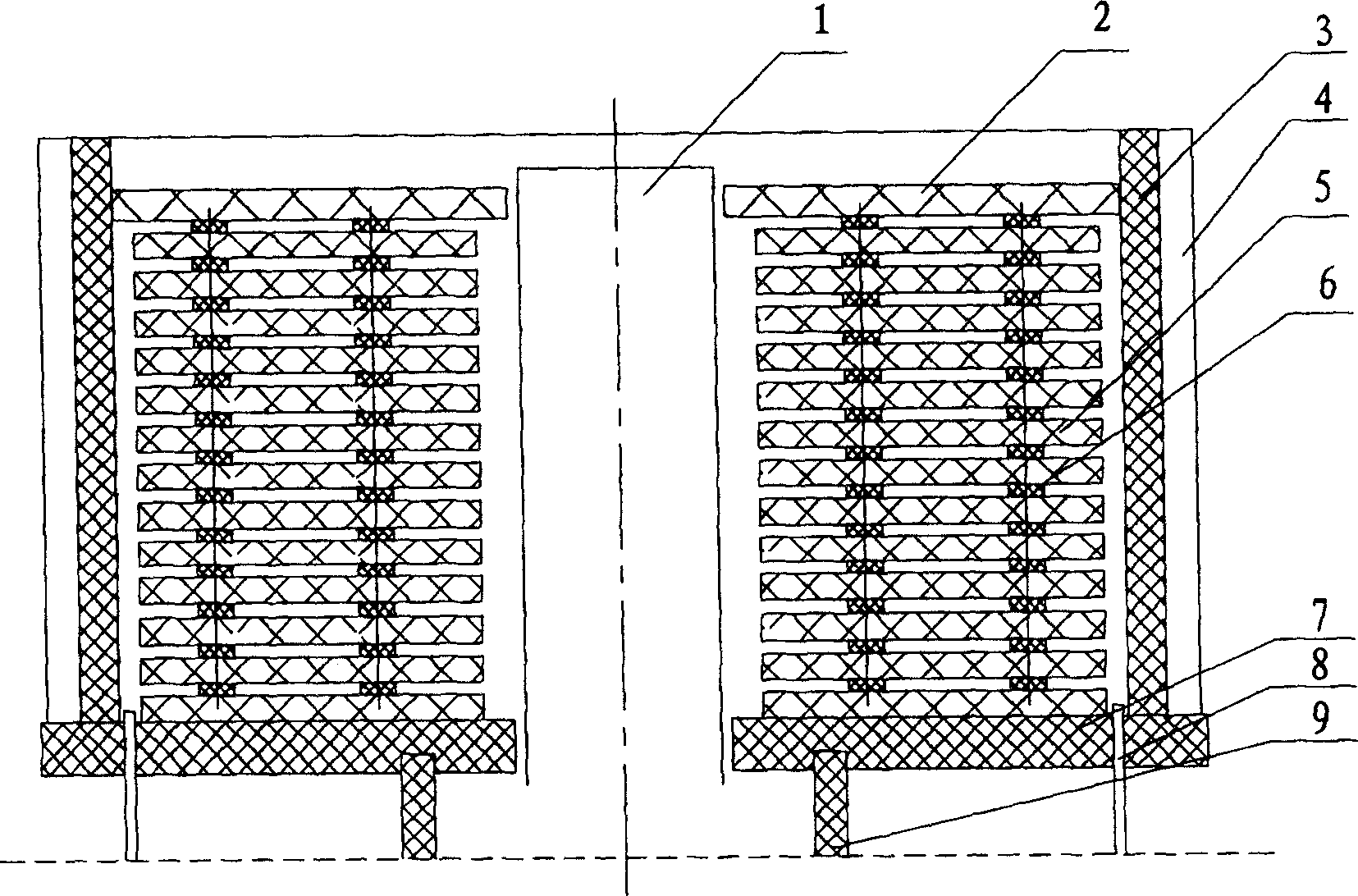

Original ecological pig farm and original ecological pig breeding method

InactiveCN101889553ANo stayUnobstructed ventilationAgricultural buildingsAnimal feeding stuffPig farmsDisease

The invention relates to an original ecological pig farm and an original ecological pig breeding method. The interval between front and rear rows of piggeries of the pig farm is more than or equal to 15m; and the activity space of pigs is formed and shade trees are planted among the piggeries; each unit piggery has large ventilation and light-transmitting area; each piggery is provided with a heat-insulating sleeping area, a manure discharge area, a manure discharge hidden channel, an inner suction dirty gas pumping device, a bathing place for cooling the pigs in hot summer days, a manure collection and hazard-free treatment system and a rainwater drainage system; and the temperature of supplied drinking water in each piggery is no lower than 5 DEG C. Through the original ecological pig farm, the pigs can restore natural habits, naturally ingest food, freely bathe in the sunshine so as to reduce the stress and obviously enhance the disease resistance of the pigs; and the internal and external environments of the piggeries are clean, air is ventilated, smooth and odorless, and pathogenic microorganisms are a few, so that morbidity is reduced; and the problems of residual toxic and harmful substances in pork, and light color and poor taste of the pork can be solved, and the pork becomes more tender, fragrant, and flavorous.

Owner:河南基正生态农业科技有限公司

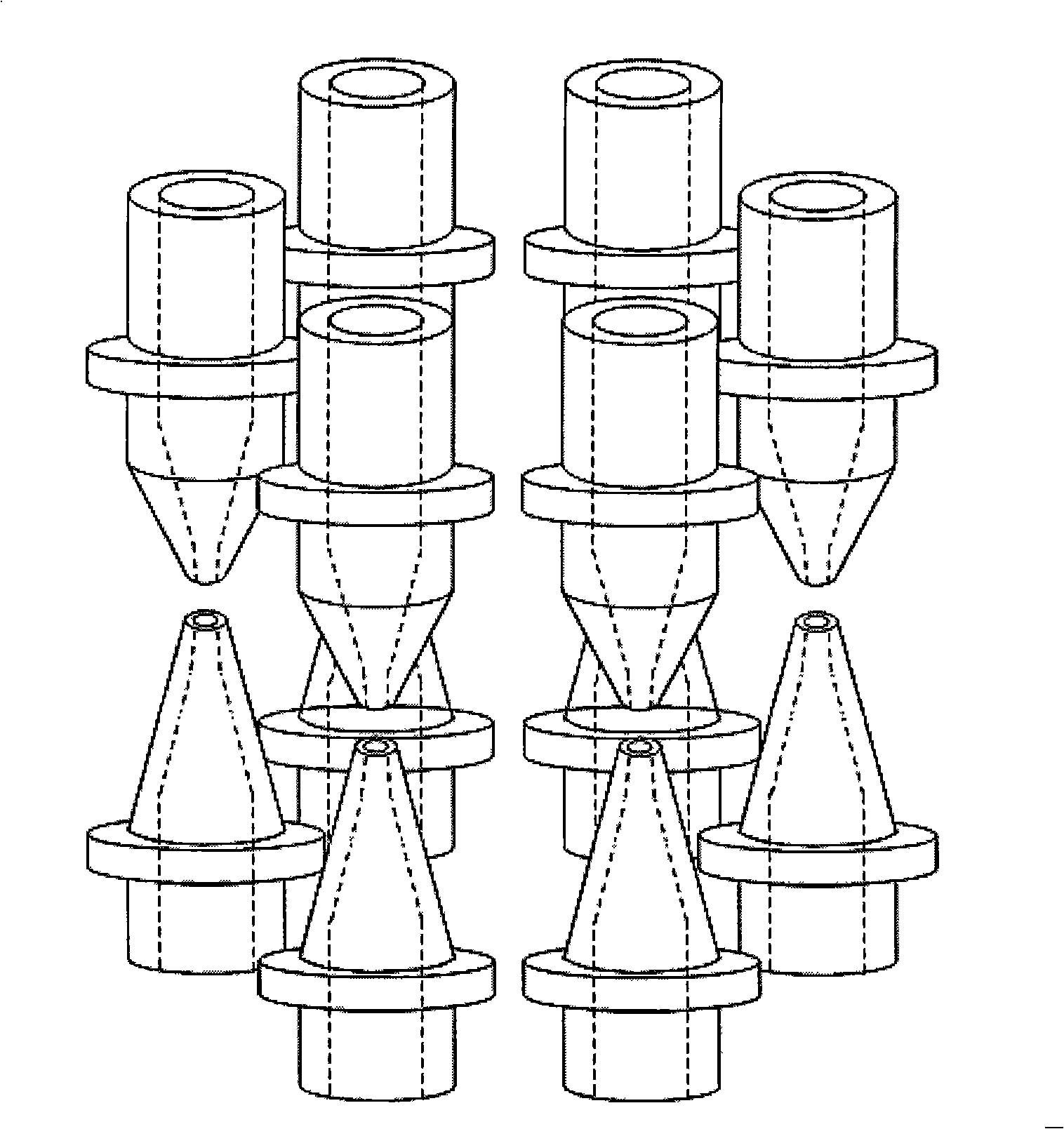

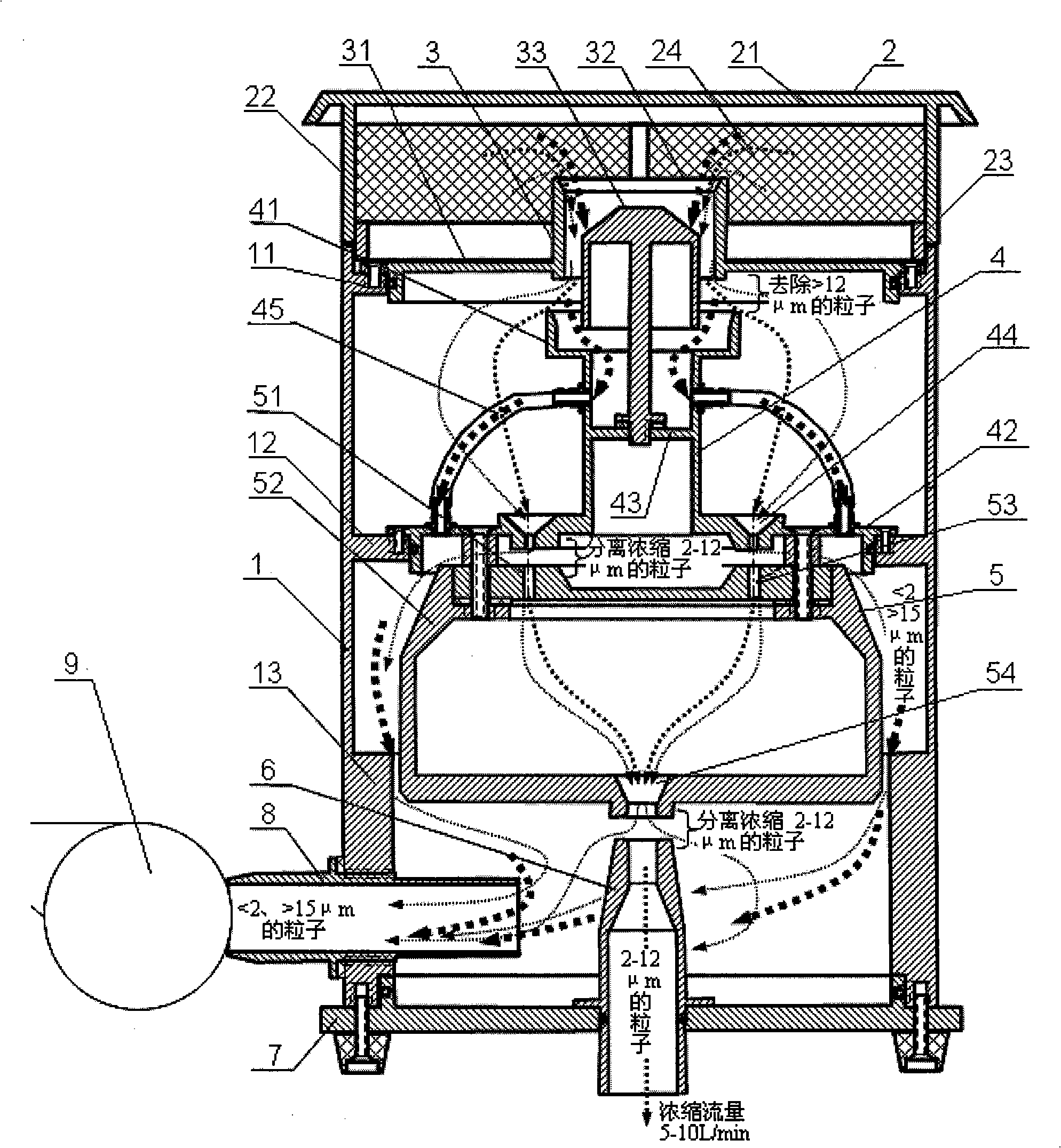

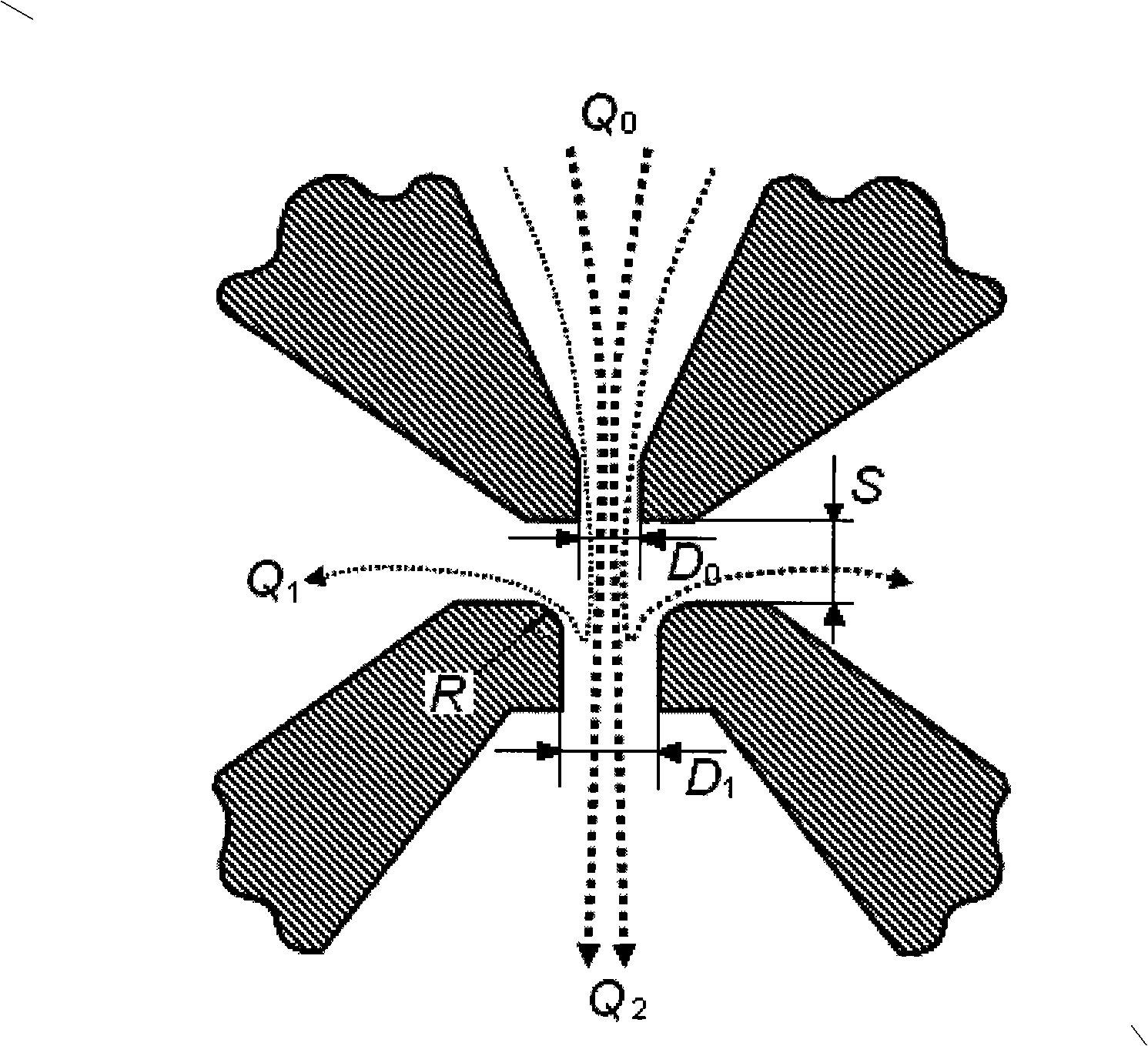

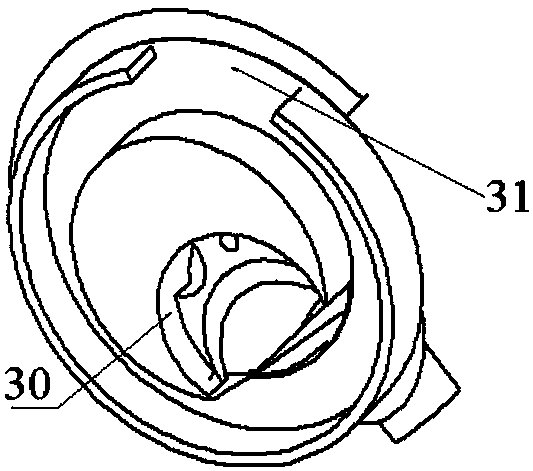

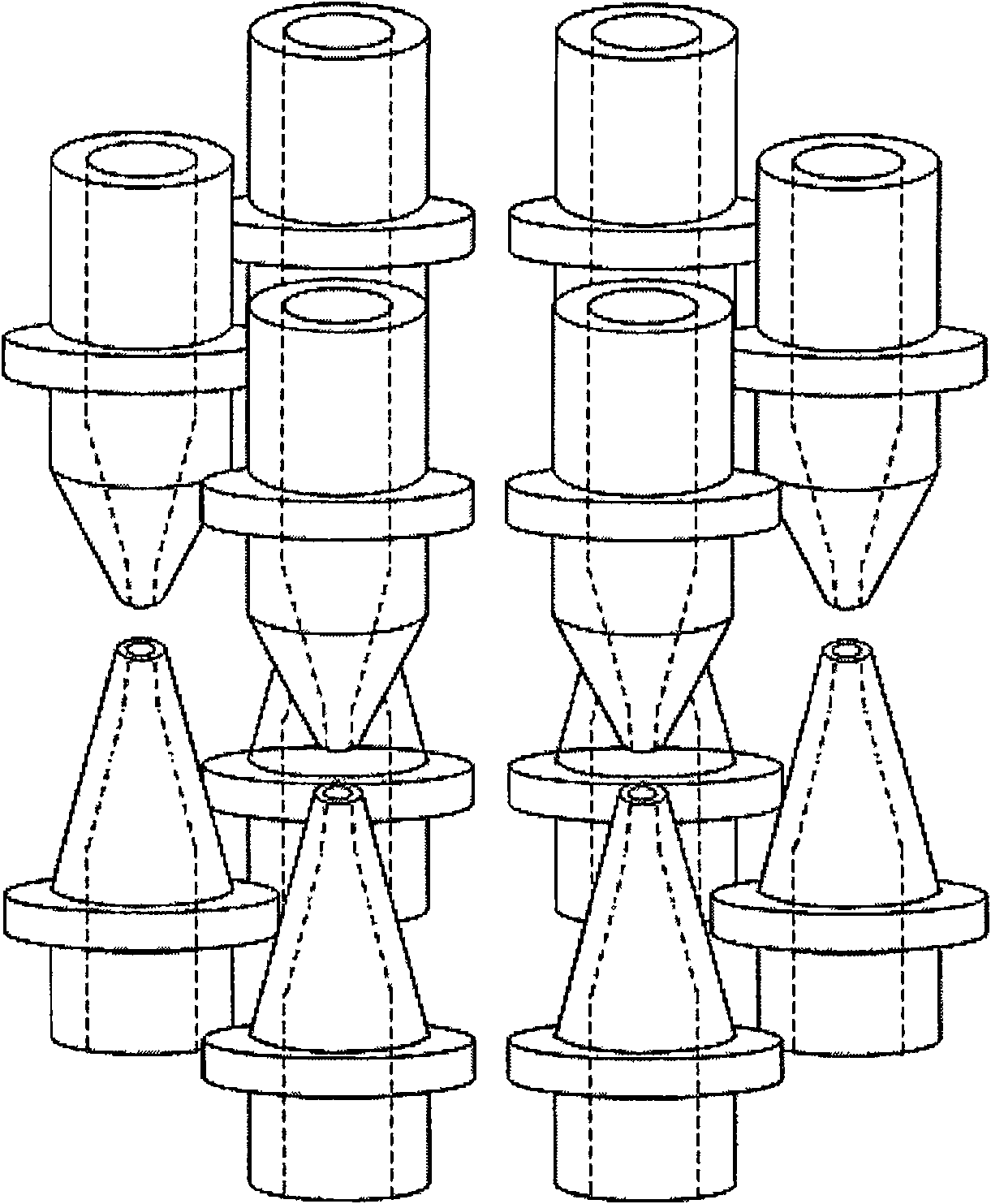

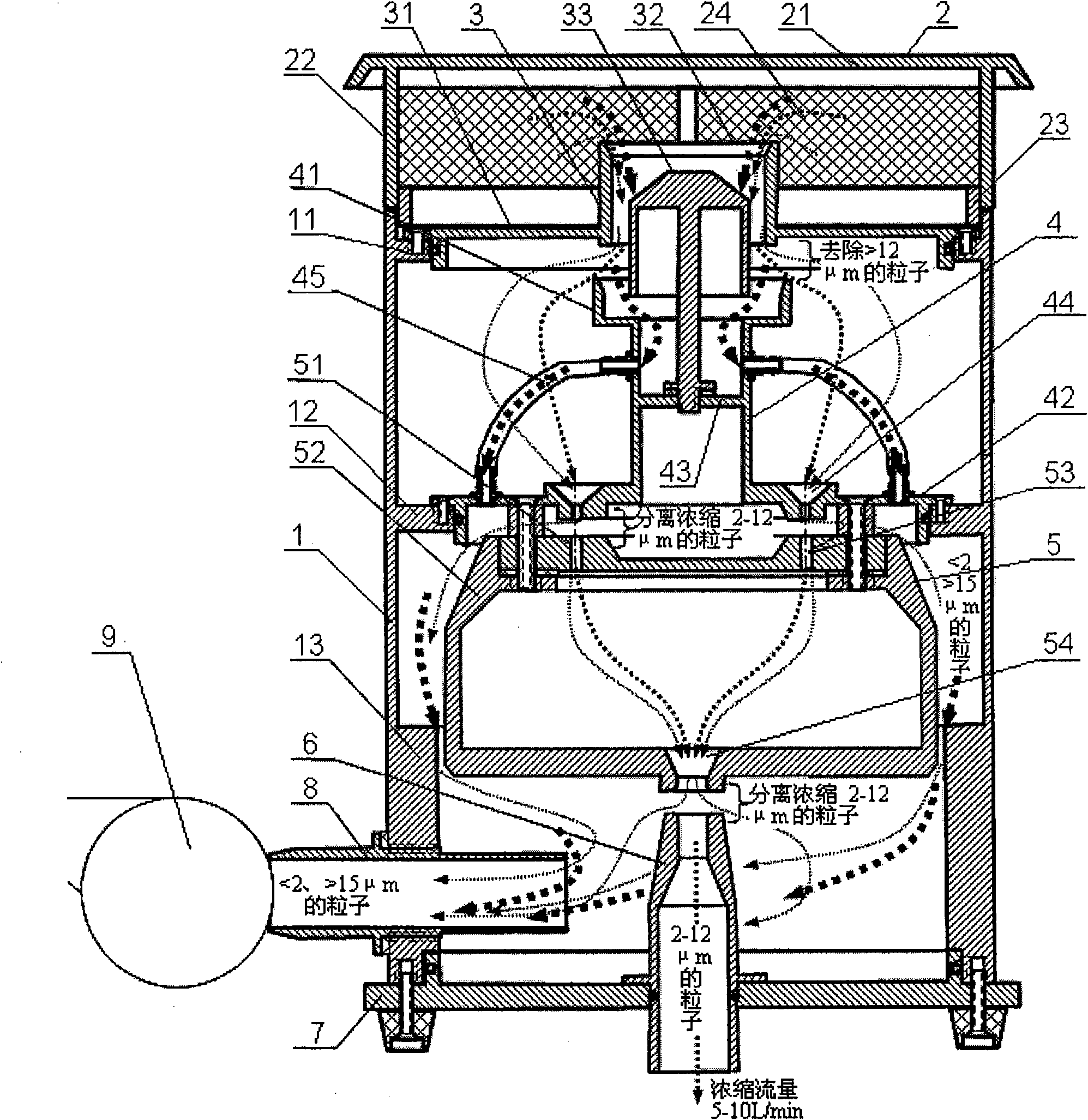

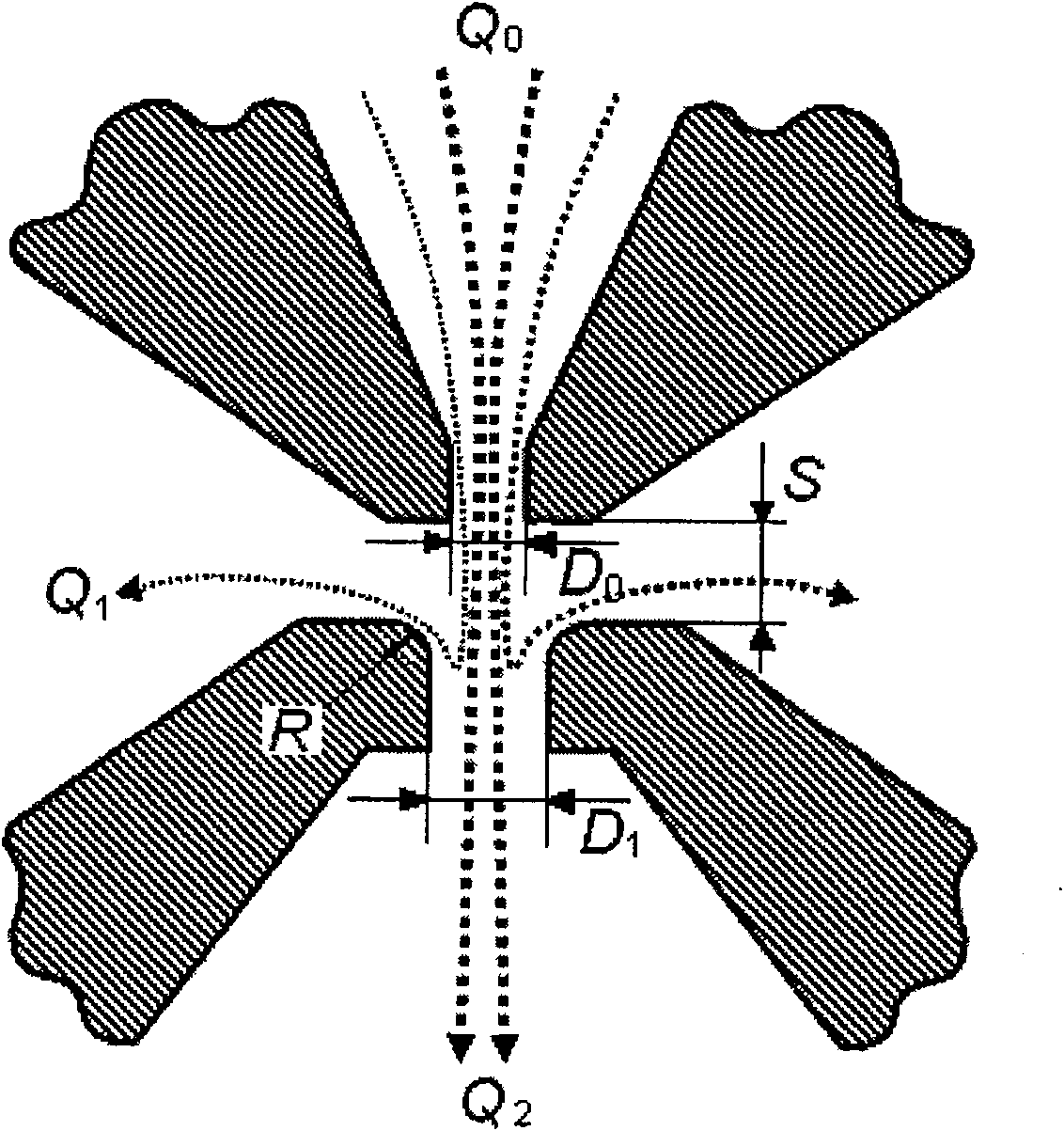

Aerosol virtual impact concentrating separator

ActiveCN101322891AEvenly distributedFree from lossDispersed particle separationThree stageEngineering

The invention relates to an aerosol virtual impacting concentration separator which is characterized in that the separator comprises an outer drum; one side of the lower part of the outer drum is provided with an exhaust port and an exhaust fan which is connected with the exhaust end of the exhaust port; the outer drum is internally provided with three stages of separation inlet components from top to bottom; the first stage component comprises an aerosol air intake, the front end of the first stage component is provided with a waterproof and inset resistant net cover, the first stage component is internally provided with a flow limit column and a ring gap is arranged between the flow limit column and the first stage component; the second stage component comprises a large particle collection port and a second stage separation intake board, the large particle collection port is correspondingly arranged under the aerosol air intake and a plurality of second stage spouts are cut evenly at the periphery of the second stage separation intake board; the third stage component comprises a tank which is connected under the second stage separation intake board, the third stage spouts are cut at the bottom of the tank and a third stage collection port is arranged under the third stage spouts. By utilizing the flying inertia of aerosol particle and adopting the virtual impacting principle, the separator of the invention separates the respirable particle with the diameter of 2 microns to 12 microns, which contains microorganism, from great air flow and concentrates the respirable particle to comparatively small air flow.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI +1

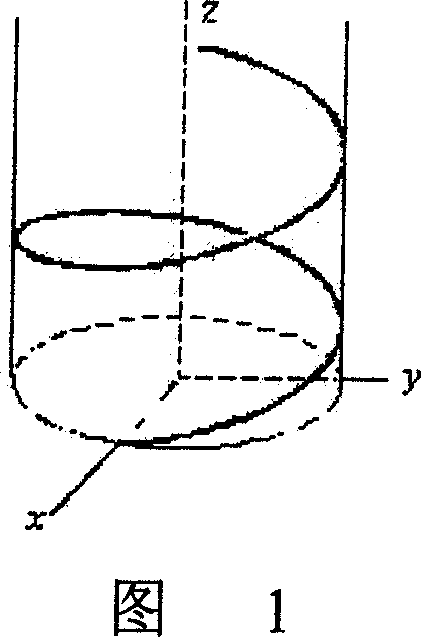

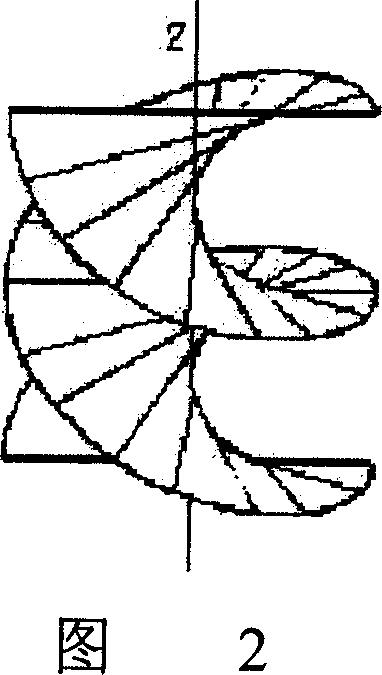

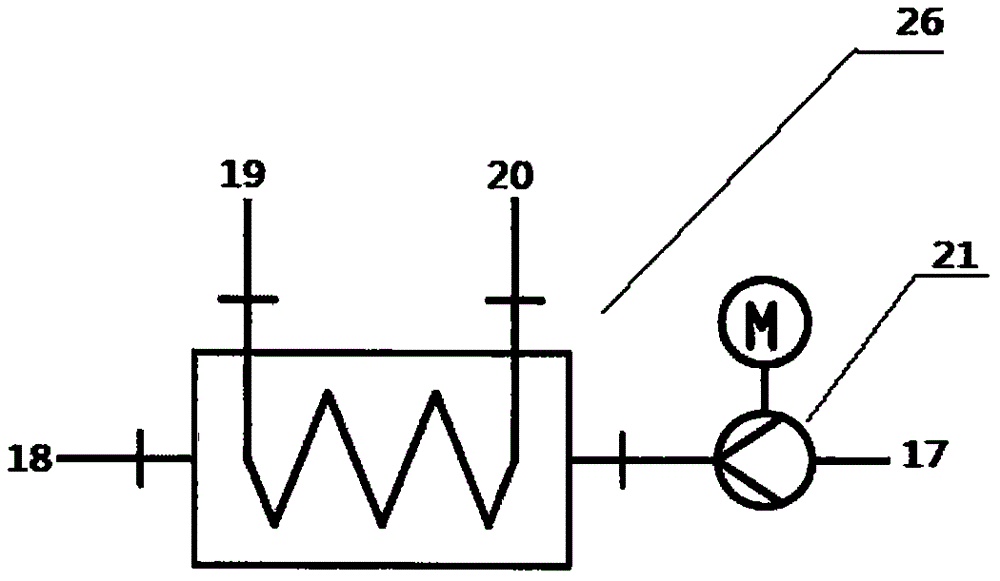

Static spiral mixer in tube

InactiveCN1939580AReduce resistanceImprove homogeneityFlow mixersTransportation and packagingMechanical engineeringHelix

Owner:俞洪燕

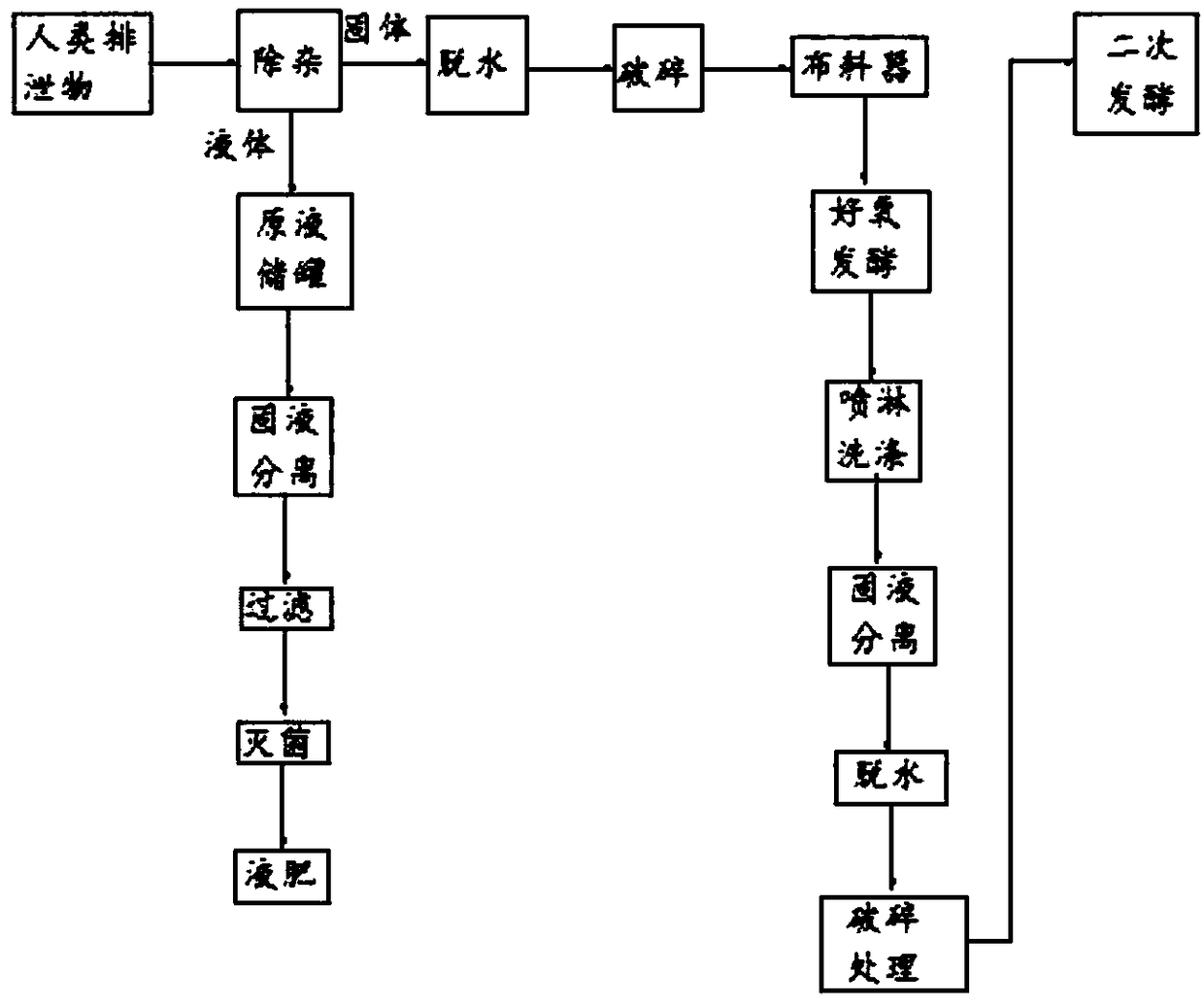

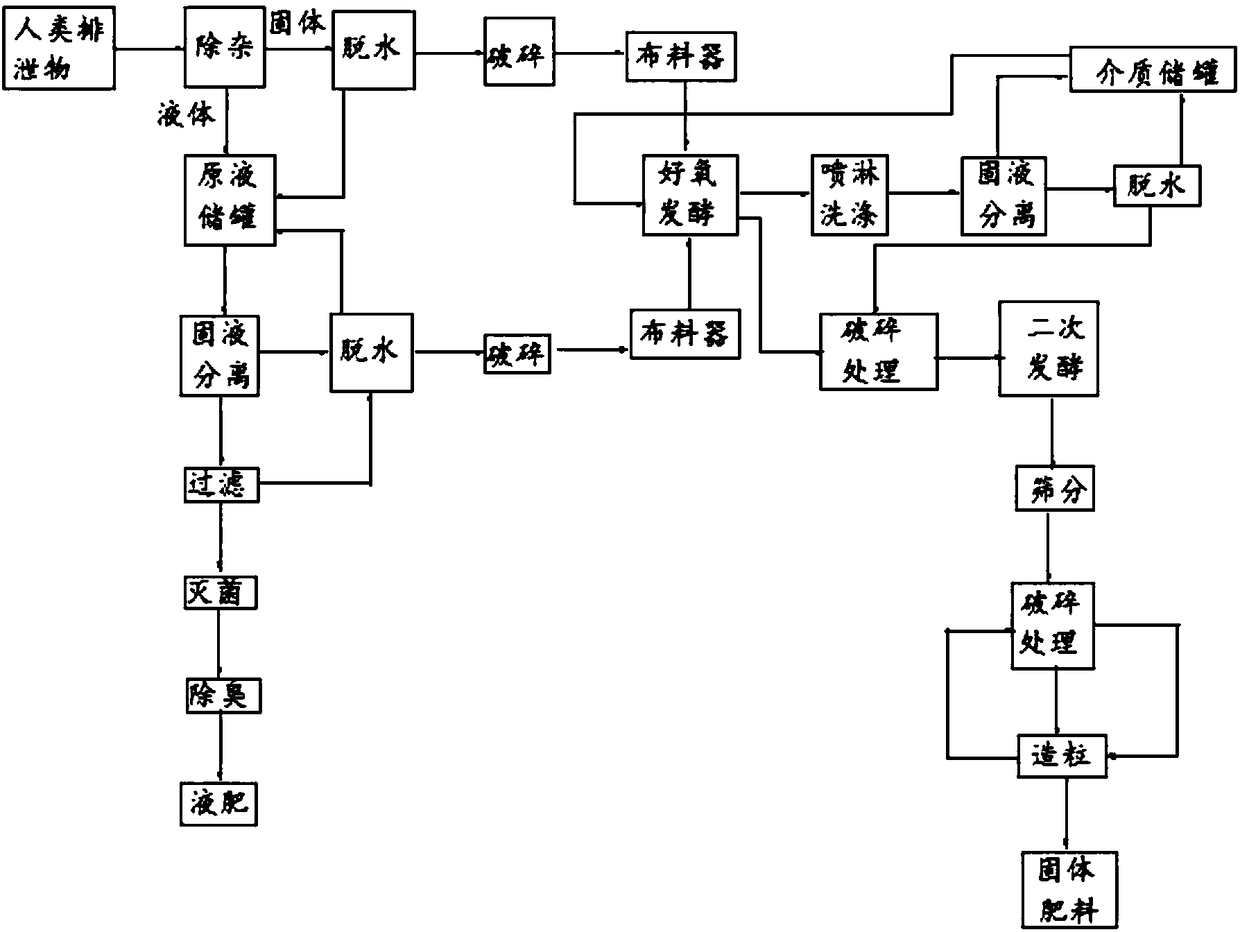

Method and system for treating human excrement

InactiveCN108218480AConducive to the protection of the environmentStrong Penetration and SolubilityBio-organic fraction processingClimate change adaptationFertilizerChemistry

The invention discloses a method for treating human excrement. The method comprises the steps as follows: (1) a liquid in the human excrement is discharged into an original liquid storage tank, and solids are dehydrated; (2) solids obtained after dehydration treatment in the step (1) are subjected to aerobic fermentation after being crushed; (3) secondary fermentation is performed; (4) materials obtained after the secondary fermentation are used as solid fertilizer. The invention also discloses a system adopting the method. The system comprises impurity removal equipment A, a dewatering deviceA, the original liquid storage tank, a crusher A, a distributor A, a full-closed fermentation tank A, an oxygen generator and the like. The method and the system for treating the human excrement havethe advantages as follows: a complete production process is provided for recycling of human excrement, a scheme is provided for urban emission reduction and sewage treatment plant pressure reduction,waste can be reused, and sustainable development can be realized really.

Owner:石伟

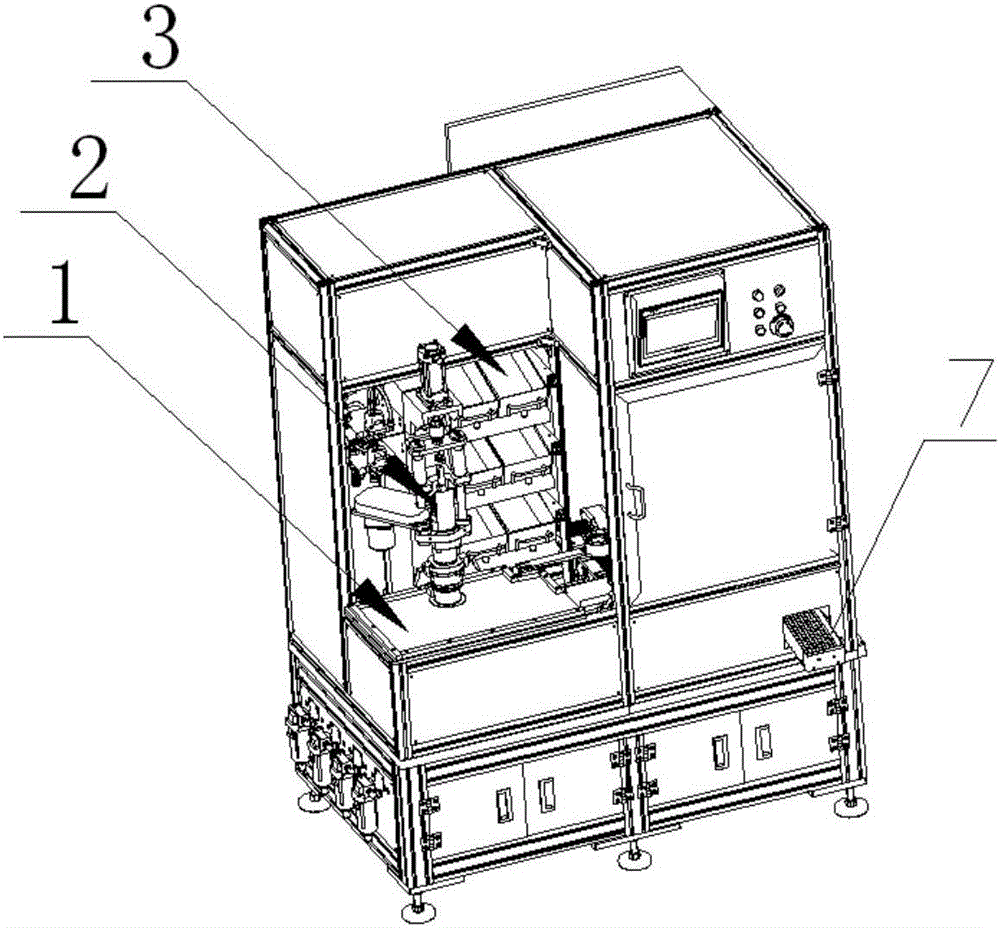

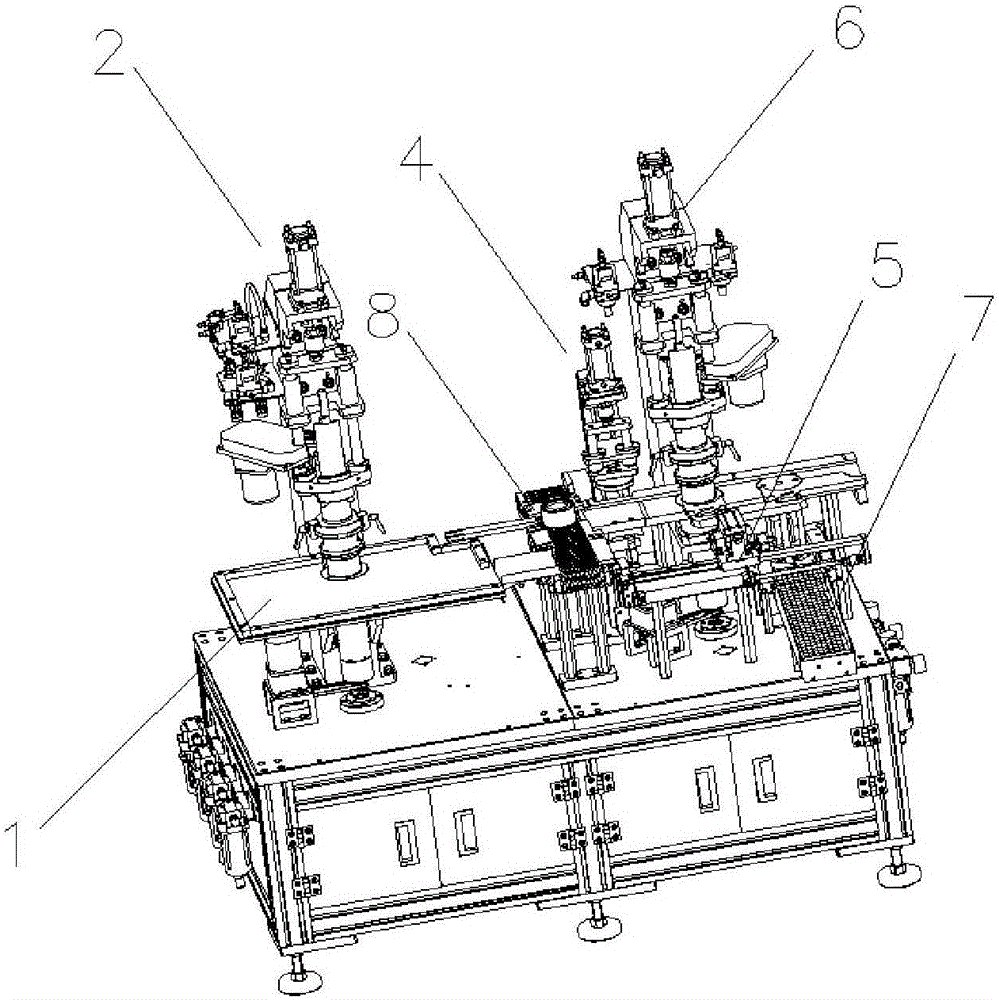

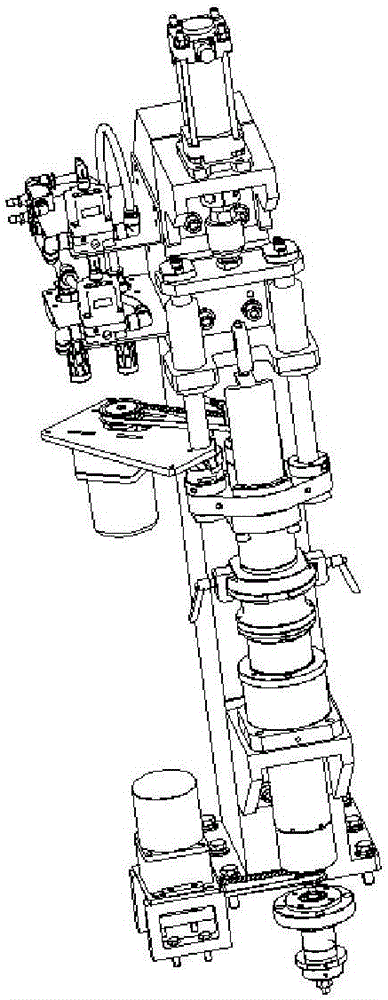

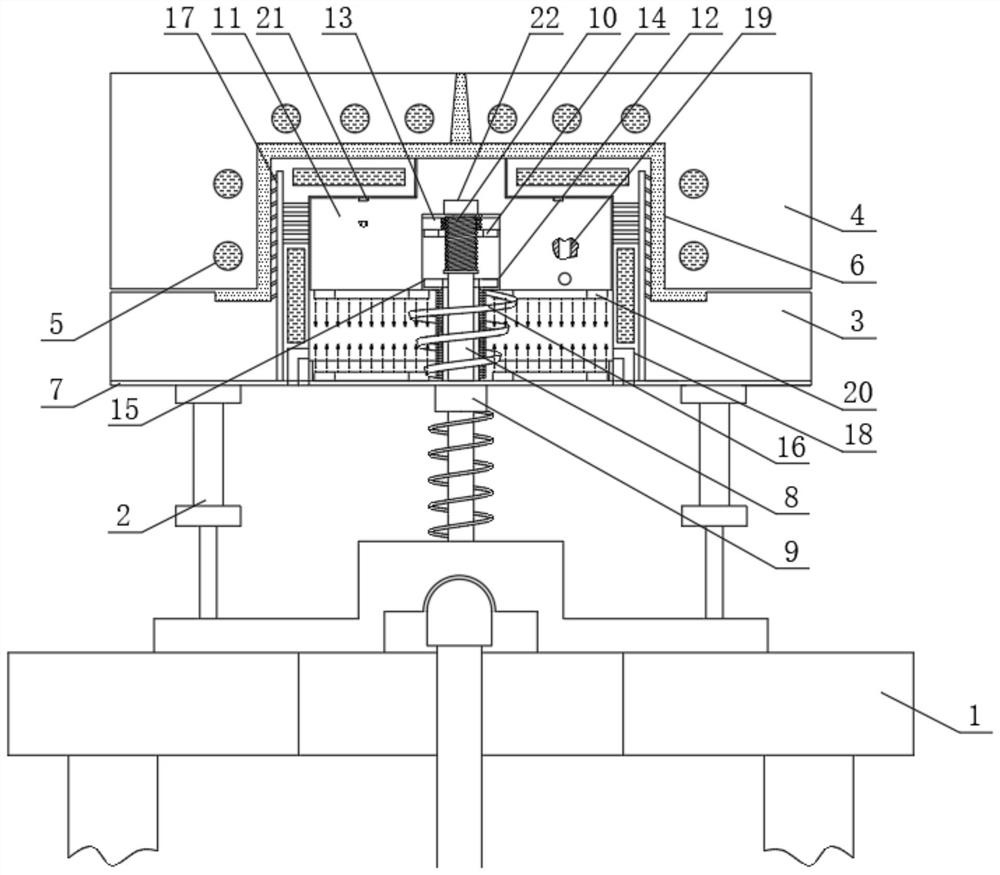

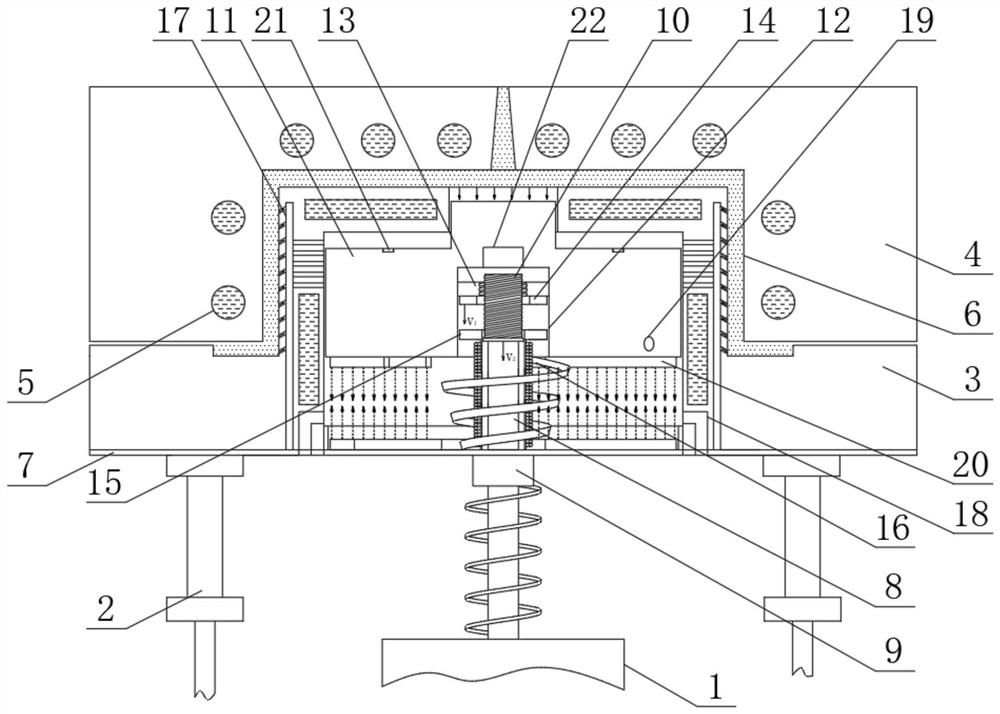

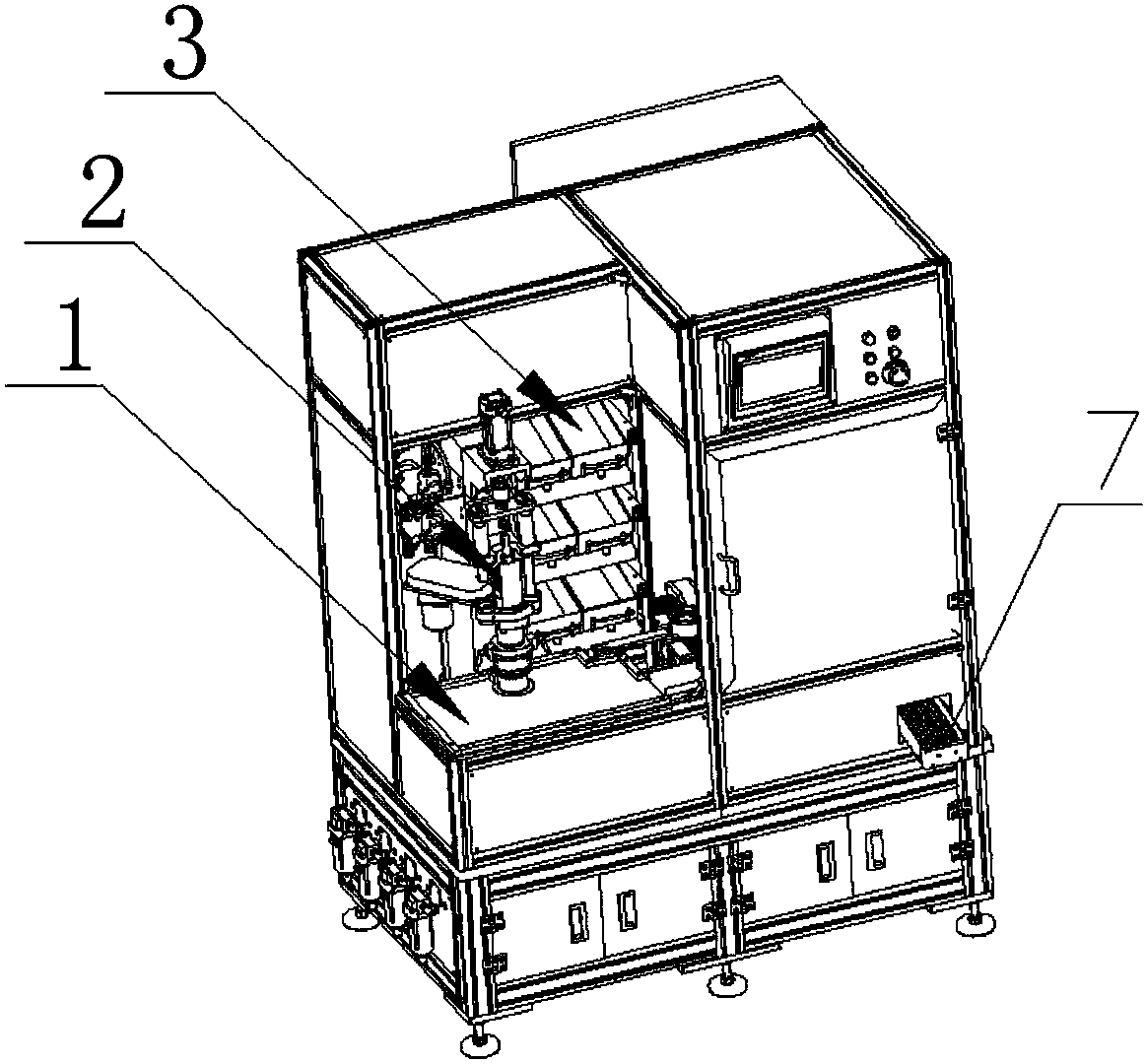

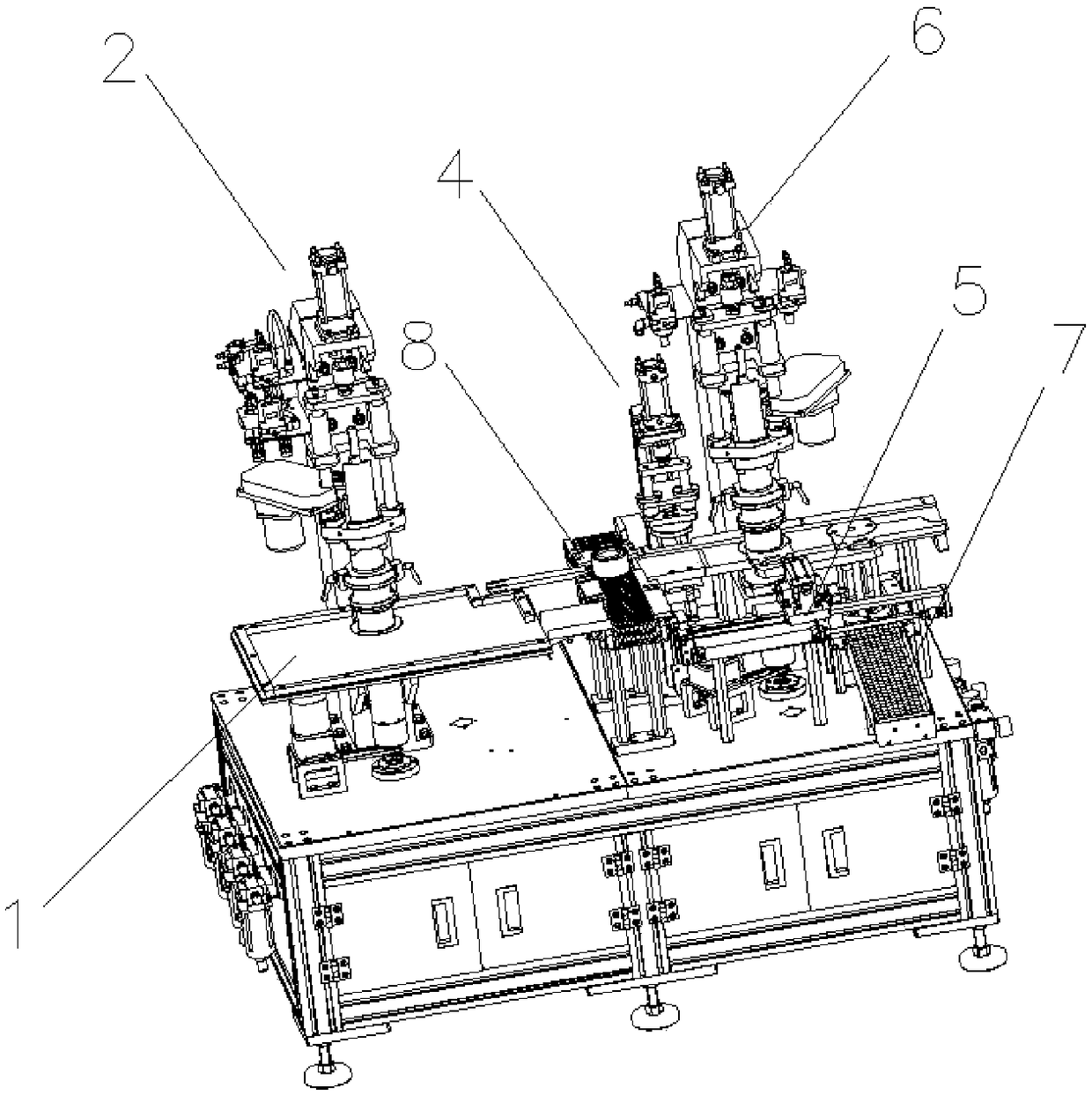

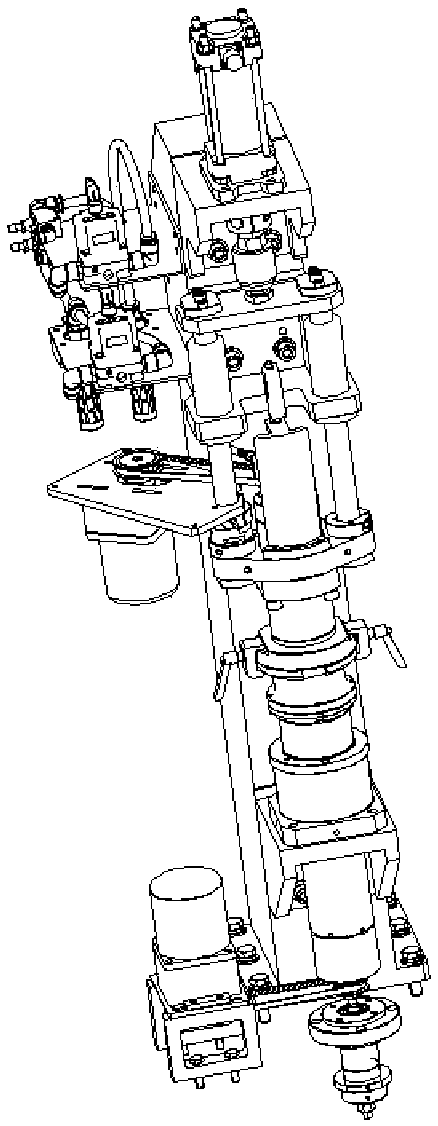

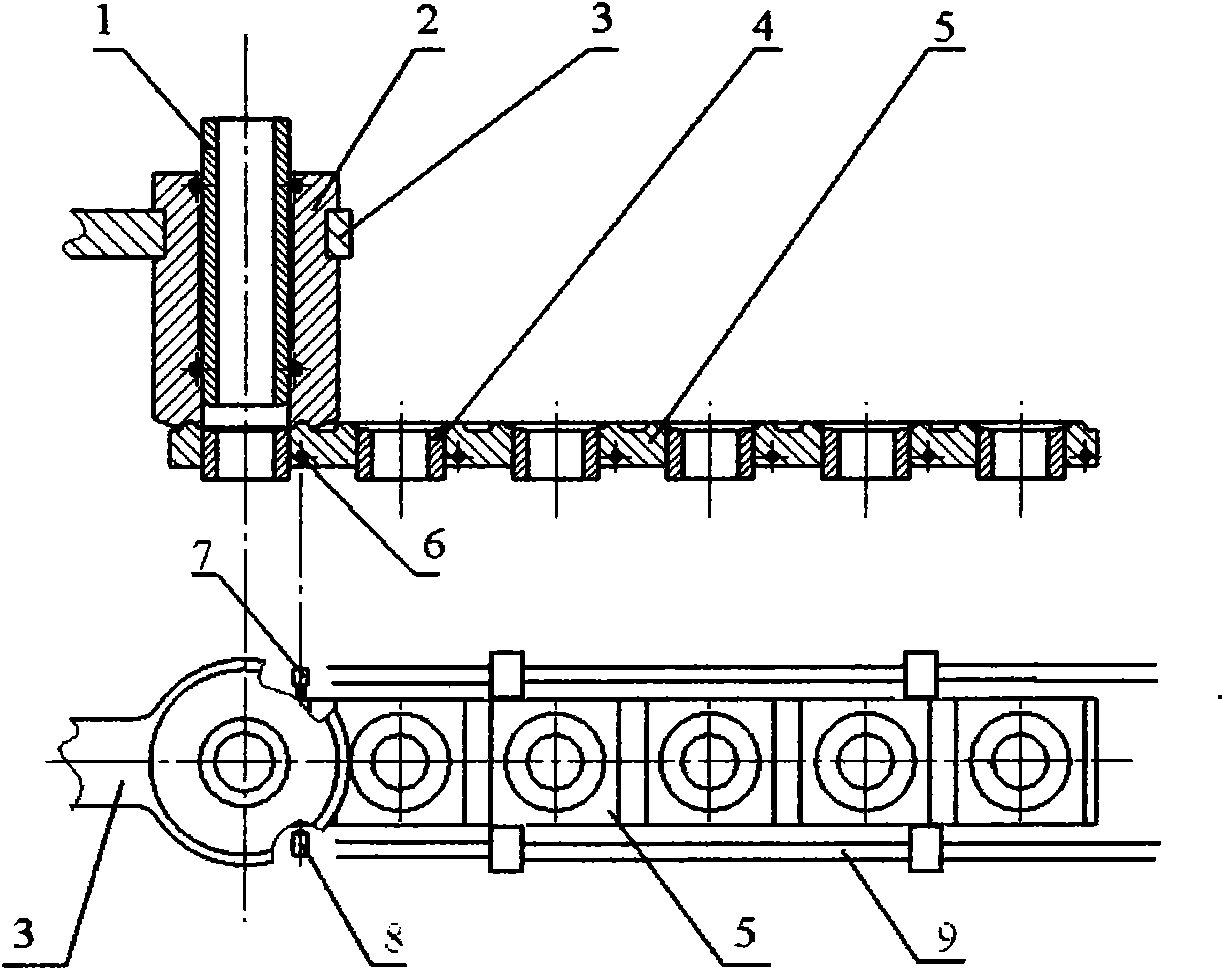

Axial clearance matching machine for hub bearing

ActiveCN106481676ANo stayTimely detection of size deviationsBearing componentsSortingControl systemThrust bearing

The invention discloses an axial clearance matching machine for a hub bearing. A preselecting mechanism can be used for measuring an axial clearance of a bearing formed by assembling a to-be-assembled inner ring, a to-be-assembled outer ring and a standard retainer combination together and transmitting information to a control system; a ball storehouse is used for placing to-be-assembled retainer combinations with different tolerance ranges; a nesting mechanism can be used for pressurizing and nesting a preassembled product formed by the to-be-assembled inner ring, the to-be-assembled outer ring and a set of to-be-assembled retainer combination; a carrying mechanism can be used for conveying the pressurized and nested product into a measuring mechanism, carrying the product in the measuring mechanism to a defective product discharging station and carrying the product on the defective product discharging station to a subsequent output station; the measuring mechanism can be used for measuring the axial clearance of the product and transmitting information to the control system; a defective product discharging mechanism can be used for discharging the product on the defective product discharging station; and the control system is used for controlling the action of each mechanism. By using the axial clearance matching machine, the fit rate is increased, the phenomenon that a great number of intermediate products are detained does not appear, and the production efficiency and yield rate are increased.

Owner:江苏康斯特智能装备有限公司

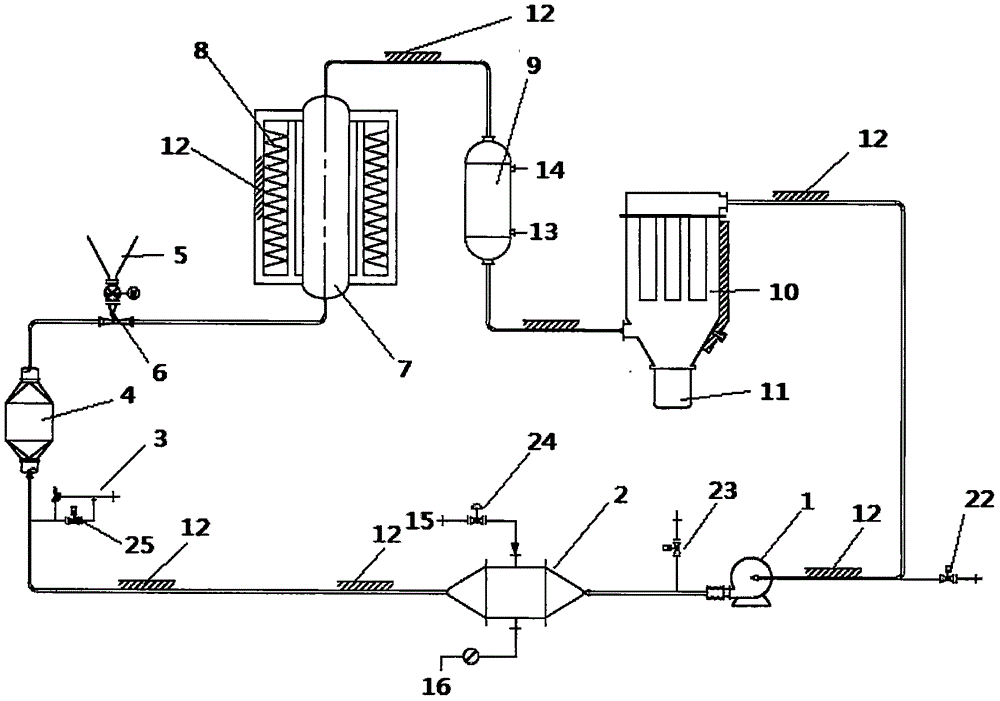

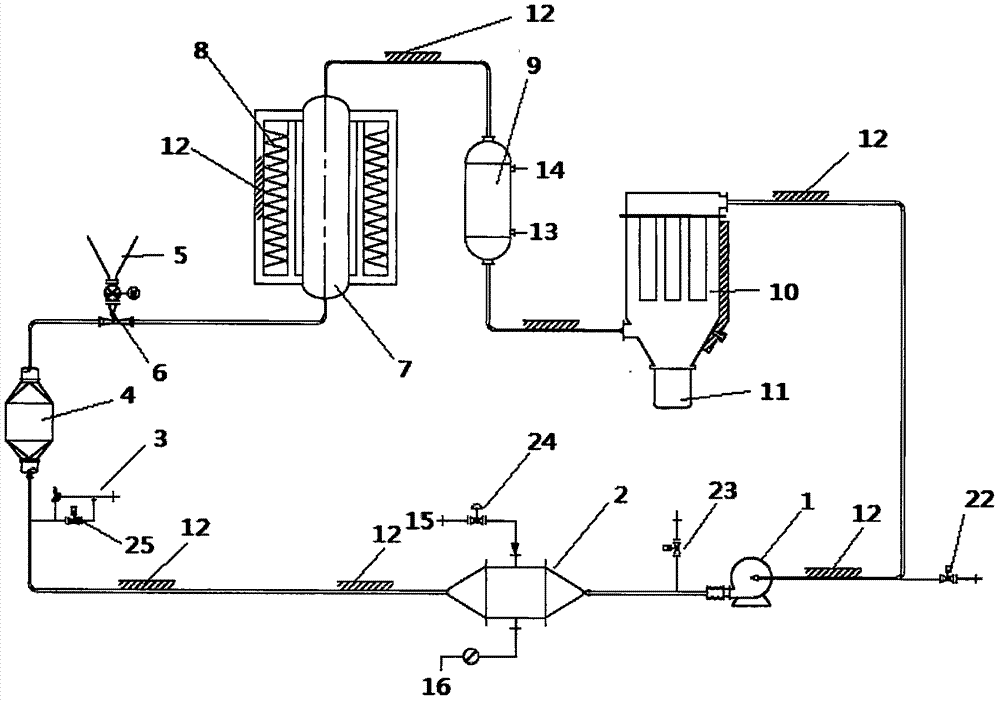

Closed-cycle high-temperature airflow reaction device

The invention discloses a closed-cycle high-temperature airflow reaction device. The device comprises a fan, a waste heat recovery device, a pressure balancing device, a secondary heater, a feeder, an accelerator, a high-temperature reacting furnace, a three-level heater, a cooling system, a dedusting system and a discharging device. Continuous reaction and continuous sintering production can be realized by virtue of a vertical box reaction cavity, the investment cost of equipment is reduced greatly, the closed-cycle high-temperature airflow reaction device has the characteristics of compact structure, convenience in operation and maintenance, good controllability, energy conservation and emission reduction, remarkable reaction effect, no material retention or piling, short reaction time, high rate of finished products, exquisite design and high practicability and can fully utilize heat of exhaust, and the investment to mated infrastructure is less.

Owner:JIANGSU XIANDAO DRYING TECH CO LTD

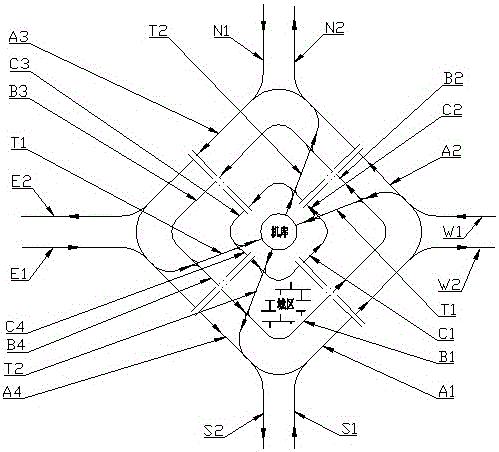

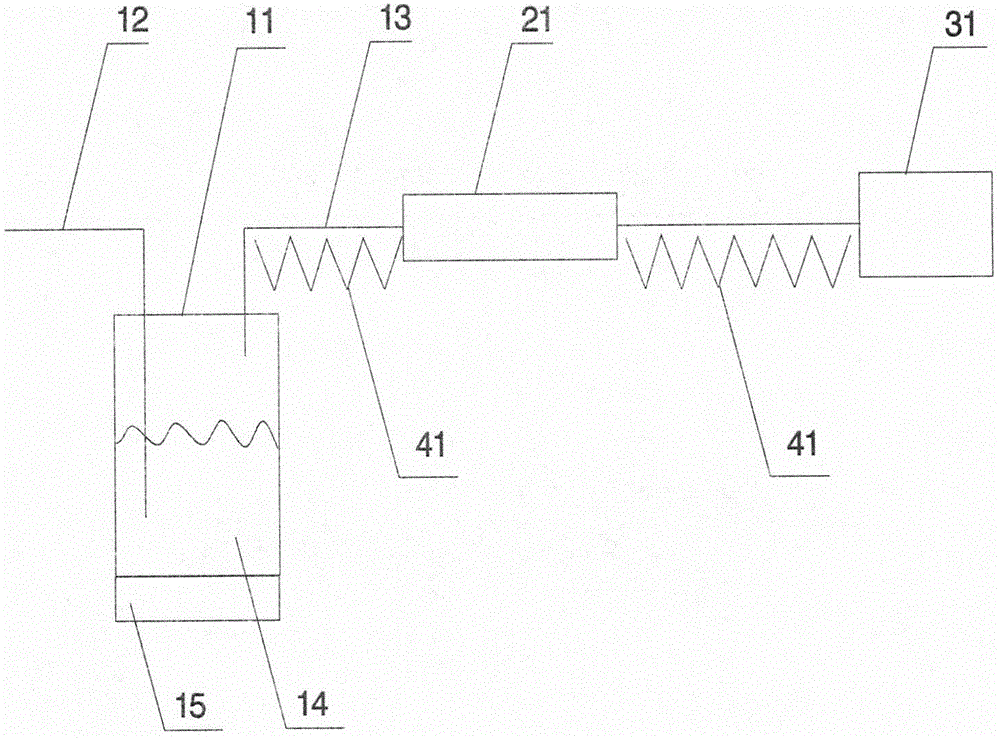

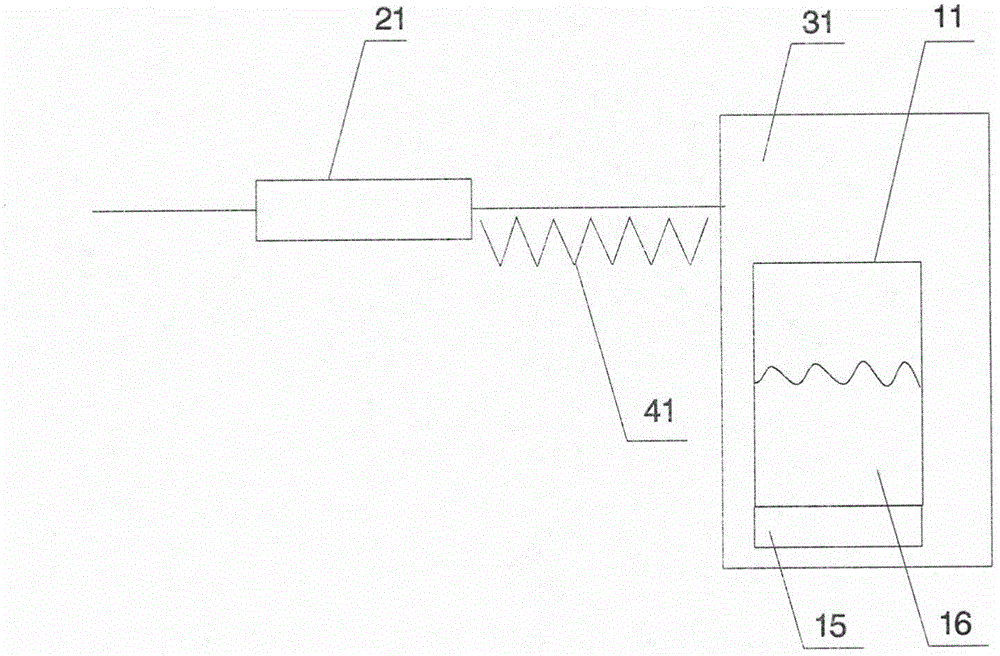

Flowing railway station, track network matched with flowing railway station and combination system of flowing railway station and track network

InactiveCN106043315AOrchestration simplificationImprove operational efficiencyRailway componentsRailway stationDeep integrationEconomic benefits

The invention provides a mobile railway station, a matching track network and a combined system of the two, belonging to the field of rail transit and urban rail transit. The combined system deeply integrates railway rail transit and urban rail transit, and changes the fixed train station into a mobile train station, which not only enables the train to get on and off passengers, greatly improves the operating efficiency of the train, and saves about 400 billion trains Occupying fixed assets has also greatly increased the coverage and frequency of train stops, and shortened the waiting time for passengers. At the same time, through the deep integration of mobile railway stations and urban rail transit, it has effectively evacuated the passenger flow of railway passengers and resolved the impact of railway passenger flow on urban traffic. The congestion caused by it greatly satisfies the passenger's demand for nearby rides, improves the quality of railway services, increases the market share of railway transportation, and reduces the harm caused by road transportation to the environment, which has significant social and economic benefits .

Owner:朱德伟

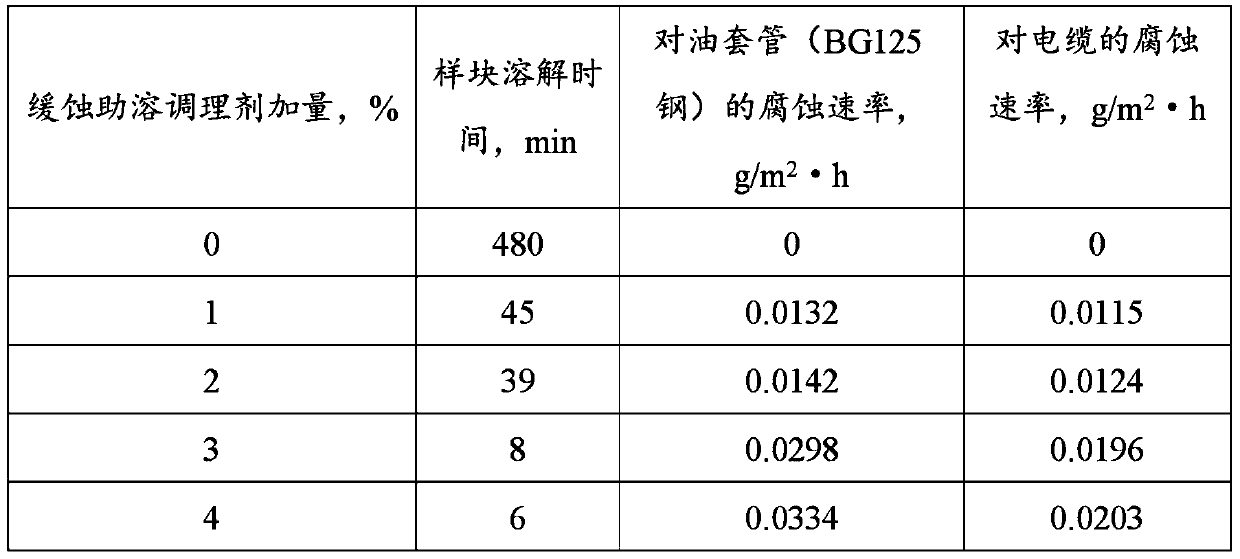

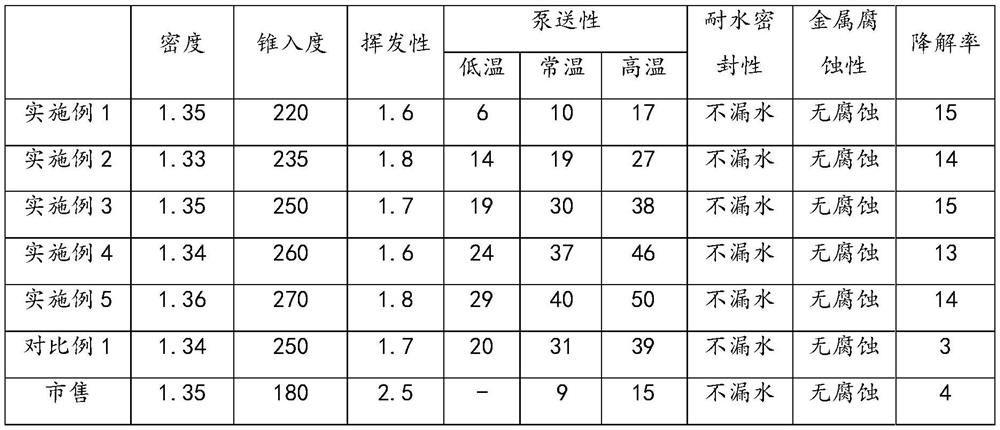

Quick dissolving solution for soluble bridge plugs and preparation method thereof

The invention discloses a quick dissolving solution for soluble bridge plugs and a preparation method thereof. The quick dissolving solution for soluble bridge plugs is prepared form, by weight, 10-18parts of ammonium chloroacetate, 5-10 parts of formaldehyde, 10-14 parts of organic acid, 15-20 parts of chloride ion salt, 5-8 parts of water-soluble corrosion inhibitor, 1-2 parts of anionic fluorocarbon surfactant and 30-54 parts of water. The quick dissolving liquid contains the organic retarding acid, the chloride ion salt, the corrosion inhibitor and a discharge aiding agent, and can generate a large amount of hydrogen ions and chloride ions under the conditions of formation temperature and pressure, so that the mineralization degree of the formation water is improved, the electrolyte concentration is increased, the electrochemical corrosion is accelerated, and the bridge plugs are quickly dissolved without causing corrosion to oil casings and cables.

Owner:四川长宁天然气开发有限责任公司 +2

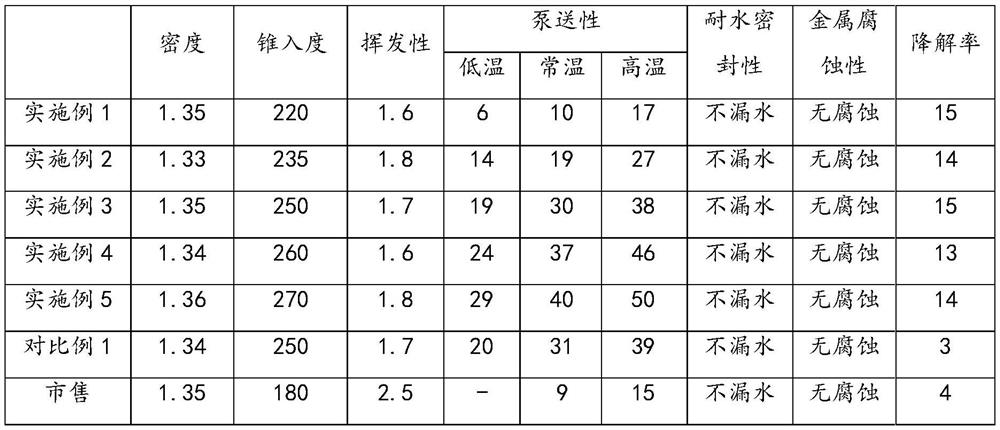

Environment-friendly shield tail sealing grease and preparation method thereof

The invention relates to shield tail sealing grease for a shield tunneling machine, and the sealing grease is prepared from base oil, a filling agent, a lubricating agent, a tackifier, an adhesive force modifier, a reinforcing agent and microcapsules and has the advantages of strong adhesive force, good sealing property, good pumping lubricating effect, quick degradation, environmental friendliness and stable quality.

Owner:CNBM ZHONGYAN TECH

Method for wet drawing Al-enclosing steel wires for electrotechnics

InactiveCN1452185ANo stayWill not affect productionBridge structural detailsCable/conductor manufactureProduction lineWork in process

A wet drawing method for manufacturing the aluminium clad steel wire used for electric engineering is characterized by that the semi-finished aluminium clad steel wire is drawn through multi-pass drawing die by drawing machine while the lubricating oil is applied.

Owner:JIANGSU ZHONGTIAN TECH CO LTD

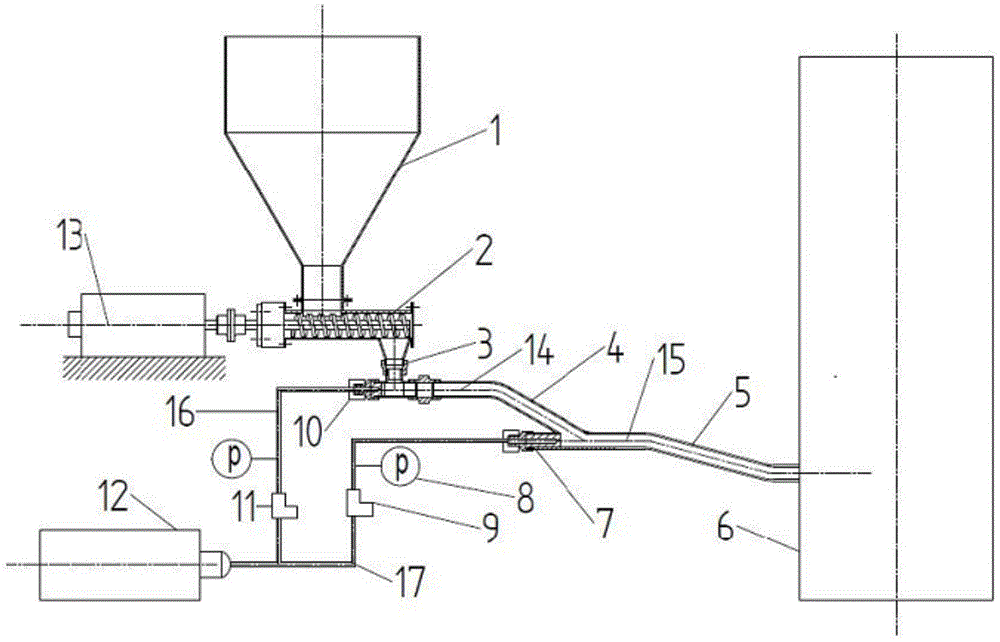

Spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis

InactiveCN104877694AAdjust feed amountPrevent blowbackBiofuelsLiquid hydrocarbon mixture productionSolenoid valveGas cylinder

The invention relates to a spiral-pulsed type pneumatic hybrid feeder for mobile biomass pyrolysis and belongs to the technical field of biomass pyrolysis. The feeder comprises a spiral feeding device, inclined delivery pipes, solenoid valves and nozzles. The discharge port of the spiral feeding device is connected to an upper horizontal delivery pipe and the inclined delivery pipe through a transition joint and is connected to a lower horizontal delivery pipe and the inclined delivery pipe, gas of a gas bottle is sprayed through the nozzles, the nozzles are capable of adjusting the feeding amount and preventing reverse spraying, the feeding process is controllable and safe, and the reliability of the producing process is improved. The feeding port advanced charring and plugging problems can be solved, the process requirements of fast biomass pyrolysis can be met, the pyrolysis equipment producing and maintaining time can be shortened, the pyrolysis oil producing efficiency is improved, the maintaining cost is reduced effectively, and the technology guaranteeing effect can be achieved for large-scale pyrolysis production development.

Owner:BEIJING FORESTRY UNIVERSITY

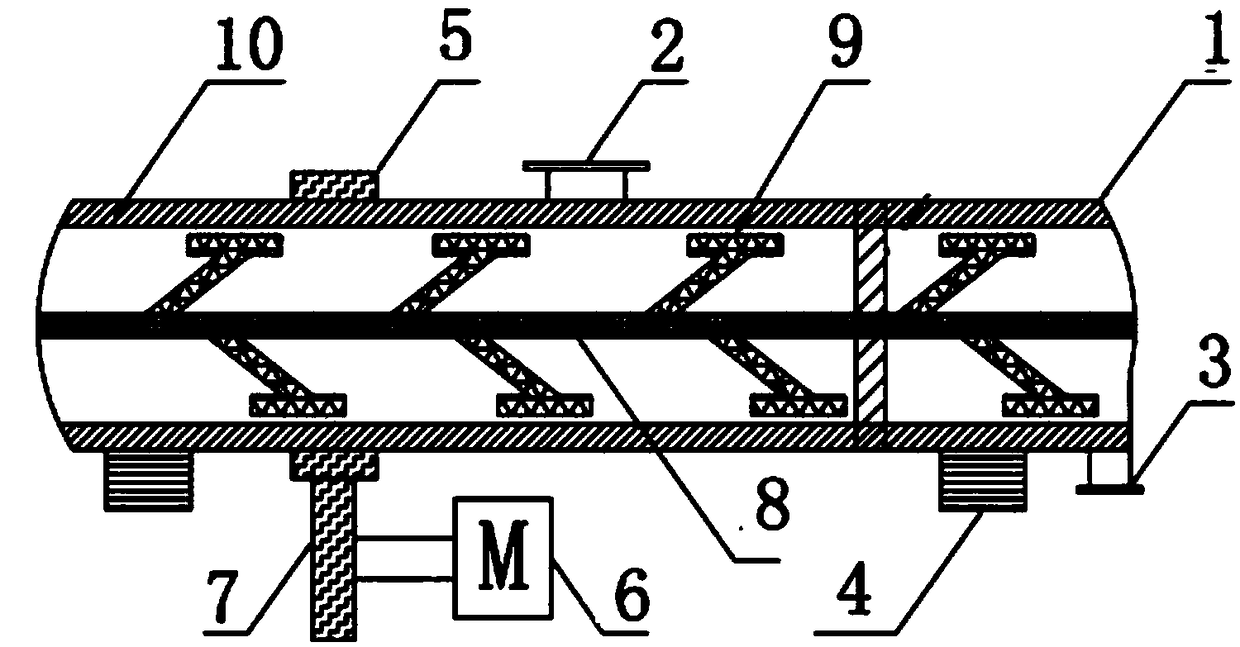

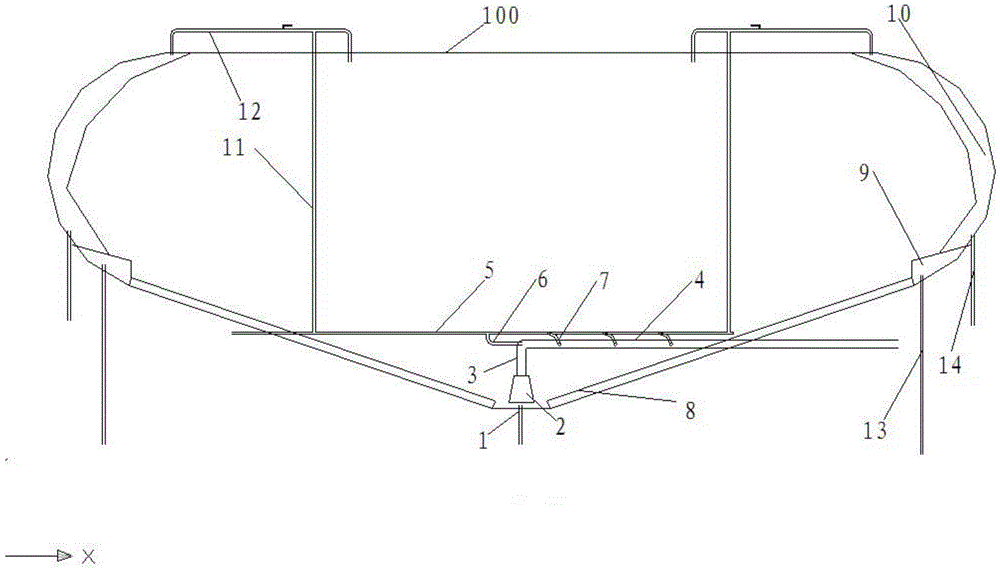

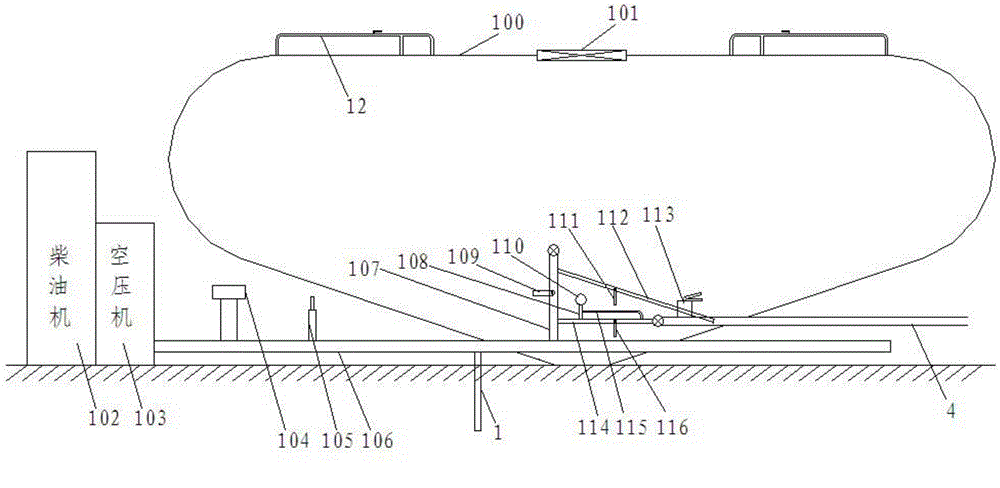

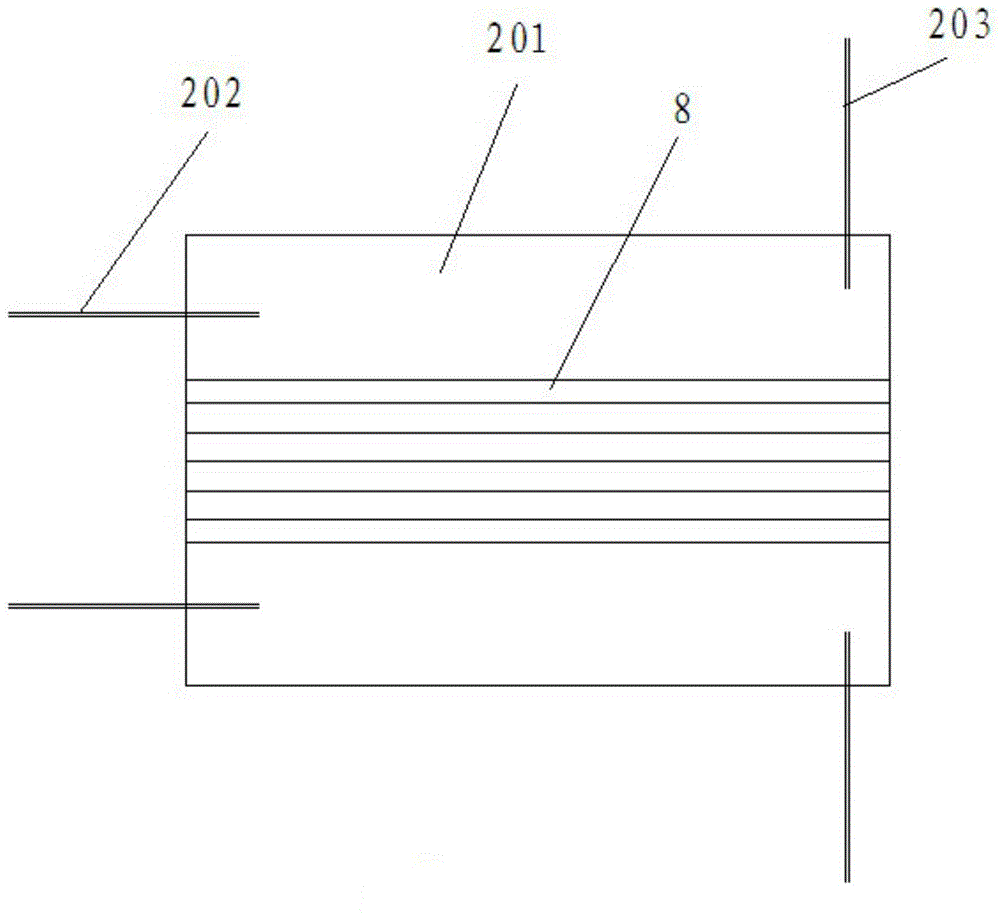

Powder storage and transportation tank truck

InactiveCN104085626AReliable unloadingImprove transportation efficiencyLarge containersTank truckWaste management

The invention discloses a powder storage and transportation tank truck. The powder storage and transportation tank truck comprises a tank body and an air supply header pipe arranged outside the tank body. The bottom of the tank body is of a funnel shape. The powder storage and transportation tank truck is characterized in that a vertical discharge pipe with the downward inlet is arranged close to the funnel-shaped bottom end in the tank body, the upper end of the vertical discharge pipe is connected with a horizontal discharge pipe extending out of the tank body, a vertical air-blowing pipe is arranged at funnel-shaped bottom end in the tank body, the outlet of the vertical air-blowing pipe is opposite to the inlet of the vertical discharge pipe, the vertical air-blowing pipe extends out of the tank body, and the inlet of the vertical air-blowing pipe is communicated with the air supply header pipe. Compared with an existing powder storage and transportation tank truck, the powder storage and transportation tank truck can discharge more quickly and reliably and improve the transportation efficiency and the management benefit.

Owner:高义武

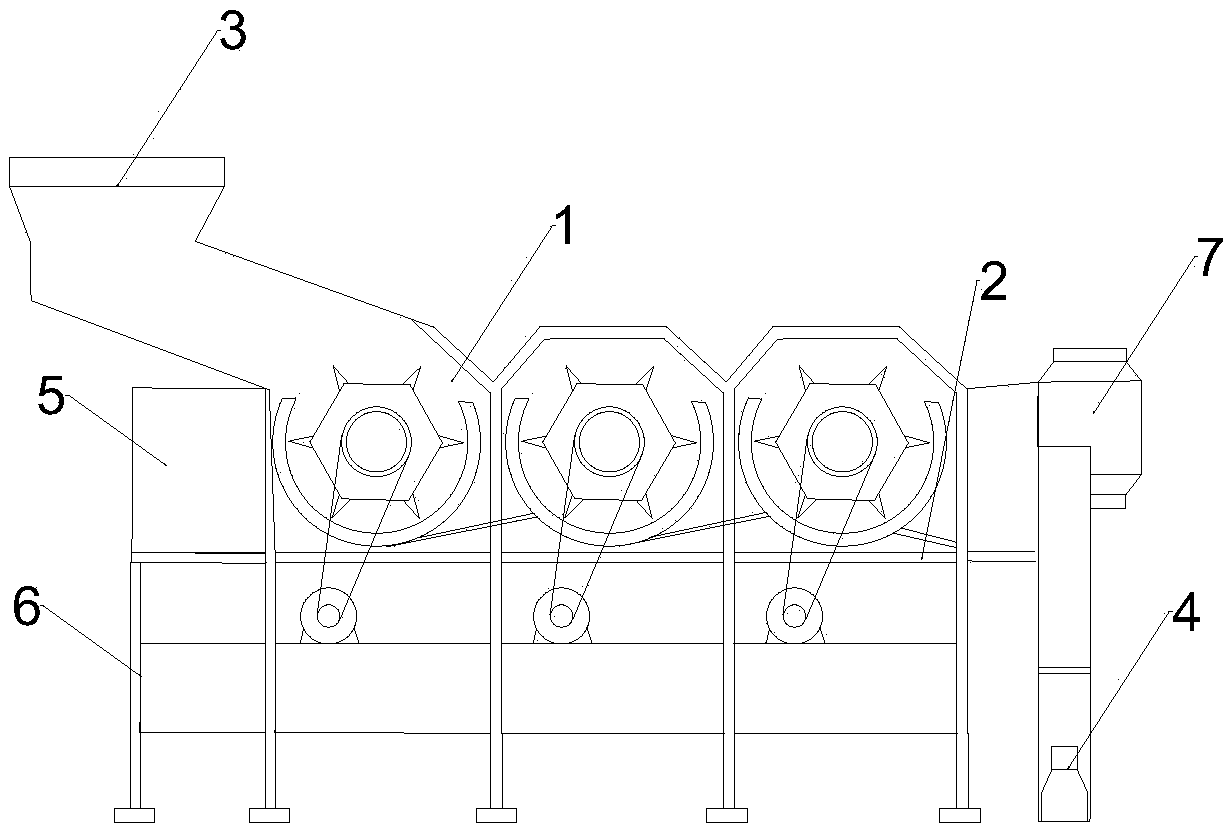

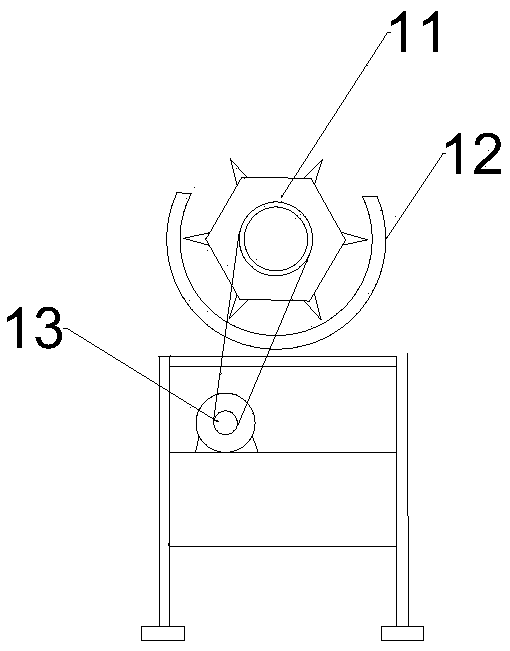

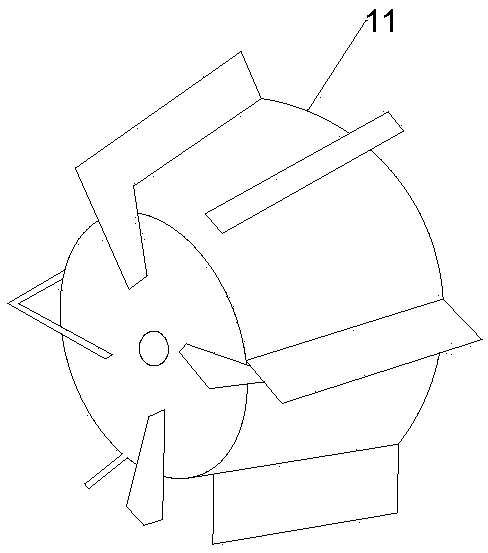

Paddy rice threshing apparatus

The invention belongs to the technical field of agricultural machines, concretely relating to a paddy rice threshing apparatus. The problem that uniaxial and biaxial threshing cylinder structures failto meet the requirement of agricultural production is resolved. In order to resolve the technical problem, the invention puts forward the paddy rice threshing apparatus comprising crushing devices, acleaning sieve board, a feeding hopper, a winnower, a fan, a frame and a whirlwind separating cylinder. The paddy rice threshing apparatus has high threshing efficiency.

Owner:JIXI YUANDAO AGRI IND TECH

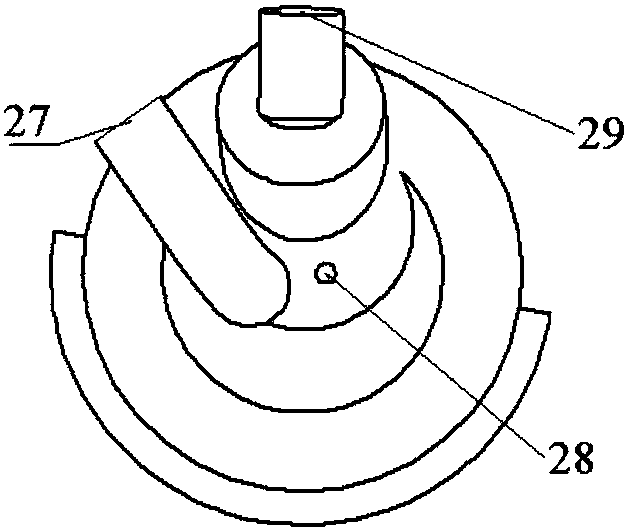

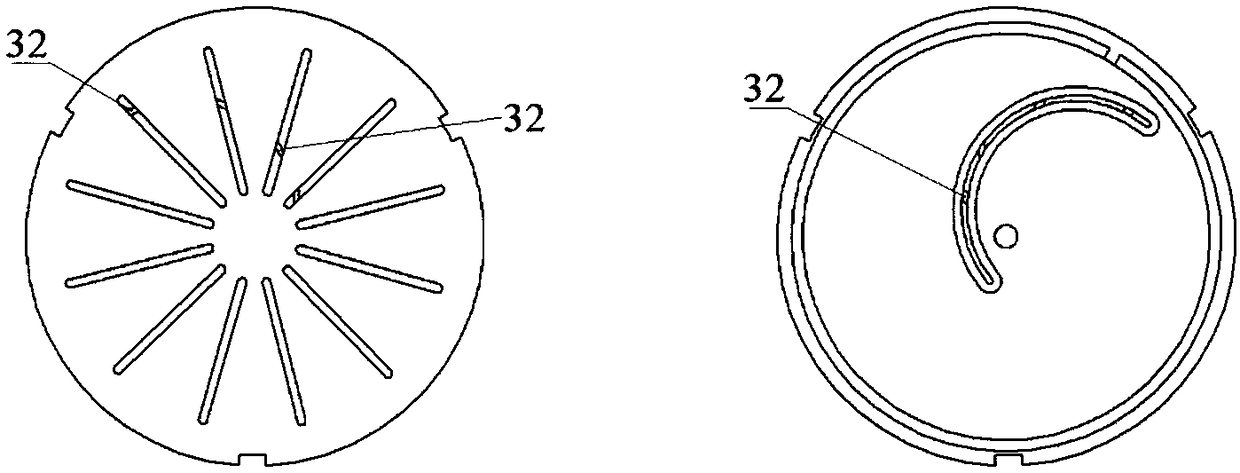

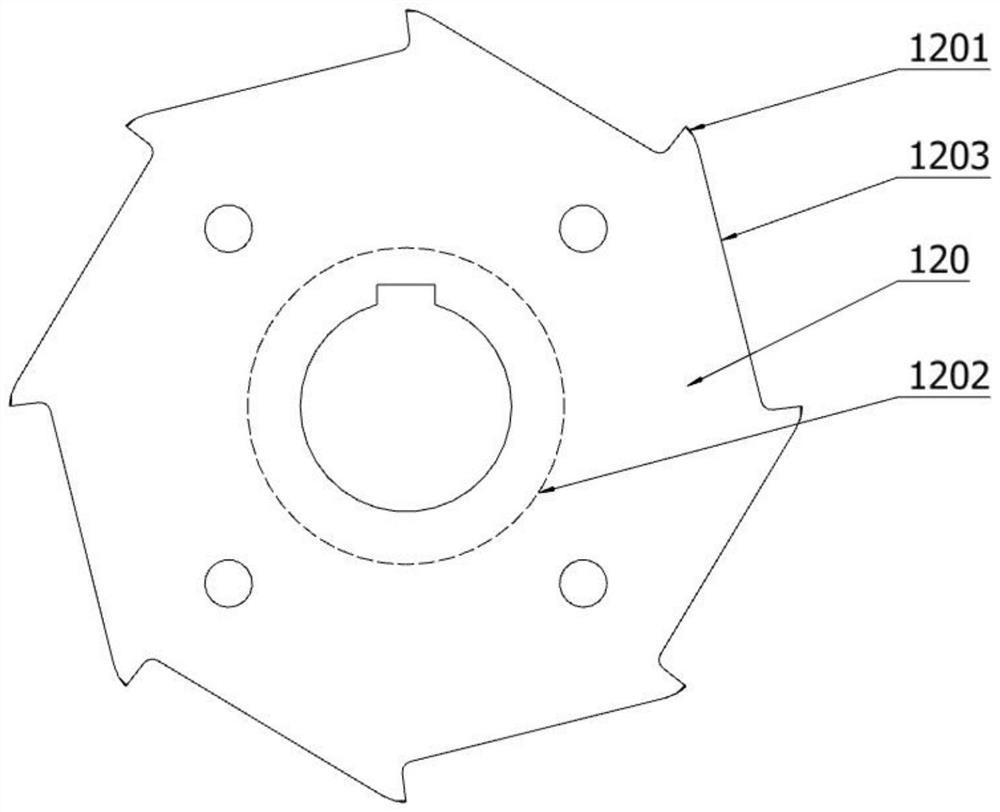

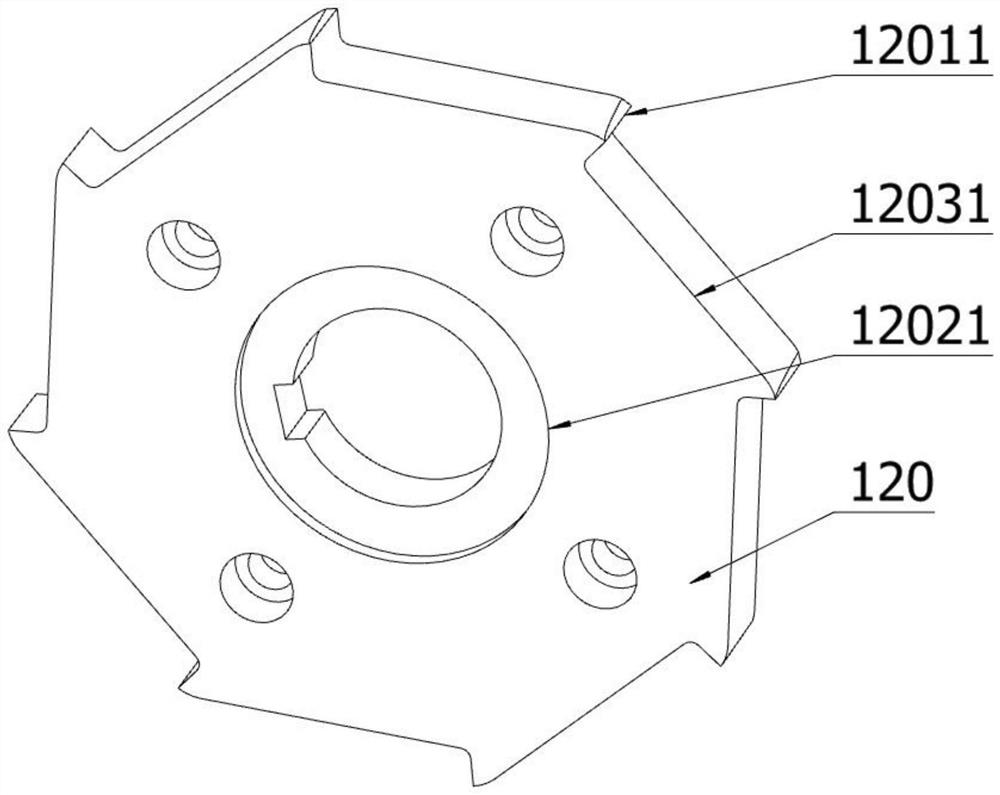

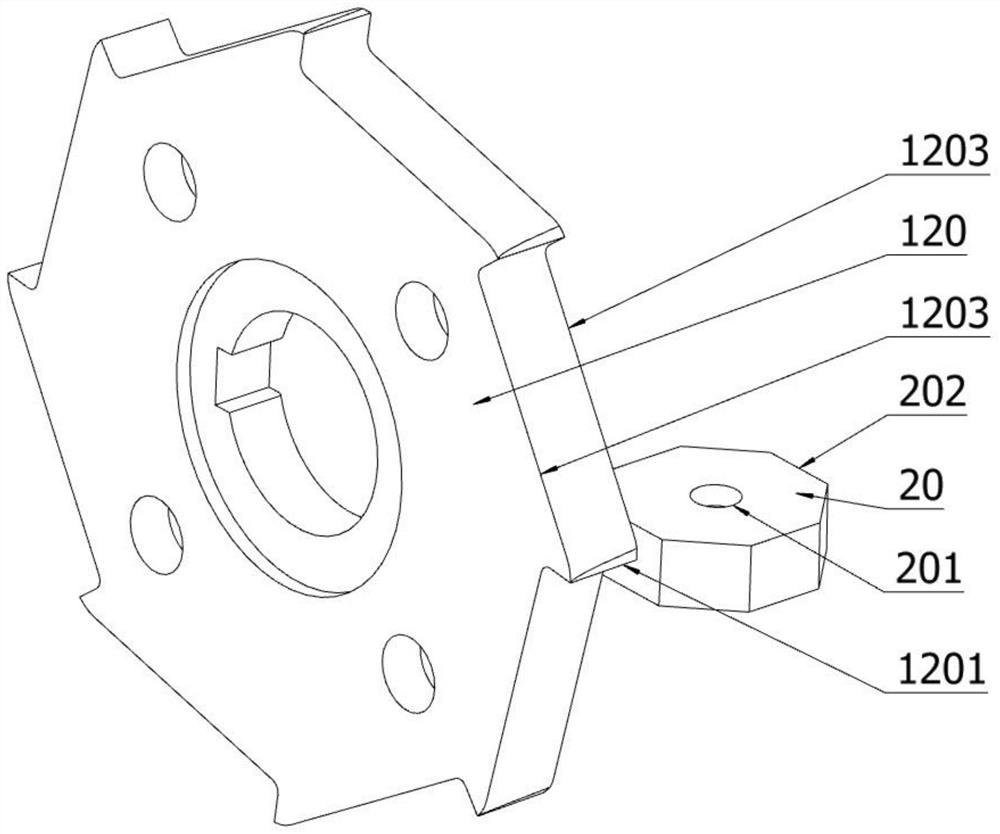

Air-suction seed-metering device for seeding in community

PendingCN108496484AUniform suctionEvenly concentrated suctionSeed depositing seeder partsPositive pressureEngineering

The invention relates to an air-suction seed-metering device for seeding in a community. The seed-metering device comprises a seed-metering device shell, a guide groove plate fixing device, a drivingplate, a guide groove plate, an air suction plate, a forced discharge plate and a seed storage shell; the seed storage shell and the seed-metering device shell are connected to form an inside closed space; the seed-metering device shell is provided with an air suction port; the forced discharge plate, the air suction plate, the guide groove plate, the guide groove plate fixing device, the drivingplate and a rolling bearing are arranged between the seed storage shell and the seed-metering device shell in sequence. In the seed-metering device, discharge guide groove holes are designed for different seeds, each discharge guide groove hole can suck only one seed, the plant distance uniformity is guranateed, and re-seeding and miss-seeding are avoided; meanwhile, under the action of positive pressure and negative pressure, seed clearing is thorough, no seed remains, and no seed is damaged.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Aerosol virtual impact concentrating separator

ActiveCN101322891BEvenly distributedFree from lossDispersed particle separationThree stageEngineering

The invention relates to an aerosol virtual impacting concentration separator which is characterized in that the separator comprises an outer drum; one side of the lower part of the outer drum is provided with an exhaust port and an exhaust fan which is connected with the exhaust end of the exhaust port; the outer drum is internally provided with three stages of separation inlet components from top to bottom; the first stage component comprises an aerosol air intake, the front end of the first stage component is provided with a waterproof and inset resistant net cover, the first stage component is internally provided with a flow limit column and a ring gap is formed between the flow limit column and the first stage component; the second stage component comprises a large particle collection port and a second stage separation intake board, the large particle collection port is correspondingly arranged under the aerosol air intake and a plurality of second stage spouts are cut evenly at the periphery of the second stage separation intake board; the third stage component comprises a tank which is connected under the second stage separation intake board, the third stage spouts are cut at the bottom of the tank and a third stage collection port is arranged under the third stage spouts. By utilizing the flying inertia of aerosol particles and adopting the virtual impacting principle,the separator of the invention separates the respirable particle with the diameter of 2 microns to 12 microns, which contains microorganism, from great air flow and concentrates the respirable particle into comparatively small air flow.

Owner:MICROBE EPIDEMIC DISEASE INST OF PLA MILITARY MEDICAL ACAD OF SCI +1

Ion source soft ionization device and method under barometric pressure

InactiveCN104538276AFully ionizedImprove detection abilityParticle spectrometer methodsIon sources/gunsSolventIonization

The invention provides an ion source soft ionization device and method under barometric pressure. The ion source soft ionization device comprises a discharge cavity, a solvent providing module and an ion source module. The input end of the discharge cavity receives carrier gas, and the output end of the discharge cavity is connected with the ion source module. The solvent providing module is used for providing a solvent with the stable content and feeding the solvent into the ion source module. The ion source module is used for ionizing matter to be tested. The ion source soft ionization device and method have the advantages of being good in quality determination and quantification, high in sensitivity, good in stability and the like.

Owner:NINGBO UNIV

an injection mold

Owner:苏州宇鑫精密模具有限公司

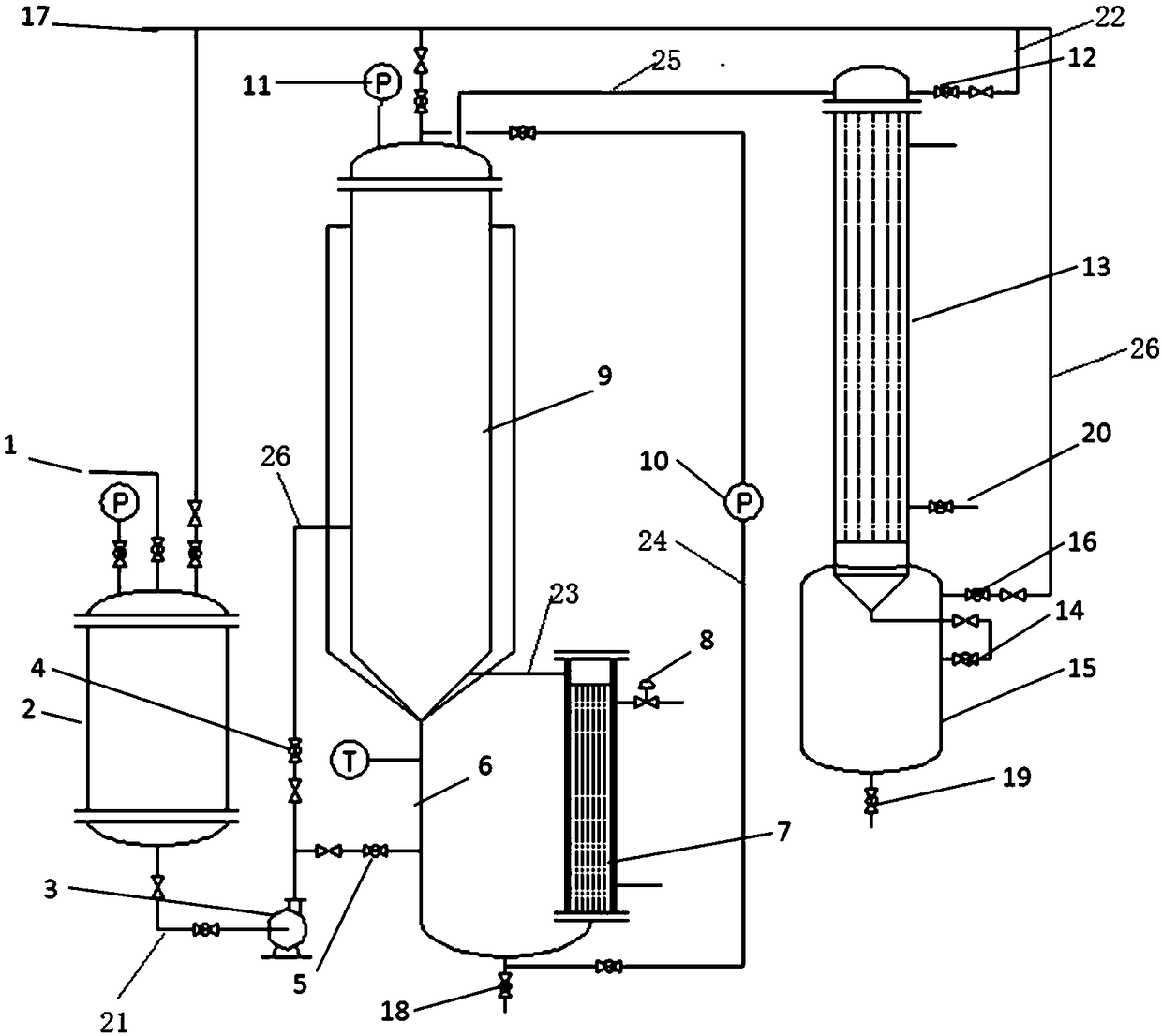

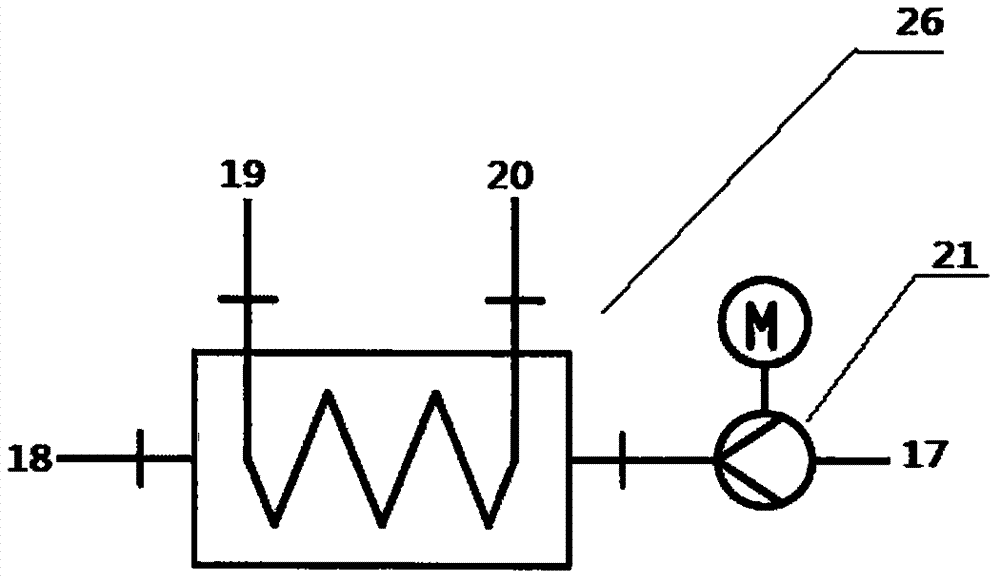

Semi-continuous automatic feed liquid evaporation device and feed liquid evaporation recovery method

PendingCN108607225AAdjustable concentration ratioAdjustable evaporation speedEvaporator accessoriesEvaporator regulation/controlRecovery methodEvaporation

The invention discloses a semi-continuous automatic feed liquid evaporation device and a feed liquid evaporation recovery method. The semi-continuous automatic feed liquid evaporation device comprisesa raw material tank, a separation chamber, a steam heating chamber, a condenser and a condensate recovery tank, wherein a separation chamber liquid level sensor is arranged on a pressure guide pipe connecting the lowest end of a lower circulation pipe with the uppermost end of the separation chamber, a steam regulating valve is arranged at a steam inlet of the steam heating chamber, the separation chamber liquid level sensor is in communication connection with a PLC, and the PLC is used for controlling the opening degree of the steam regulating valve; a secondary steam outlet in the top end of the separation chamber is communicated with the top end of the condenser through a steam pipeline, a condensate outlet of the condenser is communicated with the condensate recovery tank by a condensate inlet valve and a pipe, and a condensate discharge valve is arranged at a condensate outlet of the condensate recovery tank. The device can realize continuous feeding, intermittent discharging andfull-automatic operation, and has remote operation function.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

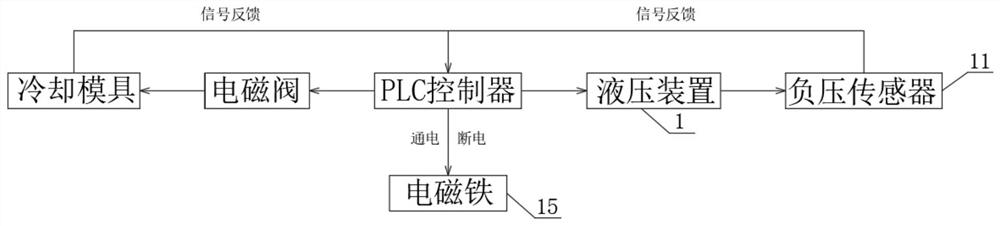

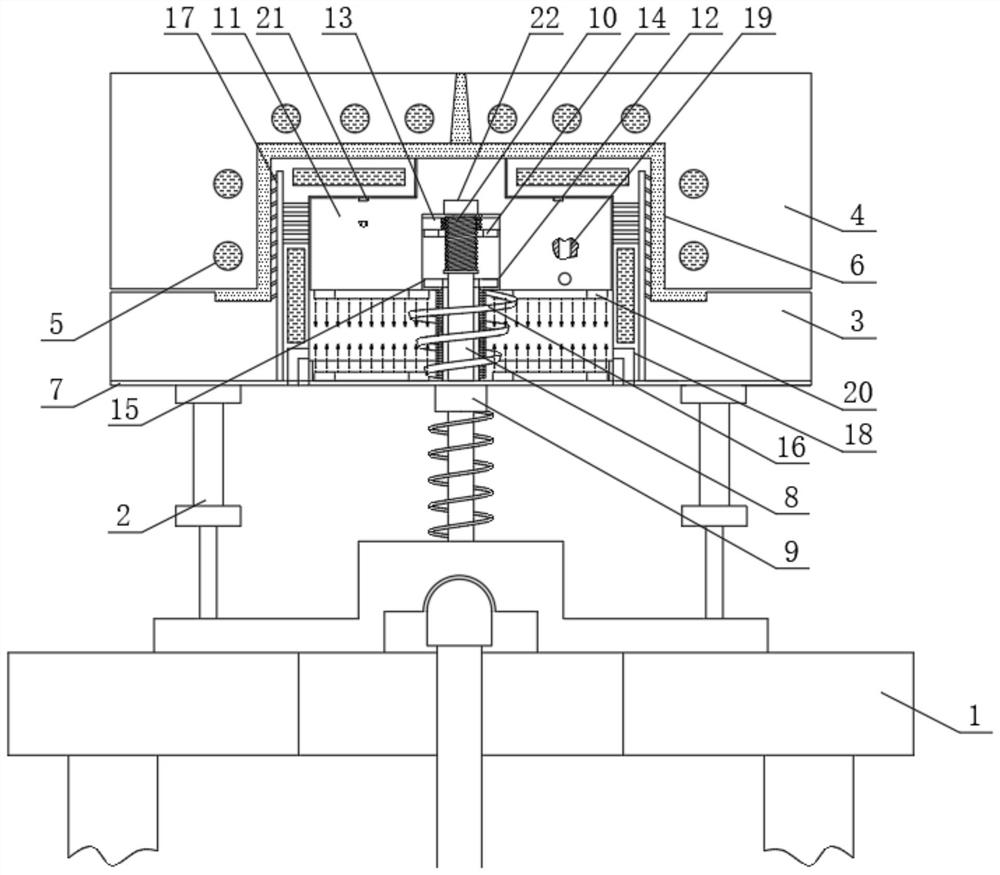

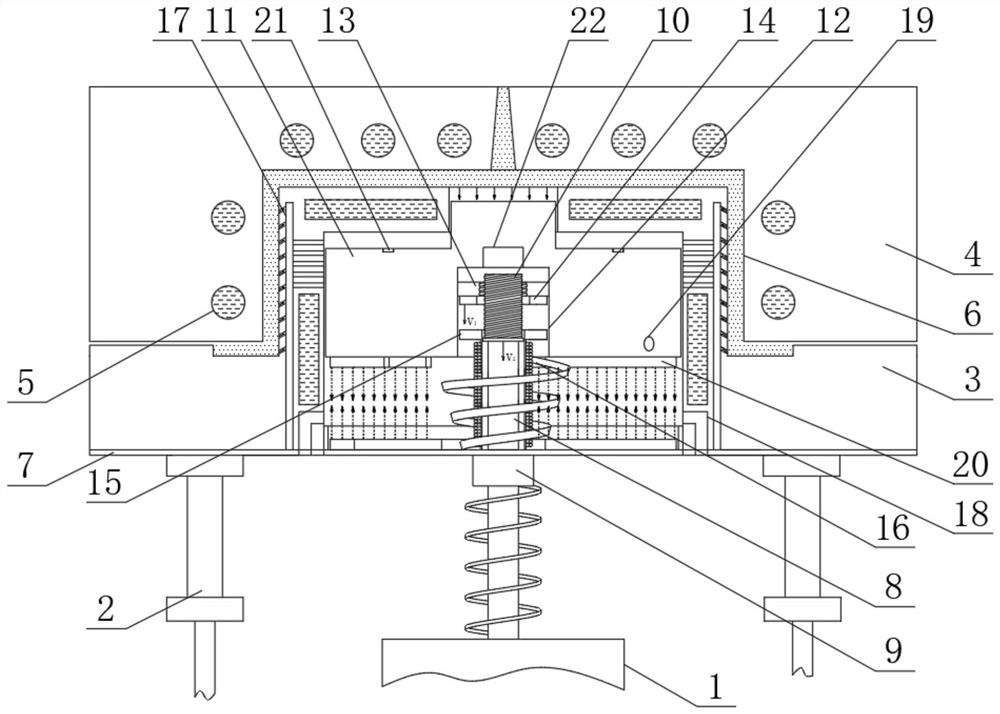

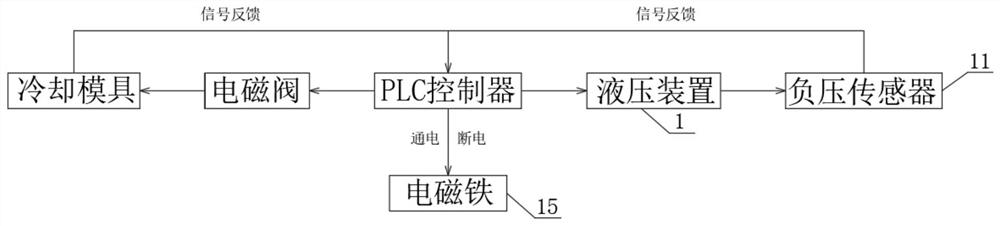

Injection mold

The invention relates to the technical field of injection molds, and discloses an injection mold. The injection mold comprises a hydraulic device, a hydraulic rod movable mold and a fixed mold, wherein the hydraulic device is in transmission connection with the movable mold through a hydraulic rod, a mold cavity is formed between the movable mold and the fixed mold, a cooling water channel is formed in the mold cavity, a pouring opening is formed in the middle of the fixed mold, the pouring opening communicates with the mold cavity and communicates with an injection molding machine, the middleof the movable mold is in a groove shape, the groove communicates with the mold cavity, a sealing piece is driven to move downwards under the action of a hollow electromagnet, and therefore gradually-changed negative pressure is formed between the sealing piece and the movable mold firstly. The gradually-changed negative pressure acts on the injection molding piece, slow separation between the outer wall of the injection molding piece and the inner wall of the fixed mold can be guaranteed, bonding resistance between the injection molding piece and the fixed mold disappears, separation from the fixed mold is achieved while the movable mold moves downwards, in the demolding process, the surface of the injection molding piece is not bonded with the fixed mold during demolding, resistance isrelatively small, and the surface quality of the injection molding piece during demolding is improved.

Owner:苏州宇鑫精密模具有限公司

Hub bearing axial clearance matching machine

ActiveCN106481676BNo stayTimely detection of size deviationsBearing componentsSortingControl systemEngineering

The invention discloses an axial clearance matching machine for a hub bearing. A preselecting mechanism can be used for measuring an axial clearance of a bearing formed by assembling a to-be-assembled inner ring, a to-be-assembled outer ring and a standard retainer combination together and transmitting information to a control system; a ball storehouse is used for placing to-be-assembled retainer combinations with different tolerance ranges; a nesting mechanism can be used for pressurizing and nesting a preassembled product formed by the to-be-assembled inner ring, the to-be-assembled outer ring and a set of to-be-assembled retainer combination; a carrying mechanism can be used for conveying the pressurized and nested product into a measuring mechanism, carrying the product in the measuring mechanism to a defective product discharging station and carrying the product on the defective product discharging station to a subsequent output station; the measuring mechanism can be used for measuring the axial clearance of the product and transmitting information to the control system; a defective product discharging mechanism can be used for discharging the product on the defective product discharging station; and the control system is used for controlling the action of each mechanism. By using the axial clearance matching machine, the fit rate is increased, the phenomenon that a great number of intermediate products are detained does not appear, and the production efficiency and yield rate are increased.

Owner:江苏康斯特智能装备有限公司

A kind of environment-friendly shield tail sealing grease and preparation method thereof

The invention relates to a shield tail sealing grease for a shield machine, which uses base oil, filler, lubricant, tackifier, adhesion modifier, reinforcing agent, and microcapsules as raw materials to prepare a grease with strong adhesion, Shield tail sealing grease with good sealing performance, good pumping lubrication effect, rapid degradation, environmental friendliness and stable quality.

Owner:CNBM ZHONGYAN TECH

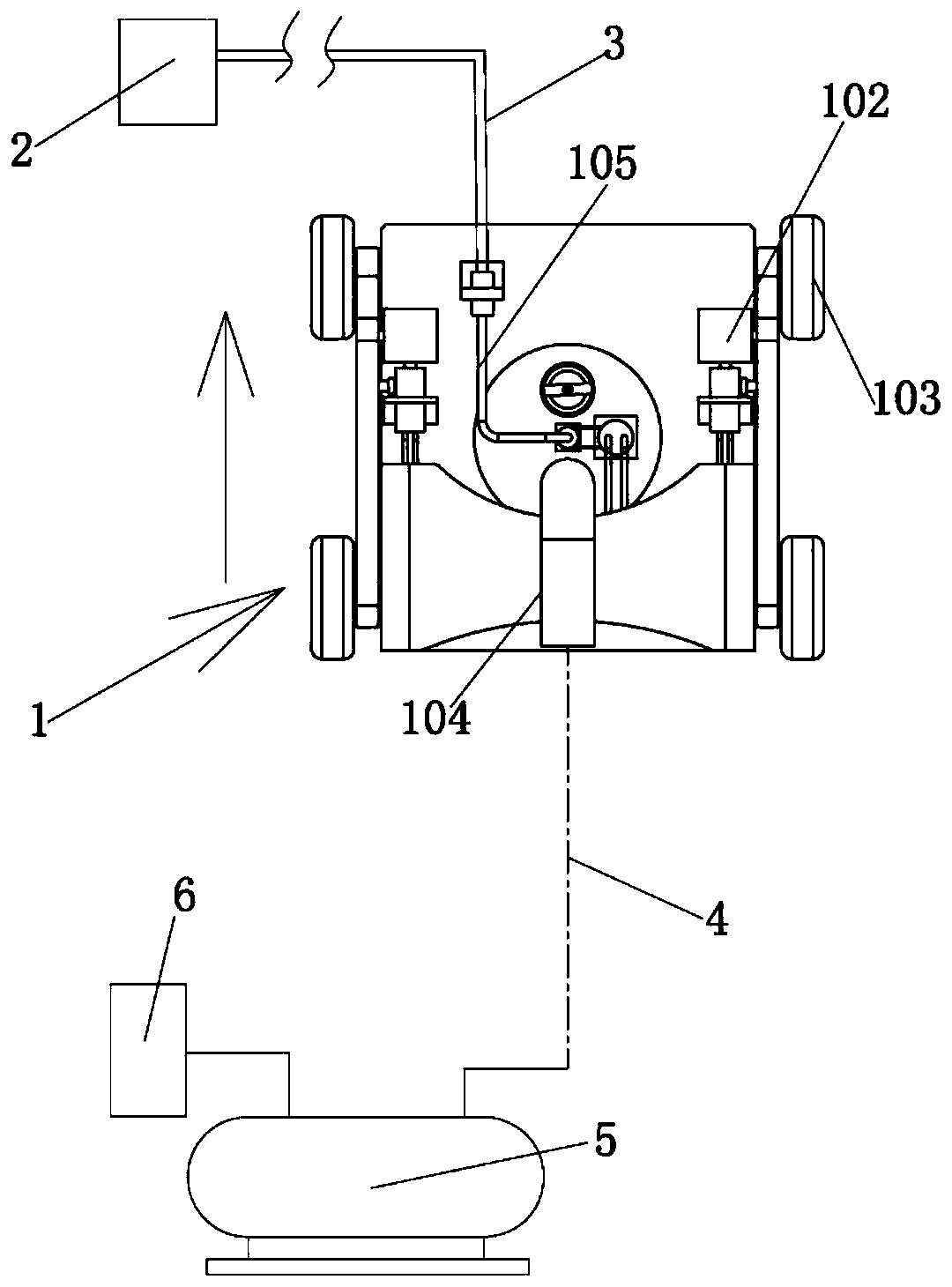

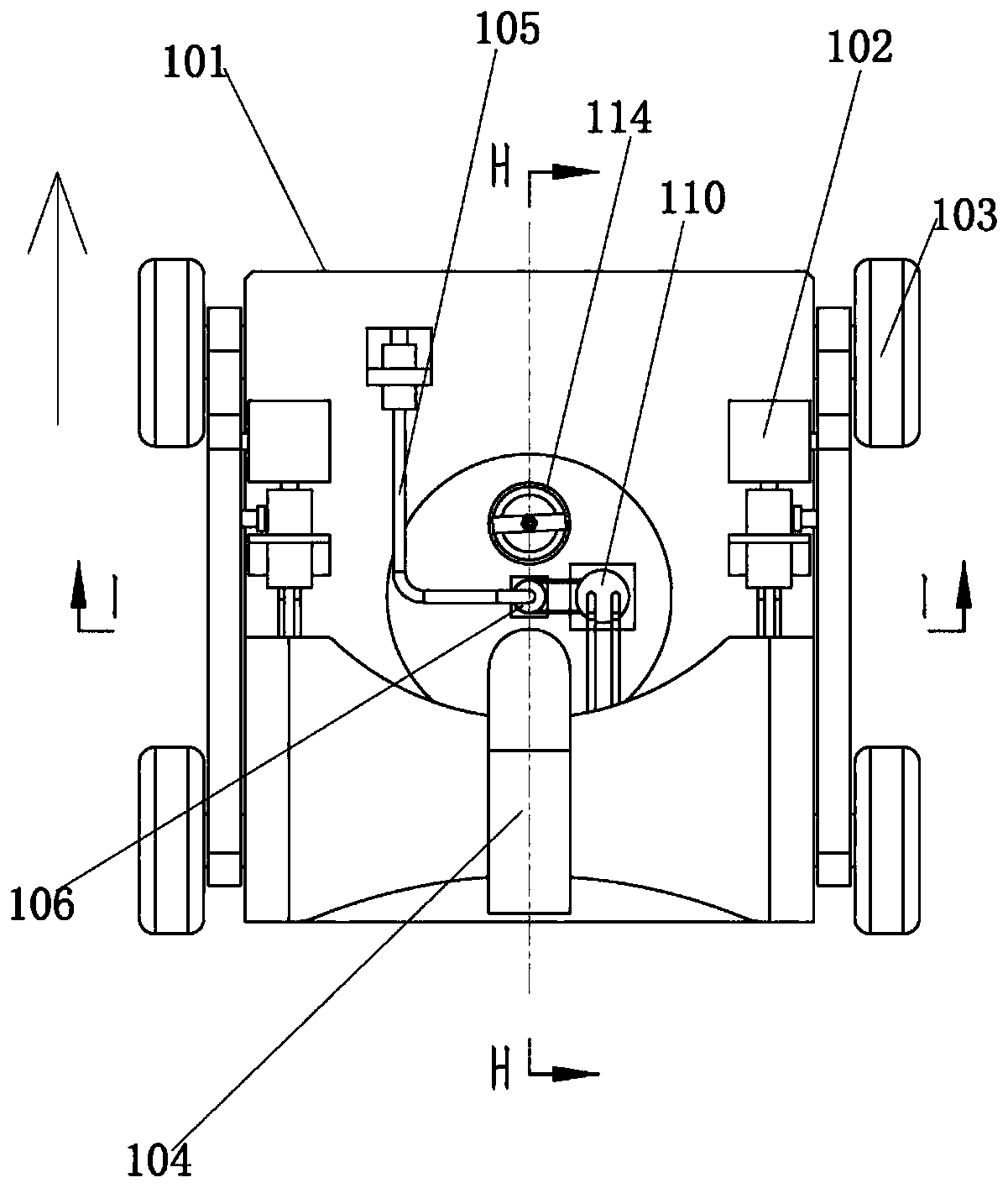

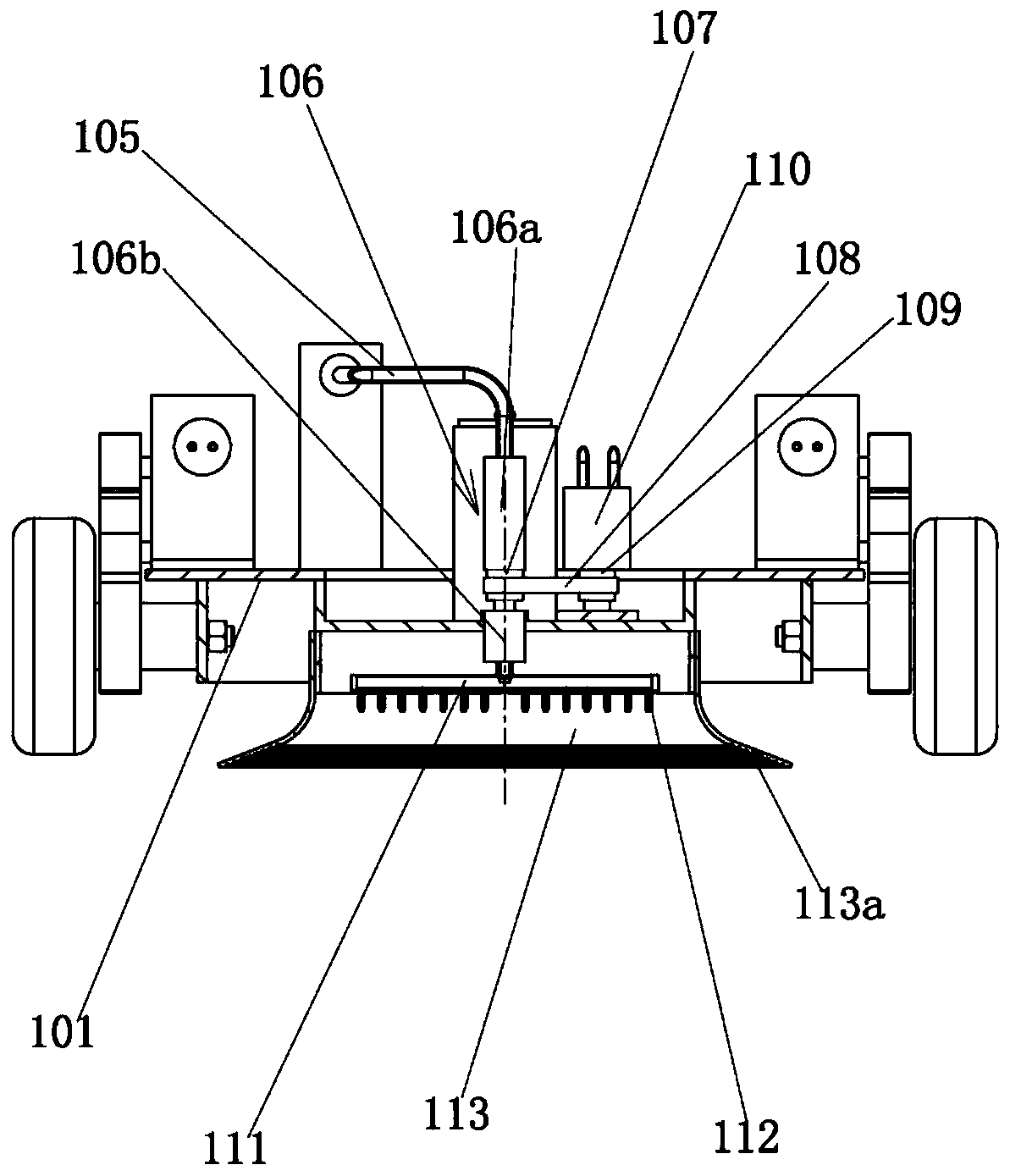

Ship body paint removing robot device

InactiveCN110949637AGood cleaning effectImprove sealingVessel cleaningHullsWater recoveryPumping vacuum

The invention relates to a ship body paint removing robot device in the technical field of environment-friendly paint removing. The ship body paint removing robot device comprises: a robot main body capable of automatically moving on a treated surface; a high-pressure spray washing mechanism which is arranged on the robot main frame; a vacuum cover which is arranged on the robot main frame and made of rubber, wherein the large end of the vacuum cover is attached to the treated surface, and the water outlet end of the high-pressure spray washing mechanism is located in the vacuum cover and right faces the treated surface; a vacuumizing connecting pipe which is mounted on the robot main frame; and a sewage recovery component, wherein the sewage recycling component comprises a sewage collecting pipe, a sewage collecting container and a vacuum pump unit, the air suction end of the vacuum pump unit is communicated with the sewage collecting container, and the vacuumizing connecting pipe iscommunicated with the sewage collecting container through the sewage collecting pipe. Manual work can be completely replaced to clean old paint on the treated surface, and sewage generated in the cleaning process can be automatically recycled.

Owner:上海宝冶工程技术有限公司 +1

Pruning device and using method

PendingCN113510203AReduce replacementReduce collisionsProfiling/shaping machinesShearing machinesStructural engineeringMachining

The invention discloses a pair of rolling scissors, and relates to the technical field of machining. In the application, the rolling scissors comprise a body, a clamping part and a cutting part, wherein the body is used for being connected with a control device; the clamping part is connected with the body, and the clamping part is used for being attached to a part; and the cutting part is connected with the body, and the cutting part is used for cutting materials. The rolling scissors are used for preventing the problems that when a punch is used for cutting redundant steel wire ends at two sides of a fence mesh, the occupied area of the punch is very large, time and labor are wasted after a cutting edge is damaged during cutting of the punch, and the machining efficiency is affected.

Owner:苏州云刚智能科技有限公司

A closed-loop high-temperature gas flow reaction device

The invention discloses a closed-cycle high-temperature airflow reaction device. The device comprises a fan, a waste heat recovery device, a pressure balancing device, a secondary heater, a feeder, an accelerator, a high-temperature reacting furnace, a three-level heater, a cooling system, a dedusting system and a discharging device. Continuous reaction and continuous sintering production can be realized by virtue of a vertical box reaction cavity, the investment cost of equipment is reduced greatly, the closed-cycle high-temperature airflow reaction device has the characteristics of compact structure, convenience in operation and maintenance, good controllability, energy conservation and emission reduction, remarkable reaction effect, no material retention or piling, short reaction time, high rate of finished products, exquisite design and high practicability and can fully utilize heat of exhaust, and the investment to mated infrastructure is less.

Owner:JIANGSU XIANDAO DRYING TECH CO LTD

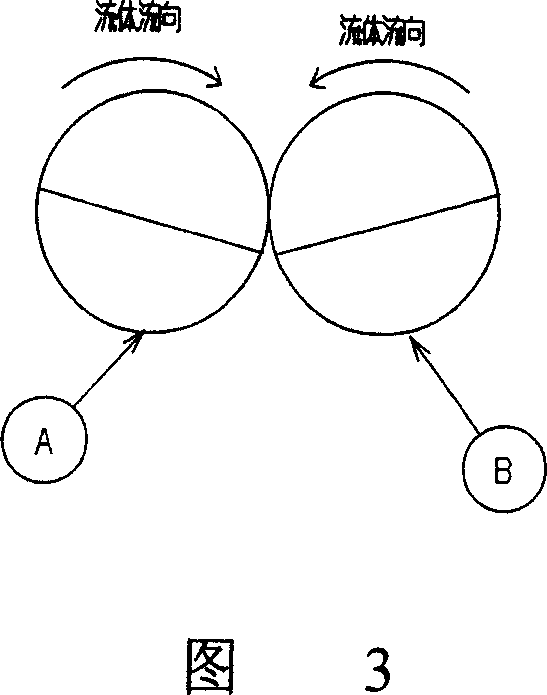

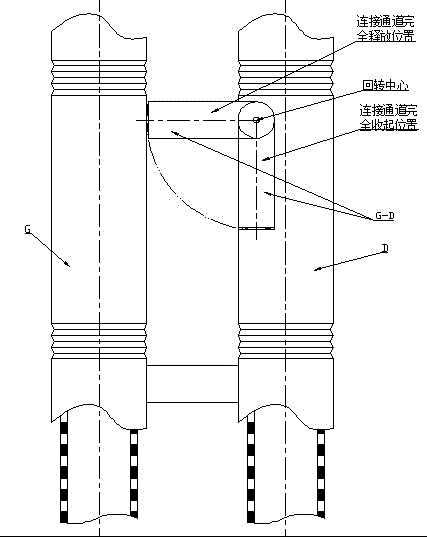

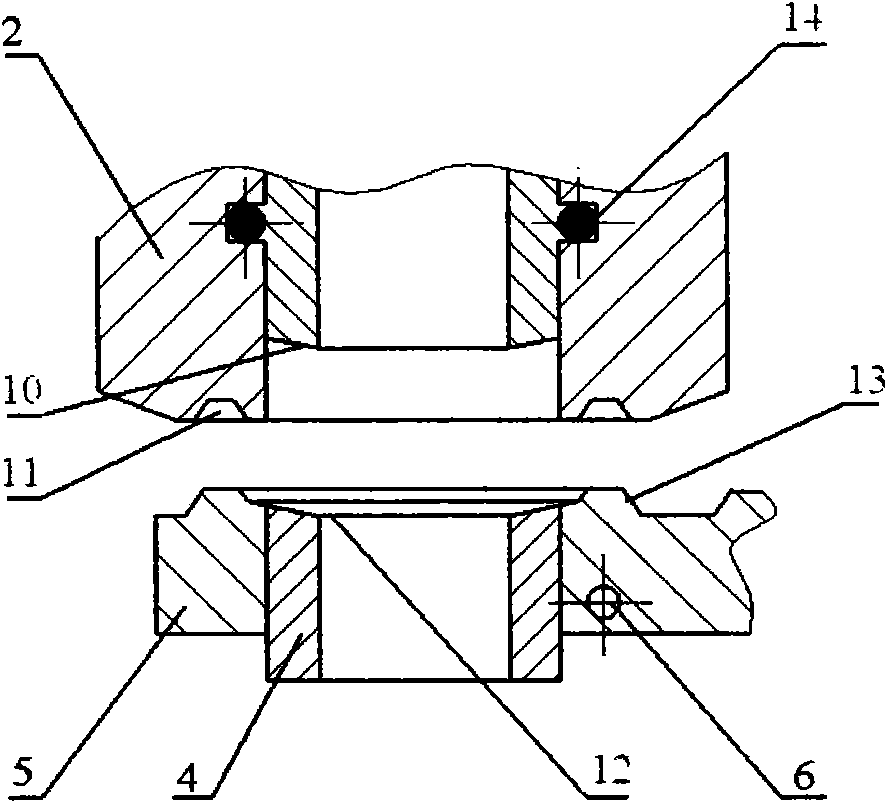

Liquid flow switching device without fluid retention

InactiveCN102374941BNo stayNo mixingPreparing sample for investigationOptical detectionBiological tissueFlange

The invention relates to a liquid flow switching device without fluid retention, and the device can be used for, but not limited to, biological tissue treaters. Before the operation of biological tissue microscopic sectioning, a biological tissue treater pumps liquid medicines of different concentrations into a treatment trough for acting on a biological tissue according to certain sequence and time. The liquid flow switching device of the invention is one of the key parts of the treater, and is composed of an upper pipe, several lower pipes, a leakproof jacket, a control ring, a lower pipe rack, location holes, an infrared light emitter, an infrared light receiver, a guide rail assembly, grooves, flanges and sealing rings. Each lower pipe is lead to different liquid medicines, and is communicated with the upper pipe in order. The leakproof jacket can move along the upper pipe. The location holes, the infrared light emitter and the infrared light receiver assist the lower pipes locating. Then the leakproof jacket moves downwards under the effect of the control ring till the grooves and flanges are jointed tightly, so that an enclosed space can form inside the upper pipe and a lower pipe. When the inside of the upper pipe bears a negative pressure, a liquid medicine can be pumped upwards from a lower pipe. The whole process generates no fluid retention.

Owner:江苏怡龙医疗科技有限公司

Method for manufacturing airplane brake wheel through narrow slit directional flow

InactiveCN1291174CImprove effective utilizationAvoid formingFriction liningHazardous substanceGraphite

The invention is a method to prepare plane carbon brake disc by slot oriented flow, and its character: holding procast bodies of the carbon brake disc in a furnace, putting equal-thickness graphite pads between these procast bodies, thus composing a slot oriented flow closed path of carbon source gas; regulating the flux of the carbon source gas according to total mass of the procast bodies in the furnace; controlling the temperature of the outside low-temperature of the procast bodies and raising the temperature in a step mode, able to hold carbon brake discs 35-45 plates. It effectively enhances utilization ratio of carbon source gas and gas oriented flow path is smooth without gas retention place, preventing harmful carbon black from forming; regulates gas flux according to total mass of procast bodies, largely reducing consumption of carbon source gas and cost.

Owner:XIAN CHAOMA SCI TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com