Hub bearing axial clearance matching machine

A technology for axial clearance and hub bearings, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of large size of sorting rings, low matching rate, and low bearing precision, so as to improve production efficiency and yield rate, reduce production costs, and improve the effect of matching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

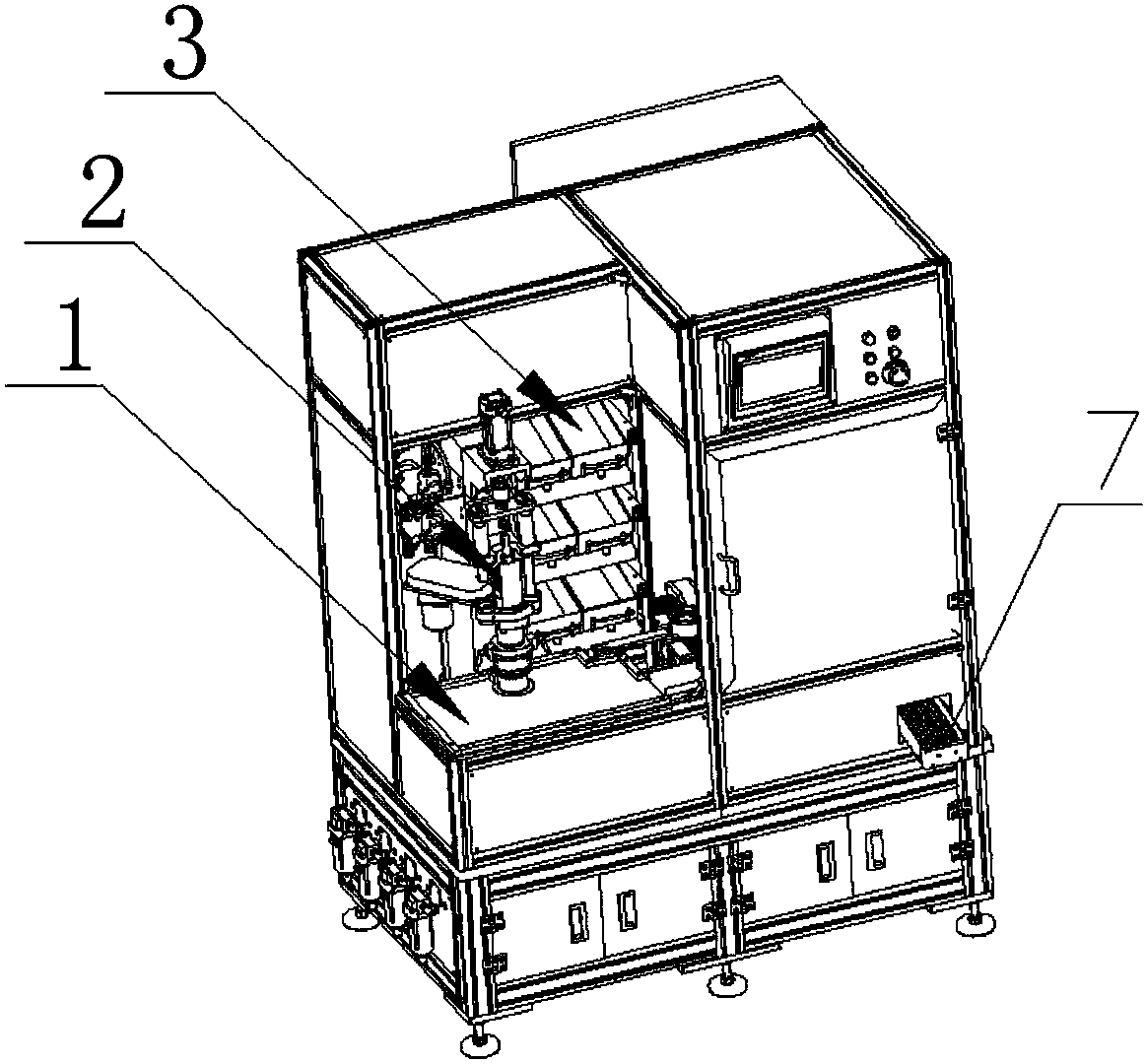

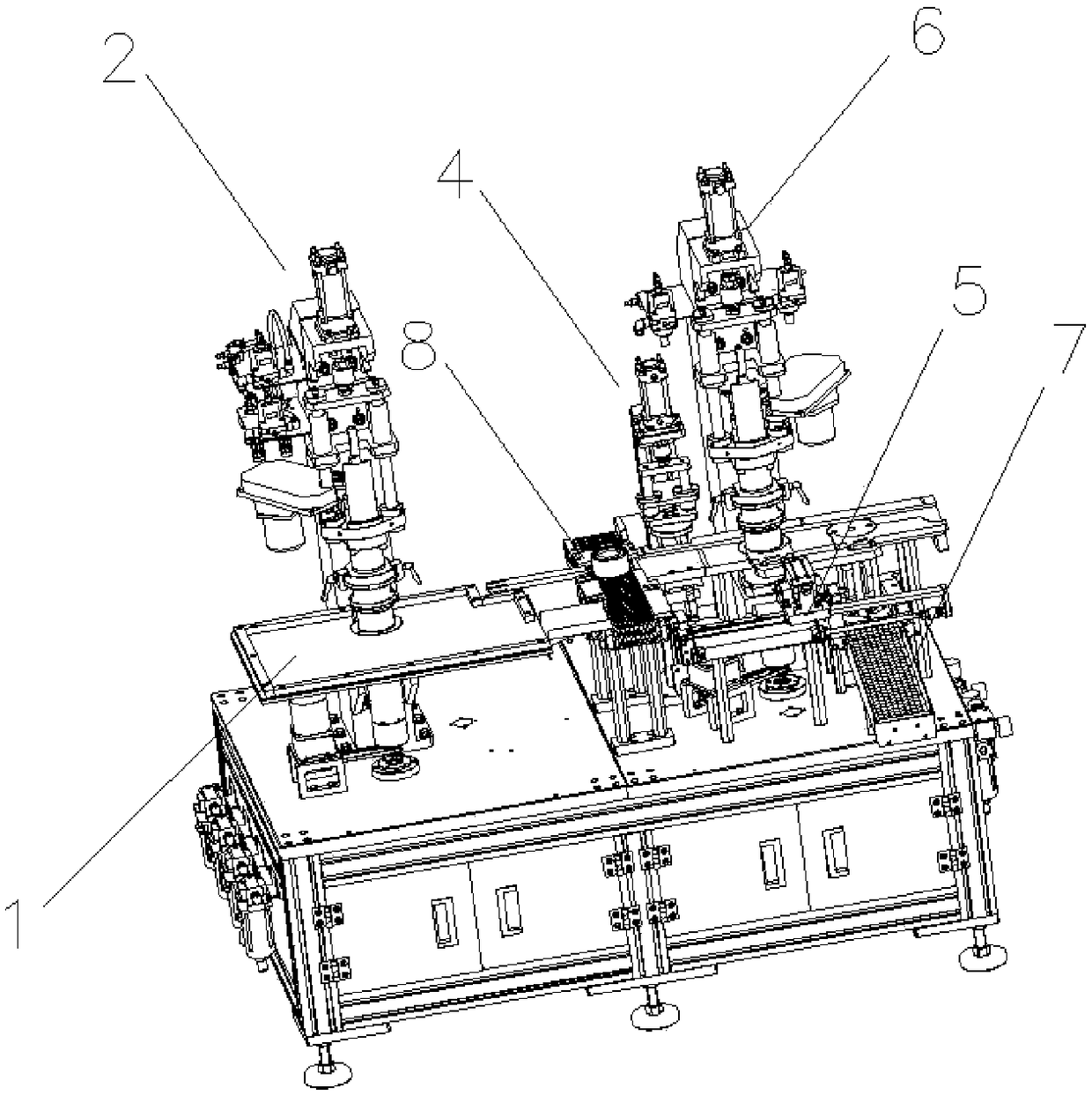

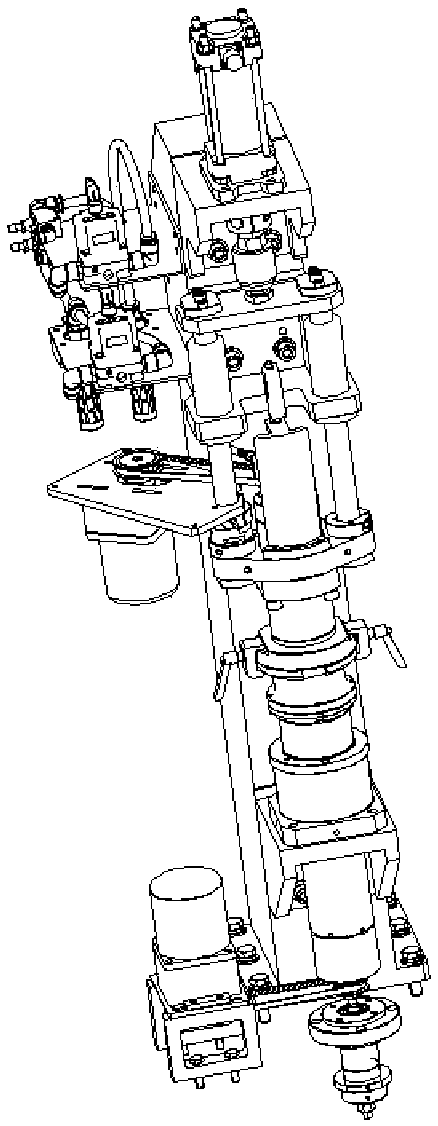

[0032]Embodiment: A wheel hub bearing axial clearance matching machine, including a table top 1, a preselection mechanism 2, a standard cage combination, a ball warehouse 3, a fitting mechanism 4, a handling mechanism 5, a measuring mechanism 6, and a defective product discharge mechanism 7 , a defective product collection area and a control system, the preselection mechanism 2, the fitting mechanism 4 and the measuring mechanism 6 are fixedly positioned on the table top 1 in sequence, and the preselection mechanism 2 can be composed of two inner rings to be assembled, one outer ring to be assembled and The bearings assembled with standard cages are used to measure the axial clearance and transmit it to the control system. Several ball chambers 3 are used to place the cages to be assembled in different tolerance ranges. The pre-assembled products formed by the combination of the inner ring to be assembled, the outer ring to be assembled and a set of cages to be assembled in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com