Pruning device and using method

A technology of control device and rolling scissors, which is applied in the field of mechanical processing, can solve the problems of affecting processing efficiency, time-consuming and labor-intensive, cutting edge damage, disassembly and maintenance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] [Example 1]

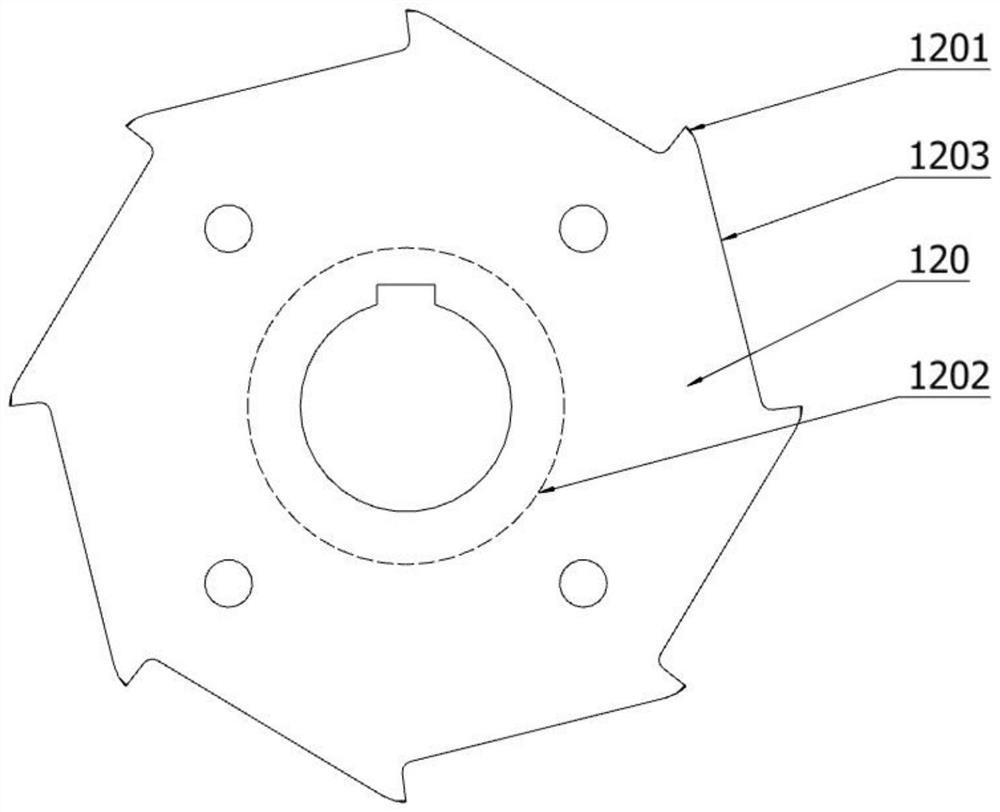

[0105] Such as figure 1 As shown, this embodiment discloses a rolling scissors, including: a body 120, the body 120 is used to connect the control device 150; an engaging part 1203, the engaging part 1203 is connected with the body 120, and the engaging part 1203 is used to attach parts ; The cutting part 1201, the cutting part 1201 is connected with the main body 120, and the cutting part 1201 is used for cutting materials.

[0106] Specifically, a placement portion 1202 for connecting the control device 150 is provided on the surface of the body 120 . The placement portion 1202 is lower than the surface of the body 120 . The placement part 1202 is set in a circular shape, and a keyway is arranged in the middle of the placement part 1202, the keyway is a through hole, and the keyway is composed of a circular hole and a rectangular hole. The surface of the main body 120 is provided with a fixing hole 2011, and the fixing hole 2011 is circular. The fixi...

Embodiment 2

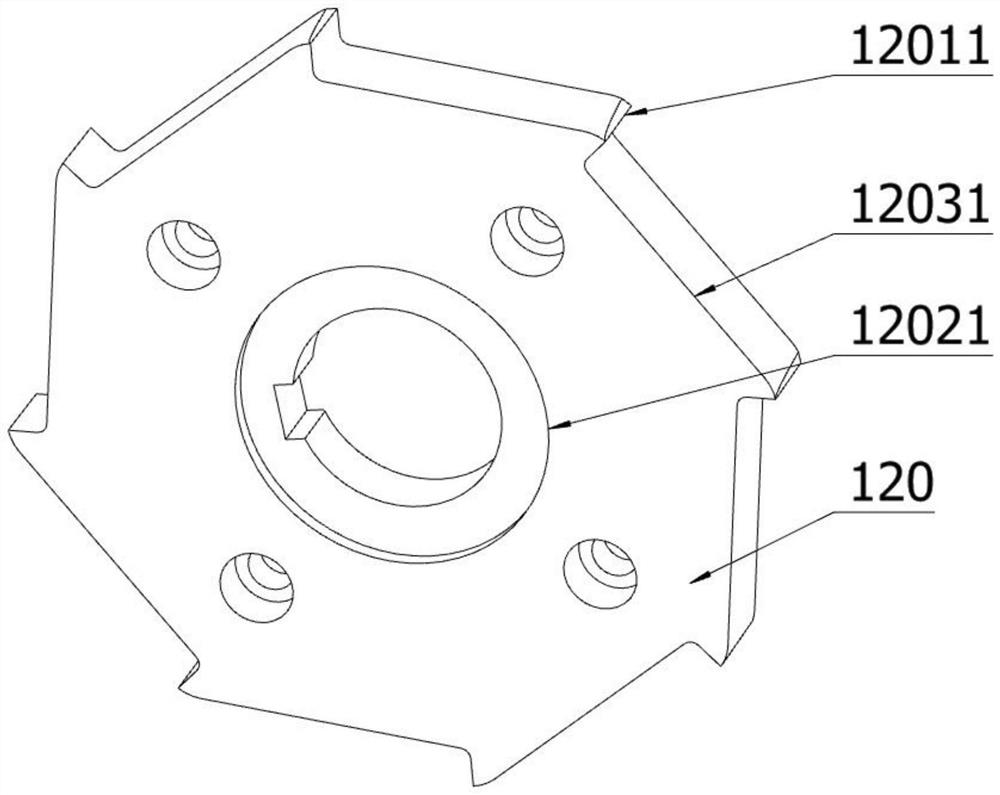

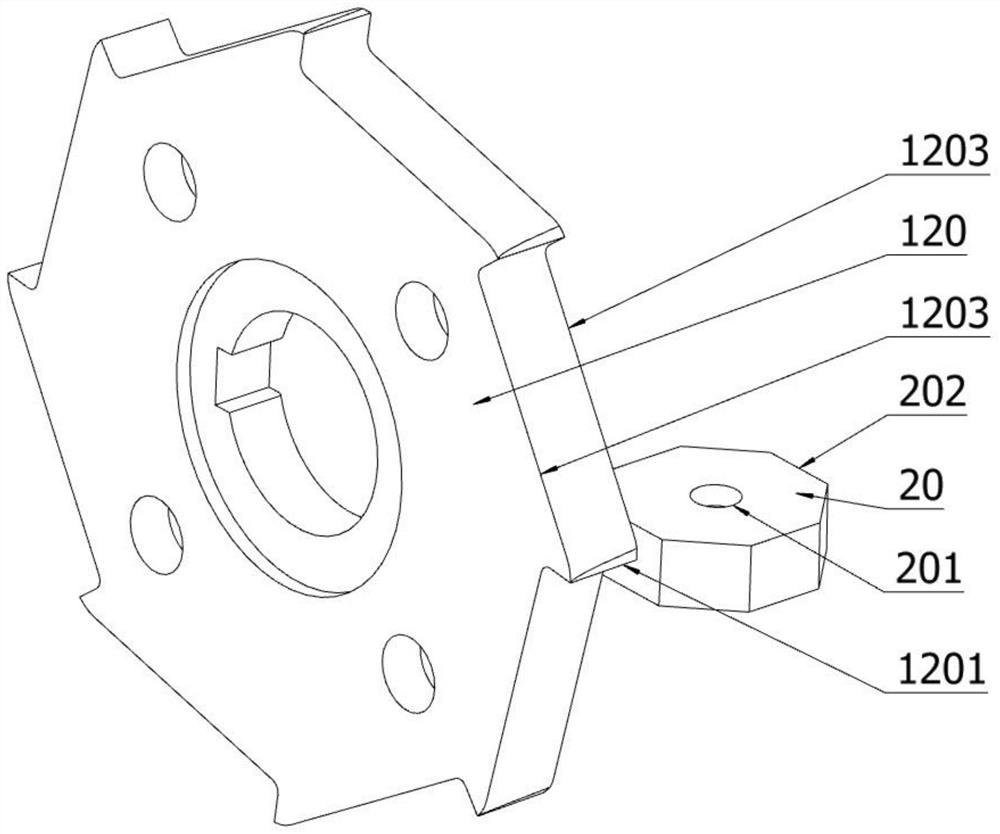

[0108] Such as image 3 , 5 As shown, the embodiment of the present application discloses a rolling shear assembly, including: a body 120, the body 120 is used to connect the control device 150; Integral structure, the engaging part 1203 is used to attach parts; the cutting part 1201, the cutting part 1201 is connected with the main body 120, the cutting part 1201 and the main body 120 are integrally formed, and the cutting part 1201 is used for cutting materials.

[0109] In the above technical solution, in order to solve the problem of using a punch press to cut the excess steel wire heads on both sides of the fence mesh, the punch press occupies a very large area, and the cutting edge of the punch press is damaged, and it takes time and effort to disassemble and maintain, which affects the processing efficiency. This application adopts features such as the phantom body 20 and the cutting part 1201 for assembly. By setting an angle at the joint between the phantom body 20 a...

Embodiment 3

[0117] Such as figure 2 , 4 As shown, this embodiment discloses a trimming device, which includes: a body 120, the body 120 is used to connect the geared motor; The wall 12031 is used to fit the mold body; the hob head 12011, the hob head 12011 is connected with the body 120, the hob head 12011 and the body 120 are integrally formed, and the hob head 12011 is used for cutting the object to be cut; the control device 150, the control device 150 is disposed on one side of the body 120 , and the control device 150 is fixedly connected to the body 120 .

[0118] In the above technical solution, in order to solve the problem of using a punch press to cut the excess steel wire heads on both sides of the fence mesh, the punch press occupies a very large area, and the cutting edge of the punch press is damaged, and it takes time and effort to disassemble and maintain, which affects the processing efficiency. The application adopts base 280, mold body 20, mesh pressing plate 50, etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com